Изменение технологических расстояний основных рабочих органов современных чесальных машин и их анализ

Автор: Ф.Ф. Казаков, Н.Н. Саттарова, Ж. Умиров, И. Ражабов

Журнал: Современные инновации, системы и технологии.

Рубрика: Прикладные вопросы и задачи применения систем и технологий

Статья в выпуске: 2 (2), 2022 года.

Бесплатный доступ

В статье рассматриваются способы повышения производительности чесальной машины при переработке хлопкового волокна, зависящей от увеличения скоростных режимов основных очесывающих органов (приемного барабана и главных барабанов), с целью улучшения качества чесальных поверхностей, увеличения площади очеса. Приведены таблицы об интервалах, которые устанавливаются на технологическом оборудовании чесальной машины. В частности, использовались два гребнечесальных сегмента, а для окончательного размягчения продукции в центральной аспирационной зоне чесальных машин использовались три гребнечесальных сегмента и устройство очистки отходов. Сегменты, установленные на машине, изготовлены Rieter.

Сорные примеси, волокна, пряжа, качество, производительность, производительное эффективность, вытяжка, вытяжной прибор

Короткий адрес: https://sciup.org/14123394

IDR: 14123394 | DOI: 10.47813/2782-2818-2022-2-2-0401-0408

Текст статьи Изменение технологических расстояний основных рабочих органов современных чесальных машин и их анализ

DOI:

Each process is very important for the production of flat and high-quality yarn in the textile industry. At the same time, the carding process is of great importance. Sticky weeds and defects remain in the fibrous layers obtained from the baking and cleaning unit, which worsens the quality of the product. For this reason, the fibers are processed by combing through the fiber layers. In the process of combing, the fibrous product is divided into separate fibers, while weeds, fluffs and defects are separated, and then a tape suitable for extraction is formed on tape machines [1]. At the same time, about 80% of the dirt is removed by the card carding machine. 20% of impurities and defects pass into the roving, and then into the yarn. Defects and nodules can also occur in the carding machine, which also affects the subsequent technological processes and consistently the quality of the yarn. The comb contains from 30 to 50% fiber, which can be spun. The degree of parallelism and straightening of the fibers in the combed tape is not very good. As can be seen from the above, many tasks in the carding machine are not fully performed. In addition, despite the fact that the productivity of carding machines when spinning cotton fiber has increased to 180-220 kg/h in recent years, it remains low compared to the subsequent technological process [2]. Thus, improving the carding process on hat-carding machines is an important task that requires constant attention of researchers. It is known that in hat-carding machines, carding is divided into two parts: the receiving drum zone and the main drum and hats.

In the part of the receiving drum, the fiber is first combed, 70-80% of the incoming bundles are separated [3]. When working cotton on carding machines, the following works are performed:

-

• combing of fibers by dividing into small pieces;

-

• cleaning the fiber from sticky weeds and defects, combing part of the short fibers;

-

• significant (100-150 times) thinning of the fibrous layer;

-

• preparation of high-quality tape from combed and cleaned fiber and put it in a basin.

The ultimate goal of the spinning mill is to get a smooth, clean and durable yarn. To achieve this goal, it is possible to loosen the fibrous material, dividing it into separate fibers, thereby cleaning it from weeds and impurities.

Modern loosening and cleaning units (POA) provide effective loosening, mixing and cleaning of fibrous material [4-6].

The fibrous flow created by the POA consists of small, fairly homogeneous particles. After the POA, the fibers need a higher degree of purification to separate waste mixtures, mainly small impurities, which is provided by the carding process, the essence of which is to separate the fibers, remove impurities and defects, and partially orient the fibrous product along the axis of movement. Thus, the main goal of the carding machine is achieved-the regular movement of fibers at subsequent stages creates the necessary conditions for extraction on exhaust devices [7].

When spinning cotton fiber cardo carding is performed on a hat carding machine. Over the past decade, the processing capacity of medium-fiber cotton has increased to 180-220 kg per hour due to the constructive improvement and improvement of machine technology [8].

MATERIALS AND METHODS

It should be noted that since the middle of the XIX century, the technological scheme of the hat carding machine has hardly changed. All the main components performing the main technological processes are preserved in the machine: the feed unit, the receiving drum unit, the "main drum-caps" unit, all the main components of the separation drum units, the comb separator and the forming tape have been preserved. To maintain or improve the quality of carding an increase in the productivity of the machine is achieved through the development of the theory of carding. Increasing the productivity of the carding machine depends on increasing the speed modes of the main carding organs (receiving drum and main drums), improving the quality of carding surfaces and increasing the area of the carding. The technique of increasing the carding of the surface is achieved on the free surfaces of card amplifiers, main and separation drums [9].

There are a number of theoretical grounds that show the high efficiency of using additional carding surfaces during carding. To test these assumptions, we conducted a technological experiment at POSCO INTERNATIONAL TEXTILE.

The object of the experiment was a RIETER C 60 carding machine.

Technical characteristics of the carding machine studied during the experiment.

-

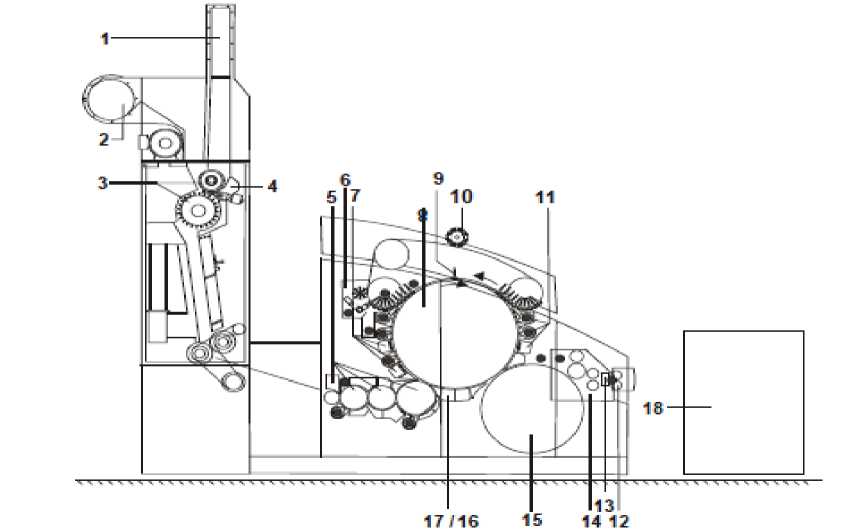

1 - separator

-

2 - pull pipe;

-

3 - baking device;

-

4 - feeding table;

-

5 - fiber loosening and control of uniform fiber transfer;

-

6 - cleaning the cap and suction of waste;

-

7 - preliminary carding part;

-

8 - main drum;

-

9 - carding carding machine bar;

-

10 - leveling device;

-

11 - combing out segments and combing out parts with a knife stroke;

-

12 - rollers;

-

13 - front line;

-

14 - separation drum;

-

15 - separation device;

16 - bottom box;

17 - drum alignment device;

18 - stacker tape device.

Figure 1 . Scheme of the carding machine With 60.

Table 1. Carding Machine performance.

|

№ |

Technological performance |

Indicators |

|

1 |

Tape weight |

89.0g/meter |

|

2 |

product |

63.5 kg/p |

|

3 |

stack |

168 m/min |

|

4 |

Change of basins |

50 min 8430m |

|

5 |

Total pulling carding machine |

141 |

Современные инновации, системы и технологии // Modern Innovations, Systems and Technologies 2022; 2(2)

6 Comb receiver

918 g/m

During the research on the carding machine, the following current distances were determined (Table 2).

Table 2. Intervals set on the carding machine.

|

Working bodies |

wiring, mm |

|

Feeding table of the receiving drum |

0.45 |

|

Receiving drum-main drum |

0.15 |

|

Main drum –hats |

|

|

- output |

0.3 |

|

- input |

0.2 |

|

main drum- separation drum |

0.8 |

|

Waste cleaning knife under the receiving drum |

0.3 |

|

Main drum –preliminary carding segments: |

|

|

- upper |

0.5 |

|

- lower |

0.55 |

|

the main drum is the last carding segment |

|

|

- upper |

0.3 |

|

- in the middle |

0.3 |

|

- lower |

0.25 |

|

- a box of collecting fluff |

0.3 |

|

Rear knife-main drum: |

|

|

- at the entrance |

0.51 |

|

- when exiting |

0.56 |

|

Front knife-main drum |

|

|

- at the entrance |

0.94 |

|

- at an output |

0.8 |

RESULTS AND DISCUSSION

The experiment was carried out on the assortment in production conditions, which required considerable time to work out different options.

Table 3 describes cotton fiber. Description of cotton fiber (the mixture consists of 95% 2-1 fiber and 5% waste).

Table 3. Description of cotton fiber.

|

Name |

Indicators |

|

Staple length, mm |

40/39.4 |

|

Modal length, mm |

36.9 |

|

Base, % |

25 |

|

humidity, % |

6.3 |

|

Pollution, % |

2.5 |

|

Number of kirovs, pcs |

11 |

|

bale weight, kg |

2288 |

|

Fiber number, No |

7840 |

|

Breaking load of fiber RvsN |

4.4 |

|

Relative value of the tensile strength of the fiber Rotn., cH/tex |

34.5 |

|

Maturity |

2 |

|

Type |

2 |

|

Grade |

1 |

There are five main groups that effectively process fiber with the RIETER C-60 carding machine:

-

1) self carding machine;

-

2) the mechanism of the tape stacker (tape stacker);

-

3) suction device;

-

4) ventilation;

-

5) pipe lines (filtrating – carding machines).

The carding machine consists of a feeding table, a feeding cylinder, a receiving and main drum, a separating drum, a set of hats, a roller device for removing the comb and an exhaust device. When processing cotton fiber, carding machines are equipped with a device for leveling dirt. The comb exits the outlet roller of the comb and then switches to the exhaust device [10, 11].

The segments installed on the machine are manufactured by Rieter. In order to improve the quality of the combing, the initial carding elements were used to ensure that the hat set was free. These elements allow the use of hats in large quantities with a large fiber capacity and high density. Depending on the raw materials and the type of carding machine, two to four carding segments can be used [12].

CONCLUSION

In our study, two combing segments were used in the posterior zone. For final softening, three combing segments and a waste cleaning device were used in the central suction system of the carding machines.