Justification of the criteria requirements for fillers in mixtures for 3D construction printing

Автор: Galina S. Slavcheva, Igor O. Razov, Valentina A. Solonina, Yulia F. Panchenko

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 4 Vol.15, 2023 года.

Бесплатный доступ

Introduction. As part of the task to create new materials for additive technologies, an analysis of the situation was carried out, and a problem was identified with the lack of common approaches to selecting raw material components for mixtures. Theoretical concept. Based on the approaches of fundamental structure rheology, physicochemical mechanics of disperse systems, the theory of packing of granular media, we theoretically justified the criteria requirements for the characteristics of fillers and suggested quantitative criteria for their evaluation. It was proposed to use these quantitative criteria for a preliminary comprehensive assessment of fillers when designing compositions of mixtures for 3D construction printing. Materials and methods. The characteristics of the fillers were evaluated using scanning electron microscopy with a scanning electron microscope Thermo Scientific™ Phenom™ Desktop SEM and processing of images by the ParticleMetric software package as well as using laser granulometry with a laser analyser of particles Analysette 22. Results. We assessed the cement and 5 types of fillers that had different sizes and played different roles in the formation of the mixture properties. We also identified their estimated criterial characteristics, including the average particle diameter, gra-nulometric constant, and particle shape coefficient. Boundary values of these characteristics were determined for particles of different morphology and dispersion degree. Conclusion. Based on the application of the suggested theoretical approaches, we determined the lines of research associated with obtaining experimental patterns of the impact of the criterial characteristics of fillers on the rheological characteristics of mixtures as well as with these characteristics according to their significance and justifying the requirements for the range of quantities of fillers depending on their size, shape, and granulometry.

Cement composites, additive technologies, modelling, fillers, rheology

Короткий адрес: https://sciup.org/142238301

IDR: 142238301 | DOI: 10.15828/2075-8545-2023-15-4-310-318

Текст научной статьи Justification of the criteria requirements for fillers in mixtures for 3D construction printing

Original article

STATE OF THE ISSUE

One of the principal issues related to the implementation of the potential of additive technologies in construction is the creation of efficient materials that are fundamentally different from traditional building materials in their technological characteristics. As for traditional construction technologies, the set of such properties is determined by the need to quickly and easily fill the mold or the formwork. In 3D printing technology, it is necessary to ensure the formation of a defect-free extruded layer and the body of a construction object in case of formwork-free shaping. Today, the set of technological characteristics of mixtures for printing includes the following elements [1]–[3]:

-

1) pumpability, that is the ability of mixture to be transported from the preparation site to the printing head.

-

2) extrudability, printability, that is the ability of mixture to form a defect-free printing layer in the course of extrusion.

-

3) shape retention, that is the ability of the extruded layer to preserve its cross section equal to the cross section of the nozzle.

DEVELOPMENT OF NEW MATERIALS

-

4) buildability, workability, that is the ability of the layer to preserve its shape under the pressure of the upper layers in a printed structure.

As part of the optimisation of these characteristics, the rheological behaviour of mixtures for 3D printing has been thoroughly studied [4]. Based on this, dozens of various materials with the technological characteristics necessary for printing have been produced and successfully tested, which have. Compositions for 3D printing are multi-component, so they contain superplasticisers, viscosity modifiers, structure formation regulators, as well as fillers and aggregates of different chemical and mineralogical compositions and dispersion degree at the same time.

As it was shown in the reviews by A. Rehman [5], Bing Lu [6], and D. Jiao [7], the roles of the binding agents, plasticisers, and viscosity modifiers in the regulation of the rheological behavior and, accordingly, in the provision of the specified technological characteristics were definitely determined. It was confirmed that the type of binding agent is the main factor in the regulation of the processes of structure formation and hardening of 3D printed composites. The introduction of superplasticisers and electrolytes is the main factor regulating the plasticity of the mixture. Viscosity modifiers (inorganic polymers and inorganic nanodispersed additives) determine the shape retention indicators.

The characteristics and concentrations of fillers are considered to be priority factors in regulating the plasticity and shape retention of mixtures. Systematisation and analysis of data on the influence of fillers on the technological properties of mixtures for 3D printing allowed discovering the following. Currently, natural and recycled aggregates are used to produce building mixtures, which can be divided into three size groups [8–24]:

– fine sand-like aggregates: carbonate and quartz sand, waste glass aggregate, plastic and rubber processing products, etc.

– microscale power-like aggregates: fly ash, mining tailings, silica fume, ground blast furnace slag, thermoplastic microspheres, crushed limestone;

– nanoscale aggregates: metakaolin, kaolin, chalk, nanoclay.

The roles of fillers of different sizes significantly differ.

Influence of fine sand-like aggregates [8–16]. The increased concentration of fillers of this dimension leads to an increase in viscosity and a decrease in the plasticity of mixtures, which is naturally associated with increased friction between particles. As a result, the pumpability and extrudability of the mixtures deteriorate. Therefore, the following strict limits were applied:

– Mass ratio of binder/ fine sand-like aggregates must be ≤ 2.

– The size of filler grains must not exceed 2–2.5 mm.

Influence of microscale power-like aggregates [17–20]. The fillers of this dimension can be introduced as a replacement for part of the cement in the composition of the binding agent, and their concentration in the optimised mixture compositions is within the range of 20–40% of the mass of cement. The impact on various technological characteristics depends to a large extent on the type of microscale power-like aggregates. The introduction of crushed limestone improves plasticity, although reduces the shape retention of mixtures. The introduction of ash, mining tailings, and ground blast furnace slag increase the yield strength and plastic viscosity of mixtures. To achieve their optimal values in 3D printing technology, a rational particle size distribution of these types of fillers must be ensured.

Influence of nanoscale aggregates [21–24]. They are used as modifying additives, and the concentration in optimised mixtures is within the range of 2–5% of the mass of cement. Nanoparticles are placed between cement grains, tightening the structure of the mixture. As a result, the values of the static yield strength and plastic viscosity increase while the dynamic viscosity and dynamic yield strength remain unchanged. This determines an increase in shape retention and workability of mixtures without any deterioration of their pumpability. At the same time, aluminosilicate fillers (such as metakaolin, nanoclay, etc.) have a crystal-chemical structure similar to cement, which allows accelerating the hydration process and increasing the strength of 3D printed composites.

Therefore, we can clearly identify that the dimension and concentration of fillers in mixture compositions have a determining influence on the set of necessary technological characteristics. The granulometry of fillers is also of great importance. In [25] Y. Weng and others used Fuller Thompson theory and Marson-Percy model approaches to design mixture compositions. It was proved that the use of sand with continuous gradation in 3D printing mixtures improves their workability. In our previous studies [26, 27] we also discovered that obtaining mixtures with the required plasticity and shape retention can be achieved by the use of polydisperse fillers of the entire size range, from nano to finely dispersed. The use of uniform gradation fillers, on the contrary, results in a loss of plasticity and aggregate stability of mixtures.

PROBLEM STATEMENT

Despite a large amount of research and development, today the empirical approach prevails in the design of mixtures for 3D printing. To a significant extent, this also applies to the choice of fillers and the regulation of their concentration in mixture compositions. Usually, the articles do not provide any justification for the selection of certain fillers and do not analyse their role in the formation of the structure of viscoplastic

DEVELOPMENT OF NEW MATERIALS mixtures. As a result, the role and the mechanism of fillers’ impact on the set of rheological properties of 3D printed mixtures have not been clearly determined. When designing compositions, quantities of fillers of a particular type are selected without the identification of the general requirements to their characteristics necessary for a priori (before experiment) of the applicability of a certain filler in 3D printing technology and of the limits of its rational quantities.

In order to solve this issue, a general scientific concept must be formed and criterial requirements to the characteristics of fillers must be justified, which is the purpose of this article. This will allow justifying general requirements to the selection of raw mixture components for 3D printing in construction.

THEORETICAL JUSIFICATION OF CRITERIAL REQUIREMENTS TO FILLERS

FOR DESIGNING COMPOSITIONS

OF MIXTURES FOR 3D CONSTRUCTION PRINTING

The justification of these requirements is based on the following approaches:

– fundamental structural rheology and physicochemical mechanics of dispersed systems, formed in the works of scientific schools of P. A. Rebinder, N. N. Kruglitsky, and N. B. Uryev [28–30].

– the theory of packing of granular media, developed regarding the problems of building materials science in the works of Belov V. V. and Korolev L.V. [31–32].

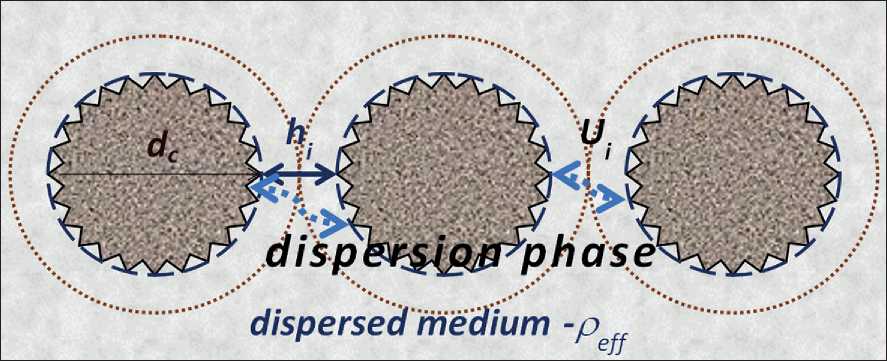

The structure of viscoplastic mixtures for 3D printing is considered to be a highly concentrated “dispersed phase – dispersion medium” system, the strength and aggregate stability of which depend on the number and strength of coagulation contacts. Mixtures for 3D printing belong to dispersion systems with near coagulation of particles sized ~ 5×10–5–10–4 m. In contrast to the design approaches of dry building mixtures which involves dense packing of particles, in mixtures for 3D printing it must be taken into account that the particles of the dispersed phase are making contact through the interlayers of the dispersion medium (Fig. 1).

To implement the technological process of 3D printing, the mixture must preserve its strength and aggregate stability at all stages:

– during transportation, under dynamic conditions of viscoplastic flow affected by high shear stresses;

– in the process of extrusion, under dynamic conditions of viscoplastic flow affected by low compressive and/ or shear stresses.

– at the stage of layer-by-layer printing, under static conditions affected by compressive stresses.

In accordance with the fundamental regulations of the structural rheology of dispersion systems (works of the schools of P.A. Rehbinder [28] and N.N. Kruglitsky [29]), the strength of the structure of a dispersion system depends on the particle size (in the region < ri ) and the strength of individual contacts and their number per unit volume of the structure, depending on the concentration of the dispersed phase j in the dispersion medium:

Pm = ^Ли2^

, (1)

where Pm is the strength of the structure, αi is the coefficient characterising the type of particle packing, Fс is the adhesion force in the contact, and n is the number of contacts between particles per unit volume.

The adhesion strength in contacts can be determined experimentally or calculated using the theory of intermo-lecular interactions of condensed phases. In accordance with the theory of adhesion of condensed phases [30], the adhesion strength between spherical particles can be determined using the following formula:

Fig. 1. Structure Model of fthe 3D printable mixtures as a system “dispersed phase – dispersion medium”

DEVELOPMENT OF NEW MATERIALS

Рс = 2к^(2агз-Су11) , (2)

where r 1 and r 2 are the radii of contacting particles; σ13 is the Gibbs energy of the interface unit between a solid body and a dispersed medium, i.e. surface tension; σ11 is the Gibbs energy of a surface unit at the boundary of contacting solid bodies (if they are identical).

The number of contacts n can be calculated using the so called globular model of porous structure [32].

n =

^3z 2^3/2

where z is the coordination number, φ is the volume concentration of particles, and d is their average size.

Based on the analysis of the above-mentioned ratios of the strength of disperse systems, we can determine the following parameters for modelling the structure of mixtures for 3D printing:

– concentration of the dispersed phase in the dispersion medium φ , which determines the thickness of the interlayer (the distance between particles hi ) between the particles of the solid phase.

– particle size dc , which determines the balance of adhesion strengths fc between the particles and the weight of particles G * in the dispersion medium.

– the shape and size distribution of particles, which determine the type of packing and the number of particle contacts.

Within these parameters, the justification of criterial requirements for the characteristics of fillers is based on the model of packing of polydisperse spherical particles suggested in [33]. The principle of the model is as follows: a certain volume Vtot is successively filled with spheres of decreasing radius r0 = rmax, r1,…, rn., and the radius of the spheres decreases as soon as the volume is completely filled with spheres of a larger radius. The gaps between large spheres are filled with spheres of smaller radius r1 < r0, so that each gap between spheres r0 has not one, but several spheres r1. This condition provides greater thermodynamic stability of the obtained package. The volume is being filled until the size of the spheres reaches rmin. As a result of laying, we obtain the following filling density:

Фп = Фо(1 + S^xd - Фо^П^С^)), (4) Г 4 1^/2

Л = [y/^W/S^i] • (5)

where ϕ0 is the packing density of spheres with maximum radius (for disordered packing –ϕ0=0,64); µ(ri/ ri–1) is the correction factor of less than one, which takes into account that not the whole volume of voids between spheres r1 can be filled, ρeff is the reduced density of the particle in dispersion medium (ρeff = ρ0–ρ1, ρ0 is solid phase density, ρ1 is dispersion media density), d is typical particle size, and g is gravity acceleration.

If the radii of the spheres are within the range from rmin to rmax, and rmin<< rmax., the continuous range of radii values must be replaced with a set of discreet values determined by the formula:

Ln(I»n»l)

LittS)

rmax6l,i = 0,l,2...N,N =

where δ < 1 is the discretisation parameter.

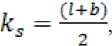

Based on these model representations, it is suggested to introduce the following numerical criteria for the evaluation of fillers:

-

1) average particle diameter, dc

Table 1

Materials characteristics

|

Material type |

Characteristics |

Size |

Role in the formation of mixture properties |

|

Metakaolin |

«VMK-45» according to TU 23.99.19-004-34556001-2017 |

Nano- |

Viscosity modifier |

|

Aleuropelite |

SiO2 content 82–90%, size distribution 0–0.06 mm |

Micro- |

Ultrafine aggregate |

|

Crushed limestone |

Limestone powder size distribution 0–0.2 mm according to GOST 26826-86 |

Micro- |

Ultrafine aggregate |

|

Fly ash |

Size distribution 0-0.2 mm GOST 25818-2017 |

Micro- |

Ultrafine aggregate |

|

Sand |

Quartz sand, SiO2 content ~ 95%, size distribution 0–1.2 mm |

Fine |

Fine aggregate |

|

Cement |

CEM I 42.5R |

Micro- |

Binder |

DEVELOPMENT OF NEW MATERIALS where ci is partial residuals on sieves, %; d1 is diameter taken as average for a certain interval (fraction), µm;

-

2) particle shape factor, ks . Calculated as the arithmetic average of three linear sizes (length l , width b, and height h ):

, _ (t+b+h)

К- — s 3

.

Taking into account that the particle size is determined using microscopic analysis, it is difficult to find one of the three sizes. In this case, the shape factor is calculated with the following two parameters:

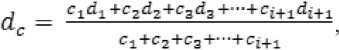

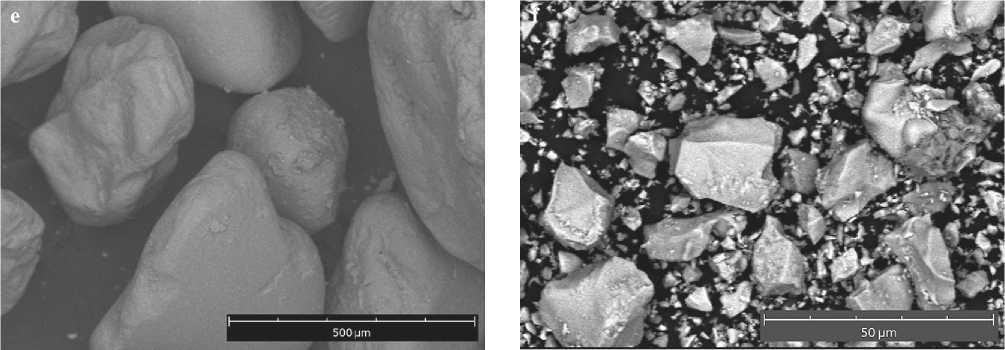

Fig. 2. SEM-micrographs of powders. Designated: a) Metakaolin; b) Aleuropelite; c) Crushed limestone; d) Fly ash; e) Sand; f) Cement

DEVELOPMENT OF NEW MATERIALS

Table 2

Numerical criteria for the evaluation of fillers

|

Material type |

Average particle diameter dc, µm |

Particle shape factor, ks . |

Particle distribution constant gpc |

|

Metakaolin |

18.3 |

1.50 |

10.9 |

|

Aleuropelite |

17.5 |

2.33 |

8.0 |

|

Crushed limestone |

66.4 |

1.46 |

19.9 |

|

Fly ash |

74.98 |

1.05 |

7.4 |

|

Sand |

438.5 |

1.30 |

2.4 |

|

Cement |

22.6 |

1.52 |

8.1 |

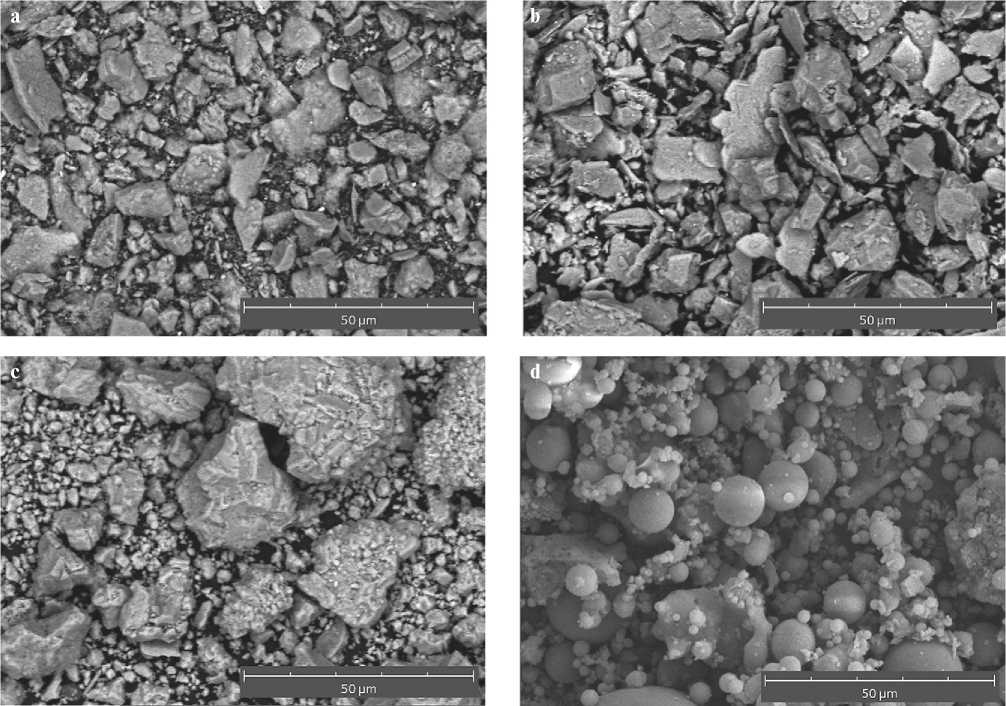

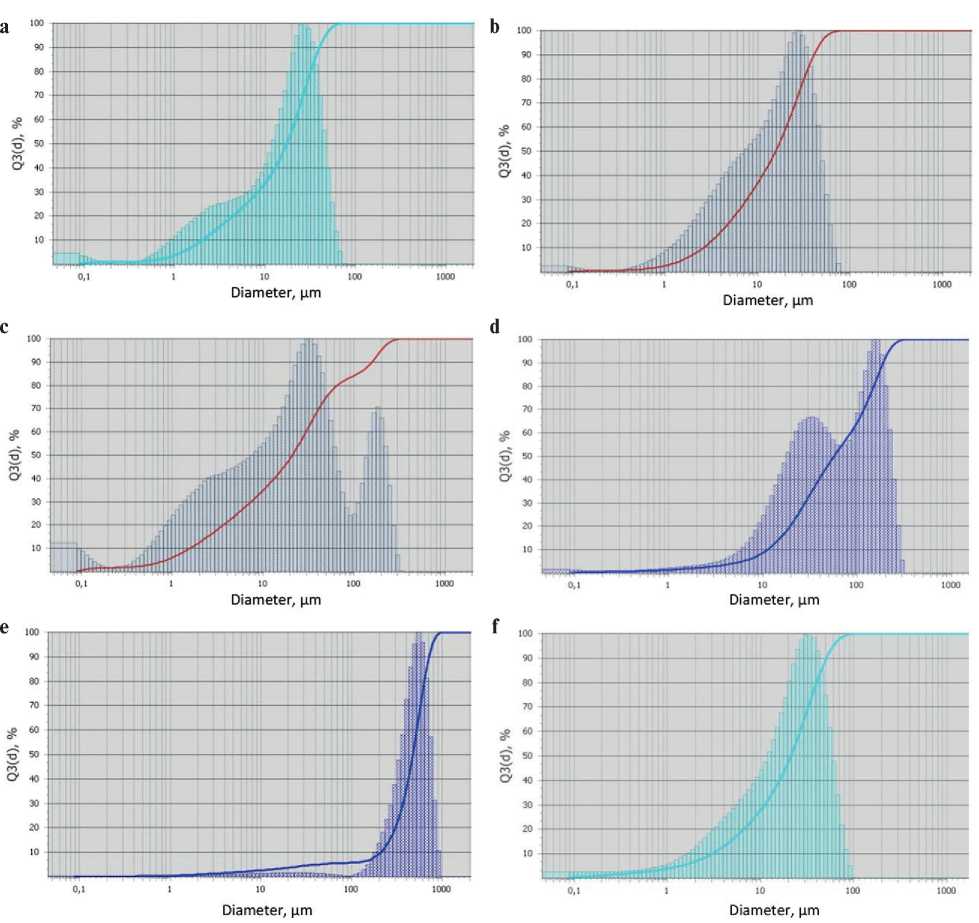

Fig. 3. Particle size distribution curves. Designated: a) Metakaolin; b) Aleuropelite; c) Crushed limestone; d) Fly ash; e) Sand; f) Cement

DEVELOPMENT OF NEW MATERIALS

3) particle distribution constant Gpc , characterizing the degree of heterogeneity of the particle size distribution:

Ст = ^ /1 л \

Vpc — , , (10)

where d 10 ( d 60) are diameters of particles, less than which the material contains 10% (60%) particles by weight, respectively.

It is suggested to use these quantitative criteria for a preliminary complex evaluation of fillers regarding the design of mixture compositions for 3D-biuld printing.

EXAMPLE OF RESULTS OF CRITERIAL EVALUATION OF DISPERSED MATERIALS

We assessed cement and 5 types of fillers with different dimensions and roles in the formation of the mixture properties (Table 1). We used scanning electron microscopy (SEM) to estimate the shape factor of the particles, and the images were taken on a Phenom XL scanning electron microscope (vacc = 15 kV, P = 0.10 Pa). The images were processed using the ParticleMetric software in order to determine length l and width b of the particles. The average particle diameter and granulometric constant were calculated based on the data obtained on a laser particle size analyzer Analysette 22 Nano Tec.

The evaluation of the particle shapes (Table 2) shows that spheric particles of ashes, sand (Figs. 2d and 2e), and particles of cement similar to cubes (Fig. 2f) are characterized by the shape factor ks = 1–1.3. Flat aleuropelite particles (Fig. 2b) are characterized by the shape factor ks = 2.33.

The particle distribution constant is rather suitable to characterise the degree of uniformity in the size distribution of particles (Figure 3). Mono-disperse limestone dust, characterised by a unimodal distribution, has the highest value of this constant Gpc = 19.9. Poly-dispersed sand, characterised by a polymodal particle curve of size distribution, shows the lowest value of the Gpc constant = 2.4.

CONCLUSION

Applied engineering solutions for the regulation of the properties of mixtures and composites for 3D printing should be based on the efficient design of their compositions. In the course of composition design, the quantity of fillers of a certain type should be selected based on the identification of the general requirements to their characteristics necessary for a priori (before experiment) determination of the applicability of a certain filler in 3D printing technology and of the limits of its rational quantities.

To design a range of efficient mixture compositions for 3D printing and create composites for various functional purposes, the following research tasks must be completed: 1) studying rheological behavior models for mixtures obtained with fillers that had different criterial characteristics; 2) obtaining experimental patterns of the influence of the criterial characteristics of fillers on the rheological characteristics of mixtures; 3) ranking these characteristics according to their significance and justifying the requirements to the range of quantities of fillers depending on their size, shape, and granulometry.

Список литературы Justification of the criteria requirements for fillers in mixtures for 3D construction printing

- Paul S.C., Tay Y.W.D., Panda,B., Tan M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Archives of Civil and Mechanical Engineering. 2018; 18(1): 311 – 319. https://doi.org/10.1016/j.acme.2017.02.008

- Ma G., Li Z., Wang L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Construction and Building Materials. 2018; 16: 613 – 627. https://doi.org/10.1016/j.conbuildmat.2017.12.051

- Mechtcherine V.et al. Extrusion-based additive manufacturing with cement-based materials – Production steps, processes, and their underlying physics: A review. Cement and Concrete Research. 2020; 132: 106037. https://doi.org/10.1016/j.cemconres.2020.106037

- Perrot A. et al. From analytical methods to numerical simulations: A process engineering toolbox for 3D concrete printing. Cement and Concrete Composites. 2021; 122: 104164. https://doi.org/10.1016/j.cemconcomp.2021.104164

- Rehman A. U., Kim J. H.3d concrete printing: A systematic review of rheology, mix designs, mechanical, microstructural, and durability characteristics. Materials. 2021; 14(14): 3800. https://doi.org/10.3390/ma14143800

- Lu B., Weng Y., Li M., Qian Y. Leong K.F., Tan M. J., Qian S. A systematical review of 3D printable cementitious materials. Construction and Building Materials. 2019; 207: 477–490. https://doi.org/10.1016/j.conbuildmat.2019.02.144

- Jiao D., Shi C., Yuan Q., An X., Liu Y., Li H. Effect of constituents on rheological properties of fresh concrete-A review. Construction and Building Materials. 2017; 83: 146–159.

- Mohan M. K., Rahul A. V., Kim V. T., De Schutter G. Evaluating the Influence of Aggregate Content on Pumpability of 3D-Printable Concrete. RILEM Bookseries. 2020; 28: 333–341. https://doi.org/10.1007/978-3-030-49916-7_34

- El-Hassan H., Alnajjar F., Al Jassmi H., Ahmed W. Fresh and Hardened Properties of 3D-Printed Concrete Made with Dune Sand. RILEM Bookseries. 2020; 28: 225–234. https://doi.org/10.1007/978-3-030-49916-7_23

- Cuevas K., Chougan M., F. Martin, Ghaffar S. H., Stephan D., Sikora P. 3D printable lightweight cementitious composites with incorporated waste glass aggregates and expanded microspheres – Rheological, thermal and mechanical properties. Journal of Building Engineering. 2021; 44: 102718. https://doi.org/10.1016/j.jobe.2021.102718

- Chen Y., Zhang Y., Pang B., Liu Z., Liu G. Extrusion-based 3D printing concrete with coarse aggregate: Printability and direction-dependent mechanical performance. Construction and Building Materials. 2021; 296: 123624. https://doi.org/10.1016/j.conbuildmat.2021.123624

- Bai G., Wang L., Ma G., Sanjayan J., Bai M. 3D printing eco-friendly concrete containing under-utilised and waste solids as aggregates. Cement and Concrete Composites. 2021; 120: 104037. https://doi.org/10.1016/j.cemconcomp.2021.104037

- Álvarez-Fernández M. I., Prendes-Gero M. B., González-Nicieza C., Guerrero-Miguel D. J., Martínez- Martínez J. E. Optimum mix design for 3D concrete printing using mining tailings: A case study in Spain. Sustainability. 2021; 13(3): 1 – 14. https://doi.org/10.3390/su13031568

- Ma G., Li Z., Wang L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Construction and Building Materials. 2018; 162: 613 – 627. https://doi.org/10.1016/j.conbuildmat.2017.12.051

- Ting G. H. A., Tay Y. W. D., Qian Y., Tan M. J. Utilization of recycled glass for 3D concrete printing: rheological and mechanical properties. Journal of Material Cycles and Waste Management. 2019; 29: 00857. https://doi.org/10.1007/s10163-019-00857-x

- Cuevas K., Chougan M., Martin F., Ghaffar S. H., Stephan D., Sikora P. 3D printable lightweight cementitious composites with incorporated waste glass aggregates and expanded microspheres – Rheological, thermal and mechanical properties. Journal of Building Engineering. 2021; 44: 102718. https://doi.org/10.1016/j.jobe.2021.102718

- Panda B., Ruan S., Unluer C., Tan M.J. Improving the 3D printability of high volume fly ash mixtures via the use of nano attapulgite clay. Composites Part B Engineering. 2019; 165: 75 – 83.

- Park C., Noh M., Park T. Rheological properties of cementitious materials containing mineral admixtures. Cement and Concrete Research. 2005; 35: 842 – 849.

- Shakor P., Nejadi S., Paul G., Malek S. Review of emerging additive manufacturing technologies in 3d printing of cementitious materials in the construction industry. Frontiers in Built Environment. 2019; 4: 00085. https://doi.org/10.3389/fbuil.2018.00085

- Liu Z., Li M., Weng Y., Wong T. N., Tan M. J. Mixture Design Approach to optimize the rheological properties of the material used in 3D cementitious material printing. Construction and Building Materials. 2019; 198: 245 – 255. https://doi.org/10.1016/j.conbuildmat.2018.11.252

- Varela H., Barluenga G., Palomar I. Rheology Evaluation of Cement Paste with Nanoclays, Nanosilica and Polymeric Admixtures for Digital Fabrication. RILEM Bookseries. 2020; 28: 144 – 152, 2020. https://doi.org/10.1007/978-3-030-49916-7_15

- Varela H., Barluenga G., Palomar I. Influence of nanoclays on flowability and rheology of SCC pastes. Construction and Building Materials. 2020; 243: 118285. https://doi.org/10.1016/j.conbuildmat.2020.118285

- Qian Y., De Schutter G. Enhancing thixotropy of fresh cement pastes with nanoclay in presence of polycarboxylate ether superplasticizer (PCE). Cement and Concrete Research. 2018; 111: 15 – 22. https://doi.org/10.1016/j.cemconres.2018.06.013

- Kawashima S., Chaouche M., Corr D.J., Shah S.P.: Rate of thixotropic rebuilding of cement pastes modified with highly purified attapulgite clays. Cement and Concrete Research. 2013; 53: 112 – 118. https://doi.org/10.1016/j.cemconres.2013.05.019

- Weng Y., Li M., Tan M. J., Qian S. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model. Construction and Building Materials. 2018; 163: 600–610. https://doi.org/10.1016/j.conbuildmat.2017.12.112

- Slavcheva G., Artamonova O., Babenko D., Ibryaeva A. Effect of Limestone Filler Dosage and Granulometry on the 3D printable Mixture Rheology. IOP Conf. Series: Materials Science and Engineering. V International Conference Safety Problems of Civil Engineering Critical Infrastructures. 2020; 972: 012042. https://doi.org/10.1088/1757-899X/972/1/012042

- Slavcheva G.S., Artamonova O.V. Controlling the Rheological Behavior of Mixtures for Construction 3D Printing: An Experimental Evaluation of the Possibilities of the “Nano” Arsenal. Nanotechnologies in Construction. 2019; 11(3): 325 – 334. https://doi.org/10.15828/2075-8545-2019-11-3-325-334 (In Russian).

- Rebinder P.A. Selected works. Surface phenomena in dispersed systems. Physical and chemical mechanics. Nauka: Moscow; 1979.

- Kruglitsky N.N. Essays on physical and chemical mechanics. Naukova Dumka: Kyiv; 1988.

- Uriev N.B. Physico-chemical dynamics of structured nano-dispersed systems and nano-dispersed composite materials. Part 1. Physical chemistry of surfaces and protection of materials. 2010; 46(1): 3 – 23. (In Russian).

- Belov V.V., Obraztsov I.V., Ivanov V.K., Konoplev E.N. Computer implementation of solving scientific, technical and educational problems. Tver: TVGTU; 2015.

- Chemical encyclopedia / ed. by N.S. Zefirov. Moscow: Great Russian Encyclopedia, V. 4; 1995.

- Korolev L.V., Lupanov A.P., Prydatko Yu.M. Packing analysis of polydisperse particles in composite building materials. Modern problems of science and education. 2007; 6: 105–108 (In Russian).