Lyophobic sols «БЕТОПРЕСС»® as additives to chemical admixtures into concrete

Автор: Khovansky V.E.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 6 Vol.15, 2023 года.

Бесплатный доступ

The article presents an innovative approach to enhancing cement concrete, bordering on a scientific breakthrough, and explains it in a way that is easy to understand. The core concept is the integration of a reactive agent with a chemical fluid to augment the material and endow it with novel characteristics. The technique, as suggested by the author, involves utilizing lyophobic sols that they have formulated as admixtures, combined with aqueous solutions of chemical additives produced by Russian companies. Due to the inclusion of these Nanostructured sols in the chemical additives, heavy cement concrete treated in this manner shows remarkable resilience. It remains unaffected by repeated freeze-thaw cycles, even when immersed in saline or mineral-rich waters. Furthermore, this advanced concrete does not demand any special measures for protection, maintenance, or repair, nor does it require additional waterproofing.

Короткий адрес: https://sciup.org/142239111

IDR: 142239111

Текст научной статьи Lyophobic sols «БЕТОПРЕСС»® as additives to chemical admixtures into concrete

" The only way to successfully compete with advance nations is the development of scientific knowledge and cutting-edge technologies, including nanotechnology and in establishing an industry based on scientific and technological innovations. There is no other way! " – the words of the Nobel laureate, and academician Zhores I. Alferov.

The article presents an innovative approach to enhancing cement concrete, bordering on a scientific breakthrough, and explains it in a way that is easy to understand. The core concept is the integration of a reactive agent with a chemical fluid to augment the material and endow it with novel characteristics. The technique, as suggested by the author, involves utilizing lyophobic sols that they have formulated as admixtures, combined with aqueous solutions of chemical additives produced by Russian companies. Due to the inclusion of these Nanostructured sols in the chemical additives, heavy cement concrete treated in this manner shows remarkable resilience. It remains unaffected by repeated freeze-thaw cycles, even when immersed in saline or mineral-rich waters. Furthermore, this advanced concrete does not demand any special measures for protection, maintenance, or repair, nor does it require additional waterproofing.

An additive is defined as ‘a substance added to a liquid to improve its properties or give new ones,’ in accordance with GOST R 51109-97 6.3.3. Extalin (M-methylaniline) holds the distinction of being recognized as the world's first additive, introduced in 1919. Over the past century, approximately 60 different types of additives have been developed, yielding significant economic and technological benefits for many developing nations, including Russia. Nevertheless, these additives have found their applications solely within fuel and engine oils."

Speaking of other industries, such as construction, is it possible to introduce additives into concrete mixtures? The answer is an emphatic no! – if we reference the specified GOST (State Standard), it states clearly that “a substance added to a liquid...” does not apply here because we are dealing with a mixture. However, this mixture can and should be enhanced with admixtures, including both chemical and mineral varieties, to improve its properties. This applies not just to the mixture in its initial form but also to the concrete as it hardens. While additives are usually applied in sparing amounts, admixtures are actually used quite substantially in contrast to their seemingly limited efficiency in some cases. The question then arises: Can we expand the effectiveness of these admixtures while simultaneously endowing them with new characteristics across the board?

Yes, we can achieve this! All components – including the same additives – are usable. The chemical additive's

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION aqueous solution serves as the ideal medium for incorporating the desired active ingredient. Upon dilution with water, every component of the chemical additive dissolves completely to the molecular and ionic level, with particles smaller than one nanometer, thereby creating a true solution within the complex. Introducing a similar ingredient will yield an identical true solution with no novel properties upon dissolution. As the saying goes, let's produce “butter-oil.”

Here you will need to add something completely different, for example, a colloidal solution in the form of a lyophobic sol is ideal. In our version, the sol is not just a true solution consisting of molecules and ions, but a liquid, in this case water, where particles of metal (iron hydroxide) or semimetal (silicon dioxide) with sizes from 1 to 100 nanometers in a stable state and in the presence of surfactants are evenly distributed over the entire volume. Such a sol will perfectly cope with the role of an additive introduced into the liquid for improving its properties and give it new properties (GOST R 51109-97).

The primary challenge we face in our country is the lack of scientific and technical advancements in colloidal chemistry that could be applied to sol modification techniques for chemical additives in concrete. Specifically, there's a scarcity of sols that are both stable and capable of interacting effectively with cement.

Despite this, for over a decade, our company, “НПО БЕТОХИМИКС”® based in Simferopol, has been actively engaged in the development, production, and distribution of ash and sol modifiers to a select group of partners, many of whom have been with us since the beginning of our activities. We are an innovative enterprise; we have never produced for import substitution, primarily because there was never a foreign analogue to replace. Hydrosols, as industrial nanomaterials, have not and will not be imported into Russia, mainly due to their non-existence in Western markets.

Our company possesses these rare hydrosols and can readily supply them to all interested parties. The demand for our stabilized hydrosols from the “БЕТОПРЕСС”® series is remarkably low – only 0.005% of the dry substance is required relative to the weight of cement, and this is the maximum! As it stands, we are the sole Russian provider that offers sol or sol modifiers easily accessible for both research purposes and the industrial production of chemical additives and cement concrete.

Upon the introducing the sol into the chemical additive, the additive undergoes a transformation, shifting from a mere common substance to a sol-modifier with a whole range of enhanced characteristics. These changes affect not only the compound but also the concrete mixture. As a consequence, concrete that contains this sol-modifier transcends to a higher category, earning the new classification of nanostructured concrete. This is attributable to the fact that the active particles within

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

the sols measure between 1 to 100 nanometers in size, which aligns with the standard definition of nano-objects, specifically nanoparticles.

Nanoparticles, with the concrete mixture as part of a chemical additive, become artificially introduced centers of crystallization, from which a spatial three-dimensional grid in the form of a matrix is generated and quickly formed, the material for its forming is the cement hydration products themselves. As a result, integrating our silica “Flux-1GF” into cement concrete as part of any polycarboxylate superplasticizer composition – using just 5 grams (dry weight) per 100 kilograms of cement – induces a qualitative transformation. This addition promotes the development of a unique matrix within the concrete, rendering it waterproof with at least a W16 rating, and reducing its water absorption to no more than 1%!

This has been extensively outlined in our earlier publications, where it is substantiated by test reports. Hence, there's no need to reiterate the same here. Regrettably, the true significance and novelty of the information presented in those articles seem to be lost on the readers, as evidenced by the utter lack of enthusiasm for both the subject of sol modification of chemical additives and our cuttingedge offerings – which, at present have no alternative.

Is it indifference, incompetence, or merely the clichéd disbelief that a small city like Simferopol could give rise to something truly innovative – not even Moscow or St. Petersburg have achieved? Given that we are all well-informed, it is most likely the latter: disbelief! Such achievements have often been eloquently described as if they were fictional... but not in our case. We exist. For over 11 years, we have been developing and successfully producing both colloidal solutions and sol modifiers, exclusively using domestic raw materials.

Our journey is evidenced by the first official laboratory test report of our sol modifier, “БЕТОПРЕСС”® Vibrofinish–a calcium stearate aqueous suspension used in the manufacturing of rigid concrete products via vibrocompression, which dates back to 2012.

The pure sols themselves may not be able to directly replace chemical additives in concrete, but they offer an opportunity to enhance the quality of cement concrete's chemical composition. Stabilized sols can be combined with various chemical additives either during their manufacturing process or just before the mixing of concrete on-site or at a stationary concrete batching plant. It is also feasible to introduce sols into the concrete mix at a proportion of merely 5 grams (dry substance) per 100 kilograms of cement as the sole additive, simply by mixing with water, provided that the production process can accommodate this method.

In absolutely any of these variants, the final product is nanostructured concrete. Take, for instance, the silica sol ‘Flux-1GF,’ which in this case acts singularly as a PMD-8* replacement. A mere 5 grams (of dry sub-

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION stance) per 100 kilograms of cement is sufficient: Once the concrete cures, it transforms from a typically hydrophilic material into a hydrophobic one. Concurrently, its compressive strength is enhanced by 25%. Just 5 grams is all it takes for this concrete to reliably develop strength, even in temperatures as low as –8оC. This exemplifies the practical nanostructuring of cement-based concrete.

Scientific and technical advancements in the formulation and application of colloidal mortars as enhancements to chemical admixtures in concrete represent a high-priority area. Such developments are crucial for any nation, arguably as significant as the well-established domain of fuel additives. This holds even greater importance for an expansive country like Russia. The focus here extends beyond merely enhancing the properties of domestic chemical admixtures and the concrete quality. It also signifies a systematic and qualitative transformation of the construction industry at large. Our range of colloidal solutions and sol modifiers exhibits remarkable longevity, maintaining their properties unaltered for extended periods, potentially spanning years.

Nanostructured concretes exhibit enhanced durability during freezing-thawing cycles and remain stable even when exposed to salts. They do not require protection and waterproofing treatments. Furthermore, these materials require minimal ongoing maintenance and repair, an attribute particularly beneficial for constructing critical infrastructure such as harbor facilities, breakwaters, docks, bridges, canals, dams, cooling towers, roadways, subways, airfields, and other key infrustructure. While lyophobic sols are not a direct substitute for chemical additives in concrete, they serve to elevate and transform the performance of these additives to a new level – with nanoparticle precision – as part of cutting-edge industrial sol modifiers, integrating seamlessly into a unified additive formulation!

The number of chemical additives in concrete produced in Russia has long exceeded four hundred, and all of them are, when diluted with water, true solutions that can be easily modified with sols of the “БЕТОПРЕСС”® series. And since we have five such sols, and each of them has its own special purposeful action, the total amount of chemical additives available should also be multiplied by five.

Consequently, our country, hitherto lacking any industrial nanomaterials, is positioned to gain a substantial advantage by acquiring an immediate assortment of two thousand diverse sol modifiers, on the basis of the integration of domestic chemical additives into concrete mixtures. Such a leap forward will empower our construction sector to exclusively build with nanostructured concrete – that would set us ahead of any developed country globally. Unfortunately, despite 11 years of persistent efforts and informative publications, not a single state institution responsible for development in

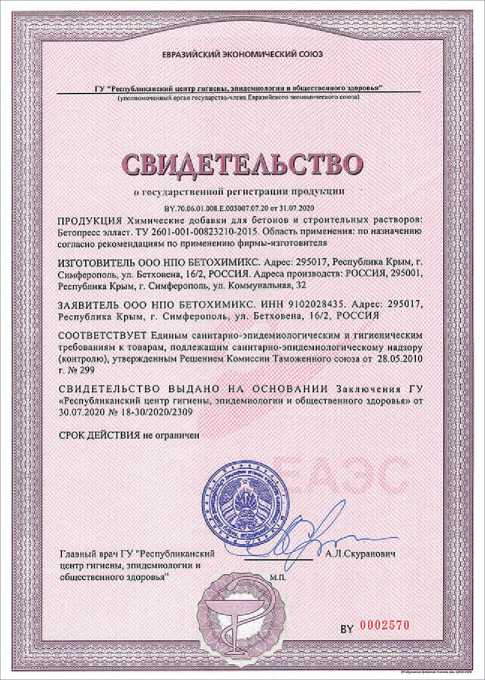

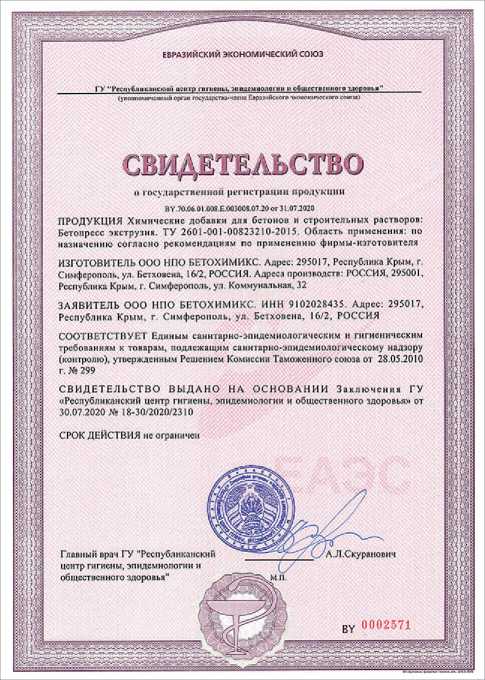

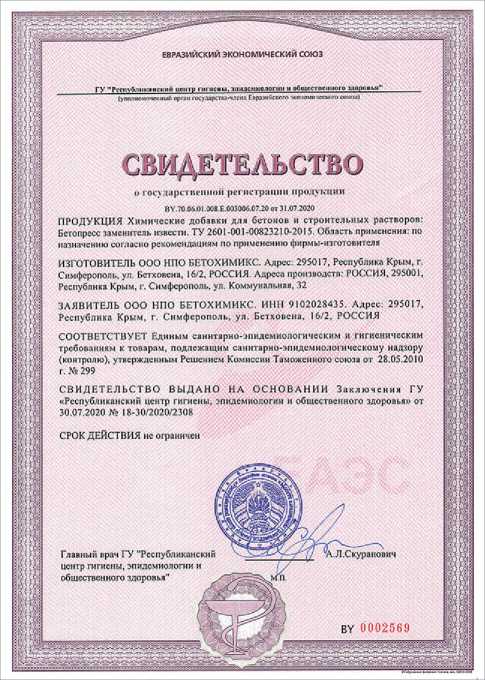

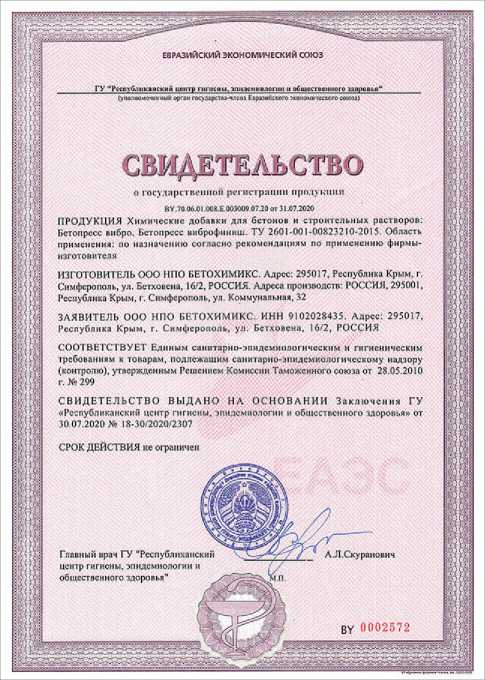

ЕВРАЗИЙСКИЙ ЭКОНОМИЧЕСКИЙ СОЮЗ о государственной регистрации

Скуранович

ЕВРАЗИЙСКИЙ ЭКОНОМИЧЕСКИЙ СОЮЗ

Продукция:

устанавливается на весь продукции на территорию

•Скуранович

Главный врач ГУ ‘Республиканский ист» гигиены, эпидемиологии я общественного"

прошла государственную регистрацию, внесена В Реестр свидетельств о государственной регистрации и разрешена для производства, реализации и использования

Главный врач ГУ "Республикансь гигиены, эпидемиологии и общее здоровья"

соответствует Единым санитарно-эпидемиологическим и гигиеническим требованиям к товарам, подлежащим санитарно-эпидемиологическому надзору (контролю), утвержденным Решением Комиссии Таможенного союза от 28.05.2010 г. № 299

о государственной регистрации BY .70.06.01.008.Е.004056.08.19 от 27.08.2019

Продукция:

Химические добавки для бетонов и строительных растворов: Бстопрссс Суперпластификатор-1 К, Бстопрссс суперпластйфикатор-2К, Бстопрссс суперпластнфикатор-ЗН, Бстопрссс супсрпластификатор-4Н, ТУ 26O1-OO1-OO82321O-2OI5. Область применения: по назначению. Изготовитель: ООО НПО БЕТОХИМИКС, Адрес: 295017, Республика Крым. г. Симферополь, ул. Бетховена, 16/2, РОССИЯ. Адреса Производств; РОССИЯ, 295001, Республика Крым. г. Симферополь, ул. Коммунальная, 32. Заявитель: ООО НПО БЕТОХИМИКС. Адрес: 295017, Республика Крым, г. Симферополь, ул. Бетховена, 162, РОССИЯ

Б^рес“"р»о°15™, ?у 2бо™о“оо8232^ Ертерресс ,p„„.]5(H), Изготовитель: ООО НПО БЕТОХИМИк-г2°15' Облас™ применения: п» назначению. Симферополь, ул. Бетховена 16/2 РОССИЯ дДрес' 95017- Республика Крым, г. Республика К»™ г г™ ’ Р0ССИЯ- Адреса производств: РОССИЯ, 295001, БЕТОХИМИКС Адоес- 2950Г7 °р°ЛЬ V”’ К°ммУнальная>32- Заявитель: ООО НПО РОССИЯ Р ' 95017>РеспУблика Крым, г. Симферополь, ул. Бетховена, 16/2,

Срок действия свидетельства о государственной регистрации период изготовления или поставок подконтрольной Ьвразийского экономического союза

Заключения ГУ ''Республиканский центр гигиены, эпидемиологии и общественного здоровья" от 27,08-2019 г. № 18-30/2019/2751

Срок действия свидетельства о государственной регистрации устанавливается на весь период изготовления или поставок подконтрольной продукции на территорию Евразийского экономического союза

'«""’Р™-’™»™»™»™ и гигиеническим требокани.м к

Настоящее свидетельство выдано на основании

^'.XLo?,^ '"■»—.™ - <,6щ,таого

АPPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION the construction field or the broader industrial sector, including numerous scientific bodies, has acknowledged the significant contributions our company's innovations could make for Russia today. It's a matter of strategic importance, one might argue!

“НПО БЕТОХИМИКС”® company has the capacity to manufacture and distribute a comprehensive line of five high-performance, versatile sol additives for use in chemical additives for concrete. These additives are highly efficient, with a maximum dosage of just 5 grams per 100 kilograms of cement for ready-mix concrete formulations, utilizing domestically sourced materials.

Moreover, we offer a line of formulation guides for sol modifiers based on polycarboxylate ether. This includes the cutting-edge hyperplasticizer PMD-35*, which is specially designed for enhancing cold weather concrete and requires a maximum of 1.7% dosage (for the liquid product variant). The formulas for these sol modifiers, while not commercial products in themselves, are freely available to all customers who purchase the sol additives. This strategy is aimed at fostering a fast and significant technological breakthrough in the national construction sector, by empowering users with the knowledge and materials needed to drive innovation and efficiency.

General Director

ООО «НПО БЕТОХИМИКС» and ООО «БЕТОХИМИКС ГРУПП»

+7 978-917-27-97, + 7 978-284-74-55

R