Investigation of properties in nanomodified polyethylene-based wood-polymer composites

Автор: Ayaz G. Khantimirov, Lyailya A. Abdrakhmanova, Rashit K. Nizamov, Vadim G. Khozin

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The study of the properties of nanomaterials

Статья в выпуске: 2 Vol.15, 2023 года.

Бесплатный доступ

Introduction. Polyethylene is by far the most widely used polymer in the production of wood-polymer composites both in Russia and in other countries. Nevertheless, these composites have a number of disadvantages: low adhesion between polymer matrix and wood filler, which reduces the strength characteristics of the products, high elasticity, and low weather resistance. In industry, such issues are often solved by using complex additives in the form of granules including binding agents, lubricants, and various thermo- and UV-stabilizers. Methods and materials. New experimental data on technological and operational characteristics of wood-polymer composites (WPC) based on low-pressure polyethylene modified with complex processing additive have been obtained. In addition to stabilizers and lubricants, multi-wall carbon nanotubes (MWCNT) were introduced in WPC to facilitate the extrusion process, their content was 30% of the total composition. WPC-based products are mainly intended for outdoor performance under mechanical load, which places special demands on them in terms of strength, weathering and water resistance. Results. An increase in the mechanical characteristics was found for WPC after the introduction of the complex additive: at a concentration of 2.6 phr, the tensile strength increased by 35%, and at 53.3 phr, the flexural strength became higher by 12%. The introduction of the additive led to a decrease in the abrasion and water absorption of the modified sample compared to that of the initial material. Regardless of the additive content, all the samples were uniformly colored, which indicated a uniform distribution of the modifier over the volume of the WPC melt during processing in the extruder. Conclusion. The introduction of a complex processing stabilizing additive into the composition of a wood-polymer composite based on polyethylene was carried out. The results of the research showed that the additive in a wide range of concentrations contributes to the improvement of the technological and operational properties of the resulting composites.

Wood-polymer composite, polyethylene, carbon nanotubes, stabilizer, extrusion, microscopy

Короткий адрес: https://sciup.org/142237966

IDR: 142237966 | DOI: 10.15828/2075-8545-2023-15-2-110-116

Текст научной статьи Investigation of properties in nanomodified polyethylene-based wood-polymer composites

Original article

R ecently, wood-polymer composites (WPCs) market has been actively developing in the construction industry due to their unique properties inherent only to these types of materials. These composites combine the positive qualities of both polymers and wood.

WPC can be produced from such thermoplastic polymers as low-pressure polyethylene (HDPE), polyvinyl chloride (PVC) and polypropylene (PP). HDPE is most widely used for producing WPCs due to its high manufacturability of its production (low processing temperature, a wide range of melt viscosities, and the absence of risk of thermal decomposition of wood filler) [1, 2]. However, HDPE-based wood-filled composites have high elastic- ity and low strength characteristics, which limit their use in construction. These disadvantages are attributed to both the low physical and mechanical characteristics of HDPE itself and the poor compatibility of the hydrophobic polymer with hydrophilic wood flour [3]. Binding agents are used to improve the compatibility of these two components.

Maleinized polyethylene is the most popular binder for polyolefin-based WPCs. Over the past decade, nanoadditives have been actively used into the production processes as compatibilizers, among which carbon nanotubes undoubtedly occupy a leading position. In recent years, a lot of studies have been carried out, in which nanotubes were added to polymer composites, including wood-filled ones [4–11].

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Zhang et al. [5] presented the results of the study of HDPE-based WPC samples with carbon nanomaterials (soot, flaky graphite and multilayer carbon nanotubes) incorporated in the amount of 3 to 12 wt.% to improve their conductive and mechanical properties. They observed a decrease in the electrical resistivity with an increase in the content of the nano-additives, which indicated the possibility of the formation of an interconnected conductive network arising as the content of carbon nanomaterials increased. However, the mechanical properties of WPCs with the addition of carbon nanomaterials decreased slightly with increasing filler content. Scanning electron microscopy revealed the carbon nanofiller clusters or agglomerates appeared as their weight fraction increased. The authors pointed to the need to find a balance between the electrical and mechanical properties when selecting the nanofiller concentration, as well as a way to prevent the aggregation of MWCNTs.

Another disadvantage of HDPE-based WPCs is their susceptibility to the negative effects of atmospheric oxygen, high temperature, and UV-radiation, leading to oxidation and degradation of the carbon skeleton of the polymer. Hence, it is necessary to use antioxidants and special pigments that change the wavelength of UV-radiation [12].

Dolgusheva et. all [13] employed IR spectroscopy to evaluate the efficiency of antioxidants at 180оС under conditions of thermal oxidation of paraffinic oil from the rate of accumulation of carbonyl groups. The following antioxidants were used: bis (3,5-di-tret-butyl-4-hydroxy-phenyl) propyl) phosphite (PFAO), pentaerythritoltetrakis (3-(3,5-di-tret-butyl-4-hydroxyphenyl) propionate (Irganox 1010), tris(2,4-di-tret-butylphenyl)phosphite (Irgafos 168), and mixtures of Irganox 1010 and Irgafos 168. It was found that P2FAO had the highest efficiency as well as a mixture of Irganox 1010 and Irgafos 168 in a ratio of 1:1 compared with their individual use. This effect was also observed by other researchers [14–18].

In addition, MWNTs can play the role of pigments that change the UV-radiation wavelength and adsorb oxygen molecules, thereby preventing oxidation of the polymer carbon chain [19, 20].

Internal and external lubricants, which reduce melt viscosity and facilitate processing, are important technological components utilized in the production of polymer composites. In the case of WPCs, polyethylene and montan waxes are traditionally used as lubricants [21–24].

Lavrov et al. [22] compared the effectiveness of using polyethylene and montan waxes as external lubricants in the PVC processing. Polyethylene wax showed the best result, but montan wax doubled the PVC processing time, which also indicated the efficiency of this lubricant.

The commonly used approach to solve the above problems is to utilize processing complex stabilizing additives in the form of ready-made pellets, which provide a possibility to improve the processability of an extrusion line without additional production operations. Due to the qualitative combination of the individual components, these complex additives ensure a synergistic effect of their application [13].

In this paper, the processing composite of the trade mark CM-1230 was used as a complex additive.

METHODS AND MATERIALS

In our study, we used HDPE of PE2NT11-285D grade (TU 20.16.10-175-00203335-2017) and coniferous wood flour of M180 grade (GOST 16361-87). The CM-1230 complex additive contained: anti-oxidant Irganox 1010 (10%), stabilizer for processing and anti-oxidant Irgafos 168 (10%), montan wax, acting as an external and internal lubricant (50%), and MWNTs under the name of Graphistrength® CM-1230 produced by Arkema (30%).

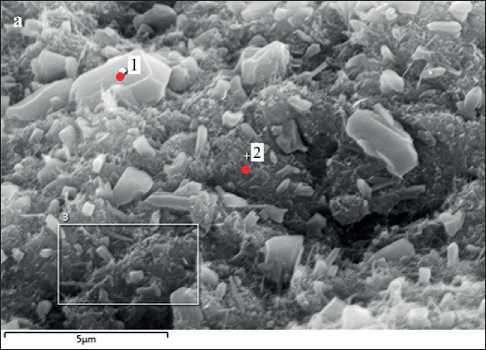

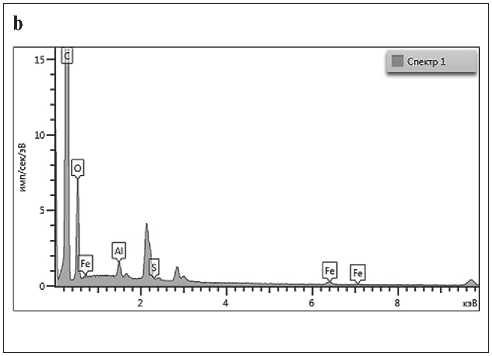

Figure 1 shows the structure of the CM-1230 complex modifier on a nanometer scale evaluated from the SEM and EDA measurements.

The CM-1230 complex modifier is represented by phases of aggregated MWNTs and a montan wax carrier with clear interface boundaries. Dispersed inclusions are a phase of montan wax with functional additives. This finding follows from the EDA data (Figure 2). The carbon and oxygen contents are 82.3% and ~17.2%, respectively (spectrum at point 1). At point 2 (the MWNTs cluster), the carbon content is 90.2%.

The compositions under study are presented in Table 1.

For the studies, extruded samples were obtained on a LabTechScientific LTE 16-40 twin-screw extruder with a 2×22 mm die. The selected processing temperature is given in Table 2. All the samples were extruded at a screw speed of 20 rpm and the processing time was 10–15 minutes.

Montan wax

Fig. 1. SEM image of the surface of the CM-1230 complex modifier

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 2. SEM surface image of the CM-1230 complex additive with analyzed points 1 and 2 (a); EDA data for point 1 on the surface of CM-1230 complex additive (b)

The technological and performance properties of the HDPE-based samples were studied in accordance with the current standards given in Table 3.

The structure of extrudates was studied using optical microscopy on an Axioskop 40 Pol laboratory polarization microscope. The microstructure of the granules of

Table 1

Experimental compositions

|

Components |

Composites |

||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

|

HDPE, phr |

100 |

||||||

|

Wood flour, phr |

50 |

||||||

|

СМ-1230, phr, including: |

– |

1.3 |

2.6 |

5.3 |

16 |

26.7 |

53.3 |

|

MWNTs, phr |

– |

0.4 |

0.8 |

1.6 |

4.8 |

8 |

16 |

Table 2

Temperature profile in the extruder zones

|

Zone No |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

Т, оС |

143 |

143 |

143 |

145 |

150 |

150 |

150 |

155 |

155 |

160 |

Table 3

Applicable regulations

|

Document number |

Name of standards |

|

ISO 178:2010 |

Plastics. Method of static bending test |

|

ISO 527-2:2012 |

Plastics. Tensile test method |

|

ISO 62:2008 |

Plastics. Methods for the determination of water absorption |

|

GOST 11012-2017 |

Plastics. Method of test for resistance to abrasion |

|

GOST 15139-69 |

Plastics. Methods for the determination of density (mass density) |

|

GOST 11645-2021 |

Plastics. Methods for determination of flow index of thermoplastics melt |

THE STUDY OF THE PROPERTIES OF NANOMATERIALS the complex modifier was studied using high-resolution scanning electron microscopy (SEM) on the Merlin microscope (CarlZeiss). The elemental composition of the complex additive was determined by employing the energy dispersion analysis (EDA) with the aid of an INCA X-MAX energy dispersion spectrometer.

RESULTS AND DISCUSSION

Let us consider the effect of the additive content in the HDPE-based WPC on its performance characteristics, which are summarized in Table 4.

Studies of mechanical characteristics have shown an extreme nature of the increase in the tensile strength, the largest increase of 30–35% was reached when a content of the complex additive ranged from 2.6 to 16 phr (compositions 3, 4 and 5), while all the modified compositions demonstrated higher strength compared to that exhibited by the original composition. Optical microscopy data showed (Figure 3a, 3b) that the composite with 2.6 phr CM-1230 has a monolithic ordered structure oriented in the direction of extrusion, which differ from a loose structure of the original composition with randomly arranged wood inclusions.

The increase in flexural strength achieved a maximum value at the modifier content of 53.3 phr (composite 7). This fact can be explained by the high content of MWCNTs in this composite (16 phr), which are capable of forming a continuous spatial rigid framework, which effectively responds to the bending forces.

The extreme character of the concentration change in abrasion corresponds to the change in tensile strength. The most durable composites have the least abrasion, namely, they are characterized by low abrasive wear. The minimum values of abrasion have composites with 16 phr CM-1230 (composition 5), for which this indicator is almost 2 times lower than that for the original composition.

Due to the denser structure of the modified samples and the presence of montan wax in the СМ-1230 composition, the water absorption was reduced by more than 4 times, while the minimum value of this index was found for the samples with 26.7 phr of processing complex.

Table 5 summarizes the technological processing characteristics of the composites.

Swelling parameter is an important technological indicator of extrusion, since it is responsible for maintaining the exact geometric dimensions of the resulting products. Compared to the original composition, the modified

Table 4

Performance characteristics of HDPE-based WPCs

|

Parameters |

Composite |

||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

|

Tensile strength, MPa |

20 |

23 |

27 |

27 |

25 |

23 |

23 |

|

Flexural strength, MPa |

33 |

35 |

35 |

34 |

34 |

35 |

37 |

|

Abrasion, µm |

50 |

40 |

39 |

29 |

27 |

38 |

41 |

|

Water absorption, % |

3.05 |

0.82 |

0.81 |

0.79 |

0.82 |

0.55 |

0.62 |

|

Density, g/cm3 |

1.01 |

1.05 |

1.05 |

1.06 |

1.09 |

1.11 |

1.12 |

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Table 5

Technological characteristics of WPC extrusion

|

Parameters |

Composites |

||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

|

Swelling |

1.00 |

0.98 |

0.95 |

0.93 |

0.95 |

0.95 |

0.93 |

|

Melt flow index at 180оC, g/10 min |

7.6 |

7.9 |

8.1 |

8.9 |

13.7 |

15.0 |

20.8 |

|

Screw speed, rpm |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

|

Engine load, % of max |

28 |

35 |

31 |

29 |

28 |

28 |

26 |

|

Pressure in the die hole, bar |

20 |

15 |

14 |

15 |

15 |

13 |

11 |

Fig. 3. Microphotographs of a longitudinal section ( × 100) of WPC-HDPE: a – original material; b – with 2.6 phr CM-1230

samples show lower swelling values due to the effective spatial binding and dense packing of the polymer network caused by the introduction of nanotubes.

The melt flow index tended to increase as the content of the complex additive became higher due to the presence of montan wax as a lubricant. Extrusion of the samples at the same screw speed showed the following output parameters: the pressure in the die hole decreased as the additive content increased, however, at a concentration of 1.3 phr, the engine load increased significantly from the maximum power, indicating that a small number of nanotubes (0.4 phr) contributed to the shear stress during the rotational movement of the melt between the screws and the wall of the working area. With a further increase in the MWCNT concentration, the engine load achieved the values at the level of the original composition.

It is worth noting that all the modified composites have a rich black color regardless of the CM-1230 content, which indicates a uniform distribution of MWNTs over the volume of the samples. This contributes to additional protection of the WPC from UV radiation. As the content of the modifier increased, the surface of the samples changed from semi-matte to glossy.

In addition, according to literature data [5, 26], the introduction of MWNTs into polymer composites prevents the formation of static electricity on the surface of the products, which prevents the accumulation of dust on them.

The analysis of the results showed that the optimal content of the CM-1230 modifier is 2.6–53.3 phr. Moreover, depending on the concentration, these WPC can be recommended for the production of various functional products. For example, composition 5 can be used in floorboards, which must possess high wear resistance, and composition 6 is applicable for terrace boards, for which water absorption is a crucial property. Compositions 3 and 4 are recommended for improvement mechanical strength of the WPC products.

CONCLUSION

The most popular WPC-based material is the decking composite, for which strength properties, weathering and water resistance are crucial. The HDPE-based composites with the СМ-1230 processing complex have improved consumer and technological properties. The introduction of 2.6 phr of modifier leads to an increase in the tensile strength of the resulting composite by 35%. At a modifier concentration of 53.3 phr, the flexural strength increases by 12%. The optical microscopy investigations revealed the differences in the structure of the composites, which caused the changes in the physical and mechanical properties. The decrease of the abrasion and water absorption of samples was found, and these findings raise a possibility to apply these composites for the decking composite production.

In addition, due to the fact that the processing complex additive contains two types of antioxidants and MWNTs, which are able to change the UV emission wavelength, one should expect an increase in the weathering resistance of the modified composites.

When the CM-1230 content was more than 2.6 phr, the processing of composites became easier, resulting in less extruder wear and reduced energy consumption.

The next stage of research will be climatic tests and investigation of the electrophysical properties of the modified composites.

Список литературы Investigation of properties in nanomodified polyethylene-based wood-polymer composites

- Faizullin I.Z., Wolfson S.I. Wood-polymer composites based on polypropylene and modified wood filler: monograph. Kazan: Publ. of KNRTU: 2020.

- Klesov A.A. Wood-polymer composites. SPb: Scientific bases and technologies: 2007.

- Nigmatullina A.I., Kozlova N.V., Lysyansky A.V. Assessment of thermodynamic compatibility of wood flour with polymers. Bulletin of Technology University. 2018; 15(8): 60-62.

- Zhang X., Hao X., Hao J., Wang Q. Thermal and mechanical properties of wood-plastic composites filled with multiwalled carbon nanotubes. J. Appl. Polym. Sci. 2018; 135 (22): 1–7. https://doi.org/10.1002/app.46308

- Zhang X., Hao X., Hao J., Wang Q. Effect of the addition of carbon nanomaterials on electrical and mechanical properties of wood plastic composites. Polymers (Basel). 2017; 9(11). https://doi.org/10.3390/polym9110620

- Amirov R.R., Neklyudov A.S., Amirova M.L. Method of obtaining compositions based on carbon nanotubes and polyolefins: Patent. Patent of the Russian Federation No 2490204: 2011.

- Gusev K., Solovyev V. Effect of carbon nanotubes on the mechanical properties of the polymeric composites. Vestn. Pskov. Gos. Univ. 2017; 11: 150–153.

- Farsheh A.T., Talaeipour M., Hemmasi A., Khademieslam H., Ghasemi I. Investigation on the mechanical and morphological properties of foamed nanocomposites based on wood flour/PVC/multi-walled carbon nanotube. BioResources. 2011; 6(1): 841–852.

- Islamov A.M., Gabbasov D.A., Khantimirov A.G., Khozin V.G., Abdrahmanova L.A. Wood-polymer composites based on polyvinyl chloride modified with aerosil. Proceedings of KGASU. 2016; 4(38): 382-387.

- Khuziakhmetova K.R., Islamov A.M., Abdrakhmanova L.A., Nizamov R.K. Compositions based on polymer blend polyvinyl chloride/acrylonitrile butadienestyrene and basalt fiber fillers. News of Higher Educational Institutions. Construction. 2022; (6): 46–55. https://doi.org/10.32683/0536-1052-2022-762-6-46-55

- Islamov A., Fakhrutdinova V. Foamed Wood-Polymer Composites Based on Polyvinyl Chloride. Lect. Notes Civ. Eng. Proc. STCCE 2021. 2021: 261–268. https://doi.org/10.1007/978-3-030-80103-8_28

- Moroz P.A., Askadsky Al.A., Matseevich T.A., Solovieva E.V., Askadsky A.A. Application of secondary polymers for production of wood-polymer composites. Plasticheskie massy. 2017; 9-10: 56-62.

- Dolgusheva M.A., Galiev M.F., Cherezova E.N. Antioxidant efficiency of bis(3,5-di-tert-butyl-4-hydroxyphenyl) propyl)phosphite in the thermal oxidation of liquid hydrocarbons. Bulletin of the University of Technology. 2019; 22(12): 28-31.

- Dwi W., Muhammad Sh., Ihda N., Ike S. Pengaruh bahan pengisi from serat kaca terhadap sifat fisik Crystalinitas polypaduan PC / ABS. Balai Besar Kulit, Karet, dan Plastik. 2017; 33(1): 43–48.

- Kirsh I.A., Beznaeva O.V., Bannikova O.A. Biodegradable polymeric composition with antimicrobial properties based on polyolefins. Patent RF. № 2725644. 2020; 18(19): 1-18.

- Junaedi H., Baig M., Dawood A., Albahkali E., Almajid A. Mechanical and physical properties of short carbon fiber and nanofiller-reinforced polypropylene hybrid nanocomposites. Polymers (Basel). 2020; 12(12): 1–25. https://doi.org/10.3390/polym12122851

- Yastrebinskaya A. V., Matveeva L.Y., Edamenko A.S. Improving the fungus resistance of polymer composites. Solid State Phenom. 2020; 299: 55–59. https://doi.org/10.4028/www.scientific.net/SSP.299.55

- Vorobyeva E.V. Changes in the structure of the phenolic antioxidant Irganox 1010 in the composition of zinccontaining polymer composite under cyclic thermal effects. ISJ Theor. Appl. Sci. 2018; 67(11): 232-239. https://doi.org/10.15863/TAS.2018.11.67.38

- Usanov D.A., Skripal A.V., Romanov A.V. Management of microwave characteristics of composite materials filled with carbon nanotubes by ultraviolet radiation. Journal of Technical Physics. 2013; 83(3): 91-95.

- Kuznetsov D.V., Muratov D.S., Cherdyntsev V.V. The study of the stability of polymer composites based on polypropylene to ultraviolet radiation. Modern problems of science and education. 2012; 6: 33.

- Vydrina T.S., Artemov A.V., Savinovskikh A.V., Shkuro A.E. Wood-polymer composites based on secondary polyethylene, wheat husk and oxo-, photogradant. Bulletin of technological university. 2020; 23(1): 28-32.

- Lavrov N.A., Belukhichev E.V., Semenova E. Comparative analysis of the effectiveness of the use of lubricants of natural and synthetic origin. Science Week. VI scientific and technical conference. 2016: 156.

- Usova K.A., Chirkov D.D., Zakharov P.S., Shkuro A.E. Wood-polymer composites based on polyethylene with crushed sunflower stems. Scientific creativity of youth to the forestry complex of Russia. 2022: 721-724.

- Poddenezhny E.N., Drobyshevskaya N.E., Boyko A.A. Obtaining biodegradable composites and products containing dried coffee grounds. Bulletin of P.O. Sukhoy GGTU. 2022; 3: 36-43.

- Yeletsky A.V., Knizhnik A.A. Potapkin B.V., Kenny H.M. Electrical Characteristics of Polymeric Composites Containing Carbon Nanotubes. Advances in Physical Sciences. 2015; 185(3): 225-270. https://doi.org/10.3367/UFNr.0185.201503a.0225