Levantine Middle Pleistocene blade industries

Автор: Derevyanko A.P.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: Paleoenvironment, the stone age

Статья в выпуске: 1 т.44, 2016 года.

Бесплатный доступ

The origin of Near Eastern Middle Pleistocene blade industries is discussed with reference to the Levallois reduction-technique. Special attention is paid to the Gesher Benot Ya'akov site, in Israel, where the Levallois technology is the earliest in the region (ca 800 ka BP). Whereas later Acheulean industries show no continuity with the Levallois tradition, the alternation of predominant Middle Pleistocene technologies indicates changing adaptation strategies caused by ecological conditions. Accordingly, the early appearance of the laminar technology in the Near East evidences local evolution rather than immigration. The major factors underlying this innovation were adaptation and the intrin sic development of the Levallois system. Laminar technologies, which are fi rst evidenced by certain Levantine sites even earlier than Gesher Benot Ya'akov, became widely distributed at the Acheulo-Yabrudian stage of the late Acheulean. A well-developed blade technology is demonstrated by the Amudian industry of Qesem, Israel, dating to 400–200 ka BP.

Levallois, gesher benot ya'akov, tabun, yabrud, qesem, blade technology, aterian, mousterian, middle paleolithic, acheulo-yabrudian, amudian, migrations

Короткий адрес: https://sciup.org/145146023

IDR: 145146023 | DOI: 10.17746/1563-0110.2016.44.1.003-026

Текст научной статьи Levantine Middle Pleistocene blade industries

Expanses of the Near East were of particular importance for the history of human formation and development. This was the main transit territory, through which migration (or migrations) proceeded about 1.8–1.5 Ma BP. This became a great cultural and historical event: representatives of the Homo species left Africa for the first time, and started occupying Eurasia. The possibilities of human migration from Northwestern Africa through the Strait of Gibraltar to Spain, or from the north of the African continent through Sicily to the south of Italy, are debating-points. Humans and animals could move from Africa to Eurasia and back only through the Levantine corridor. Possibly, when the sea-level lowered during some periods of cooling in the Pleistocene, a land-bridge connecting Africa with the Arabian Peninsula appeared, or a vast shelf with small water-patches formed in the place of the Bab-el-Mandeb Strait, which has a width of 28 km and a maximum depth of 100 m.

The second global migration-flow from Africa was also related to an event of world-historic importance: the occupation of Eurasia and Australia by modern humans. Having formed in Africa 200–150 ka BP, they started penetrating to the Levant and Arabia through the Levantine corridor and using a temporary passage through the Bab-el-Mandeb Strait. Obviously, there were several such waves of migration from Africa to the Near East. Archaeological materials testify that the first wave of modern humans reached Eurasia approximately 120–110 ka BP, when an arid climate became established

in Northeastern Africa; while the Near East, and even desert areas of Arabia, provided favorable conditions for habitation by animals and humans.

Interbreeding, a complex process of no less importance, took place in the Levant territory in the Near East, about 120–50 ka BP, between three populations: modern humans, who were migrating from Africa; the autochthonous population; and Neanderthals. From the Near East, H. sapiens populations with Neanderthal admixtures in their genome could migrate to other parts of Eurasia.

To solve the problem of ancient Middle Pleistocene migrations, we have selected the origin of the Levallois primary reduction-strategy and blade-industry as the most significant cultural and historical marker.

The study of the Levantine Paleolithic has a prolonged history. Dozens of Paleolithic localities, attributable to different periods, from the Early to Late Paleolithic, are known in the region. It is of vital importance that open-air and cave sites with a great number of culturebearing horizons have been discovered and are being studied here.

Favorable climatic conditions in a considerable part of this area were beneficial not only for the development of material and intellectual culture, and for the appearance of new stone-working technologies among the earliest local population; but also for the penetration of people from Africa and Eurasia. This was a peculiar melting-pot: human populations from different regions and ecological niches met here, accompanied by intense acculturation of the African and Eurasian population, this population subsequently spreading from the Near East to the west and to the east.

It was in the Levant, at the Gesher Benot Ya’akov site, that the primary reduction-strategy for detachment of Levallois flakes formed for the first time in the world. Blade-blanks that appeared at the multilayered Yabrud and Tabun localities in the Late Acheulean held a high position in the manufacture of tools in the Amudian industry. The Levantine blade-industry was embodied most impressively during the final stage of the Middle Pleistocene and in the Upper Pleistocene. It appeared in the region in the Late Acheulean, and attained perfection in the Middle and Upper Paleolithic.

Appearance of the Levallois reduction-technique in the territory of Levant

Determining the place and time of origin of the Levallois primary reduction-strategy, which has played an important role in the development of technocomplexes among ancient African and Eurasian human populations, is one of the problems in Paleolithic studies. The studies conducted in recent decades suggest that this technology first appeared in Eurasia at the unique Acheulean site of Gesher Benot Ya’akov (Goren-Inbar, 1992, 2011a, b; Goren-Inbar, Belitzky, 1989; Goren-Inbar, Saragusti, 1996; Goren-Inbar et al., 2000; Goren-Inbar, Sharon, 2006; Sharon, Goren-Inbar, 1999; Derevianko, 2015b; and others).

The site of Gesher Benot Ya’aqov is located in the northern part of the Great African Rift Valley, 2 (4) km to the south of the former coastline of the Lake Hula, in the northern part of Israel, at an elevation of about 61 m above the average sea-level. The locality lies within the Middle Pleistocene Gesher Benot Ya’aqov Formation. It was studied in the 1930s and 1960s by D. Garrod, M. Stekelis, I. Gilead, and other scholars. The major multidisciplinary studies have been carried out here since 1989 under the supervision of N. Goren-Inbar (Goren-Inbar, Belitzky, 1989; Goren-Inbar et al., 1994; and others).

Fluviolacustrine deposits of the Gesher Benot Ya’akov Formation were uncovered to a depth of 34 m. They represent a fragment of the sedimentary deposits in the eponymous gulf. The deposits were highly deformed and displaced as a result of tectonic processes, and formed an anticline fold in the excavation-area. Within the stratigraphic sequence, it has been possible to identify 14 archaeological horizons that were located above the Brunhes-Matuyama boundary. According to the data from some researchers, the age of the entire sequence of deposits is 50 ka BP (Goren-Inbar, 1992, 2011a; Goren-Inbar et al., 2000; Goren-Inbar, Sharon, 2006; and others); but according to other data, 100 ka BP (Goren-Inbar et al., 2008; Feibel, 2004). The deposits correspond to six sedimentational cycles, and belong to MIS 18–20 (Feibel, 2004).

The discovery of stone artifacts around fireplaces, the presence of animal-bone remains (including some in an articulated state), and also other planigraphic features of culture-bearing horizons, suggest minimum displacement of the finds and an indisputably prolonged cultural sequence at this site.

Abundant and varied inventories have been discovered here. Researchers have distinguished tools of four main types: bifaces (hand-axes); cleavers; flakes and tools on flakes; and cores plus tools on cores. Cleavers and bifaces at the Gesher Benot Ya’akov site were made mainly from basaltic flakes. Flint-knappers could also make them from large partings or pebbles; but, according to researchers, they did so very rarely (Sharon, Alperson-Afil, Goren-Inbar, 2011: 391). Cleavers were shaped by small spalls on the ventral side; the number of spalls did not exceed ten. Occasionally, additional treatment was also provided from the dorsal side. Bifaces were shaped more thoroughly, but they also showed less negative scars on the ventral surface. Thinning of the enlarged biface part (butt) was performed more thoroughly; sometimes, a knapper had to make up to ten spalls of different sizes to maximize the tool’s efficiency. The biface- and cleaver-shaping technology remained unchanged during the entire period of archaeological sequence-formation of this site. This was established by G. Sharon and coauthors when studying certain technological and stylistic features of biface tools (Ibid.: 390).

Excavations at the site of Gesher Benot Ya’aqov provided a large scope of materials to researchers, both for the comparative study of stone tools and in the realms of geology, site geomorphology, fauna and flora. Remains of fruits, grains, plants, bark, wood, and even a wooden board showing traces of polishing have been found in the cultural horizons.

Sharon et al. have carried out a critically important analysis of the relationship between the traditional and the innovative traits of inventories discovered at this site (Ibid.). Conservatism in the manufacture of stone tools is expressed in the fact that bifaces from all Gesher Benot Ya’aqov horizons demonstrate a single reduction-pattern. According to scholars, this persisted throughout the duration of several dozens of thousands of years (Ibid.). Variability was evidenced by the fact that some horizons contained a great number of bifaces and cleavers, while others yielded only rare, or no, tools of this type. In the opinion of Sharon et al., different numbers of bifaces and cleavers in the culture-bearing horizons are caused mainly by changes in the various activities and behavioral patterns of hominins (Ibid.: 395).

The cultural horizons differed in their amounts not only of bifaces and cleavers, but also of remains of crustaceans, and bones of mammals, birds, fishes, wood, bark, and fruits. The following human activities were reflected at the Gesher Benot Ya’akov site: traces of the butchering of elephant ( Palaeoloxodon antiquus ) and numerous bifaces were discovered in horizon 1 of layer II-6; and accumulations of basaltic bifaces, well-preserved remains of Dama sp., and various faunal remains were recorded in horizons 4 and 4b of layer II-6. Horizons with a large number of bifaces were probably associated with the butchering and dressing of animalcarcasses. Notably, the use of fire is recorded at Gesher Benot Ya’aqov locality, as well as at the earlier site of Ubeidiya (Goren-Inbar et al., 2004; Goren-Inbar, 2011a).

Several types of cores are prominent in primary reduction at the earliest stage of human tool-making activities in the Late Pliocene. The earliest Paleolithic localities, which have a minimum age of 2.52 Ma, have been discovered in Ethiopia, in the basin of the Kada Gona River and its tributaries (Semaw, 2000; Semaw et al., 2003). During excavations, 33 cores were discovered at the East Gona localities (EG 10 and 12). Those treated mainly by unifacial and bifacial techniques have been distinguished among them. Approximately 20 % of cores excavated at the EG 10 site were worked by bifacial flaking. 55 % of cores show bifacial flaking features in the materials of the EG 12 site. No less than 8 and no more than 14 flakes were detached from one core at the EG 10 site, while the corresponding figures for the EG 12 site are 3 and 23. Cores from these sites include rare discoid and orthogonal shapes, and core-scrapers. According to the Oldowan classification, a considerable number of the cores were designated as side- and endchoppers (Semaw, 2000). In our view, the majority of these pieces were used for production of flakes and, after additional treatment of one of the laterals sides, they were transformed into tools. At the OGS 7 site dated to 2.58 Ma BP, which was discovered in 2000 at the steep slope of a nameless ephemeral stream running into the Ounda Gona 3 km to the southwest from the EG 10 and 18 sites, bifacial and unifacial cores amounted to more than 86 % (Stout et al., 2010).

The West Turkana localities in Kenya are among the most informative Late Pliocene sites (Roche et al., 1999; Delagnes, Roche, 2005). Of particular importance are the Lokalalei 2A, 2C, and 1 localities, situated in the vicinity of the Lokalalei catchment-basin at a distance of 1 km from each other. The Lokalalei 2A locality is dated to 2.34 ± 0.04 Ma BP, Lokalalei 1 is younger by approx. 100 ka BP (Brown, Gathogo, 2002). The researchers have distinguished five main types of cores at the Lokalalei 2C site (Delagnes, Roche, 2005). Cores of the first type, with one flaking-surface, are most abundant, and include 22 pieces. Cores with one flakingsurface and traces of striking-platform rejuvenation were assigned to the second type (8 pieces). Cores with one main flaking-surface and final spalls on the other surface were designated as the third type (10 pieces). The fourth type is represented by 15 cores with at least two flaking-surfaces. The fifth type includes 15 cores having several flaking-surfaces. Summing up the results of the Lokalalei 2C site studies, A. Delagnes and H. Roche noted that its inhabitants had a planned tool-production with an established structure (Ibid.: 467).

Less-developed lithic technology was used at the Lokalalei 1 site, though it is younger than Lokalalei 2C (Kibunjia, 1994). According to Delagnes and Roche, the tools are either the result of labor of different taxons (early Homo at the Lokalalei 2C site and Australopithecus aethiopicus at the Lokalalei 1 site), or represent different technical and cultural traditions (Delagnes, Roche, 2005).

The Late Pliocene industries of the Kada Gona valley and West Turkana sites suggest that ancient flint-knappers had a notion of the properties of the raw materials, had a good command of the main primary reductiontechniques, and used three approaches: production of blanks from cores with a hard hammer gripped by hand, a bipolar method, and stone-smashing by throwing it onto the anvil. Early representatives of the Homo species already had sufficiently advanced cognitive abilities, and could properly control hand and arm movements during their work with cores and hammers. The exactness of percussion, small defect-ratio, and maximum exhaustion of the core during flaking allow us to draw a conclusion about the use of established reduction-techniques.

It is very important to note that even during the final stage of the Pliocene and in the Early Pleistocene, Homo acquired a tendency towards minimum preparation of the striking platform for further flaking; in particular, for using the negative of an earlier detached flake as a point for the next percussion to detach a blank from the opposite side. The peripheral ridge of discoidal cores was often used as a striking-platform.

Unifacial flaking employed one surface for working: the pebble surface adjoining it at a sharp angle was an untreated striking-platform. The core-chopper type artifacts also had a sharp angle. Already, at the earliest stage of stone reduction, Homo had acquired the technical skills of using sharp angles and convex surfaces. Thus, the elements of core-preparation for the detaching of blanks appeared in the Early Pleistocene at the very primary stage of stone use by humans.

In the Early Pleistocene, H. erectus with pebble-and-flake industry, who left Africa about 1.8 Ma BP, occupied vast expenses of Eurasia rather fast (Derevianko, 2015a). This industry was not unified. Some similarity of Early Paleolithic localities from the Atlantic to the Pacific Oceans, in terms of types of artifacts and techniques, is explained by the fact that erectus had similar cognitive possibilities and sensorimotor abilities. The typological set of tools and the tool-shaping techniques employed by Paleolithic people were not very large; therefore similarity, though not identity, could be related to convergence determined by the fact that populations resided at considerable distances from each other, but in similar environmental conditions. Different environmental conditions required development of relevant adaptation strategies from H. erectus . This led to the appearance of various innovations in the primary reduction of stones and the shaping of tools.

Apart from discoid, unifacial, and bifacial cores, the Acheulean collections contain Kombewa and Levallois cores. Four core-shaping technologies were used at the Gesher Benot Ya’akov site: bifacial, Kombewa, reduction of flat blanks, and Levallois. Sharon has also distinguished irregular cores with the signs of different-orientation detachments (Sharon, 2007).

The Gesher Benot Ya’akov technocomplex is the earliest evidence of the use of the Levallois primary reduction-strategy in Eurasia (Goren-Inbar, 1992, 2011a, b; Goren-Inbar, Grosman, Sharon, 2011; and others). The Levallois reduction-strategy has played a considerable role in the formation of Acheulean industries in Eurasia. Notably, the Acheulean industry in Eurasia from 600 to 250 ka BP was characterized by bifaces and cleavers. Besides, two of these crucial historical and technological markers could have occurred at Paleolithic localities at different times and in different quantitative relations, while in certain European regions the classical Acheulean industry has not been recorded at all. The appearance of the Levallois primary reduction-strategy is attributed to later time, approx. 300 ka BP (Tuffreau, Lamotte, Marcy, 1997; White, Scott, Ashton, 2006; and others): it is one of the markers of the Lower to Middle Paleolithic transition.

The appearance of the Levallois primary reductiontechnique at the site of Gesher Benot Ya’aqov is associated with the working of large cores for detachment of big flakes that served as blanks for manufacture of bifaces and cleavers. The appearance of techniques that allowed the production of large flakes marks a definite stage in the development of the Acheulean technocomplex. The earliest culturebearing horizons of the Gesher Benot Ya’akov site are dated to 780 ka BP. In our view, this site is the key to solving the Levallois problem; attention was originally paid to this by one of the leading researchers of the Eurasian Paleolithic, N. Goren-Inbar (Goren-Inbar, 1992; Goren-Inbar et al., 1994; Madsen, Goren-Inbar, 2004; Goren-Inbar, Grosman, Sharon, 2011; and others). An invaluable contribution to studying the problem was also made by Sharon (Sharon, 2007) and other scholars.

The Levallois primary reduction-technology has not received a generally accepted definition so far. Though the Levallois technique has been repeatedly considered at different international symposiums, Paleolithic archaeologists hold varied opinions about it. Two points of view are the most-discussed among specialists: those of E. Boëda (Boëda, 1995; Boëda, Geneste, Meignen, 1990) and L. Inizan with co-authors (Inizan et al., 1999). One of the main features of Levallois reduction is that cores have a striking-platform, the pebble surface of which could be partially preserved at early stages of this technology’s formation; and a second feature is the presence of a convex surface, adjoining the striking-platform, for the detachment of blanks. In the Early Acheulean, during early stage of the Levallois technique’s use, such cores served for flaking; and in the Late Acheulean and the Middle Paleolithic, cores acquired a shape sub-triangular in plan, and were used mainly for production of Levallois points and blades.

Goren-Inbar, and other researchers, associate the Levallois technology at the Gesher Benot Ya’akov site with giant cores, and large flakes detached from these. Basaltic partings recovered directly from trappean sediments served as primary blanks for the partings’ further use as cores. The techniques for recovery of such partings (slabs) from basaltic rock masses are unknown in detail, but they probably involved using a lever or fire, or both (Goren-Inbar, Grosman, Sharon, 2011). After recovery of a basaltic parting, it was split into several smaller pieces that were subsequently transformed into giant cores. According to researchers, inhabitants of the Gesher Benot Ya’akov site employed blanks of a special shape. With the presence of a sharp angle, they detached flakes from the adjacent surface without preliminary rejuvenation of the strikingplatform. Experimental study showed that fragmentation of basaltic partings was performed using a very heavy hammer; and the subsequent removal of large flakes, using the natural sharp angle, required a light hammer (Madsen, Goren-Inbar, 2004). Goren-Inbar does not rule out the possibility that a soft hammer could have been used for the final shaping of stone implements at this locality (Goren-Inbar, Grosman, Sharon, 2011).

The Levallois technique at the site of Gesher Benot Ya’akov is represented by small flakes (Goren-Inbar, 2011a: Fig. 8, 1), and also by big flakes that were subsequently transformed into bifaces and cleavers (Goren-Inbar, 1992). One of the most impressive Levallois cores was found under a crushed elephant’s skull in horizon 1, layer II-6 (Goren-Inbar et al., 1994). This fully complies with the definition of the recurrent Levallois technique for working of cores proposed by Boëda. Flakes detached from this core are large, and at least one of the negatives points to production of a large side-spall which could serve as a blank for a biface (Goren-Inbar, Grosman, Sharon, 2011). Goren-Inbar correctly reasons that the use of Levallois technique during so early a period (MIS 18–20) is indicative of the cognitive sophistication of the Gesher Benot Ya’akov site inhabitants, and their command of advanced technological skills (Goren-Inbar, 2011a; Goren-Inbar, Saragusti, 1996; and others). She comes to conclusion that the Gesher Benot Ya’akov site is more ancient than localities with the earliest Levallois manifestations in Africa, and provides an example of the established Levallois reduction-method and the ability to produce flakes from small cores (Goren-Inbar, 2011b: 91). Already after the first years of field studies in Gesher Benot Ya’akov, Goren-Inbar pointed to the necessity of revising the conclusion about the influence of African industries on the site’s industry, which was drawn with regard to some typically “African” traits such as extensive use of basalt, application of the block-on-block technique, and a large number of cleavers among bifaces (Goren-Inbar, 1995: 108–109).

The originality of this industry, which can be traced at the Gesher Benot Ya’akov site in all components of the cultural sequence, is also emphasized by other scholars. Thus, Sharon and co-authors consider that substantial variability of the toolkit is typical not only of the Gesher Benot Ya’akov site, but of some Acheulean sites of Eastern Africa as well. However, neither of the Gesher Benot Ya’akov industries has analogs in Acheulean variants of African technocomplexes. This special feature was earlier noted by M.P. Kleindienst (1961). F.A. Howell and D.D. Clark explained distinctions between the African Acheulean industry and the Gesher Benot Ya’akov industry by differences in activities and behavioral patterns (1963).

The most precise determination of the place occupied by the Gesher Benot Ya’akov collections in a range of known technocomplexes belongs to Goren-Inbar. In her opinion, the Gesher Benot Ya’akov industries cannot be assigned either to African or to Asian industries. This is a phenomenon with Paleolithic characteristics and a broad spectrum of special features, many of which have local origin, and only some of them can be a result of outside influence (Goren-Inbar, 1992: 67).

Researchers hypothesize that two exoduses from Africa of hominins with Acheulean industry occurred. These have been reflected in materials of the sites of Ubeidiya (about 1.4 Ma BP) and Gesher Benot Ya’akov. According to many anthropologists, a speciation process took place in Africa about 0.8 Ma BP: H. erectus sensu lato gave birth to a new species that was given different names such as H. heidelbergensis , H. rhodesiensis , H. sapiens (Rightmire, 1998; Bräuer, 2007, 2012; Hublin, 2001, 2009; and others). The new H. heidelbergensis species could migrate from Africa to Eurasia, and the Gesher Benot Ya’akov locality is related to this taxon.

In our view, the possibility of development of the main techno-typological complex, represented at the Gesher Benot Ya’akov site, on the ancient autochthonous basis cannot be ruled out. It is possible that Acheulean industries that are the interlink between Ubeidiya and Gesher Benot Ya’akov will be discovered at this or other localities in Levant. After migrating from Africa to the Near East, H. heidelbergensis met indigenous population in the Levant and, in consequence of acculturation, the autochthonous industry in Gesher Benot Ya’akov, as noted by Goren-Inbar, acquired certain “African” traits.

It is difficult to ascertain what innovations could have been brought by H. heidelbergensis to Levant. Perhaps, the Levallois technology in primary reduction? Let us consider this issue.

The Levallois reduction-strategy, which was first recorded in Israel at the Gesher Benot Ya’akov site, is one of the most ancient technologies throughout the world. In Africa, it appeared much later. The earliest example of laminar primary-reduction has been recorded at the Kapturin locality (ca 500 ka BP) (Tryon, McBrearty, 2002, 2006; Johnson, Brearty, 2010; Derevianko, 2015a; and others). Collections from this locality and from the Gesher Benot Ya’akov site have little in common with each other, so they cannot be combined into a single complex.

Manifestations of technology providing detachment of large flakes from cores were recorded in Southern Africa as early as the 1920s (Sharon, Beaumont, 2006). In the Vaal River basin, in the neighborhood of the town of Victoria West, several Acheulean localities were discovered, which represent a technical tradition of detaching one big flake from a well-prepared large core, where the flake was subsequently used to make a cleaver or a biface. This tradition is known as Victoria West. According to some researchers, the cores from the locality near Victoria West are among the earliest examples of Acheulean cores that existed before appearance of the Levallois technology (Kuman, 2001).

Localities containing well-prepared cores for production of large flakes were being destroyed in this region for a long time, owing to human impact. In different years, amateur and professional archaeologists collected Paleolithic artifacts in dumps and on the surface here. They managed to gather quantitatively large collections; however, these did not belong to stratified localities. The average size of cores prepared for detachment of large flakes is 15–25 cm; some have 40 cm in length, 20–25 cm in width, and weigh as much as 68 kg. Flakes up to 30 cm long were detached from cores. The large flakes were predominantly used to manufacture cleavers and small numbers of bifaces (Sharon, Beaumont, 2006).

Discovery of the Gesher Benot Ya’akov core-shaping technology, which is close to the one represented at localities in the vicinity of Victoria West, raises the question of the chronology of these sites separated by thousands of kilometers. The issue of the age of Paleolithic localities in the Vaal River valley remains unsolved so far. Owing to the absence of reliable stratigraphic indices, researchers are unable to determine the chronological framework of the complexes.

The Gesher Benot Ya’akov site attributable to MIS 18–20 is probably more ancient than African ones. Several explanations for the technological similarity under consideration can be proposed. According to the first, appearance of the ancient Levallois (proto-Levallois) technology in Southern Africa was related to infiltration of populations from the Near East. The second explanation implies that similar core-preparation techniques appeared in different territories independently of each other, i.e. convergently. And the third explanation suggests that innovative technologies were transferred from one human population to another in the course of short-term contacts, or during long-distance expeditions. However, the version implying that the technology of giant-core preparation for detachment of a large flake was passed from Africa to the Near East and vice versa like a baton is not confirmed by materials from the Acheulean localities situated in the transit-territory between Southern Africa and Eurasia.

In our view, the technologies of massive-core preparation for production of a large flake, and subsequent use of the latter to manufacture tools, formed independently in various regions, in a convergent manner. This is supported by the fact that manifestations of this technique can be traced at localities separated not only by thousands of kilometers, by also by a long lapse of time. The technology of detachment of a large flake from a core is known in various modifications in Southern Asia, Caucasus, and Central Asia. In these territories, it could have appeared already under the influence of Near East populations. Traces of the use of a large flake have been recorded at the Paleolithic locality in Tsagaan Agui Cave, located in the northern part of the Gobi Desert (Derevianko, Petrin, 1995; Derevianko, Olsen, Petrin et al., 1995; Derevianko, Olsen, Tseveendorj et al., 1996). Raw material for manufacture of stone tools was in the immediate vicinity of the cave; however, it was of poor quality. It was special laminated flint in the form of angular blocks, with numerous internal cavities and inclusions of other rocks. The majority of cores from the Lower Grotto did not bear any traces of special preparation, and flakes were often detached from them in a disorderly manner. Only a small proportion of the cores was subjected to systematic preparation. A.I. Krivoshapkin and co-authors thoroughly studied the sequence of operations related to the shaping and use of these cores (Krivoshapkin, Brantingham, Kolobova, 2011: 4). In Tsagaan Agui, ventral surfaces or massive lateral and/or distal parts of large (more than 10 cm) spalls were used to shape the working-surfaces of cores. Researchers have distinguished two main categories of cores: those with a wide flaking-surface, and those with a narrow flaking-surface (narrow-faced).

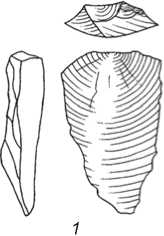

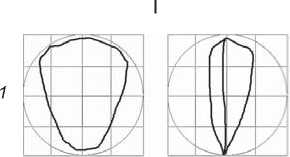

Working-surfaces of prepared cores with wide flaking-surfaces were shaped on ventral surfaces of large spalls (Fig. 1, 1 ). This category of artifact can be divided into single-platform cores (Fig. 1, 2 ), and single-platform cores with a rejuvenated distal part (Fig. 1, 3 ). Both were intended to produce convergent detachments. As a rule, cores of both shapes have faceted striking-platforms and moderately rejuvenated lateral faces. Certain parallels can be discerned between the preliminary preparation of such cores and of classical Levallois cores for the manufacture of points.

Fig. 1. Diagram of core-shaping in Paleolithic complexes of Tsagaan Agui Cave (Krivoshapkin, Brantingham, Kolobova, 2011: 5).

1 – large blank-spall; 2 – single-platform convergent core with a wide flaking-surface arranged on the convex ventral surface of a spall; 3 – single-platform core on a spall with a wide flakingsurface having rejuvenation traces in the distal part; 4 – core with a narrow flaking-surface (narrow-faced core), shaped on the massive lateral face of a spall.

Many industries of the Early, Middle and, besides, Upper Paleolithic in Africa and Eurasia show resemblance in the techniques used for the preparation of cores and the shaping of tools, toolkit types, etc. Accordingly, there is no need for a mandatory search for the center from which one innovation or another could have spread—especially if localities with similar innovative technologies are separated by large areas and/ or by a considerable chronological gap. The typological set of tools, and also tool-shaping techniques employed by Paleolithic people, were not especially great; so populations residing at considerable distances from each other, but in similar environmental conditions, could develop similar adaptation-strategies.

Among prepared cores, bifacial, unifacial, Kombewa, and radial cores are most typical of the Early Paleolithic in Africa. Cores for detachment of blades appeared in the Kapturin Formation in Africa approx. 500 ka BP (Johnson, Brearty, 2010). Boëda noted that blade- reduction was performed by the Hummalian volumetric method, which shows some differences from the

Levallois one (1995). Most likely, well-prepared cores for production of large flakes that represent the Levallois (proto-Levallois) technique first appeared in the territory of Israel, and then in Africa. The spread of stoneworking innovations cannot be explained by technical convergence alone, since new technologies could be transferred in the course of migrations of human groups, short-term contacts, etc.

Specialists cannot always easily identify the center or centers of appearance of one innovation or another in human culture. One such innovation is represented by carinated end-scrapers, or core-shaped scrapers, encountered in the Lower Paleolithic. The finds from Eastern Africa are considered to be the earliest: they are dated to ca 1.5 Ma BP. Carinated end-scrapers are known in Arabia (Amirkhanov, 2006), in the Caucasus (Lyubin, Belyaeva, 2004), in the Altai (Prirodnaya sreda…, 2003), and in other territories. Such artifacts

occupying the vast territory of Eurasia had similar cognitive and motor abilities and, according to their adaptation strategies, could have manufactured different and similar stone tools.

Returning and non-returning boomerangs are among the later tools from various areas of Africa and Asia, for which the place of origin and pathways of distribution into other regions can hardly be determined. They have been familiar to humans since the early Holocene and is represented on all continents apart from the Antarctic. In our view, the appearance and spread of this very difficult-to-make tool can be associated with convergence, migrations, diffusion of cultural standards, etc. Subsequent forms of evolution of the Levantine Lower and Middle Paleolithic industries substantiate the assumption of wide use of the Levallois and blade technologies in systematic production of blades by hominins in this area, long before the arrival of Neanderthals (Goren-Inbar, 2011b).

discovered at the Karama site in the Altai are dated to ca 800 ka BP. African and Altaian core-shaped scrapers are similar, but they are separated not only by a distance of several thousands of kilometers, but also by a time gap of 700–800 ka. Undoubtedly the appearance of such endscrapers in the Altai, as well as in some other regions, is a result of technological convergence. Quite a few such examples can be provided. Obviously, H. erectus

Levantine blade industries at the final stage of the Lower Paleolithic

For several hundred thousand years, peculiar industries were developing in the Levant that showed some resemblance to the Early and Middle Paleolithic industries in Africa and Europe, but at the same time were considerably different from them in many techno-typological characteristics. The Levant is a unique region for studying the Paleolithic period: cave and open-air Paleolithic localities with thick soft sediments that comprise a great number of culture-bearing horizons have been discovered, and are being studied, in this area.

The Levallois primary reduction (flaking) strategy, revealed for the first time at the Gesher Benot Ya’akov locality, cannot be clearly traced at later Acheulean sites. Perhaps the Berekhat Ram Late Acheulean locality, discovered at the Golan Heights, is the only exception in this respect (Goren-Inbar, 1985). Bifaces, denticulate and fine-denticulate tools, end-scrapers, and burins have been discovered there. The cores are represented by discoid and Levallois types. The majority of Levallois cores (87.5 %) were intended to detach flakes that were of one of the main kinds of primary blanks for the manufacture of tools. At the end of the Acheulean, cores for detachment of blades and blade-blanks in primary reduction were used at the Acheulo-Yabrudian industry localities in Israel and Syria. It should be noted that during certain periods of the final stage of the Levantine Acheulean, the role of laminar and Levallois reduction-technology for producing blanks alternately decreased (with the predominance of flaking) then increased, again became crucial. Possibly this process resulted from changes in environmental conditions and, as a consequence, in adaptation strategies in the region. In our opinion, this process was not related to the replacement of population.

Several key sites containing Final Acheulean and Acheulo-Yabrudian materials, on the eastern slopes of the Anti-Lebanon range, Yabrud (western Syria), have been studied since the 1930s (Rust, 1950; Solecki, 1968). Six rock-shelters and one cave have been discovered in this region. The most ancient cultural horizons were unearthed in the sections under Yabrud Shelter IV. The shelter was oriented towards the south, and located at an elevation of 1432.5 m above sea-level. The thickest deposits (11.35 m) were exposed along the outer part of the shelter, near the cliff. The excavations have revealed 22 geological layers, divided into 87 horizons. Soft deposits were composed mainly of interstratified alluvial and aeolian sediments such as sand, gravel, and loess. The mass of soft sediments contained homogeneous archaeological materials.

R. Solecki, who discovered the ground under Yabrud Shelter IV, has studied the lithic industry found during excavations, and given it the name of the Shemsian culture. The excavated lower horizons yielded Tayacian tools, including points, bifacially-worked scrapers, backed knives, and carinated end-scrapers. Many pieces were worked with denticulated retouch. Primary reduction was associated with pyramidal, multi-platform globular and formless cores. Small and blade flakes, typically with a smooth striking-platform, were detached from cores.

A somewhat greater amount of archaeological materials, blanks of larger size, and tools manufactured with the use of finer retouch, are contained in the upper part, as compared to other parts. The upper part is distinguished by a pronounced sequence of tools, and the appearance of typical Levallois short spalls. Levallois cores and Levallois spalls have also been discovered in Yabrud Cave, located in the immediate vicinity of the shelter. Stone tools were found in the lower sediments. The upper part of the soft sediments was destroyed in the recent past. Only small fragments, in the form of breccia “stuck” to the cave walls at a height of 4 m from the modern floor, have remained of it.

Opposite Yabrud Shelter IV, Yabrud Shelter I, which was excavated by A. Rust and R. Solecki, is located. In the lower part of the cave sediments, the researchers distinguish three variants of interstratified industries (from bottom to top): Yabrudian (layers 25 and 22–20, 16, 14, 11), Acheulo-Yabrudian (layers 24, 19, 11), Acheulean (layers 23 and 17), Micoquian (layer 18), pre-Aurignacian (layers 15, 13), and pre-Mousterian (layer 12). They attributed layers 10–2 to the Mousterian, having distinguished the Acheulo-Yabrudian pre-Mousterian evolving into the Yabrudian Mousterian and Micro-Mousterian.

Small tools manufactured on blades and blade-flakes have been found in lower Yabrudian layer 25. Other overlaying layers represent blade-industry related to the reduction of blade pyramidal and Levallois cores. The most impressive blade-industry (pre-Aurignacian) is recorded in layer 15, dominated (up to 90 %) by tools made from narrow blades 5–6 cm long. L.B. Vishnyatsky has pointed out that among unretouched pieces found in layers 13 and 15 in Yabrud I, there were 18 triangular blades, two of which can be referred to as typical (2000). Faceted striking-platforms are recorded on a small number of blades.

According to researchers, in Yabrud I technocomplexes of three industrial developmental trends either co-exist in the underlying culture-bearing horizons, or interstratify in them; while at the end of the Riss-Würm and at the beginning of the Würm, the Yabrudian Mousterian and the Levallois Mousterian formed on the basis of these industries. The Yabrudian Mousterian is characterized by large blade-blanks, massive side-scrapers and endscrapers. The industry preserves microbifacial shapes. Blade-blanks usually do not have faceted strikingplatforms. The Levallois Mousterian, which formed on basis of the Late Acheulean, is distinguished by the presence of blades and points with faceted striking platforms. The tools are large in size. Their working edges are shaped through regular large-faceted retouch. The tools are predominantly side-scrapers.

It is difficult to agree with the conclusions of researchers who attribute the Levantine Middle Paleolithic industry to the Mousterian; however, we turn our attention to this problem in an article that will be published in the next issue of this journal. The legitimacy of distinguishing four rather different development-trends in the Yabrudian industry is doubtful. Replacement of industries can be explained by the arrival of population with a different industry; or by changes in the environmental setting, triggering adjustments to adaptation strategies that lead to the appearance of new stone-working techniques, or different basic techno-typological characteristics of the toolkit. It is hardly likely that all industries (Acheulean, Acheulo-Yabrudian, and Yabrudian) belonged to varied taxons that could alternately occupy grounds under the shelters, and, after some time, leave them, giving place to an anthropologically different population. Obviously, another explanation of this phenomenon is required.

In view of this, let us emphasize again the significance of the Gesher Benot Ya’akov site: here, the cultural sequence of a considerable period yields a large number of bifaces and cleavers in some horizons; and single or no such artifacts in others. Nevertheless, researchers associate the Gesher Benot Ya’akov site with a single taxon. In a duration of 50 (100) thousand years, many changes could have occurred in its techno-typological complex. The legitimacy of distinguishing such a large number of industrial complexes, on the part of Rust, is also doubtful. Since new dates for the Acheulo-Yabrudian industry in Israel have been obtained, it is necessary to revise the chronology of this industry in Syria as well.

In the Levantine Early Paleolithic, for example, in Gesher Benot Ya’akov, elements of Levallois reductiontechnique appeared very early. However, clear continuity with the Levallois reduction-traditions has not (so far) been traced in materials of later localities. In Tabun Cave, in the lowest layer G, shortened pyramidal cores for blade-detachment and four Levallois cores have been found. In our opinion, the tradition of producing bladeblanks should not have been broken. It is not improbable that further studies will help in tracing a continuous development-trend of technology for producing bladeblanks from Levallois, pyramidal, flat-faced, and other shapes of core, in the Early and Middle Paleolithic.

Mass production of blade-blanks at the final stage of the Lower Paleolithic in the Levant is associated with the pre-Aurignacian industry. In Yabrud I, this industry has been found in layers 15 and 13. Unlike overlying layers 16 (Yabrudian) and 17 (Late Acheulean), primary reduction in these layers is dominated by prismatic and pyramidal single-platform cores for detachment of blades (Rust, 1950). Their striking-platforms were mainly smoothed by single spalls. The traces of grinding and faceting are absent. Cores are small (4–6 cm). F. Bordes has characterized the pre-Aurignacian industry by a high degree of plasticity, approx. 40 % (Bordes, 1955). Among the tools, the number of bladebased pieces is three times greater than the number of flakes. The toolkit comprises side and diagonal burins on blades and blade-flakes; points shaped on the dorsal sides of laminar spalls; unifacial points, borers, knives, and combination tools represented by end-scrapers with additional retouch along one edge; and notched-denticulate and denticulate tools.

The study of the Yabrudian pre-Aurignacian industry has revealed secondary use of tools in the technocomplex of Micoquian orientation from layer 18 (Rust, 1950). Pre-Aurignacians often used bifaces to manufacture narrow blades. A substantial proportion of artifacts at the Yabrud I locality is represented by tools of Upper Paleolithic types: end-scrapers on flakes and retouched blades; carinated end-scrapers; and dihedral burins on truncated blades and on flakes, etc. (Bordes, 1955).

On the basis of many techno-typological indices, the pre-Aurignacian industry is close to the Amudian, which was considered by Garrod to be the regional version of the pre-Aurignacian. Many tools in the Tabun (layer E), Abri-Zumoffen, and Zuttiyeh caves were made from knife-like blades; though a small number of bifaces were discovered there. Unlike the Amudian horizons, the pre-Aurignacian horizons at the Yabrud I locality did not contain bifaces, and included burins, end-scrapers on blades, and carinated pieces.

In the Paleolithic Age, the industry-development processes in the Syrian and Israeli territories were similar. Some researchers divide the Lower Paleolithic in Israel into Early, Middle and Late; others into Early, Middle Acheulean and Late Acheulean—the last-named including the Acheulo-Yabrudian, pre-Aurignacian, Amudian, and Hummalian industries. Notably, some specialists attribute the Amudian, pre-Aurignacian, and Hummalian industries to the Middle Paleolithic (Bar-Yosef, 1989; Jelinek, 1992).

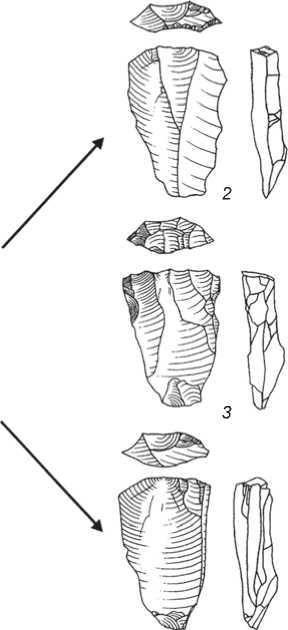

One of the most important and spectacular sites of the Paleolithic Age is Tabun Cave, located in Israel on the western slope of Mount Carmel 20 km from Haifa, at an elevation of 45–63 m a.s.l. and 31 m above the valley’s bottom (Fig. 2). This is a solutional cave consisting of three chambers. Each of these has a cavity in the form of a reversed swallowtail in the floor. The southern chamber—the only one where the roof is

Fig. 2. General appearance of Tabun Cave. Photograph by K. Pavlenok.

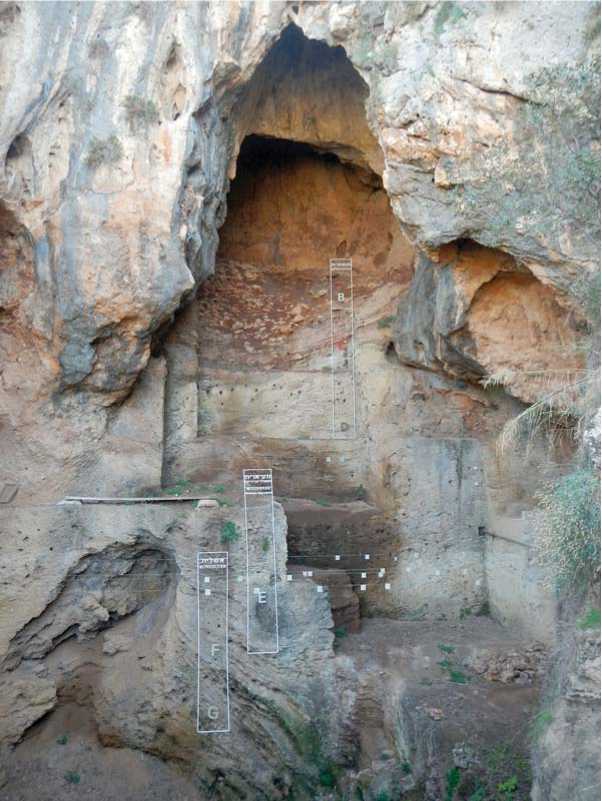

Fig. 3. Generalized view of Tabun Cave profile (after (Shimelmitz, 2015: 35)).

preserved—has its surface exposure in the form of a chimney. Excavations in Tabun Cave were carried out by D. Garrod (1929–1934), A. Jelinek (1967–1972), and A. Ronen (1975–2003) (Shimelmitz, 2015). The excavations have revealed a sequence of soft sediments (about 25 m thick) which is indicative of cave-occupation during the Middle and Upper Pleistocene periods (800– 100 ka BP) (Zviely, Ronen, 2004).

A generalized profile of Tabun Cave is presented by R. Shimelmitz (Fig. 3) (2015). Garrod has distinguished seven major units of culture-bearing deposits (from bottom to top): G, F, Ed, Ec, Eb, Ea, D, C, B, and A (The Stone Age…, 1937). Jelinek carried out excavations mainly in a 10-meter stepped section, and unearthed the layers E, D, C, and B determined by Garrod. Within this sequence, he has identified 14 main culture-bearing layers including 86 horizons, where, in turn, he has distinguished additional internal intercalations (Jelinek, 1975, 1982; Jelinek et al., 1973). Layer I mainly corresponded to Tabun layer C. Artifacts in layers II–VIII were in a mixed state as a result of sedimentogenesis. Layer II corresponded to Tabun layer D, while layers X–XIV correlated sufficiently well with Tabun layer E, according to the classification proposed by Garrod.

Ronen has carried out excavations in different sections within the cave; but his field-studies of the lower part of the cave’s soft sediments (Ronen, Gisis, Tchernikov, 2011), and the results of sorting the block that had fallen off from the basic profile (Ronen, Gisis, Safadi, 2003; Zviely, Ronen, 2004), are our main interest.

The bottom of the karst funnel in Tabun Cave was obliquely overlaid by the lowest culture-bearing layer G, 3.8 m thick, which was attributed to the Tayacian industry (The Stone Age…, 1937). 464 stone tools were recovered from the layer during excavations. The artifacts included notched pieces abruptly retouched to create denticulate working-surfaces; single sidescrapers, single amorphous burins, and chopper-like tools. Cores are represented by shortened pyramidal, single-sided shapes for detachment of amorphous blades and blade-flakes, and also by irregular cores.

In layer F, 1.6–3.6 m thick, 4370 items have been discovered. Bifaces (1233 pieces) and side-scrapers with various modifications (844 pieces) were the most abundant types. 210 cores have been found. Four Levallois cores have been distinguished among those with single- and double-platform. Garrod has attributed this layer’s industry to the Acheulean. Materials of the lower layers G and F in Tabun Cave suggest that Levallois and laminar knapping was used for primary reduction; but as a whole, the technology of producing blanks for toolkit-manufacture was oriented towards detachment of flakes from cores. Making technological characteristics of the industry of two lower horizons,

Jelinek noted a minimum proportion of the Levallois technique (IL=1, ILty=1.2), low plasticity index (Ilam = = 20.9), poorly manifested treatment of strikingplatforms (IF=22.2; IFstr=4.3), and a ratio between tools, flakes, and cores of 20.1 : 60.9 : 19.0 (Jelinek, 1975). However, owing to the presence of Upper Paleolithic tools (burins and end-scrapers), this industry may be interpreted as considerably advanced.

The almost 45,000 tools discovered in layer E, of thickness 7 m, were divided by Garrod into four large groups. According to specialists, the industry of this layer pertains to the Final Acheulean/Acheulo-Yabrudian technocomplex. At an early stage of research, it was seen as containing features of various industries (Rust, 1950). At first, Garrod considered the industry of Tabun Cave layer E to be Micoquian; but later, generally Yabrudian. This researcher noted interstratified horizons with a predominance of Acheulean and Yabrudian elements; in the upper part of layer E, she distinguished a horizon saturated with blades, for the industry of which she proposed the name Amudian.

Subsequently, three facies or three industrial complexes have been distinguished in the Tabun materials: 1) Yabrudian, oriented mainly towards producing flakes and manufacturing Quina-type sidescrapers; 2) Acheulean, predominantly related to the manufacture of bifaces, side-scrapers, and flakes; 3) Amudian, intended for production of Upper Paleolithic blades and tools (Copeland, 2000). In the early 1980s, Jelinek, on the basis of his excavations, came to the conclusion that all alternating facies of the layer E industry, including the Amudian one, pertained to the same Mugharan industrial tradition. He explained the presence of various facies by the adaptation of ancient populations to various living environments (Jelinek, 1981, 1982). In his opinion, the Amudian tradition developed gradually, on the basis of preceding local cultural traditions; while the Levallois-Mousterian industry was derived from the Mugharan tradition.

Tabun Cave is a unique site of global importance. A thick series of soft sediments accommodating approx. 90 cultural horizons in the historical and cultural sequence (from the Middle Acheulean to the final stage of the Middle Paleolithic) allows us to trace the industry’s sequence of changes in one region over a span of at least 600,000 years. Field-studies that were started by Garrod as early as the late 1920s, and have been carried out (with small interruptions) for several dozen years, are not yet finished. Studies of a large block that collapsed in the winter of 1997/98 have made it possible not only to identify new material for characterization of the industry, but also to clarify some important questions relating to sedimentation in the cave (Ronen, Gisis, Safadi, 2003; Zviely, Ronen, 2004).

This block, with dimensions of 0.8 × 0.6 × 0.3 m, which was given the name Tabun-Mapolet, included artifacts of Acheulo-Yabrudian industry Ed and Ec. It was studied by A. Ronen in 2000. It has been possible to recover 810 pieces of flint from this block (Ronen, Gisis, Safadi, 2003). The majority of cores in Tabun-Mapolet (more than 40 %) have no traces of regular knapping, and were attributed by Ronen to the category of amorphous. Among well-prepared cores, 16 spheroid, 6 discoid, one prismatic, and one pyramidal one are distinguished. The toolkit included tools of the Upper Paleolithic type, such as end-scrapers, burins, borers, etc. Ronen defines the Tabun-Mapolet industry as generally flake-based, with numerous side-scrapers and a relatively small number of hand-axes (bifaces). It is not the Levallois industry (Ibid.: 482). The results of studying a small Tabun-Mapolet block confirm the following observation: multilayered sites, well-saturated with artifacts, can contain areas with large and small numbers of stone tools in the same culture-bearing horizon.

The Tabun-Mapolet primary-reduction industry is characterized as follows: the Levallois index (IL) is 3.48; the typological Levallois index (ILty) is 7.82; the faceting index (of platforms) (IF) is 22.54; the strict faceting index (IFs) is 6.82; and the lamination index (Ilam) is 10.30 (Ibid.). Side-scrapers (76 pieces) stand out within the toolkit both in quantity and in typological variability. The most numerous group is composed of simple and combination double side-scrapers; their proportion reaches 25 % of the number in the toolkit. The Charentian index (IC) is 13.9 (calculated on the basis of simple convex and transversal side-scrapers). These types of side-scrapers are typical of the Charentian/ Quina Mousterian. Among others, déjeté scrapers (10 pieces) stand out. The side-scrapers of these two types constitute the Yabrudian index (IYab), equal to 18.2 (Ibid.: 480). In general, the Tabun-Mapolet industry fits into the typological ensemble of the Tabun Cave’s layers Ed and Ec. The presence of Upper Paleolithic tools in this toolkit suggests an advanced level for this industry.

The study of the Tabun Cave collections using different approaches to research offers the possibility of revealing new special technological features in the Final Acheulean and Middle Paleolithic industries. Shimelmitz analyzed collections from excavations made by Jelinek and Ronen with regard to the possibility of secondary use of artifacts (Shimelmitz, 2015). The presence of two patinas, different in depth, on the surfaces of stone tools is indicative of various chronological intervals in their formation. Researchers of lithic industries have long ago discovered traces of the reshaping of tools: for example, bifaces from Tabun Cave (Ronen, 1992; DeBono, Goren-Inbar, 2001) and also from Yabrud localities (Rust, 1950). Shimelmitz managed to ascertain the percentage composition of tools, including core-tools and cores on flakes, reshaped with the presence of patinas, different in depth, on the same surface. Cores for flaking, made on blanks with an earlier patina, were found in the earlier layer F and lower parts of Ed; while reshaped tools were uniformly distributed across the layers. In the Acheulo-Yabrudian industry, traces of secondary use are demonstrated by artifacts of the Yabrudian (2.3 % of the overall size of toolkit) and Acheulean (0.4 %, and almost absent in the Amudian facies) complexes (Shimelmitz, 2015).

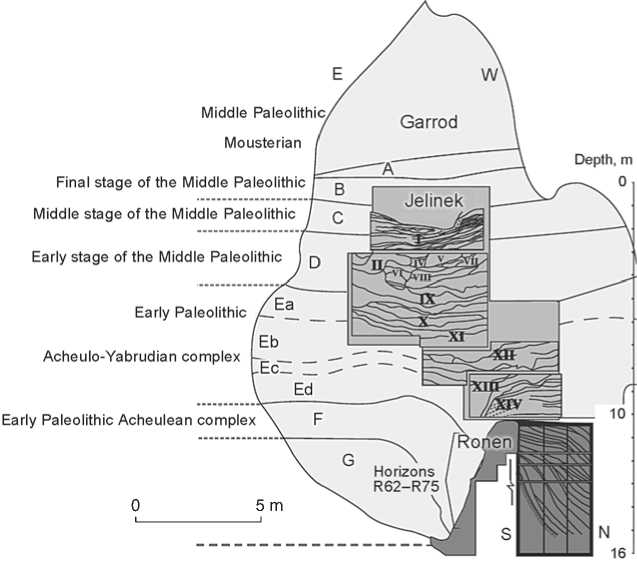

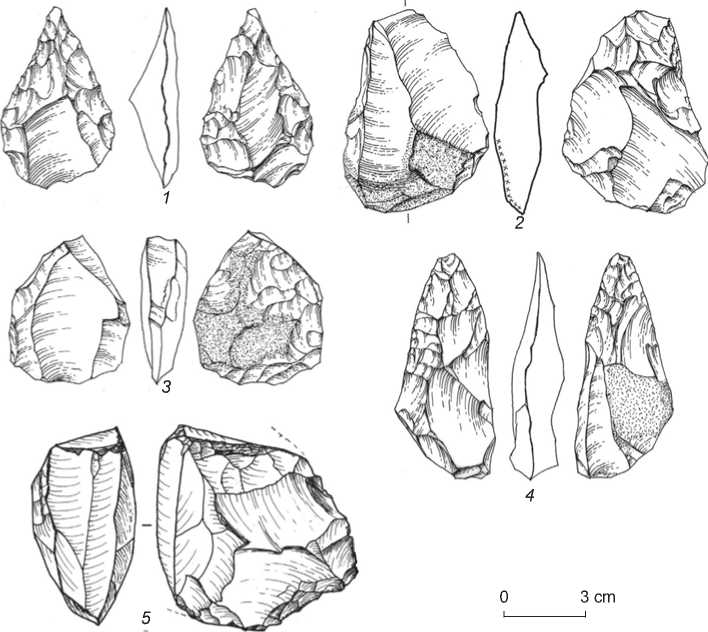

Hand-axes (bifaces) were subjected to reshaping most frequently: their proportion exceeds 27 % of the total number. The maximum percentage of bifaces showing signs of reshaping is observed in the collection of layer F; they reach almost 45 %. Shimelmitz identifies several methods used to adapt bifaces for operation as cores: detachment of Levallois flake from the butt (Fig. 4, 1, 3 ); detachment of flakes from various parts, resulting in severe deformation of the biface (Fig. 4, 2 ); and laminar detachments from the narrow edge, as a result of which the biface lost its shape and turned into a narrow-faced core (Fig. 4, 4 , 5 ) (Ibid.). The first and the third techniques for detachment of blanks from a biface were typically Levallois.

Shimelmitz has managed to trace a peculiarity in the distribution of pieces throughout the Tabun Cave layers according to the intensity of their reshaping. For example, pieces that were used as cores on flakes and as tools are more frequent in the lower culture-bearing Acheulean layer F, and in the lowest Acheulo-Yabrudian complex of layer E. On average, the proportion that were used as tools and cores exceeded 12 % of all pieces. In layers X–XIV, the proportion is considerably lower.

Secondary use of flint implements in the culturebearing layers of Tabun Cave decreases from bottom to top. Such pieces are fewest in the Middle Paleolithic horizons. According to Shimelmitz, this can be explained, first, by the fact that raw materials of higher quality were required for Levallois technology in primary reduction; and second, by planigraphic peculiarities of the living surface. Generally, the largest number of secondarily-used implements corresponds to the period when fire was not yet used regularly.

The study carried out by Shimelmitz, devoted to the secondary use of tools, is of great methodical and methodological importance, because reshaped tools are encountered at stratified localities and sites with a surface occurrence of archaeological materials. They are especially frequently found at long-term settlements and workshop-sites. Materials from thick soft sediments in Tabun Cave allow us to trace the evolution of stoneworking technologies, and the character and organization of the repeated occupation of the cave by humans over extended periods.

Fig. 4. Hand-axes with traces of secondary use as cores in Tabun Cave (after (Shimelmitz, 2015: 40)).

Qesem Cave, in Israel, was discovered in 2000. The next year, salvage operations were carried out in it. Field-studies have revealed comprehensive and impressive materials characterizing the final stage in development of the Amudian industrial tradition (Barkai et al., 2003, 2009; Barkai, Gopher, Shimelmitz, 2005; Barkai, Lemorini, Gopher, 2010; Gopher et al., 2005; Shimelmitz, Barkai, Gopher, 2011; Shimelmitz et al., 2014; Lemorini et al., 2006; and others). Qesem Cave is situated 12 km east of Tel-Aviv, in the western foothills of the Samaria Hills. The cave was formed in Tournaisian limestone. According to researchers, it has undergone several stages of natural and man-induced impact, as well as subsidence and sinking. The cave’s ceiling was destroyed as a result of natural erosion and construction works (Barkai et al., 2003: 977). However, cultural horizons are preserved, mainly in the stratigraphic sequence. The series of archaeological horizons is included in soft sediments 7.5 m thick. As a whole, the stratigraphic sequence is divided into two parts: the lower one, approx. 3 m thick, composed of sediments containing detritus and gravel; and the upper one, approx. 4.5 m thick, composed mainly of cemented deposits with large ash inclusions (Shimelmitz, Barkai, Gopher, 2011: 459).

All cultural horizons include materials pertaining (basically) to the final developmental stage of the Acheulo-Yabrudian cultural complex: the Amudian industry. During field-studies, five Amudian complexes of stone tools from various areas of the cave, and from various sectors of the stratigraphic sequence, were identified (Shimelmitz, Barkai, Gopher, 2011: 460).

The value of finds from the Qesem Cave Amudian horizons lies in the fact that in terms of quantity, they considerably exceed the inventories from Amudian horizons discovered earlier at localities with the Acheulo-Yabrudian cultural complex in the Levant. All these comprehensive materials were thoroughly examined, particularly from the techno-typological point of view.

In a number of studies we considered the hypothesis of the migration of ancient populations of the final Lower Paleolithic—including bearers of the Mugharan industrial tradition—from the Near East to Altai. In our opinion, this is supported by the cultural and historical sequence of the deposits in Denisova Cave, and at other localities in the Altai Mountains (Derevianko, 2001, 2005a, b; 2009a, b; and others). It is difficult to find incontestable evidence, since the territories of the Near East and Altai are separated by great distances; so any technological traditions were subject to change during long movements, owing to the migrating populations’ need to adapt to new environmental settings (e.g. different climate, plant and animal life, raw material for manufacture of stone tools, etc.), and also under the influence of the technological traditions of the autochthonous population. In addition, it is not easy to determine the origins of the industry of the final Lower Paleolithic and the beginning of the Middle Paleolithic in Altai, because of the differences in the extent of our knowledge about the Paleolithic of the territories of transit, from the Near East to Southern Siberia. Nevertheless, detailed reconstruction of primary and secondary stoneworking techniques in the Amudian industry facilitates the revelation of common techno-typological elements in the Levantine and Altaian industries.

Qesem Cave is located in a region abundant with raw materials for the manufacture of tools (Barkai, Gopher,

7 8910

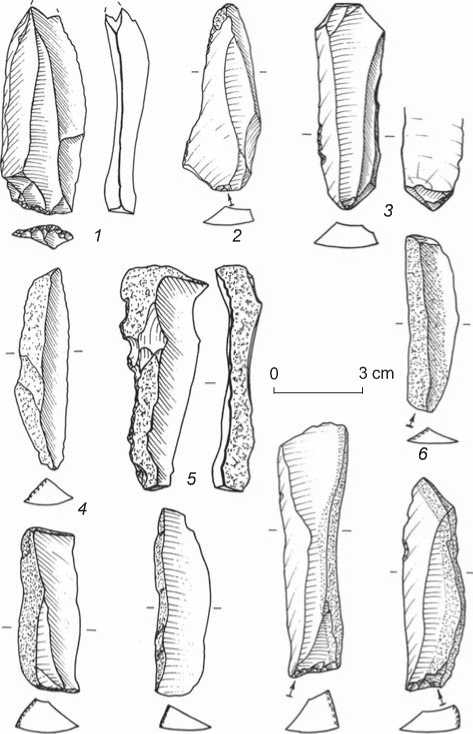

Fig. 5. Blade-pieces of three types from Qesem Cave.

1–3 – blades; 4–6 – blades with cortex on one of the faces; 7–10 – naturally-backed knives (after (Shimelmitz, Barkai, Gopher, 2011: 462)).

Shimelmitz, 2005; Shimelmitz, Barkai, Gopher, 2011). Raw materials were collected from the surface, and from quarries. The studies have established that the sources of flint for manufacture of blades were at a distance of 1–5 km from the cave.

The availability of bifaces is typical of the entire Levantine Acheulo-Yabrudian complex. Only 7 handaxes attributable to the Final Acheulean have been found in the Amudian horizons of Qesem Cave. They are made both from large flakes and from cores. Side-scrapers are made on large flakes (62 pieces; their average length is 60 mm, the width is 40 mm) and blades (7 pieces).

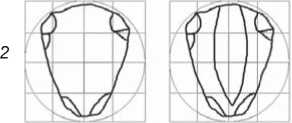

The results of studies of the blade-industry, which is well presented in Amudian materials of Qesem Cave, are of great importance for us. Researchers assess blade-implements as most impressive in the toolkit (Shimelmitz, Barkai, Gopher, 2011). Their manufacturing operations were reconstructed on the basis of analysis of 19,167 pieces. The majority of the artifacts were recovered from the lower part of the cave (only in section K/10, sediments were studied at a depth of 300–420 cm). The proportion of blades in the culture-bearing horizons of Qesem Cave increased from bottom to top (Barkai, Gopher, Shimelmitz, 2005). Stone inventories, though represented variously within five unearthed sections, were integral in terms of technology, which enabled researchers to consider the entire collection as a single complex.

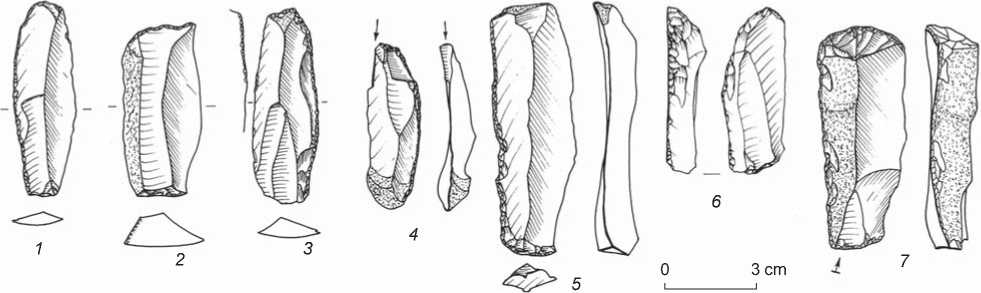

Blade-implements from the Amudian horizons were divided into three types: blades; primary blades with partial remains of pebble surface on one of the faces; and naturally-backed knives, which were manufactured not only on blades but also on flakes (Fig. 5). The following artifacts have been discovered in five sections: blades and bladelets, 761 pieces; primary blades and bladelets, 664 pieces; naturally-backed knives, 696 pieces. Researchers have attributed more than 2200 pieces, together with ready tools, to the blade-complex, which amounts to more than 11 % of the total number of finds discovered in the cave. Among 1397 ready tools, there were 657 pieces (47 %) made on laminar spalls. In section G/19-20, which is located in the middle of the stratigraphic sequence in depth, blade-implements represent 58.2 % of the amount of debitage and ready tools. This suggests that blades played a very important role in the Amudian industrial complex. About 500 blades had retouch, of which 400 pieces were predominantly retouched on the ventral side. Blades were used to manufacture end-scrapers, scrapers, burins, notched-denticulate pieces, and other tools (Fig. 6). Blade-spalls, which researchers have designated as naturally-backed knives (58 pieces in total), were rarely subjected to retouching. Among blade implements, blades with traces of secondary rejuvenation account for 35.4 %, primary blades for 21.6 %, and naturally-

Fig. 6. Pieces made on blades from Qesem Cave.

1 , 5 – blade-pieces with retouch; 2 , 3 – blade-pieces with retouched distal part; 4 – burin; 6 , 7 – end-scrapers (after (Shimelmitz, Barkai, Gopher, 2011: 465)).

backed knives for 12.3 % (Shimelmitz, Barkai, Gopher, 2011: 461). The small percentage of blade-pieces showing signs of rejuvenation of the cutting edges is indicative of the fact that such pieces were often used to butcher animalcarcasses without additional working. This was also confirmed by use-wear studies.

Studies of the Amudian quartzite materials have demonstrated that butchering was the basic activity of the site’s inhabitants. Predominantly, heads and upper extremities were brought to the cave. Butchering involved cutting, scraping-off, and multifunctional separation of tissues from bones. Flint tools were more rarely used for gathering herbage and woody plants (Lemorini et al., 2006; Barkai, Lemorini, Gopher, 2010).

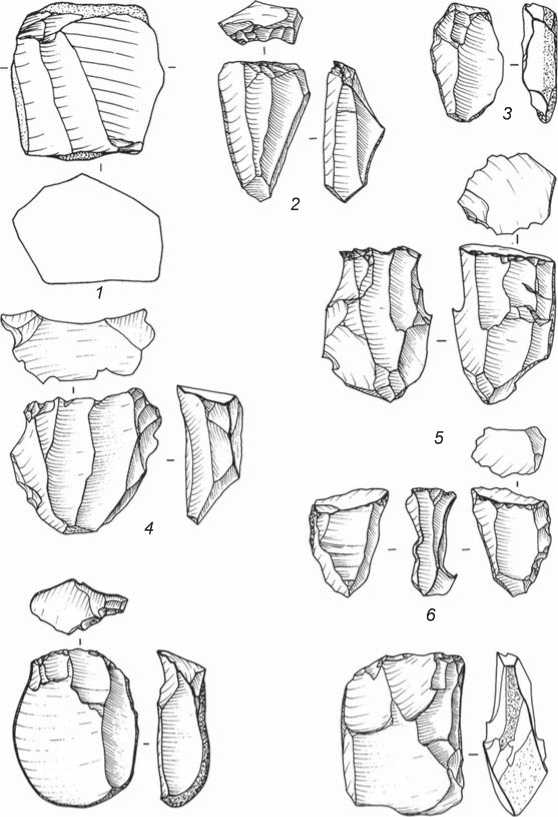

The results of studying the primary shaping of cores in the Amudian complex of Qesem Cave are of major importance for the comparison of the industries of the Levant and the Altai Mountains. 318 cores discovered in the cave were divided into three classes: cores for flaking, blade-cores, and pre-cores with traces of the testing of raw materials (Shimelmitz, Barkai, Gopher, 2011). Among blade-cores, the researchers have distinguished blade-cores with a working-surface showing negatives from detachment of (mostly) blades alone (Fig. 7, 1–6 ); and cores with negatives from detachment of blades and flakes (Fig. 7, 7 , 8 ). Among blade-cores, shapes with parallel edges (28 pieces) were identified, where only blades had been detached from the flat flakingsurface. These cores are closest typologically to the prismatic ones.

It is important to note that their parallel edges were not shaped, because the specially-

78 0 3 cm

Fig. 7. Cores for detachment of blades and flakes from Qesem Cave. 1–6 – for detachment of cores; 7 , 8 – for detachment of cores and flakes (after (Shimelmitz, Barkai, Gopher, 2011: 469)).

selected flat subrectangular flint-pieces served as the basis for cores of this type.

Such cores had cortical surfaces, with the exception of flaking-surfaces and a striking-platform that were predominantly shaped by a single spall (40.7 %), faceting (33.3 %), a combined method with the use of both techniques (3.7 %), or retained natural cortex (22.2 %).

Among blade-cores, prismatic cores with a relatively flat flaking-surface and negatives of blade-detachments have been distinguished (14 pieces). Unlike the cores with parallel edges, they lack features indicative of the invariability of working platform’s outline; on the contrary, this changed throughout the entire process of working (Fig. 7, 2–4 ). Rolled stones or amorphous nodules were used to manufacture such cores. 28.5 % of cores retained natural cortex on the surface, except for the working-surface and striking-platform; and 50 % had cortex only on one side.

Pyramidal shapes (7 pieces) are also assigned to blade-cores. They have a curved flaking-surface and a sharpened base (Fig. 7, 5 , 6 ). Circular detachment of laminar spalls, including so-called plunging spalls, led to the formation of a sharpened base. Rolled and amorphous nodules were used as raw material.

The researchers of the Qesem Cave industry have reconstructed the sequence of preparation of cores for flaking and rejuvenation of cores during detachment of blade-blanks and flakes (Barkai, Gopher, Shimelmitz, 2005; Barkai et al., 2009; Gopher et al., 2005; Shimelmitz, Barkai, Gopher, 2011; and others). The technology of core-preparation for the detachment of blades and flakes depends largely on the selection of raw material. The Qesem Cave’s inhabitants paid great attention to this issue: the further process of shaping a core and the detachment of blanks from it was determined to a considerable extent by the initial shape of the flint parting. Large, flat pieces of flint and rolled or amorphous nodules were most frequently encountered in this region.

The striking-platform was shaped by detachment of a large spall to form a flat surface; then it was flattened by faceting, or retained the natural surface. Generally, it made an angle of 70–80° with the flaking-surface, which was very convenient in terms of technology for further detachment of blanks. The bases of cores were not usually shaped. Initial reduction resulted in the production of blanks in the form of cortical blades and bladelets, primary spalls with a plunging proximal end, and crested blades. With regard to the properties of the initial material, the amount that could be subsequently exploited was already determined at an early stage of preparation of the core for further flaking; cores with parallel edges mainly served to produce blades and bladelets. Therewith, the narrow face was most commonly used to detach blade-blanks of various sizes. This technology of frontal flaking, or the strategy of the use of narrow cores (narrow faces), was very common in the Paleolithic industries of the middle or early stages of the Upper Paleolithic (for instance, at the Kara-Bom locality in the Altai Mountains) (Derevianko, Petrin, Rybin et al., 1998).

Cores that were shaped on rolled and amorphous nodules at the final stage of this process had prismatic or amorphous working-surfaces. Blade-blanks were detached by strong percussion, using a hard hammer against the core striking-platform. The working-surface shaped on a wide face was used to detach blade-blanks and flakes, whereas the latter often served as spalls for shaping of the core’s front. Of great importance is the observation made by researchers regarding two methods for detachment of blanks from cores, which resulted in blade implements of three types (Barkai, Gopher, Shimelmitz, 2005; Shimelmitz, Barkai, Gopher, 2011). One of these methods allowed the creation of cores with parallel edges, while another made it possible to produce prismatic and pyramidal cores with amorphous workingsurfaces (Shimelmitz, Barkai, Gopher, 2011).

Cores with parallel edges were obtained by thorough selection of pebbles or pieces of the same rock with two straight and parallel surfaces, between which a flat flaking- or working-surface was located. During detachment of blanks, the working-surface, while retaining a constant outline, gradually became exhausted. The employed material did not require thorough preshaping, and was easily transformed into a core for producing a large number of similar blades. Laminar spalls, after minor retouching, were suitable for working operations.

The second method for preparation of cores was used to produce prismatic and pyramidal cores with an amorphous working-surface. Rolled or amorphous blanks that required more intense and careful working were selected for their shaping. The striking-platform of such a core, and of cores with parallel faces, was mainly shaped using the same techniques: one or several transverse spalls smoothed the surface, which was occasionally rejuvenated by smaller spalls. One of the side-surfaces, which was positioned at an acute angle to the striking-platform, was selected as the working-surface. The working-surface was shaped by detachment of primary spalls, whose dorsal surfaces retained natural cortex. Subsequently, detachment of blanks in the form of blades and flakes was performed. On the basis of experimental studies, specialists have drawn the conclusion that wide flaking-surfaces required combined detachment of blade-pieces and flakes (Ibid.: 474). If blanks were predominantly detached from a

II

III

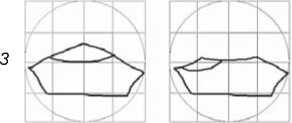

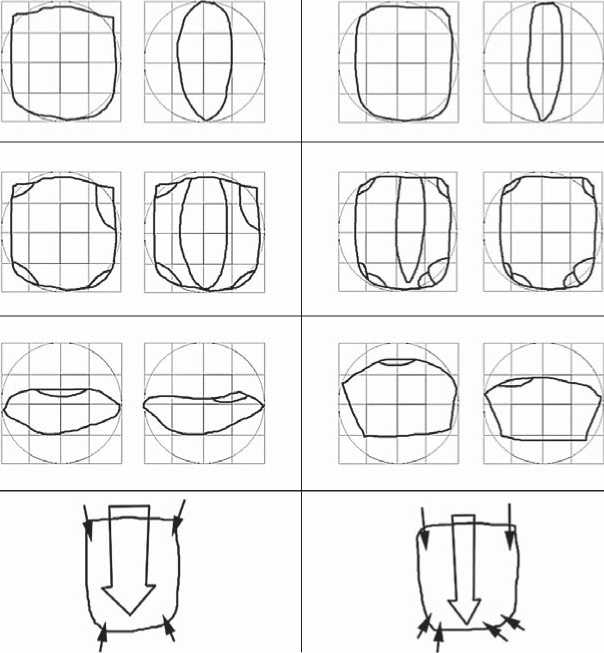

Fig. 8. Variants of core-reduction strategy in Qesem Cave, depending on raw materials (I–III), proposed by P.V. Volkov.

1 – shape of cores on the side of front and main detachments; 2 – dislocation of preparatory and main detachments; 3 – dislocation of first and last main detachments on the side of platform; 4 – reduction diagram.

single surface, then the latter shifted towards the core dorsal surface and widened, while the core acquired a prismatic shape. If a core had several flaking-surfaces, detachment of blades and plunging spalls resulted in a pyramidal core.

The researchers are of the opinion that bladeimplements in Qesem Cave were made using two techniques, similar in many respects. Blade-pieces of three types (blades, primary blades, and naturally-backed knives) had many coincident characteristics. All this suggests that the Qesem Cave’s inhabitants adhered to a single strategy (plan) for shaping cores, with some variations determined by raw materials. During field-works, researchers rarely find cores prepared for detachment of blanks: most often, exhausted cores are encountered, as they were unsuitable for detachment of blanks.

The technology of core-preparation and the process of working with cores can be reliably reconstructed in the case of maximally complete refitting of the cores and spalls that are preserved at the site. Otherwise, even experiments in the production of cores and their flaking will not help in creating an authentic picture of primary reduction. P.V. Volkov has developed a reconstruction, based on the published materials from Qesem Cave, of the reduction process, in three variants depending on the characteristics of the raw material; we provide this in the form of a diagram (Fig. 8)*.

When striving to produce blade-pieces from high-quality (homogeneous in composition, and relatively isotropic) raw material in the form of large flat or rounded blocks of flint, ancient knappers performed reduction of cores following one and the same scheme, including creation of an elongated front of main detachments, typical of prismatic cores; and the use of a natural or specially-prepared platform. Blade-blanks were detached by the application of force in parallel-oriented directions. Three variants of support actions allowed retention of the pre-determined proportions of a front, in spite of the front’s being changed in the course of producing main detachments. In essence, only prismatic reduction strategy was used for flaking; its variants were determined by the quality and shape of blanks. Special features of the reduction process are reflected by the cores, including prismatic, pyramidal (a result of extreme exhaustion of initially prismatic precores), and amorphous.

The studies in Qesem Cave have allowed considerable extension of our knowledge of the degree of the bladeindustry’s development during the Final Acheulean in the Levant. The inhabitants of this territory in the Late Acheulean had an idea of the quality of raw materials, and probably took into account the proximity of sources of such when selecting a place for their site. They developed a strategy of blank-manufacturing technology, and a core-preparation plan with some variations that considered the possibilities of the initial material. The strategy of manufacture technology was aimed at producing a large number of bladeblanks that, with minimal modification or without any additional rejuvenation, were subsequently usable for various household purposes. After the arrival of H. heidelbergensis in the Levant from Africa approx. 800 ka BP, other taxons also appeared in this area; and the development of the physical type of humans and their industries proceeded autochthonously. Certainly this did not preclude short-term contacts and genetic drift between the indigenous Levantines and populations of the adjacent regions; however, this process cannot be revealed by archaeological materials. The Acheulo-Yabrudian industry formed in the Levant on the basis of the earlier Acheulean industry.

The issue of dating the Acheulo-Yabrudian industry in Levant is vitally important, and complicated. The Yabrudian localities in Syria were dated in the range of the final Riss to the Riss-Würm and the beginning of Würm, or MIS 6 and 5. The dates established earlier by the samples from the cultural horizons in Tabun Cave were not totally reliable: they created the impression of a late transition from the Lower to the Middle Paleolithic in the Levant.

In the last two decades, the chronological framework of the Acheulo-Yabrudian industry has been considerably pushed back in time: layers Ed–Ea of Tabun Cave were attributed to the range of 385–240 ka BP (Jelinek, 1992; Bar-Yosef, 1995; Schwarcz, Rink, 1998), and the Levallois-Mousterian industry of layer D to the range of 263–244 ka BP (Mercier et al., 1995). The MSU Laboratory of Dosimetry and Environmental Radioactivity has obtained the dates of 260 ± 60, 270 ± 60, 340 ± 80, 410 ± 110, and 480 ± 120 ka BP for layer E of Tabun Cave (Laukhin et al., 2000); on the basis of the ESR and uranium series, the date of 387 ± ± 49–36 ka BP has been obtained for the lower layer Ed (Rink et al., 2004).

At present, the following dates for Tabun Cave are the most-discussed: layer XIV – 415 ± 27; layer XIII – 390 ± 50 and 302 ± 27, layer XII – 324 ± 31, layer XI – 264 ± 28, layer Х – 267 ± 22, layer IX – 256 ± 26 ka BP; for Tabun С, lower layer I – 165 ± 16 (TL) and 120 ± 16/140 ± 21 (ESR EU/LU), upper layer I – 102 ± 17; 122 ± 16 (ESR EU/LU) (Mercier et al., 2000; Mercier, Valladas, 2003; Rink et al., 2004; Shea, 2007). For the Amudian culture-bearing layers in Qesem Cave, dates within 400 to 220 ka BP have been obtained (Barkai et al., 2003; Gopher et al., 2010; Mercier et al., 2013).

Thus, formation of the Acheulo-Yabrudian industry in the Levant started approx. 400 ka BP and continued to the Middle Paleolithic (260–250 ka BP). Obviously, it is also necessary to revise the dates of the Acheulo-Yabrudian industry represented in the territory of Syria: judging by its techno-typological characteristics, it should pertain to the same chronological interval.