Irrigation channel lining using shotcrete with additives

Автор: Moldamuratov Zh.N., Iglikov A.A., Sennikov M.N., Madaliyeva E.B., Turalina M.T.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Manufacturing technology for building materials and products

Статья в выпуске: 3 Vol.14, 2022 года.

Бесплатный доступ

Introduction. Shotcrete lining is the most economical and quite fully mechanized in production among all the known varieties of concrete linings. The construction practice of hydraulic structures has accumulated numerous examples of the use of a wide variety of building materials in lining – from stone to modern films made of synthetic resins. Despite the very active efforts to find more suitable materials, concrete lining will remain the main one for a long time. Accordingly, concrete lining requires further improvements, increasing durability and reducing cost. Methods and materials. The studies were carried out by the comparison method of laboratory tests of shotcrete with nanostructured surfactants additives. In the form of nanostructured additives, SCL (sulfite-cellulose liquor), NAR (neutralized air-retaining resin), cotton soap and bitumen were used in various consistency. The tests were conducted on strength properties, shrinkage, tension deformation, adhesion strength and water permeability. Structural changes in the properties were studied by electron-microscopic analysis. Results and discussion. It is established that the optimal proportion of SCL additive to the shotcrete gauged water, under the spraying condition, is 0.5% by the cement weight. NAR additive is not observed. When cotton soap additive with gauged water are added into the shotcrete, the water content in the placed shotcrete increases as the amount of the additive added increases, the optimal cement content in the shotcrete is observed when 0.3% cotton soap additive by the cement weight is added. The “rebound” decreases when the additive proportion grows. The 0.3% SCL additive by cement weight added in 1:4 dry mixture shotcrete increases its compression strength by 16%, bending strength by 1% and tension strength by 20%. Conclusion. All nanostructured surfactant additives increase the shotcrete shrinkage. The shotcrete with SCL additive shows the smallest increase in the shrinkage, and the largest – with bitumen emulsion. The additives used in shotcrete significantly increase its tension deformability, and in a wide range reduce the values of the shotcrete instantaneous elasticity modulus, i.e. enhance its plastic properties. The surfactants and bitumen emulsion reduce the adhesion strength between shotcrete and reinforcement, however, it remains at a higher level than that of conventional concretes.

Nanostructured additives, shotcrete, surfactants, bitumen, neutralized air-retaining resin, sulfite-cellulose liquor

Короткий адрес: https://sciup.org/142232054

IDR: 142232054 | DOI: 10.15828/2075-8545-2022-14-3-227-240

Текст научной статьи Irrigation channel lining using shotcrete with additives

Original article

M ost irrigation systems in Kazakhstan do not have anti-filtration lining on the channels. This is one of the main reasons for the very low efficiency of systems, as well as resalinization and waterlogging of suspended land [1].

Further development of agriculture in the Kazakhstan requires radical change in the prevailing views on the irrigation channels lining. The dwindling land reserve for new irrigation and the ever-increasing need for capital costs of reclaiming old irrigation land will sooner or later require a transition to fully lined systems. Therefore, there is already a very serious need for extensive scientific and industrial research of all kinds of materials and structures, methods of work and design of machines to install linings [2].

The construction practice of hydraulic structures in various countries has already accumulated numerous examples of the use of a wide variety of building materials in the lining- from stone to modern films made of synthetic resins. However, despite the very active efforts to find

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS more suitable materials, concrete lining will remain the main one for a long time. Accordingly, concrete lining requires further improvement, increasing durability and reducing cost [1–5].

Shotcrete lining is the most economical and quite fully mechanized in production among all the known varieties of concrete linings [6].

In Kazakhstan and Central Asia, there are almost no shotcrete linings, there are only small areas, although in some foreign countries, for example, in the USA and China, they have been used for a long time and are being re-built [7, 8].

Due to the simplicity, construction mechanization and great economy compared to monolithic and prefabricated linings made of ordinary concrete, shotcrete linings will take a proper place in irrigation construction.

METHODS AND MATERIALS

Research [9–12] determined the optimal parameters for the shotcrete work production. In experiments, the angle between material flow direction and the land to be treated was 90 degrees with the distance from the nozzle to the panel 90–110 cm. In the experiments, we used sand taken from the Syrdarya riverbed, with the volume weight of 1.44 kg/l, a specific gravity of 2.7 kg/l and voidness of 46.5%, Portland cement grade 400 of Zhambyl Cement Plant and water from State utility enterprise on the right of economic management “Taraz Su”.

By applying shotcrete to special panels at an angle of 90 degrees to their surface, shotcrete plates were made, which were cut into figures of certain sizes at the horizontal position of the panel. This facilitated the samples production and improved their quality.

We took cubes sized 3×3×3 cm to test shotcrete compression strength, and prisms 3×3×24 cm in size were used to test the bending properties. We prepared prisms 3×3×8 cm in size, which were placed in normal-type briquettes and the “rounding-off shoulders” were filled with cement-water paste made of fine-ground cement. During the tension test, there were cases of “rounding-off shoulders” shearing, so we designed special dies from roofing iron with wooden plungers and the workshops machined them.

The proportions of sand and cement to prepare dry mixture were taken by weight. The composition of the shotcrete was determined by the specific method [10, 11]. Experimental samples were tested after storing them in wet sand for 7, 28, 60, 90, 180, 360, 720 days. At least three twin samples were tested at each stage. The strength properties of shotcrete (kg/cm2) without additives at 28-days are given in Table 1.

At 18-months, shotcrete had the following strength (% of 28-days): by 1:2 composition of the dry mixture – 116, by 1:3 and 1:4 – approximately 100, by 1:5 – 106 (in compression), by 1:4 – 184 and 1:5 – 164 (in bending). In later stages, the strength increases significantly during bending and slightly during compression. At 24-months, the compressed shotcrete has the following strength (% of 28-days): by 1:3 composition of the dry mixture – approximately 100 and by 1:5 – 174 accordingly.

The ratios of bending strengths to compressive strengths, average for various periods of storage, increase with a decrease in the fat content of the dry mixture from 0.32 for a composition of 1:2 to 0.42 for a composition of 1:6. Average ratios of tensile strength to compressive strength increase from 0.13 for 1:2 dry mixture to 0.29 for 1:6 dry mixture.

In addition to sufficient compressive, bending and tensile strength, water permeability is of great importance for the lining material. Shotcrete with an undamaged structure has a high water permeability [15]. When lining was installed at channels K-18, K-20 in the Maktaral district of the Turkestan region, shotcrete with 1:5 dry mixture composition mixed with cement grade 400 and Zhetysay sand (lining thickness 5–7 cm) at 28-days stage withstood a pressure of 6–8 atm (Fig. 1).

Shrinkage was determined on prism shaped samples sized 5×5×50 cm using a designed and manufactured saddle-type indicator tensometer. The relative shrinkage values (ε×10–5) for shotcrete at 14 and 28-days are as follows (Table 2).

To determine the effect of water evaporation from the sample on its shrinkage, some samples were coated with paraffin. Dry mixture composition 1:4. Shrinkage was measured on a 5×5×50 cm sample. The paraffined sample shrank for 2 days gradually, due to contraction: then the shrinkage stopped, amounting to 9.4 µ. During

Table 1

The strength properties of shotcrete (kg/cm2)

|

Type of test |

Dry mix composition |

||||

|

1:2 |

1:3 |

1:4 |

1:5 |

1:6 |

|

|

Compression |

281 |

230 |

179 |

150 |

100 |

|

Bending |

105 |

73 |

72 |

62 |

40 |

|

Tensile |

38 |

32 |

27 |

32 |

19 |

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 1. Pilot sites of irrigation channel lining installation using shotcrete in the south of Kazakhstan

Table 2

Relative shrinkage values of shotcrete

The disadvantages of cement material, from the point of view of its use for channel lining, are 1) excessive stiffness and brittleness, which increase over time, and 2) sufficiently large temperature-shrinkage deformation. The first disadvantage does not allow to built thin concrete lining (5–7 cm), as it would be highly susceptible to destruction even with minor base deformations (subsidence and suffosion process). Therefore, monolithic concrete lining is usually 10–15 cm thick and are often reinforced with iron. The second disadvantage leads to the need to disturb the coating by cutting temperature-shrinkage seams, and this worsens coating operational performance and complicates construction work. In this regard, it is desirable to increase the deformative properties and creep of cement material, in particular shotcrete [11–14].

The influence of nanostructured surfactants on the shotcrete creep was revealed when we add SCL (sulfitecellulose liquor), NAR (neutralized air-retaining resin) and cotton soap into gauged water. Bitumen substance has high plastic properties under certain conditions. It can transmit these properties to the input materials. Bitumen substance was added into the shotcrete as bitumen solution in kerosene and bitumen emulsion.

The effect of appending organic surfactants should affect the wetting ability of the gauged water and the me- chanical properties of the shotcrete [16]. The influence of organic surfactants on the wetting ability of gauged water with the additive was determined by measuring the capillary suction of solutions. To determine the capillary suction of distilled water with and without additives, a simple device is made consisting of four tubes with a diameter of 3.2, 1.2, 0.5 and 0.3 mm, fixed on a measuring scale with the ends of the tubes extending beyond the scale by 20 mm. The tubes were immersed in the liquid. To measure the capillary suction, the average of three experiments was taken.

RESULTS

SCL was added in the amount of 0.5, 1 and 1.5%, NAR – 0.05, 0.1 and 0.15, cotton soap – 0.1, 0.3 and 0.5%. As a result, it was found that SCL increases the wetting ability of water, and the more additives the higher wetting ability is. NAR causes a slight increase, and cotton soap significantly reduces it.

To find out the effect of additives on the shotcrete spraying process, a set of experiments was carried out, the results obtained are given below. In experiments, a 1:4 dry mix shotcrete with various amounts of SCL, NAR and cotton soap was used. To make the research, the group of scientists took 10 kg of dry mixture and defined the composition of the shotcrete applied to the panel and its weight. According to the spraying conditions, the optimal amount of SCL additive is 0.5% by the cement weight. With such an amount of additive, shotcrete contains a minimum amount of water, a maximum amount of cement and has the smallest “rebound”.

The optimum addition of NAR is not observed. As it increases from 0.05 to 0.1% of the cement weight, the water content in the cast-in-place shotcrete increases from 12.4 to 13.1%, cement content increases from 29.5 to 30.9, and the shotcrete weight changes from 4.3 to 5.3 kg, i.e. the “rebound” decreases.

When cotton soap mixed with gauged water is added to the shotcrete and as its amount increases, the water content in the shotcrete inhances. It is noted that the optimal amount of cement in shotcrete is by the addition of 0.3% cotton soap by cement weight, or 0.57% by water weight. The weight of the cast-in-place shotcrete increases from

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

-

4.38 kg with 0.1% cotton soap from the cement weight to 5.88 kg with 0.5% addition, i.e.the “rebound” decreases.

In order to determine the effect of surfactant additives on strength properties, 5×5×5 cm cubes, 5×5×31 cm prisms, and normal-type briquettes were made. Beams sized 5×5×50 cm were tested for shrinkage. Also beams of the same dimentions with the released reinforcement ends d = 10 mm were tested for deformation ability under the condition of a slowly increasing static tensile load. The shotcrete creep was examined under the constant static load. The rings with a diameter of 20 cm and a thickness of 5 cm were tested for water permeability (Fig. 2).

The ideal proportion of additives in concrete and ordinary mortar was established during laboratory and industrial experiments: SCL is about 0.25%, NAR is 0.03 %, and cotton soap is 0.1% by the cement weight.

To try shotcrete strength out, three twin samples were used. The tests were carried out at 28, 90, 180 and 270 days of samples storage in wet sand. 1:4 dry mixture composition. The results are shown in the Table 3.

The SCL in the amount of 0.3% by the cement weight increases the compressive strength on the average of 16%, bending strength by 1%, and tensile strength by 20%. Shotcrete compressive strength increased on the average of 16%, the bending and tensile strengths decreased in comparison with the shotcrete corresponding strengths without additives when SCL 0.5% by cement weight was added. The average compressive and tensile strengths remained approximately at the same level as the shotcrete corresponding strengths without additives, and the bending strength increased by 20% when SCL 1% by weight of cement was added.

Based on the experiment results, it can be concluded that SCL increases the shotcrete strength properties almost at the same limits as in ordinary cement mortars and concretes, so SCL in the amount of 0.3% by the cement weight can be recommended to use to increase the shotcrete strength in structures.

NAR and cotton soap reduced the shotcrete strength properties, and the more they are added the greater the strength decreases. The proportion of additives used in experiments showed that cotton soap reduces the compressive and tensile strength to a greater extent than NAR. And only shotcrete bending strength was higher with cotton soap added than with added NAR. This is explained by the fact that surface-active additives of hydrophobic type, adsorbed on the surface of concrete components, form films of water-solublecalcium soaps and therefore

Fig. 2. Shotcrete samples

Table 3

Results of the shotcrete strength test

|

Type of shotcrete |

Quantity of additive, % by cement weight |

Water/ Cement in shotcrete |

Strength limits of samples in kg/cm2 at the 24-hour period |

|||||||||||

|

compression |

bending |

tensile |

||||||||||||

|

28 |

90 |

180 |

270 |

28 |

90 |

180 |

270 |

28 |

90 |

180 |

270 |

|||

|

Without additive |

– |

0.52 |

259 |

218 |

259 |

– |

94 |

85 |

142 |

– |

34 |

33 |

37.9 |

– |

|

0.3 |

0.43 |

317 |

270 |

301 |

– |

108 |

– |

125 |

– |

38 |

38 |

50.8 |

– |

|

|

With additives |

0.5 |

0.28 |

293 |

328 |

247 |

377 |

83 |

83 |

132.5 |

136 |

23 |

31 |

35.6 |

47.9 |

|

SCL |

1.0 |

0.47 |

255 |

190 |

301 |

471 |

103 |

128 |

139 |

128 |

31 |

32 |

41.3 |

– |

|

NAR |

0.03 |

0.37 |

183 |

260 |

165 |

293 |

74 |

83 |

78 |

131 |

26 |

24 |

36.8 |

38.5 |

|

0.06 |

0.58 |

147 |

265 |

273 |

– |

65 |

85 |

69 |

– |

22 |

25 |

32.4 |

– |

|

|

0.12 |

0.74 |

131 |

142 |

195 |

– |

55 |

62 |

– |

– |

12 |

27 |

25.2 |

– |

|

|

Cotton Soap |

0.1 |

0.71 |

166 |

156 |

138 |

182 |

65 |

76 |

97 |

55 |

20 |

19 |

31.8 |

– |

|

0.2 |

0.93 |

176 |

243 |

181.5 |

192.5 |

92 |

65 |

125 |

45 |

12 |

14.7 |

16.8 |

18.1 |

|

|

0.6 |

0.61 |

134 |

163 |

231 |

278 |

75 |

60 |

88.5 |

65 |

18 |

14 |

27.0 |

– |

|

|

Bitumen emulsion* |

0.25 |

0.6 |

137 |

174 |

180 |

263 |

77 |

60 |

87 |

96 |

20 |

– |

27.6 |

– |

|

0.5 |

– |

91 |

– |

154 |

– |

27 |

– |

57 |

– |

10 |

– |

14.2 |

– |

|

* The bitumen content is given as a percentage by the shotcrete weight

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS reduce the rate of hydration and hydrolysis of clinker minerals and, consequently, the increase in the strength over time. The plasticizing effect is based on air entrainment, which occurs in the concrete mixing process, but it does not occur during pneumatic spraying process, so there is no plasticizing effect [17].

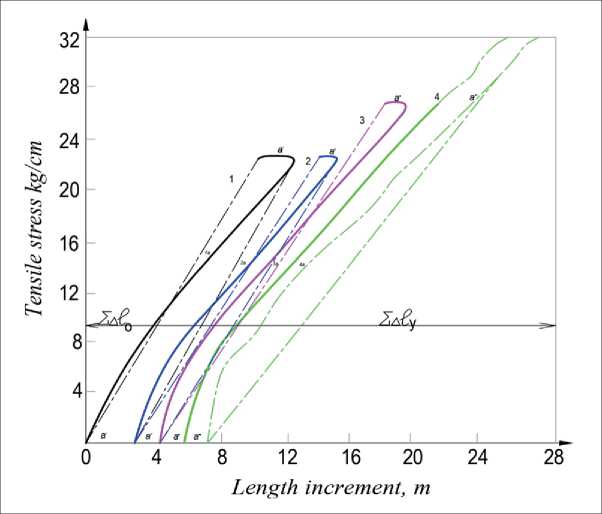

The deformability of shotcrete containing various additives of different proportions was determined under the influence of permanent step load.

The experiment shows that the speed of load application is approximately constant, so the task to define the comparative deformability indicators of shotcrete with additives can be considered fully completed.

The prism shaped samples at the 28-days sized 5×5×50 cm were tested during the experiment. Deformation was measured by indicator tensometer. Deformation reports were taken at stress intervals of 2 kg/cm2. Three twin samples were tested, and the number of loading and unloading cycles ranged from 4 to 15. Two samples were destroyed and one was left to be tested again at the 3-months. Aside the deformation reliance on the stress, there were also determined the number of plastic deformations at certain stress levels (sometimes close to Rp ), maximum extensibility, and tensile strength limits.

The figures show the deformation reliance graph ∆ l = f ( σp ), based on the experiment results, where almost all traffic curves of the second loading cycle are taken for the samples that showed most logical change (out of three twin samples) in deformation reliance. Shotcrete creep was determined based on measurements of 28.5 cm.

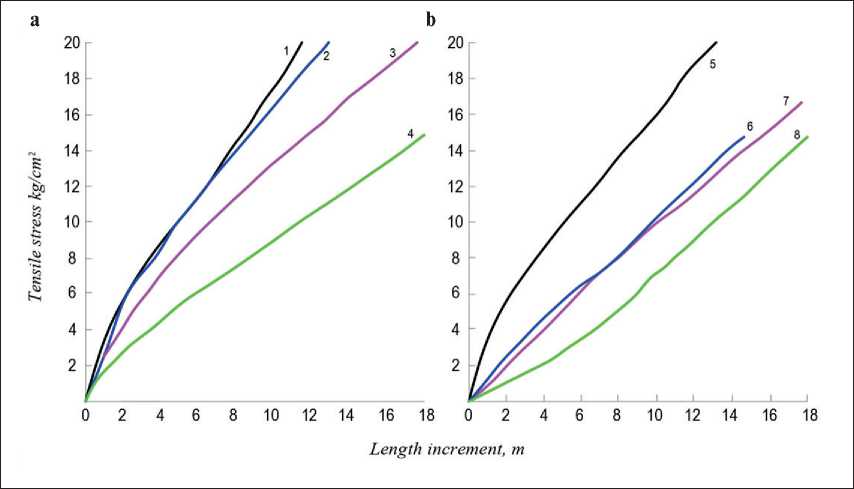

Fig. 3 shows deformation reliance on the stress for shotcrete with different proportions of SCL and NAR additives, as well as control curves for shotcrete without additives. All kinds of samples were made from cement dry mixtures and sand in a ratio of 1:4. The graphs show that SCL additive greatly increase the shotcrete deformation ability under certain load; the more additive added, the more sharply the deformability increases, and this fact is observed in an overall increase of the shotcrete with SCL additive strength properties. SCL increased the specific deformability, and consequently reduced the value of the instantaneous and long-term deformation modulus and thereby enhanced the plastic deformations as well. This is also indicated by a significant length reduction of the initial straight-line portion on the graphs.

The influence of additives on the maximum tensile strength of 28.5 cm of the prism section is characterized by the following data (1:4 dry mix composition, Table 4).

Graphs of shotcrete deformability with NAR additive show that NAR even more sharply than SCL increased the deformation ability of the shotcrete, however, this is already observed at a time when strength properties decreased substantially. NAR slightly changes the nature of the deformation curves: they approach the straight lines and the curve 8 changes the curvature sign.

Cotton soap increases the deformability of the shotcrete more significantly than SCL and NAR, but it is particularly marked under a higher ultimate tensile strength decrease compared to the shotcrete with the NAR addition (Fig. 4a).

Fig. 3. Graph of shotcrete deformation reliance on load and additive ∆ l = f ( σpD ): 1 and 5 without additive, ∆ l = 0.3– 0.86; 2 – 0, % SCL, ∆ l = 0.4–0.62; 3 – 0.5% SCL, ∆ l = 0.5–1.2; 4 – 1.0% p SCL, ∆ l = 0.6–1.5; 6 – 0.03% NAR;

7 – 0.06% NAR; 8 – 0.12% NAR (for NAR ∆ l = 1.0)

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Table 4

Effect of additives on the ultimate tensile strength value

|

Quantity of the additive, % |

Ultimate tensile strength, kg/cm2 |

Maximum elongation, µ |

|

Without additive |

28 |

22 |

|

SCL |

||

|

0.3 |

34.6 |

21 |

|

0.5 |

27.9 |

26–27 |

|

1.0 |

20 |

33 |

|

NAR |

||

|

0.03 |

20 |

42 |

|

0.06 |

19 |

46–47 |

|

0.12 |

14 |

20 |

|

Cotton Soap |

||

|

0.1 |

20.4 |

35 |

|

0.2 |

16.1 |

32 |

|

0.6 |

11 |

22 |

|

Bitumen |

||

|

0.25 |

16 |

8 |

|

0.5 |

11 |

18 |

Bitumen was added into the shotcrete with gauged water as an emulsion in 0.25 and 0.5% proportions (Fig. 4b). Curve 2 corresponds to the deformation of the samples added 0.25% additive; with a few additives, the difference in elongation indicators compared to shotcrete without additive is not significant. The 0.5% additive increased significantly the shotcrete deformability, as is the case with NAR additive. Curve 3 has already a clearer inverse curvature, which logically should indicate the decrease in the plastic component of deformation as the stress increases. Bitumen additive dramatically reduced the tensile strength and even the ultimate tensile strength, although the specific tensile strength remained approximately the same.

For a more prominent comparison of the tensile strength (at 28-days), depending on its composition and additives, the values of the total increment of the samples length µ are given below based on the accepted measurement when the samples reach the tension of 5 and 10 kg/cm2 (with additives, the dry mixture composition is 1:4, Table 5).

SCL increases the deformability under static load by 2–2.5 times, NAR – by 2,5–4 times, cotton soap – by 3–5 times, bitumen – by about 2 times.

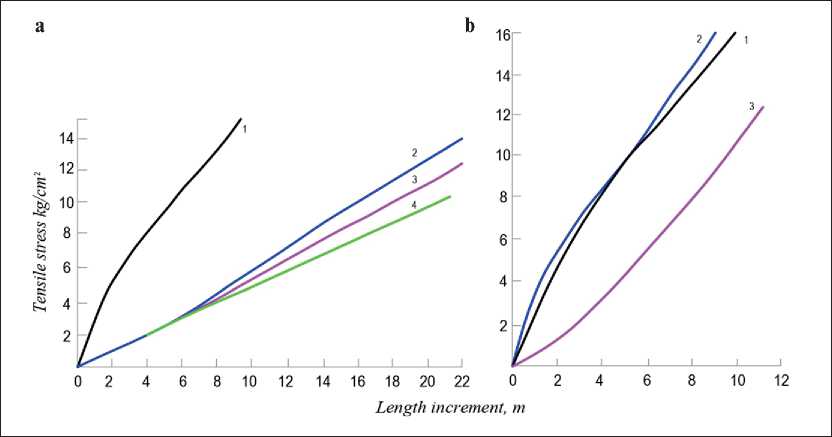

The shotcrete deformability was determined from 4 to 15 cycles of alternate loading and unloading.

Fig. 5 show the deformation reliance graph of the test of 1:4 dry mix shotcrete without additives at 5 loading cycles. The curves of different cycles are almost parallel (parallelism of tangentsat points of equal loads), although, with an increase in the number of cycles, they would have to straighten out due to a process similar to “hardening”. When the load is reset for the next loading cycle, the indicator arrow does not return to its initial position, but always shows a longer length, a sample by a value a' , a'ʹ and etc. As the number of loading cycles increases, the values of a , being as a residual deformation, decrease and are practically reduced to zero. The absolute values of a depend, apparently, on the material of the samples, the stage, and the present tension.

Fig. 4 (a, b). Graph of shotcrete deformation reliance on load and additive ∆ l = f ( σpD ): a – cotton soap additive, %;

1 – without additive, ∆ l = 0.3–0.86; 2 – 0.1, ∆ l = 1.5; 3 – 0.2, ∆ l = 1.7; 4 – 0.6, ∆ l = 2.15; b – bitumen additive, %;

1 – without additive, ∆ l = 0.3–0.85; 2 – 0.25, ∆ l = 0.3–0.86; 3 – 0.5, ∆ l = 0.74

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Table 5

Comparison of shotcrete tensile strength

|

Dry mix composition and additive percentage |

5 kg/cm2 |

10 kg/cm2 |

|

Without additive 1:2 |

0.2 |

0.4 |

|

1:3 |

0.7 |

2.0 |

|

1:4 |

1.8 |

5.0 |

|

SCL 0.3 |

2.1 |

5.0 |

|

0.5 |

2.7 |

6.7 |

|

1.0 |

5.0 |

11.5 |

|

NAR 0.03 |

5.0 |

10.0 |

|

0.06 |

5.2 |

10.2 |

|

0.12 |

8.0 |

13.4 |

|

Cotton Soap 0.1 |

8.8 |

16.2 |

|

0.2 |

10.0 |

18.6 |

|

0.6 |

10.6 |

21.0 |

|

Bitumen 0.25 |

2.0 |

5.3 |

|

0.5 |

5.6 |

9.5 |

Thus, the reliance curve ∆l = f(σp) sums up the elastic and plastic deformation components during the forward course (tension increase), and the second branch of the curve corresponding to the tension relief, on the contrary, differentiates them. In experiments, the rate of increase and decrease of the load is quite high; we can assume that the plastic component of deformationis restored. As the number of loading and unloading cycles increases, the angle of the graph inclination (lines 1, 2 and 3) to the abscissa axis decreases, and the value of the elastic modulus decreases along with the integrity violation of the shotcrete structural constructions.

This phenomenon is observed in all the tests we have performed with a large number of loading and unloading cycles. During 1:4 dry mixture sample test with the 0.06% NAR additive, the instantaneous elastic modulus found according to the graph of the second cycle was 285 000 kg/cm2, and according to the graph of the 15th cycle – 259 000 kg/cm2.

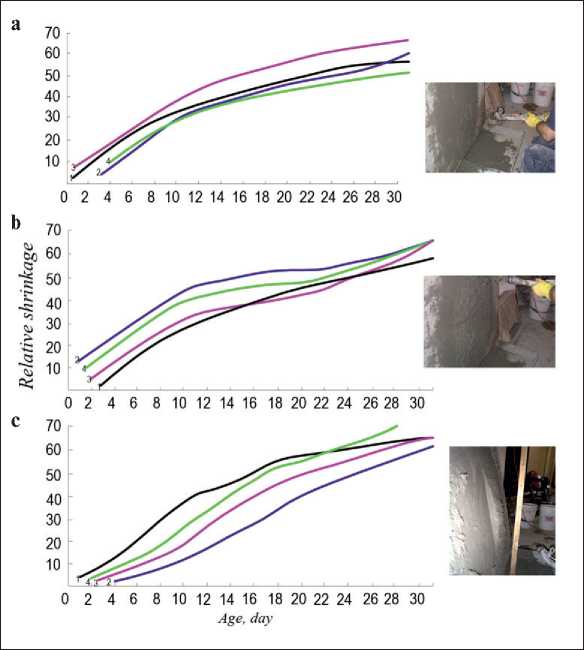

During the experiments to identify the shotcrete shrinkage, we were interested, firstly, in its shrinkage deformations, since shotcrete differ significantly from ordinary concretes and mortars in the placing method and water consumption, and, secondly, in the effect of surfactants additives and bitumen on the shotcrete shrinkage.

Shrinkage was determined on prism shaped samples sized 5×5×31 cm and 5×5×50 cm using special devices. A set of control measurements showed that the relative shrinkage obtained on samples of different lengths differ very little. Shrinkage of the samples was observed for 2–3 months. According to the shrinkage graphs of shotcrete samples without additives and with the initial 1:3 and 1:4 dry mixtures compositions as well as with 0.3 and 0.5% SCL additives (by the cement weight), it can be concluded that the first three compositions have

Fig. 5. Curves of shotcrete deformation reliance on load ∆ l = f ( σp ) at 5 load cycles

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 6. Graphs of shotcrete shrinkage reliance on time εy = f (t): а – SCL additive, %; 1 and 2 – without additive (mixture 1:4); 3 – 0.3, mixture 1:4; 4 – 0.5, mixtures 1:4; b – NAR additive (mixture 1:4), %; 1 – without additive; 2 – 0.03; 3 – 0.06; 4 – 0.12; c – cotton soap additive (1 – 0.1%, 2 – 0.2, 3 – 0.6) and bitumen (4 – 0.25%, 5 – 0.5); mixture 1:4

approximately the same shrinkage rate, and the fourth composition has a slightly higher one (Fig. 6a). This is due to the high cement content in the fourth composition, as well as the acceleration of cement hydration as a result of the SCL peptizing effect and the accelerating processes of diffuse water absorption by cement.

Shotcrete with NAR additive (1:4 dry mixture composition) has higher shrinkage than shotcrete without additive. According to the curves position (Fig. 6b), it can be seen that the cement content has a greater influence on the shrinkage rate than water, so the compositions with higher cement content correspond to curves of greater shrinkage rate.

Shotcrete with soapstock soap additive and bitumen has a slightly lower shrinkage rate in the first 15 days of testing, and in the subsequent days it has a higher one. (Fig. 6c) By the end of the month, the shotcrete with bitumen has the greatest shrinkage. To compare, the relative shrinkage values for all shotcrete compositions are given below (for shotcrete with 1:4 additives) at 14 and 28-days. The additives used in the first month increase the shotcrete shrinkage, the highest indicators were found in shotcrete with bitumen (Table 6).

Table 6

Relative shrinkage rates

|

Dry mixture composition and additive percentage |

Relative shrinkage 14 days |

t y × 10–5 at 28-days |

|

Without additive 1:4 |

35.0 |

53.5 |

|

1:3 |

36.0 |

57.0 |

|

SCL 0.3 |

39.0 |

55.0 |

|

0.5 |

48.0 |

63.7 |

|

NAR 0.03 |

49.0 |

59.5 |

|

0.06 |

44.0 |

58.5 |

|

0.12 |

36.0 |

55.0 |

|

Cotton Soap 0.1 |

44.0 |

62.5 |

|

0.2 |

23.4 |

55.0 |

|

0.6 |

35.0 |

60.3 |

|

Bitumen 0.25 |

40.0 |

68.0 |

|

0.5 |

37.0 |

66.0 |

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

The adhesion strength between concrete and reinforcement is the most important factor that ensures their joint and reliable operation in constructions. It is caused by three main causes: friction and shear resistance. Numerical value of adhesion strength is determined empirically, and its shear resistance ( Rad and τad ) is expressed by the adhesion strength (kg/cm2) assigned to the total outside surface of the reinforcement Experiments have shown that τad for concrete ranges from 25 to 40 kg/cm2, and for shotcrete it is slightly higher – 38–62 kg/cm2 [18].

DISCUSSION

In our experiments, we tried to trace the effect of additives on the shotcrete adhesion strength. Adhesion strength was determined by pulling out 10–12 mm long reinforcing rods from prism shaped samples with the cross- section of 50×50 mm and the length of 15– 17 cm. The length of restraint of the reinforcement end was 10–12 cm. The adhesion strength between shotcrete and reinforcement has the same cohesion as the strength properties. SCL additive increased significantly the adhesion strenth (almost in twice), and all other additives lowered it (Table 7).

However, by the 3-months, the SCL additive did not increase the shotcrete adhesion strength, while in shotcrete without additives and with hydrophobic additives, adhesion strength increase is observed. In some cases, the adhesion strength between concrete and reinforce- ment reaches 200% of the 28-days adhesive strength. By the 3-months, all shotcrete compositions got the adhesion strength τad, close to one τad for ordinary concretes or even higher. Thus, it can be noted that the adhesion strength τad between shotcrete with additives (SCL, NAR, cotton soap, bitumen in proportions close to ours) and reinforcement is at a very satisfactory level, and therefore the minimum embedment length of the reinforcement can be calculated according to the principles that apply in ordinary concrete, i.e.

where l – is the minimum required embedment length of the reinforcement; Ra H – is the standard resistance of the reinforcement.

To compensate for shrinkage deformations, the creep of the shotcrete under static load is of great importance [19–27]. Sample shrinkage deformations at 1-month, taken for testing from wet sand, were larger than the creep in a certain period of time: this became clear after testing 9 sets of samples (shotcrete without additives, as well as with SCL and NAR).

Starting from the 10th set, where the samples made from dry mixture of cement and sand 1:4 with 0.6% cotton soap additive (by the cement weight) were used, the deformations shown by the sample under the influence of the tension load were divided into shrinkage and creep by subtracting from them the shrinkage values obtained

Table 7

Adhesion strength between shotcrete and reinforcement indicators

|

Additive proportions, % |

Dry mixture composition |

Shear strength (kg/cm2) at the particular time |

||

|

1 month |

3 months |

6 months |

||

|

1:2 |

34 |

53 |

52 |

|

|

Without additive |

1:3 |

29 |

48 |

41 |

|

1:4 |

26 |

41 |

47 |

|

|

SCL 0.3 |

1:3 |

46 |

43 |

41 |

|

0.3 |

1:4 |

44 |

– |

– |

|

0.5 |

– |

40 |

37 |

36 |

|

1.0 |

– |

25 |

– |

40 |

|

NAR 0.03 |

– |

23 |

46 |

46 |

|

0.06 |

– |

21 |

34 |

52 |

|

0.12 |

– |

17 |

22 |

31 |

|

Cotton Soap 0.1 |

– |

12 |

24 |

– |

|

0.2 |

– |

15 |

31 |

23 |

|

0.6 |

– |

10 |

20 |

26 |

|

Bitumen 0.25 |

– |

19 |

25 |

18 |

|

0.5 |

– |

16 |

– |

– |

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Table 8

Shotcrete creep indicators

Due to the shrinkage effect, the shotcrete creep is not observed by direct measurements at low loads – 0.2 ÷ 0.3 Rp . As the load increased over 0.5 Rp , almost all tested shotcrete compositions showed creep deformation, which was recorded directly by tensometer. However, this process was fading; after 4–6 hours, the shrinkage again exceeded the creep and tensometer began to show shortening of the samples.

A sample made from dry mixture 1:4 with 0.5% SCL additive was tested for creep effect. Regardless of the tension acting on it, the total deformations (creep, shrinkage) were permanently negative, i.e. the sample was shortened, and the shortening of 11 cm base fluctuated within the following limits (Table 8).

An increase of the tensile load on the shotcrete reduces its shrinkage deformations: this occurs due to the rise in the creep intensity and as a result of the creep efforts increase resisting shrinkage deformations. Table 9 shows the nature of the elastic deformation increment of the shotcrete during a stepping, highly dispersed in time load increment.

The experiment, the results of which are summarized in the Table 9, was carried out as follows. When the sample was being effected by a continuous load, up to 6.4 kg/cm2, we took the tensometer readings, then after 21 hours the load was completely removed, the tensometer arrow was set to zero point, and after that, the sample was affected by the load again, up to 9 kg/cm2. The sample elongation was 15.2 and 14.5 µ, respectively. After 48 hours, we repeated the same process again.

Data from tables and graphs (given only for one set of shotcrete samples) showed that in the general case, the relience ∆ l = f ( σp ) is curvilinear, and the curvature of the graphs is of the same direction (sign) as in the tests of shotcrete under continuous static loading.

Water permeability tests were performed on disk samples with a diameter of 200 mm and a height of 50 mm (three samples per point at the 28-days). The pressure increased by 1 atm. after 4 hours. Samples were cut from 50 mm thick shotcrete slabs using a die and plunger. The test results are given below (Table 10).

The effect of appending of nanostructured surfactants does not reduce the shotcrete water permeability, even the samples with 1% SCL additive by cement weight can withstand the 6 atm pressure. If SCL additives increase the shotcrete compression capacity and keep it at the level of its compressive capacity without additives, they also cannot reduce the water permeability.

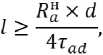

Electron-microscopic analysis of shotcrete with nanostructured additives of surfactants has shown that the strength properties, shrinkage, tensile deformability and water permeability have significantly improved indicators compared to ordinary concrete and confirm the results of the experimental work. The microstructure of

Table 9

Increment nature of shotcrete elastic deformations

|

Sample tension strength, kg/cm2 |

Number of hours before the load is applied |

Sample elongation at the base of 110 mm, µ |

||

|

Right tensometer |

Left tensometer |

Average |

||

|

6.4 |

14.3 |

13.2 |

13.75 |

|

|

9.0 |

21 |

15.2 |

14.5 |

14.85 |

|

10.0 |

48 |

16.0 |

15.4 |

15.70 |

|

11.2 |

48 |

17.0 |

16.0 |

16.50 |

|

12.4 |

48 |

17.6 |

16.9 |

17.25 |

|

13.6 |

240 |

18.9 |

17.7 |

18.30 |

|

15.2 |

120 |

19.1 |

18.9 |

19.00 |

|

16.0 |

144 |

20.7 |

20.1 |

20.40 |

|

17.0 |

24 |

21.0 |

22.1 |

21.55 |

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Table 10

Test results of shotcrete water permeability

|

Additive proportion, % |

Dry mix composition |

Pressure sustained by samples, atm |

|

Without additive |

1:4 |

6 |

|

1:2 |

6 |

|

|

SCL |

||

|

0.3 |

1:3 |

6 |

|

0.3 |

1:4 |

6 |

|

1.0 |

6 |

|

|

NAR |

||

|

0.03 |

* |

6 |

|

0.06 |

* |

6 |

|

Cotton Soap 0.1 0.2 |

* * |

1* 6 |

* Samples burst when the pressure increased the samples was examined on the JEOL JSM7500 scanning electron microscope with an X-ray spectral analysis attachment (Fig. 7).

CONCLUSION

Based on the results of the study, the following conclusions can be drawn:

-

1. Nanostructured additives of surfactants have different effects on the water wetting ability and the shotcrete strength: SCL and NAR additives increase them, while NAR does it slightly. Cotton soap additive significantly reduces the water wetting ability and, probably, therefore reduces the shotcrete strength in case if gauged water is mixed with it.

-

2. The optimal proportion of SCL additive to the shotcrete gauged water, under the spraying condition, is 0.5% by the cement weight. The optimum of NAR additive is not observed When cotton soap additive with gauged water are added into the shotcrete, the water content in the placed shotcrete increases as the amount of the additive added increases, the optimal cement content in the shotcrete is observed when 0.3% cotton soap additive by the cement weight is added. The “rebound” decreases when the additive proportion grows.

-

3. The 0.3% SCL additive by cement weight added in 1:4 dry mixture shotcrete increases its compression strength by 16%, bending strength by 1% and tension strength by 20% (compared to the corresponding shotcrete strengths without additives).

Fig. 7. Microstructure of shotcrete samples: a – with SCL additive; b – with NAR additive; c – with cotton soap additive; d – with bitumen additive

-

4. The 0.5% and 1% SCL, 0.06 NAR, and 0.12%, cotton soap additives taken by 0.1, 0.2 and 0.6% by cement weight, bitumen in the form of an emulsion 0.25 and 0.5% by shotcrete weight (from 1:4 dry mixture) reduce the shotcrete compression, bending and tension strengths compared to the corresponding strengths of it without additives.

-

5. All nanostructured surfactant additives increase the shotcrete shrinkage. The shotcrete with SCL additive shows the smallest increase in the shrinkage, and the largest – with bitumen emulsion.

-

6. The nanostructured surfactant additives used in the shotcrete (by the 28-days) significantly increase its tension deformability.

-

7. The nanostructured surfactant additives in a wide range reduce the values of the shotcrete instantaneous elasticity modulus, i.e. enhance its plastic properties.

-

8. The surfactants and bitumen emulsion reduce the tension strength between shotcrete and reinforcement (except for SCL), however, it remains at a higher level than that of ordinary concrete.

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Список литературы Irrigation channel lining using shotcrete with additives

- Jakiyayev B.D., Moldamuratov Z.N., Bayaliyeva G.M., Ussenbayev B.U., Yeskermessov Z.E. Study of local erosion and development of effective structures of transverse bank protection structures. Periodicals of Engineering and Natural Sciences (PEN). 2021. 9(3): 457. Available from: https://doi.org/10.21533/pen.v9i3.2191

- Sennikov M.N., Omarova G.E., Moldamuratov Z.N. Study of the development of soil in the formation of channels hydraulic and static stability of cross-sectional shapes. World Applied Sciences Journal. 2014. 30(1): 99–104. Available from: https://doi.org/10.5829/idosi.wasj.2014.30.01.14008

- Hammer A.L., Thewes M., Galler R. Empirical forecasting model to determine the strength development of shotcrete. Geomechanik Und Tunnelbau. 2019. 12(6): 730–738. Available from: https://doi.org/10.1002/geot.201900054

- Çakıroğlu M.A., Kaplan A.N., Süzen A.A. Experimental and DBN-Based neural network extraction of radiation attenuation coefficient of dry mixture shotcrete produced using different additives. Radiation Physics and Chemistry. 2021. 188. Available from: https://doi.org/10.1016/j.radphyschem.2021.109636

- Kloft H., Krauss H.W., Hack N., Herrmann E., Neudecker S., Varady P.A., Lowke D. Influence of process parameters on the interlayer bond strength of concrete elements additive manufactured by Shotcrete 3D Printing (SC3DP). Cement and Concrete Research. 2020. 134. Available from: https://doi.org/10.1016/j.cemconres.2020.106078

- Armengaud J., Casaux-Ginestet G., Cyr., Husson B., Jolin M. Characterization of fresh dry-mix shotcrete and correlation to rebound. Construction and Building Materials. 2017. 135: 225–232. Available from: https://doi.org/10.1016/j.conbuildmat.2016.12.220

- Bekbasarov I., Nikitenko M., Shanshabayev N., Atenov Y., Moldamuratov Z. Tapered-prismatic pile: driving energy consumption and bearing capacity. News of the National Academy of Sciences of the Republic of Kazakhstan, Series of Geology and Technical Sciences. 2021. 6(450): 53–63. Available from: https://doi.org/10.32014/2021.2518-170X.119

- Wang J., Niu D., Wang Y., Wang B. Durability performance of brine-exposed shotcrete in salt lake environment. Construction and Building Materials. 2018. 188: 520–536. Available from: https://doi.org/10.1016/j.conbuildmat.2018.08.139

- Shen Y., Wang Y., Yang Y., Sun Q., Luo T., Zhang H. Influence of surface roughness and hydrophilicity on bonding strength of concrete-rock interface. Construction and Building Materials. 2019. 213: 156–166. Available from: https://doi.org/10.1016/j.conbuildmat.2019.04.078

- Watanabe T., Hosomi M., Yuno K. Hashimoto C. Quality evaluation of shotcrete by acoustic emission. Construction and Building Materials. 2010. 24(12): 2358–2362. Available from: https://doi.org/10.1016/j.conbuildmat.2010.05.007

- Wang J., Niu D., He H. Frost durability and stress–strain relationship of lining shotcrete in cold environment. Construction and Building Materials. 2019. 198: 58–69. Available from: https://doi.org/10.1016/j.conbuildmat.2018.11.264

- Chen L., Ma G. Liu G., Liu Z. Effect of pumping and spraying processes on the rheological properties and air content of wet-mix shotcrete with various admixtures. Construction and Building Materials. 2019. 225: 311–323. Available from: https://doi.org/10.1016/j.conbuildmat.2019.07.104

- Armengaud J., Cyr M., Casaux-Ginestet G. Husson B. Durability of dry-mix shotcrete using supplementary cementitious materials. Construction and Building Materials. 2018. 190: 1–12. Available from: https://doi.org/10.1016/j.conbuildmat.2018.09.107

- Cui S., Liu P., Cui E., Su J., Huang B. Experimental study on mechanical property and pore structure of concrete for shotcrete use in a hot-dry environment of high geothermal tunnels. Construction and Building Materials. 2018. 173: 124–135. Available from: https://doi.org/10.1016/j.conbuildmat.2018.03.191

- Khooshechin M., Tanzadeh J. Experimental and mechanical performance of shotcrete made with nanomaterials and fiber reinforcement. Construction and Building Materials. 2018. 165: 199–205. Available from: https://doi.org/10.1016/j.conbuildmat.2017.12.199

- Trujillo P.B., Jolin M., Massicotte B., Bissonnette B. Bond strength of reinforcing bars encased with shotcrete. Construction and Building Materials. 2018. 169: 678–688. Available from: https://doi.org/10.1016/j.conbuildmat.2018.02.218

- Liu P., Cui S., Li Z., Xu X., Guo C. Influence of surrounding rock temperature on mechanical property and pore structure of concrete for shotcrete use in a hot-dry environment of high-temperature geothermal tunnel. Construction and Building Materials. 2019. 207: 329–337. Available from: https://doi.org/10.1016/j.conbuildmat.2019.02.125

- Kaufmann J., Loser R., Winnefeld F., Leemann A. Sulfate resistance testing of shotcrete – Sample preparation in the field and under laboratory conditions. Construction and Building Materials. 2021. 276. Available from: https://doi.org/10.1016/j.conbuildmat.2020.122233

- Pan G., Li P., Chen L., Liu G. A study of the effect of rheological properties of fresh concrete on shotcreterebound based on different additive components. Construction and Building Materials. 2019. 224: 1069–1080. Available from: https://doi.org/10.1016/j.conbuildmat.2019.07.060

- Duarte G., Bravo M., de Brito J., Nobre J. Mechanical performance of shotcrete produced with recycled coarse aggregates from concrete. Construction and Building Materials. 2019. 210: 696–708. Available from: https://doi.org/10.1016/j.conbuildmat.2019.03.156

- Liu G., Zhao J., Zhang Z., Wang C., & Xu Q. Mechanical properties and microstructure of shotcrete under high temperature. Applied Sciences (Switzerland). MDPI. 2021. Available from: https://doi.org/10.3390/app11199043

- Zhu C., Zhou N., Guo Y., Li M., & Cheng Q. Effect of doped glass fibers on tensile and shear strengths and microstructure of the modified shotcrete material: An experimental study and a simplified 2D model. Minerals. 2021. 11(10). Available from: https://doi.org/10.3390/min11101053

- Liu M., Liu D., Qiao P., & Sun L. Characterization of microstructural damage evolution of freeze-thawed shotcrete by an integrative micro-CT and nanoindentation statistical approach. Cement and Concrete Composites. 2021. 117. Available from: https://doi.org/10.1016/j.cemconcomp.2020.103909

- Wang Y., Shi C., Ma Y., Xiao Y., & Liu Y. Accelerators for shotcrete – Chemical composition and their effects on hydration, microstructure and properties of cement-based materials. Construction and Building Materials. Elsevier Ltd. 2021. https://doi.org/10.1016/j.conbuildmat.2021.122557

- Xu Y., He T., Ma X., & Yang R. The research on mechanism of C–S–H nanocrystal improving early properties of shotcrete at low temperature by thermodynamic modeling. Construction and Building Materials. 2022. 325. Available from: https://doi.org/10.1016/j.conbuildmat.2022.126738

- Shang Y., Guo Y., Zhang W., Zhao W., & Tan Y. Influence of new compound admixture on shotcrete performance. Journal Wuhan University of Technology, Materials Science Edition. 2017. 32(6): 1392–1396. Available from: https://doi.org/10.1007/s11595-017-1758-8

- Zaki Saaid I. Application of ultra cellulose fiber for the enhancement of the durability and shrinkage of cement pastes exposed to normal and aggressive curing conditions. Nanotechnologies in Construction. 2015. (7)4: 121–142. Available from: https://doi.org/10.15828/2075-8545-2015-7-4-121-142