Энергетические характеристики типичных жилых домов в строительном секторе

Автор: Маодус Никола, Радека Мирослава, Кочетов Мишулич Татьяна

Журнал: Строительство уникальных зданий и сооружений @unistroy

Рубрика: Энергоэффективность и энергосбережение

Статья в выпуске: 11 (26), 2014 года.

Бесплатный доступ

Растущая обеспокоенность по поводу изменения климата на планете побудило мировое экологическое сознание возродить производство строительных конструкций на основе древесины. В статье анализируется эффективность использования конструкций из дерева и на основе древесины в строительной отрасли в Юго-Восточной Европе. Несколько примеров типичных слоистых несущих конструкций, характерных для региона Балкан рассматриваются с анализом их теплопроводности и диффузии водяного пара. Выводы подтверждают эффективность использования древесины и конструкций на ее основе в строительном секторе.

Продукты на основе из дерева, энергоэффективность, энергетические параметры, коэффициент u, диффузии водяного пара

Короткий адрес: https://sciup.org/14322062

IDR: 14322062 | УДК: 69

Текст научной статьи Энергетические характеристики типичных жилых домов в строительном секторе

The growing concern about earth climate changes has induced the worldwide ecological awareness and consequently the revival of construction which uses wood and wood based products in the last few decades. The aim of the paper is to promote building structures of wood and to point out its sustainability and energy efficiency in South Eastern Europe construction sector. A few examples of typical multi-layered structural wall systems present in the Balkans region, accompanied with the analysis of the thermal transmittance coefficients "U" and the water vapour diffusivity are given in the paper. The conclusion points out a suitable, reasonable and advisable use of wood in the building sector.

Contents

Wood based products60

Comparison of thermal and water vapour properties of typical residential wall systems61

Conclusion66

Acknowledgements66

Construction of Unique Buildings and Structures, 2014, №11 (26)

Designing of the constructions is a very complex process, comprising different activities such as analyzing, calculating, comparing, deciding about materials, layer thickness, detailng, etc. Each design activity leads to numerous solutions - some better than the others in particular design situations. In this article, the basic aim is to draw attention to the advantages of utilization of wood and wood based products (WBP) in structural and construction manner, as well as to point out the advantages of good environmental impact of wood and WBP. The consideration of material choice in SEE is primarily determined by designer's own professional experience and, on the other hand, by code, law and regulation provisions, that are sometimes, in the case of timber structures, outdated or falling behind the market requirements i.e. architectural and investor's demands.

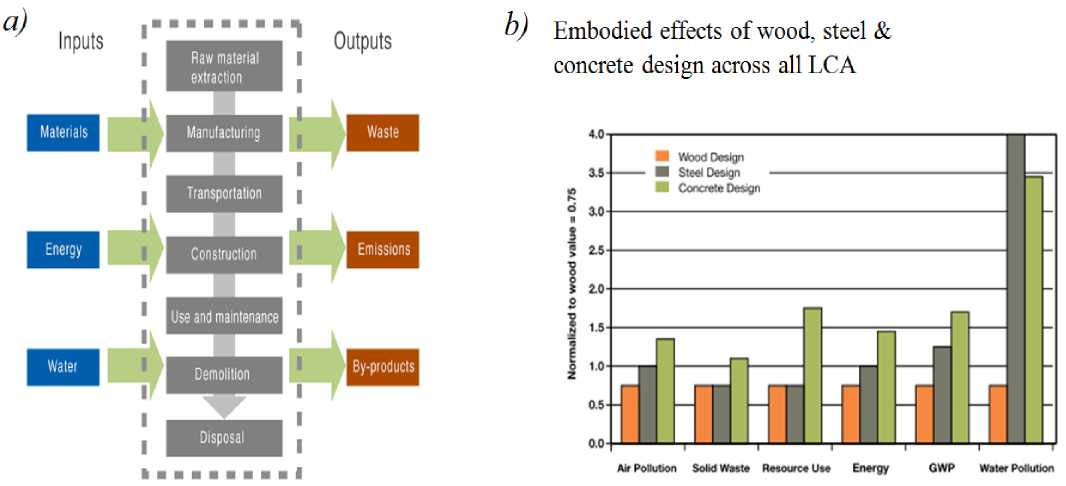

However, due to the growing concern about earth climate changes that induced the worldwide ecological awareness, wood and WBP nowdays occupy a significant position in the construction sector because of its sustainability, CO 2 neutral position and carbon storage effect. Wood is the only industrial raw material which is widely available and renewable, as well. Its environmenntal impact, assesed trough life cycle (LCA) methods, has been considered in many comparative case studies and projects.

The LCA procedure was standardized in ISO 14040-42 protocol in the late 1990s. After that time, a lot of muliticriteria approaches have been developed in order to assess the sustainable construction tools and the choice of construction materials, esspecially after EU Directive 31/2010 on the energy performance of buildings [1] and EU Regulation 305/2011 on construction products [2], when "Sustainable use of natural recources" was introduced as one of basic work requiremnents (BWRs).

LCA considers all inputs and outputs concerning construction materials from aquisition to final destruction and waste, possibility of recycling and waste management with production of the orphan products, Fig. 1 a). Wood and WBP construction show great advantages in all parameters, Fig. 1 b), comparing with other traditional materials suitable for residential bulidings, like steel and concrete [1- 25].

Figure 1. a) LCA relevant parameters; b) Energy efficiency comparison

Wood based products

Due to innovative technologies, a great progress in improvement of existing and creating of new products in the wood production sector has happened in last 2-3 decades. Products derived from wood - glulam, cross laminated timber (CLT), laminated veneer (LVL), different boards – have assumed a leading role in sustainable and prestigious building design across the world and Europe. They are shown in Table 1 with their excellent basic and thermal properties as well as their ecological footprint in structural applications [8, 9].

Table 1. Wood based products - structural role and basic thermal properties

Massive CLT structural panels λ [W/mK] = 0.10 - 0.13 µ (/)=40/ 70 (depend on moisture and numb. of layers)

LVL panels or linear girder elements λ [W/mK] = 0.11 - 0.20 µ (/)=50/70-150/200

Glulam girders (linear or curved) λ [W/mK] = 0.11-0.20

µ (/) = 20-60 (depend on density and moisture cont.)

Particle or chip boards as structural/finishing elements λ [W/mK]=0.07-0.18 µ (/)=10/50 - 20/50

MDF/HDF boards as structural/finishing elements λ [W/mK] MDF = 0.07-0.17 µ (/)=10/50 λ [W/mK] HDF = 0.14-0.22 µ (/)=5/10-20/30

OSB boards as structural/finishing elements

λ [W/mK] = 0.12-0.13 µ (/)=30/60 - 200/220

Structural properties of wood and WBP, that qualify timber products for structural use, are:

-

- self-weights (between 300-700 kg/m3), min 4 times less than RFC,

-

- bending properties (for Glulam of 1 or 2 class equal to RFC MB 35 or 30),

-

- MOE & slenderness/allowed stresses ratio,

-

- dynamic properties that promote CLT as unique innovative material for skyscrapers and safe material for building in seismic regions,

-

- improved fire performance , by new coatings, technical details and modern code concepts for calculating the fire performance risk,

-

- Ecological balance and sustainable energy efficient design from renewable sources, with a short period of the construction of a building.

Although SEE and the Balkans region are relatively reticent about building structures of wood and WBPs, the use of wood in residential and advanced timber structural systems has grown in the last decade. The recent experiences, after severe earthquakes and caused damages in the region (2012), have confirmed the validity of strategic decisions of EU countries that have taken steps toward reducing the greenhouse gas emissions and increasing the safety of buildings in seismic regions. Strategic decisions, that are not present in SEE current building politics, are based on obligatory percentage of new buildings that have to be made from WBPs. Such decisions should foster the wood production sector and global building market of one country.

Comparison of thermal and water vapour properties of typical residential wall systems

Actual "Requirements on Energy Efficiency in Buildings" [3] represent the first step in Serbian legal policy about sustainable building and energy savings. At this stage, "Requirements" put emphasis on the energy performances of building envelopes, regarding the thermal and water vapour properties of a building pursued by energy efficient buildings.

Energy efficient buildings comprise good thermal insulation, correct ventilation and optimal use of solar and internal advantages. Low thermal transmittance (U=1/ΣR) quantifies insulation quality. Besides the requirements about good energy efficiency, an increasing interest in improving building performance in general has been aroused. The building performance entails the need for good thermal insulation as well as the importance of 61

Маодус Н., Радека М., Кочетов Мишулич Т. Энергетические характеристики типичных жилых домов в строительном секторе. /

Maodus N., Radeka M., Kocetov Misulic T. Energy performance of typical residential buildings in SEE construction sector. © keeping accurate air, vapour and water transport control. This could be achieved by fulfilling a great number of performances specified as thermal insulation, air tightness, transient response, moisture tolerance, thermal bridging and others [10].

Therefore, the key of the success for energy efficient envelopes lies in the application of insulation material with defined low thermal conductivity properties, their correct installation in the correct locations and with continuity of insulating elements in order to achieve adequate air tightness and good control of moisture tolerance.

The moisture tolerance comprises built-in moisture (excess humidity present at the start of building process) and the water that comes from water vapour (hygroscopic water, water originated from surface and interstitial condensation).

If the interstitial condensation appears in insulation layer of exterior wall then there is a risk that moisture will be trapped within the construction, where it can reduce the performance of the insulation and provide a risk of promoting mould growth. In that case it is evident that the usage of the correct insulation with small capability of absorbing moisture is equally important as making sure that the insulation zone is continuous.

That is the reason why it is important to know how to prevent condensation as well as how to choose thermal insulation with defined properties (low water absorption capacity).

In this article, the comparative analysis of a few basic parameters of residential wall systems most present on the market is given, performed in order to promote the usage of wood systems.

1. Residential structural wood systems

Residential timber houses are generally built in massive or frame system, Table 2.

Regardless of chosen wood structural system, insulation is usually present in wall structures. The most common insulation types are fibrous (easy to install and with open porosity) and rigid plastic foams (demanding for installation and air and vapour tight). If they are well-designed, the envelopes of timber buildings, usually made as opaque wooden, plaster or transparent, help a lot in controlling thermal comfort, upgrading indoor air quality and increasing energy efficiency.

Although plenty of external wall types find application, the most frequently used prefabricated timber panel system and commonly used masonry systems (bricks or light weight elements) with so called "demit" facade will be discussed in this article. The assessment of used materials will be done through their thermal and hygric properties, with comparison of necessary thickness of the facade's insulating layers in order to meet the code requirements.

Table 2. Wood based structural wall systems in residential houses

Modern massive CLT wall system

Traditional massive log wall system

Light-framed solid timber system

Prefabricated lightframe wall system ("panel")

2. Relevant parameters for comparative analysis

In Table 3, the details of three typical external wall constructions have been analysed in order to illustrate the principles relevant to reducing heat loss in new buildings constructed to meet the Requirements on energy efficiency of buildings (EEBR).

All chosen examples have external facade of the same type, but with different insulation thickness. The discussed wall examples are chosen as representatives in line with tradition of residential building in the Balkans and SEE.

The evaluation of materials built-in the particular external wall assembly has also been discussed regarding their properties and moisture appearing in excess of the hygroscopic equilibrium that may attack the open pores. The details have been developed to minimize the risk of both surface and interstitial condensation.

Thermal transmittance was determined according to the EEBR [3] while the hydrothermal properties were calculated according to the standards [4-5] and EEBR [3].

The values for in- and outdoor conditions used for calculation of thermal and hygroscopic properties are: ɵi=20oC, ɵe=-5oC (internal and external temperatures), ϕi=55%, ϕe=90%, (internal and external relative humidity) Rsi=0.13 W/m2K, Rse=0.04 W/m2K (internal and external surface thermal resistances).

Additionally, thermal transmittance is evaluated concerning the temperature factor on the internal surface (fRsi) of a thermal bridge (Light-framed timber wall) in order to check the possibility of mould appearance on the surface. If fRsi drops below 0.7, the probability to see mould growing and the amount of condensed water on the internal surface is high.

Table 3. Three typical residential exterior wall properties in SEE

|

External walls : Layers (thickness ) |

Thermal conduct. λ [W/mK] |

Vapour resistance factor µ (/) |

The results of analysis according to procedure and criteria in EEBR |

||

|

5 го ф tn Ф С га а. i 5 ■□ ф Е S 12 Е |

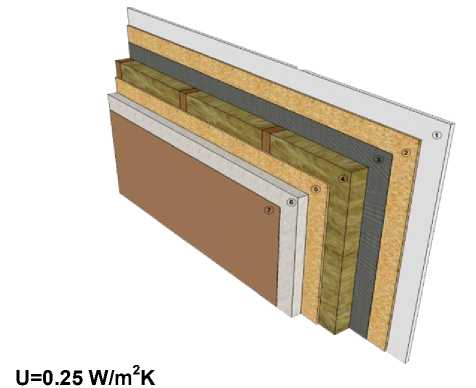

(i) from interior |

U=0.25 W/m2K Risk of surface condensation: R= 3.99 m2K/W R min =0.179 m2K/W (R>R min ) Mould control at thermal bridges-studs: f Rsi =0.746 > 0.7 |

|||

|

1. Gypsum board 0.018m |

0.23 |

8 |

|||

|

2. Sheathing (OSB) 0.010 m |

0.13 |

60 |

|||

|

3. Vapour retarders (PVC ) 0.0002 m |

0.19 |

42 000 |

|||

|

4. Mineral wool 0.08m |

0.034 |

1 |

|||

|

5. Sheathing (OSB) 0.01 m |

0.13 |

60 |

|||

|

6. Expanded polystyrene 0.05 m |

0.041 |

45 |

|||

|

7. Plaster 0.02m |

0.87 |

20 |

|||

|

(e) to exterior |

|||||

|

^ 5 о 12 ^ О го 3 |

(i) from interior |

U=0.281 W/m2K Risk of surface condensation: R= 3.56 m2K/W R min =0.179m2K/W (R>R min ) |

|||

|

1. Plaster 0.015 m |

0.87 |

20 |

|||

|

2. Brick 0.250 m |

0.61 |

6 |

|||

|

3. Expanded polystyrene 0.12m |

0.041 |

45 |

|||

|

4. Plaster 0.020 m |

0.85 |

15 |

|||

|

(e) to exterior |

|||||

|

О) 5 о (Л го 3 |

5 ф 2 о с о о |

(i) from interior |

U=0.237 W/m2K Risk of surface condensation: R= 4.23 m2K/W R min =0.179 m2K/W (R>R min ) |

||

|

1. Plaster 0.015 m |

0.87 |

20 |

|||

|

2. Light concrete block B5.0/600, 0.25 m |

0.16 |

7 |

|||

|

3. Expanded polystyrene 0.10m |

0.041 |

45 |

|||

|

4. Plaster 0.02 m |

0.85 |

15 |

|||

|

(e) to exterior |

|||||

2.1 Light -framed Timber wall (prefabricated shear wall)

The timber-framed wall with the studs (0.050x0.080 m) at a centre distance of 0.6 m, with thermal insulation between the studs and "demit" facade of 5 cm is discussed, Figure 2. The analysed layers have the exact thickness as it is common in production delivery. Important advantages of this system are architectural flexibility, prefabricated elements with controlled quality, small self-weight, good seismic behaviour, easy manipulation and fast and dry assembling, etc. The advantages in the sense of thermal and hygric properties are: the possibility of insulation upgrading (up to passive houses) and the moisture control of built-in materials during the production process. The disadvantages of timber are: low thermal inertia, critical air tightness and less moisture tolerance than bricks.

Timber framed shear wall

-

1. Gypsum board - 0.018m

-

2. Sheathing (OSB) - 0.010m

-

3. Vapour retarders (PVC )

-

4. Mineral wool - 0.08m

-

5. Sheathing (OSB) - 0.01m

-

6. Exp. polystyrene - 0.05m

-

7. Plaster - 0.02m

Total width : 0.188m

Remark:

No surface and interstitial condensation .

-

Figure 2. Relations of thermal & hygric properties for Layered Timber Framed Wall

Thermal transmittance (U-value):

of houses on the market, without any upgrading, meets the requirement EEB (U

Moisture tolerance

Construction moisture : the timber framing could have moisture content up to 75 kg/m3. Other applied WBPs generally are not moisture sensitive (e.g. OSB plates that are not hygroscopic and its water vapour resistance factor could reach value over 200), if they have a moderate vapour resistance, [6].

Rain: The rain control in this type of construction is based on the compactness of mortar and its treatment with water repellent materials.

Surface condensation: Surface condensation is avoided by using good thermal insulation (R>R min ).

Interstitial condensation: Due to water sensitivity of the softwood used, timber-framed construction is inherently less moisture tolerant than a massive construction. A vapour control layer is essential on the warm side of the insulation to reduce the risk of damaging internal condensation on the inner surface of the sheathing. Although the use of the OSB plate with high vapour resistance factor makes the utilization of water vapour barrier unnecessary in the presented example, it still remains in the wall for the safety reasons.

Mould control: As the temperature factor on the internal surface ( f Rsi ) of the thermal bridge is greater than 0.7, the probability for mould development is negligible, so the analyzed timber-framed wall is acceptable.

Air tightness

Air tightness is important for the efficient thermal and moisture control. Generally timber envelopes are not air-tight, especially because the timber dries out and shrinks and assemblies' joints could be in direct air infiltration path. In the analyzed wall, "demit" facade and water vapour barrier have a function of air infiltration barrier.

2.2 Masonry brick wall

The second analyzed wall example is made from traditional bricks (thickness of 25cm), plastered inside and finished by expanded polystyrene and plaster on the outer side. The thickness (12cm) and the type of thermal insulation are chosen to accomplish the criteria given in EEBR and to avoid interstitial condensation, Figure 4.

Thermal transmittance (U-value): Brick has high thermal conductivity value. When common thicknesses of exp. polystyrene (of 5, 8 or 10 cm) are applied, the insulated brick wall does not meet the required EEBR criteria (U 5 =0.543 W/m2K; U 8 =0.389 W/m2K; U 10 =0.327 W/m2K > U max =0.3 W/m2K). In the case of mineral wool application, the obtained values regarding thermal transmittance are better than in the previous case (U 5 =0.497W/m2K; U 8 =0.352W/m2K; U 10 =0.294W/m2K>U max =0.3 W/m2K and U 12 =0.253W/m2K), but interstitial condensation appears between the third and the fourth layers (drying is within acceptable limits). Due to a high capillary moisture capacity of bricks, wetting from foundation could increase moisture content and consequently thermal transmittance value.

U= 0.281 W/m2K

Masonry brick wall

-

1. Plaster - 0.015m

-

2. Brick - 0.250m

-

3. Exp. polystyrene - 0.12m

-

4. Plaster - 0.020m

Total width: 0.405m

Remark:

High capillary moisture capacity of bricks and great probability of appearance of hydrating salts.

Figure 3. Relations of thermal & hygric properties for Masonry Brick Wall

2.3 Masonry - lightweight wall

Moisture tolerance

Construction moisture: Considering the low critical moisture content of a brick (≤100 kg/m3) and low vapour resistance, built-in water dries fast. If the brick contains hydrating salts, it is very likely that the wall will stay wet for a long time.

Surface condensation: There is no risk of surface condensation (R>R min ).

Interstitial condensation: Control of interstitial condensation indicates that the usage of expanded polystyrene is preferable.

Air tightness

The way to achieve air tightness includes the usage of low porosity plaster finish, that the applied "demit" satisfies, filling the gaps and decreasing the air paths.

The third analysed wall is made from autoclaved aerated concrete blocks (600x200x250 mm, with density 600 kg/m3 [7]) that are glued with thin-bed mortar, plastered inside and finished by expanded polystyrene (10cm) and plaster on the outer side, Figure 5.

Thermal transmittance: thermal conductivity of applied blocks is very near to timber value. Expanded polystyrene insulation of 10cm meets the EEBR criteria and provides avoidance of interstitial condensation. Less insulation thicknesses could be achieved if mineral wool is applied (for 8 cm U 8 =0.25W/m2K, whereas for 10 cm thickness better value is reached U 10 =0.22W/m2K). However, interstitial condensation between the third and the fourth layer appears (drying is within acceptable limits).

Moisture tolerance

Construction moisture: Due to autoclaving, fresh blocks contain up to 200 kg per m3 of water. The drying process depends on inside relative humidity and even may take more than 12 years for 30 cm thick outer wall. Drying requires additional energy that increases the overall heating. The external plaster should be permeable for water vapour in order to accelerate drying process.

Surface condensation: There is no risk of surface condensation (R>Rmin).

Interstitial condensation: Interstitial condensation is avoided by using expanded polystyrene.

Air tightness

Because of the necessity for dry construction, air-tightness is unlikely to be achieved.

Masonry light - weight concrete block wall

-

1. Plaster - 0.015m

-

2. Light concrete block

-

3. Expanded polystyrene

B5.0/600 - 0.25m

-

- 0.10m

-

4. Plaster - 0.02m

Total width: 0.385m Remark :

Due to high built in moisture, drying process is very slow.

Conclusion

The results reported here indicate that all three analyzed walls satisfy the EEBRs, but proscribed criteria do not assume the heterogeneity of material properties and do not take into account the moisture changes during the exploitation period that could increase thermal transmittance values and decrease durability:

-

- The fact that light-framed timber wall is prefabricated in controlled conditions eliminates the majority of uncertainties. Besides, timber wall meets the same or better thermal and hygric properties allowing a larger net of residential surface and concerning necessary insulation upgrading for other two masonry wall systems. Also, the cost of this wall type is competitive.

-

- The ability of brick to absorb a considerable amount of water by capillary action as well as the ability of hydrating salts to increase this amount within the brick, can lead to the reduction of the thermal resistance of the brick wall.

-

- In the instance of the lightweight wall, the humidity of the applied blocks is very high upon installation, while the drying process is slow; therefore, the magnitude of real thermal transmittance increases.

It can be concluded that wood is an eco-friendly building material that can provide designers and consumers with both environmental and performance benefits, like attractive appearance, important influence on the microclimate and quick return of investments.

Acknowledgements

The paper is supported by the scientific research projects “Theoretical, experimental and applied research in Civil Engineering", developed at the Department of Civil Engineering and Geodesy, Faculty of Technical Sciences, University of Novi Sad, Serbia.

Список литературы Энергетические характеристики типичных жилых домов в строительном секторе

- Directive 2010/31/EU on energy performance of buildings, OJEU 18.6.2010, 23 p.

- Regulation (EU) No 305/2011 on Construction Products, OJEU 4.4.2011, 39 p.

- Requirements on Energy Efficiency in Buildings, OJ RS, no. 61/2011, 46 p.

- SRPS EN ISO 13788: Hygrothermal performance of building components and building elements-Internal surface temperature to avoid critical surface humidity and interstitial condensation-Calculation methods, ISS Belgrade, 2008., 38p.

- SRPS EN 1745: Masonry and masonry products-methods for determining design thermal values, ISS Belgrade, 2009, 52 p.

- Buxbaum C., Seiler A., Pankratz O. Hygrothermal performance of passive house wall systems -simulation and monitoring, 11th Canadian Conference on Building Science and Technology, Banff, Alberta, 2007. Pp. 11-22.

- YTONG Ž system URL: http://www.ytong.rs/rs/docs/130319_YTONG_Katalog_proizvoda_2013.pdf (date of reference 10.09.2014)

- URL: http://www.dataholz.com/(date of reference 10.09.2014)

- BS EN 13986: Wood-based panels for use in construction -Characteristics, evaluation of conformity and marking, BSi, London, 60 p.

- Hens H. Performance Based Building Design1, From Below Grade Construction to Cavity Walls, Wilhelm Ernst & Sohn, 2002, Germany, 274 p.

- Cointe A., Castéra P., Morlier P., Galimard P. Diagnosis and monitoring of timber buildings of cultural heritage, Structural Safety. Vol.29 (4), 2007, Pp. 337-348.

- Morrell J. J. Wood-based building components: what have we learned? (2002) International Biodeterioration & Biodegradation, Vol. 49(4) Biodet.of Constr. Materials. Pp. 253-258.

- Blom I., Itard L., Meijer A. Environmental impact of dwellings in use: Maintenance of façade components (2010) Building and Environment. Vol. 45. Issue 11. Pp. 2526-2538.

- Haapio A., Viitaniemi P. Environmental effect of structural solutions and building materials to a building//Environmental Impact Assessment Review. 2008. Vol. 28. Issue 8. Pp. 587-600.

- Zelazna A., Pawłowski A. The environmental analysis of insulation materials in the context of sustainable buildings, environmental engineering, in: The 8th International Conference, Vilnius, Lithuania, May 19-20, 2011, Pp. 825-829.

- Ватин Н. И., Горшков А. С., Немова Д. В. Энергоэффективность ограждающих конструкций при капитальном ремонте//Строительство уникальных зданий и сооружений. 2013. №3 (8). С. 1-11.

- Горшков А. С., Немова Д. В., Ватин Н. И. Формула энергоэффективности//Строительство уникальных зданий и сооружений. 2013. №3 (8). С.49-63.

- Горшков А. С., Ватин Н. И., Дацук T. A., Безруков A. Ю., Немова Д.В., Какула П., Виитанен А. Альбом технических решений по применению теплоизоляционных изделий из пенополиуретана в строительстве жилых, общественных и промышленных зданий. АТР -СПУ -02 -14: материалы для проектирования//Строительство уникальных зданий и сооружений. 2014. №5 (20). С. 71-439.

- Murgul, V. Features of energy efficient upgrade of historic buildings (illustrated with the example of Saint-Petersburg) (2014) Journal of Applied Engineering Science, Vol. 12 (1), Pp. 1-10

- Мургул В. Возможности использования солнечной энергии для энергоснабжения жилых зданий исторической застройки Санкт-Петербурга и улучшения качества городской среды//Архитектон: известия вузов. 2012. 4 (40). С. 54-62.

- Pintarič, K., Premrov, M. Mathematical modelling of timber-framed walls using fictive diagonal elements (2013) Applied Mathematical Modelling, 37 (16-17), Pp. 8051-8059.

- Ber, B., Premrov, M., Štrukelj, A., Kuhta, M. Experimental study of timber-glass composite wall elements (2013) COST Action TU0905 Mid-Term Conference on Structural Glass -Proceedings of COST Action TU0905 Mid-Term Conference on Structural Glass, Pp. 253-260.

- Žegarac Leskovar, V., Premrov, M., Vidovič, K. Architectural geometry of timber-glass buildings and its impact on energy flows through building skin (2013) COST Action TU0905 Mid-Term Conference on Structural Glass -Proceedings of COST Action TU0905 Mid-Term Conference on Structural Glass, Pp. 133-139.

- Leskovar, V.Ž., Premrov, M. An approach in architectural design of energy-efficient timber buildings with a focus on the optimal glazing size in the south-oriented façade (2011) Energy and Buildings, 43 (12), Pp. 3410-3418.