Laboratory separator of bulk materials

Автор: E. G. Danilenko, S. V. Telegin

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 4 vol.21, 2020 года.

Бесплатный доступ

New materials for spacecraft radiation screens engineering require a fine classification of powder materials by particle size. The article concerns the construction of powder materials laboratory separator. This type of material separation is related to gravity methods. The Moseley laboratory separator serves as the prototype of the construction with table longitudinal shaking and diametrical vibrations by means of buffers during the separation process. The unbalanced oscillator yields deck separation surface harmonic vibrations in all directions. The unbalanced oscillator DC motor voltage control gradually alters the vibration frequency and supports finer separation of the material. A power pipe enables to conduct perpetual separation process. In prototype, in contrast, up to 100 g weight is processed for up to 5 minutes. To improve the materials fine and small classes separation efficiency, riffles are made on the separation surface, which determine the places of concentration of material particles. As a result of the conducted researches for elimination of the secondary circulation flows, a system of diametrical reefing is worked out: the riffle is approximately equal to the maximum particle size of the separated material and is equal to 0.2 mm in this construction; the distance between riffles is equal to 50 mm, the tilt angle is 80 degrees relative to the deck longitudinal side. The particle motion depends on the inclination angle of the separation surface. Large particles move upwards at angles of up to 5 degrees, and downwards at angles higher than 5 degrees. Vibration frequency and amplitude alteration, as well as adjusting the inclination angle of separation surface enables to move and adjust the speed of different properties and sizes of test material. The laboratory separator work is based on the physical effects, which enable to vary the location of the power pipe. This fact allows the construction to be adapted to a variety of specific conditions and expands the construction sphere. The separator construction is simple for production and operation, and can be quickly reconfigured if necessary. The separator portability allows it to be transported.

Shielding, composite material, separator, fractional composition, boron carbide.

Короткий адрес: https://sciup.org/148321778

IDR: 148321778 | УДК: 621.928:66.047.75 | DOI: 10.31772/2587-6066-2020-21-4-550-555

Текст научной статьи Laboratory separator of bulk materials

Introduction. In materials science, composite materials are a separate sphere with their own industries and markets. Nano sized and ultrafine powders are mainly used as fillers for the composite materials production [1–3].

Shielding is considered to be one of the main means of protection against ionizing radiation effects on the Earth's orbit [4–6].

The most sensitive to ionizing radiation are semiconductor and optical materials, then go polymeric materials and metals have the highest resistance.

Aluminum and its alloys is the main material in the production of passive protective screens against ionizing radiation of devices and precision devices in space technology [7].

The AeroCube 8 project (4 vehicles A, B, C, D, also known as IMPACT) tested a radiation shielding material based on CNT / PEEK (Poly-ether-ether-ketone with the addition of carbon nanotubes) on board [8]. The Oufti-2 mission, scheduled for launching in 2021, is preparing an experiment as an additional payload to test the effectiveness of a multi-layer laminated coating on the basis of resins with additives and a tungsten alloy [9].

Ultrafine powders can improve the quality of materials used in rocket and mechanical engineering. Ultra dispersed metal powders are used for creation substances such as rocket fuel, explosives, pressed and sintered products. Some powders are used as fillers, they allow to obtain effective tread, antifriction, antiwear, resourcesaving, hydrophobic, self-cleaning and bio inert composite materials [4].

The efficiency of the screens declines sharply at thicknesses over 1 cm, since the interaction of charged particles with the nuclei of the screen material produces intense electromagnetic bremsstrahlung radiation, which has a high penetrating ability [10]. An increase in the mass of protective screens leads to an increase in the cost of launching satellites into orbit by 25–50 % [11–12]. Therefore, an actual question about the development and creation of a new type of protection based on a multilayer structure, where the first layer is made of a composite material, arises.

In the course of studying the effect of the fractional composition on the properties of composites weakening ionizing radiation, it became necessary to classify more finely the initial boron carbide powder.

Fraction is composed of particles of the size range between their maximum and minimum values. The shape and size of particles significantly affects the technological properties of composites and, through them, the density, strength, and uniformity of material properties [13].

Historically, manual stripping of minerals was the earliest form of processing, followed by primitive forms of gravity beneficiation. They were known more than 2 thousand years ago, the first descriptions were found in the works of Pliny [14] and then Agricola [15]. Gravity methods remained prevailing until the 20th century.

Gravity separation technologies allow to conduct separation or beneficiation using highly efficient and not complex equipment with minimal energy consumption in comparison with other beneficiation processes. Gravitational enrichment is a physical process in which the separation of one mineral from another depends on their relative movement under the influence of gravity and some other forces [16]. The main parameters which determine the movement of particles are their mass, size, volume and density. If these parameters differ significantly from each other, then separation takes place relatively easily. It must also be taken into consideration that if two particles have the same density, then a particle of a larger diameter has a higher final velocity and this is the characteristic of a homogeneous material, and if two particles have the same diameter, then a heavier particle has a higher final velocity, what takes place during enrichment.

There is a wide variety of equipment, but it can be divided into two general classes: those related to particle motion in the vertical plane – enrichment in the pulp volume; and related to the motion of particles along an inclined plane – separation in a thin layer. The efficiency of sizing is an important factor in the final product. Thus, an ideal gravity separation process would separate 100 % of one product size in one fraction and 100 % of excellent size in another.

In laboratory conditions, concentration tables are mainly used. The particles of the material are given periodical movements, caused by the movement of the working surface - the deck. Under the influence of the cross flow of the pulp and the longitudinal vibrations of the deck, the particles move in the longitudinal and transverse directions. Each particle of the separated material, depending on its density and size, acquires a certain speed and direction of movement relative to the deck of the concentration table.

There is a laboratory separator Moseley, which consists of a separation surface, inclined in one direction and performing simple harmonic oscillations [17]. Separation of material with a particle size from 10 to 200 microns is carried out by longitudinal shaking and lateral vibrations using buffers. The buffers are pulled from the rod by a cam mechanism and roller system and returned by a spring. Samples weighing 5–100 g are placed in the upper part of the tray, damp and vibrate on the working surface for 3–5 minutes. Heavy particles remain on the separation surface or (with a type of end impact) move slowly upward. Light particles flow down into the discharge container under the influence of a small stream of spray water. Depending on the desired result, a longitudinal slope of 1.75–3 ° is selected, the oscillation frequency is 60–110 min – 1, the amplitude is 6–15 mm, and the irrigation fluid flow consumption is about 3 l / min.

Experimental part. Production, assembly and refinement were carried out with the Spektr design bureau of the REC IKIVT SibGU named after M. F. Reshetnev participation.

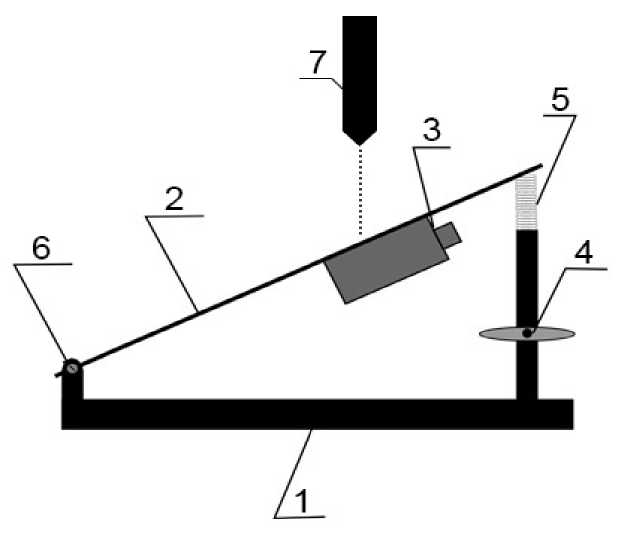

The aim of the work was simplifying the design and redaction the time of separation. The schematic diagram of the separator is shown in fig. 1.

Working surface 2 is a polished copper plate (fig. 1), not rigidly attached to the base 1 by hinges 6 , along which the powder, depending on the vibration frequency, is transported down, up and across. The unbalanced vibrator 3 sets the vibration frequency of the working surface. With the help of the adjusting screw 4 , the angle of inclination of the working surface is changed. Buffer 5 creates an additional impact on the separation surface.

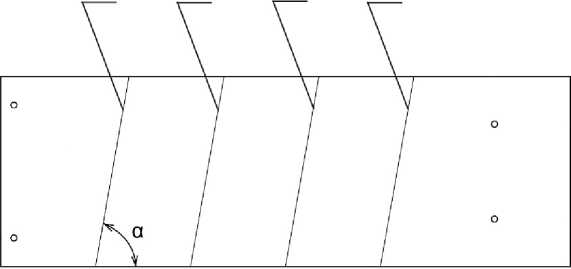

The device works as follows. The feed pipe 7 is located above the vibrating working surface 2 between 8.1 and 8.2 grooves (fig. 2) from the upper edge at a height of 3–5 cm, and the material to be separated is fed. On the rear side of the working surface, an unbalanced vibrator is rigidly fixed, which is an unbalanced rotor driven by a DC motor. By controlling the engine speed, the vibration frequency of the working surface is achieved, at which the particle flow begins to split into two or more streams, depending on the separation requirements. Streams can form from the supply pipe upwards, above the 8.1th riffle; right or left between 8.1 and 8.2, 8.2 and 8.3, 8.3 and 8.4 riffles and down – below 8.4 riffles.

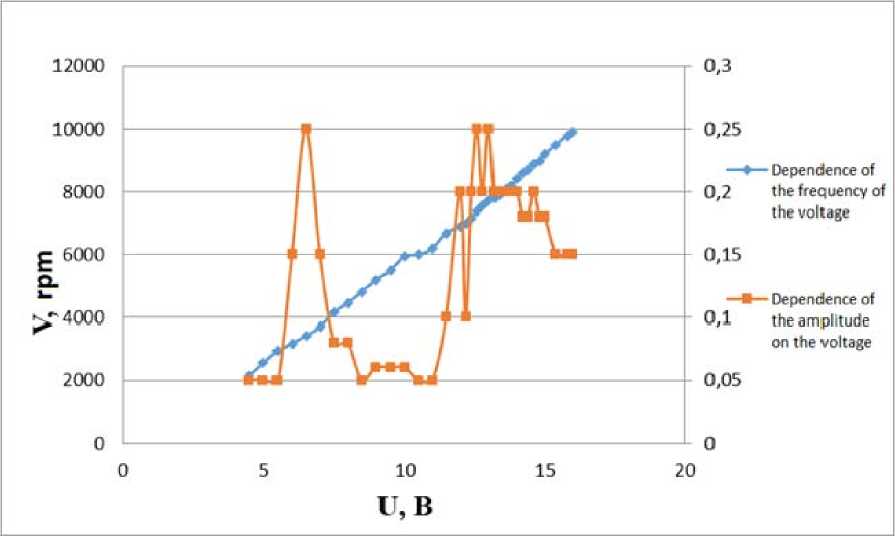

The study of the dependence of the amplitude of oscillations of the free end of the working surface and its frequency on the voltage supplied to the motor of the vibration drive (fig. 3) on the powder В4С is carried out.

Several experiments were carried out at different voltages on the vibrating motor. The amplitude of vibrations of the working surface was measured by a microscope, and the frequency – by a frequency meter. The graph (fig. 3) shows that at a voltage of 11 to 13 V, a plateau in amplitude with two surges up to 0.25 mm is observed. There is also an outburst in the range from 5 to 7 V, but it does not lead to the separation of particles into fractions, the B4C powder actually rolls down the plate.

The process of separating particles in the proposed device is continuous. Particle movement depends on the angle of inclination of the working surface. At angles up to 5 degrees, large particles move upward, and small particles move downward, at large angles – in the opposite direction.

Fig. 1. Separator scheme:

1 – base; 2 – working surface; 3 – unbalanced vibrator;

4 – adjusting screw; 5 – buffer; 6 – joint; 7 – nutrient nozzle

Рис. 1. Схема сепаратора:

-

1 – основание; 2 – рабочая поверхность; 3 – дебалансный вибратор;

4 – регулировочный винт; 5 – буфер; 6 – шарнир;

-

7 – питающий патрубок

8.4 8.3 8.2 8.1

Fig. 2. Scheme rifle

Рис. 2. Cхема нарифлений

Fig. 3. Dependence of the amplitude and frequency of oscillations of the working surface on the voltage on the vibration motor

Рис. 3. Зависимость амплитуды и частоты колебаний рабочей поверхности от напряжения на вибромоторе

The area of particles passed through different streams under different modes

|

U, В |

Bottom |

Middle 1 |

Middle 2 |

Top |

|

11 |

– |

– |

– |

– |

|

11.2 |

29–40 mkm2 |

20–30 mkm2 |

– |

5–19 mkm2 |

|

11.6 |

12–40 mkm2 |

5–23 mkm2 |

– |

– |

|

11.8 |

17–40 mkm2 |

11–29 mkm2 |

– |

5–22 mkm2 |

|

12.5 |

27–40 mkm2 |

14–32 mkm2 |

9–23mkm2 |

5–16 mkm2 |

|

13.5 |

26–40 mkm2 |

18–29 mkm2 |

10–23 mkm2 |

5–17 mkm2 |

|

13.5; angle 16° |

30–40 mkm2 |

16–30 mkm2 |

10–18 mkm2 |

5–14 mkm2 |

|

14.2 |

– |

– |

– |

– |

To increase the efficiency of separation of thin and small classes of materials, riffles are made on the working surface (fig. 2), which serve as a place of concentration of particles of a certain size. The design of the working surface should be made in such a way, which would allow to exclude the likelihood of secondary circulation flows in the interstitial spaces [18].

As a result of the experiments carried out, a reefing system 8 was developed: the riffle height is approximately equal to the maximum particle size of the separated material, in this design it is 0.2 mm; the distance between the grooves is 50 mm, the angle of inclination α is 80 degrees; the riffle shape is round (fig. 3).

The research was carried out on the B4C powder of fraction F150 in the state of delivery, in which, in addition to particles with a size of 63–106 microns, there were also smaller particles up to 15 % by weight. By preliminary separation carried out on the same separator, a part of the powder with a size of 5 to 40 microns was isolated.

When working on a laboratory installation, the powder falling out of the hopper branch pipe is divided into several streams in different parts of the working surface, from which samples for fractional analysis were taken. The angle of inclination of the working surface is 12 degrees.

The analysis was carried out on a Levenhuk DTX 30 microscope at x230 increase with the MicroCapture Plus software, included in the set of delivery of the microscope, application. The analysis results are shown in table.

As seen from Table 1, the optimum vibrator voltage is 11.2 V. Under other voltages, an overlap of particle size is observed in different samples. At 11 and 14.2 B separation does not occur. The angle of inclination of the working surface increase up to 16 degrees made it possible to select a narrower fraction of 5–14 microns. The powder consumption is 100 g / min.

By changing the frequency and amplitude of vibration, as well as adjusting the angle of inclination of the working surface made it possible to move and regulate the speed of movement of the test material of different properties and sizes.

Conclusion. The studies carried out allowed: to simplify the design of the separator by introducing an unbalanced vibrator; to reduce the analysis time, excluding the operation of drying the material; to carry out powder classification continuously by installing a hopper with a branch pipe.

The physical effects, on which work of the laboratory separator is based on, make it possible to vary the location of the supply pipe in it. This allows the design to be adapted to a variety of specific conditions, what broadens the sphere of the device application. The design of the device is simple in production and operation; in case of necessity it is possible to adjust the work of the device quickly.

Acknowledgments. This work was supported by the Regional Science Foundation № 12/20 of 18.06.2020.

Список литературы Laboratory separator of bulk materials

- Suzdalev I. Nanotekhnologiya: fiziko-khimiya nanoklasterov, nanostruktur i nanomaterialov [Nanotechnology: physical chemistry of nanoclusters, nanostructures and nanomaterials]. In 2 books. Moscow, ComBook Publ., 2006, 592 p.

- Novikov L. S. Radiatsionnye vozdeystviya na materialy kosmicheskikh apparatov [Radiation effects on materials of spacecraft: a tutorial]. Moscow, University book Publ., 2010, P. 4–5.

- Perspektivnye materialy. Struktura i metody issledovaniya [Advanced materials. Research structure and methods]. Ed. D. L. Meersona. Togliatti: TSU, MISIS Publ., 2006, 536 p.

- Bezrodnykh I. P., Morozova E. I., Petrukovich A. A., Kazantsev S. G., Kochetov I. V., Semenov V. T. [Bremsstrahlung of electrons in the substance of the spacecraft. Calculation method]. Voprosy elektromekhaniki. Tr. NPP VNIIEM. 2011, Vol. 120, No 1, P. 37–44 (In Russ.).

- Gusev N. G., Klimanov V. A., Mashkovich V. P., Suvorov A. P. Zashchita ot ioniziruyushchikh izlucheniy [Protection against ionizing radiation]. In 2 books. Moscow, Energoatomizdat Publ., 1989.

- Ying Wang, Guangke Wang, Tao Hu, Shipeng Wen, Shui Hu, Li Liu. Enhanced photon shielding efficiency of a flexible and lightweight rare earth/polymer composite: A Monte Carlo simulation study. Nuclear Engineering and Technology. 2020, Vol. 52, No. 7, P. 1565–1570

- Kuznetsov N. V. Radiatsionnaya opasnost' na okolozemnykh orbitakh i mezhplanetnykh traektoriyakh kosmicheskikh apparatov [Radiation hazard in near-earth orbits and interplanetary trajectories of spacecraft]. Available at: http://nuclphys.sinp.msu.ru/crd/crd3.htm (accessed 19.10.2020).

- Richard P. Welle, David Hinckley Aerospace Nano / Picosatellites Program. Available at: https://space.skyrocket.de/doc_sdat/aerocube-8-impact.htm (accessed 20.10.2020).

- Guillaume T. OUFTI-2 educational CubeSat project of University of Liège , Belgium OUFTI-2 educational CubeSat project of University of Liège, Belgium 2017. May.

- Bezrodnykh E. I. Morozova A. A. [Petrukovich and others. Radiation conditions in geostationary]. Voprosy elektromekhaniki. Tr. NPP VNIIEM. 2010, Vol. 117, No 4, P. 33–42 (In Russ.).

- Daniel Dupont. Nuclear explosions in orbit. In the world of science (Scientific American) 2004, No. 9, P. 62–70.

- Lobanovskiy Yu. I. Tsena kosmosa: skol'ko stoit vykhod na orbitu? [Cost of space: how much does it cost to enter orbit?]. Available at: http://www.synerjetics.ru/article/cost.pdf. (accessed 25.10.2020).

- Vaytuzin O. P., Kuznetsov A. A. Izuchenie mikrostkury metallov metodom komp'yuternoy opticheskoy mikroskopii [Study of the microstructure of metals by the method of computer optical microscopy]. Krasnoyarsk, Siberian state aerospace un-t Publ., 2006, 100 p.

- Pliny, С. Р. S. (circa 70). Natural History Book 33, 21.

- Agricola, G. (1556). De Re Metallica Trans Hoover, H. C. and Hoover, L. H., Dover Publications, N. Y. 1950, Book XIII.

- Bert R. O., Millza K. Tekhnologiya gravitatsionnogo obogashcheniya [Gravity separation technology]. Moscow, Bosom Publ., 1990, 574 p.

- Anon (1979). British-developed laboratory separator aids small-scale mineral studies. Min. Mag, Jan. 45–48.

- Shokhin V. N., Lopatin A. G. Gravitatsionnye protsessy obogashcheniya [Gravitational enrichment processes]. Moscow, Bosom Publ., 1980, P. 256–257.