Machinability of stainless tool steel using nitrogen oil-mist coalant

Автор: Elshwain Amad E., Elmunafi Mohamed H., Yusof Noordin M., Redzuan Norizah, Kurniawan Denni, Wahab Hassan A., Mohamed Yasir A.

Журнал: Вестник Воронежского государственного университета инженерных технологий @vestnik-vsuet

Рубрика: Химическая технология

Статья в выпуске: 3 (73), 2017 года.

Бесплатный доступ

For all dry machining process, temperature generated in the cutting zone is the major challenge. It causes tool failure and results in unsatisfactory surface finish. Application of flood coolant method during machining processes can significantly reduce the temperature and consequently extend the cutting tool life. However, it has serious concerns regarding environmental pollution, operator health and manufacturing cost. These issues are usually attempts to be overcame by using minimum quantity lubrication (MQL) technique. This method merges the advantages of both dry cutting and flood cooling by spraying a small amount of lubricant to the cutting zone using vegetable oil. In this paper, another technique is proposed in order to further enhance the machineability of the stainless tool steel (STAVAX ESR 48 HRC). This involves using of nitrogen gas (N2) and air as cooling medium in combination with oil mist lubricant (MQL). The results show that the combination between nitrogen and oil-mist lubricant much more prolonged the tool life and improved the surface finish than the air-oil mist lubricant medium.

Mql, cutting fluid, tool wear, cutting forces, surface roughness, tool life, nitrogen

Короткий адрес: https://sciup.org/140229414

IDR: 140229414 | DOI: 10.20914/2310-1202-2017-3-143-147

Текст научной статьи Machinability of stainless tool steel using nitrogen oil-mist coalant

DOI:

Dry hard turning has become an alternative machining process to grinding due to its ability to increase material removal rate, reduce production cost and enhance of material properties. However, dry hard turning has several issues such as high temperatures at the tool-chip and tool-workpiece interfaces, which are negatively affects the quality of the machined parts and terminates the tool life. Using conventional cutting fluid methods (flood coolant) can improve machining performance by reducing the temperature in the cutting zone, however, it causes environmental pollution, has hazardous effect on operator health and increases the capital cost of the machined products. These issues have encouraged the researchers to replace the conventional cooling method by another one. Recently, machining with minimum quantity lubrication (MQL) has been introduced as a replacement to the traditional one. It is considered as green manufacturing processes since only very little quantity of lubricating oil mixed with compressed air is delivered at the tool–workpiece interface. However, the suitability of this technique in enhancing the machineability of hardened stainless tool steel is still under investigation. In reported literature an appreciable efforts have been made in investigating this new technique and compare with dry cutting when machining different hard materials. Elmunafi et al [1] investigated the use of MQL in turning AISI 420 stainless steel and compared

the results with dry cutting. They concluded that that MQL has offered a better surface roughness and extended the tool life by reducing the temperature at the cutting zone. In another report, Rahim et al. [2] stated that applying of MQL technique using vegetable oil resulted in better machining performance when compared with dry cutting where the cutting force and temperature have been reduced. The good experimental results obtained by using MQL, make it as an alternative technique to flood cooling method when machining hardened steels and aluminum alloys [3]. For machining other materials and steel grades, this new technique was also investigated. It was found that applying MQL when machining Inconel 718 at high speed resulted in extending the tool life and reducing cutting forces [4]. Sharma et al [5] reported that temperature was significantly decreased and surface finish was improved when machining AISI D2 alloy steel using MQL with vegetable oil and tungsten carbide cutting tool. For further machineability enhancement of different materials, a combination between nitrogen and oil-mist (MQL) has been used. Handawi et al [6] conducted their experiments under nitrogen-oil mist and air-oil mist lubricant conditions during high-speed turning of stainless steel (AISI 420). The result shows that the machining performance with nitrogen-oil mist was better than air-oil mist in terms of tool life and surface finish. Shizuka et al [7] investigated the use of nitrogen-oil-mist when turning carbon steel (AISI 1045) using both cemented carbide and

cermet tools. It was found that N 2 significantly reduces the oxidation that occurs at the chip and the tool interface, and the tool wear took place by different wear mechanisms such as adhesion, chipping and abrasion. Wear by oxidation was not noticed, and only some micro cracks were found at the flank face near the cutting edge. However, the later lubricant techniques were not investigated when machining stainless tool steel (STAVAX ESR-48 HRC) using wiper coated carbide cutting tool.

In general, finish machining is meant to accomplish smooth level of surface texture, which is usually depicted with low feed and depth of cut. Wiper geometry cutting tools is another modification on the machining process to achieve better finish and increase the metal removable rate by increasing the feed rate as well [8]. Surface roughness has significant influence upon the tool life. For manufacturing parts by machining, low surface roughness is required since it will lead to reduce the friction and wear rate, and thus, improves the corrosion resistance [9]. Therefore, in this work both air-oil-mist and nitrogen-oil-mist cutting conditions with biodegradable vegetable oil were investigated, and the results were compared with dry machining.

Experimental Details

Workpiece Materials, Cutting Inserts and Experimental Procedure

Turning tests were performed on hardened stainless tool steel (STAVAX ESR) using Alpha 1350 S CNC lathe machine. The chemical composition of this workpiece material was 0.38% C, 0.9% Si, 0.5% Mn, 13.6% Cr and 0.3% V, having hardness of 48 HRC as labeled by the manufacturer. Experiments were conducted using tungsten carbide coated with single-layer ТiАlN. The coated carbide tool has an ISO designation of CNMG 120408, with wiper geometry and 0.8 mm nose radius. The inserts were mounted on tool holder ISO designation (MCLNR 1616Н12). The insert with the tool holder has the following angles: side cutting edge angle is -5°, entering angle 95°, end and back rake angles is 5°, end and side relief angles is 5° and end cutting edge angle is 5°. Flank wear growth was monitored at regular cutting time intervals (30 seconds). The measured responses are the main cutting force, tool life and surface roughness. The criteria for tool failure was set at maximum flank wear of 0.12 mm, when the tool is broken (catastrophic failure) or if the surface roughness of the machined workpiece is beyond 1.6 μm. Optical Microscope (Zeiss, Type Stemi 2000-C) and FEI QUANTA 200 FESEM were used to capture and evaluate the wear on flank surfaces. For measuring the centerline average (CLA) surface roughness values (Ra), Mitutoyo profile meter, type: SJ-301 was used. The surface roughness measuring length on the machined surface was kept at 0.8 mm.

Cutting Parameters

The machining parameters (cutting speed, feed and depth of cut) were selected based on tool manufacturer's recommendation for finish machining of hardened stainless steel using coated carbide tool as tabulated in Table 1.

Table 1.

Cutting parameters

|

Cutting speed, V c (m/min) |

100 |

135 |

170 |

|

Feed, f (mm/rev) |

0,16 |

0,2 |

0,24 |

|

Depth of cut (mm) |

0,2 |

||

Coolant and Lubricant Conditions

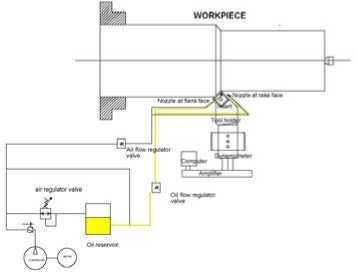

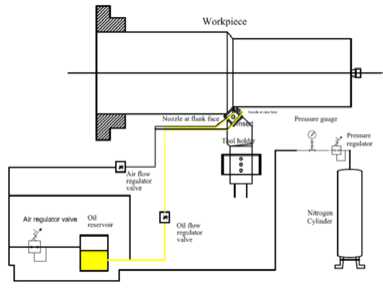

In air-oil mist system (MQL), a compressor was used to supply air at pressure of 5 bar with flow rate 50 ml/h using vegetable oil (castor oil) which was supplied by MQL system (Unist type) as shown in Fig. 1. For nitrogen-oil mist system, nitrogen cylinder with suitable pressure regulator was used to supply the nitrogen gas at pressure of 5 bar at 50 ml/h flow rate as shown in Fig. 2. Two nozzles were used to target the face and flank surfaces of the tool. Dry cutting with the same parameters was also conducted as control.

Figure 1. Schematic diagram of air-oil-mist condition

Figure 2. Schematic diagram of nitrogen-oil-mist condition

Results and Discussion

In this section, main results were detailed and discussed. Graphics showing the surface roughness, tool life and wear mechanism at three different conditions of dry, air-oil-mist and nitrogen-oil-mist were presented.

Tool Life

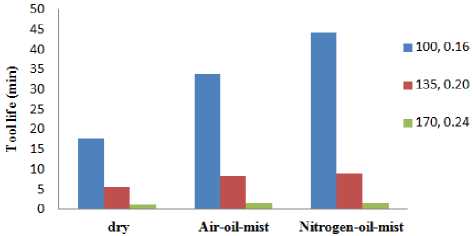

The tool life values obtained from dry, airoil-mist and nitrogen-oil-mist cutting machining conditions are presented in Table 2. As it was expected, varying the cutting speed and feed rate affected the cutting tool life (Fig. 3) . Thus, increasing cutting speed and feed rate in dry cutting resulted in decreasing the tool life. However, when air-oil-mist was employed the tool life was significantly extended by 90%, 50% and 66% for low, medium and high cutting conditions (cutting speed and feed) respectively. Comparing these tool life results of the nitrogen-oil mist with the air-oil mist, it was found that the tool life was moderately prolonged at the three combinations of speed and feed. This indicates that the later lubricant method (nitrogen-oil-mist) is very practical lubrication for extending the tool life. These good results is attributed to the fact that nitrogen gas atmosphere retards oxidation due to the developed heat at cutting zone during machining, which leads to reduce the cutting temperature and extend the tool life [7]. Tool life of nitrogen-oil-mist at high level of cutting speed and feed rate seems to be moderately extended. The reason is that at high machining conditions, the temperature generated at the cutting zone was high enough to cause catastrophic failure for both lubrication methods. Fig. 3 illustrates the tool life obtained from the three different machining conditions.

Table 2.

Tool life at different machining conditions

|

Cutting conditions |

Tool life (min) |

|||

|

Cutting speed (m/min) |

Feed (mm/rev) |

Dry |

Airoil-mist |

N 2 -oil-mist |

|

100 |

0,1 |

17,7 |

33,7 |

44,3 |

|

135 |

0,20 |

5,5 |

8,3 |

9,81 |

|

170 |

0,24 |

0,9 |

1,5 |

1,75 |

Figure 3. Histogram of tool life for different machining conditions

Wear Mechanism under Air-Oil Mist and Nitrogen-Oil Mist Conditions

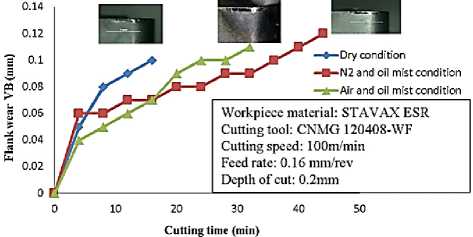

The comparative experiments were also used to investigate tool wear when turning stainless tool steel (STAVAX ESR) under air-oil-mist and nitrogen-oil-mist machining conditions. Fig. 4 shows the progression of flank wear (VВ mах ) on the minor flank face of the coated carbide tool under dry, airoil-mist and nitrogen-oil-mist conditions respectively. It’s obvious that the flank wear (VВ mах ) under dry condition grew rapidly (Fig. 4) . While it’s rate of growth decreased by air-oil-mist and nitrogen-oil-mist lubricants. After 17 minutes of machining time, the micro drops of oil-mist were evaporated because of the rise in cutting temperature that caused by the tool wear. This prevented the oil film to interact at tool-workpiece interfaces. However, the tool wear rate in the case of nitrogenoil mist was less. This is due to the reduction of oxidation wear, which led to extend the tool life by reducing the propensity to progressive wear at the WC–Co cutting tool faces.

Figure 4. Progression of tool wear (VB) versus cutting time under dry, air-oil mist and nitrogen oil mist conditions

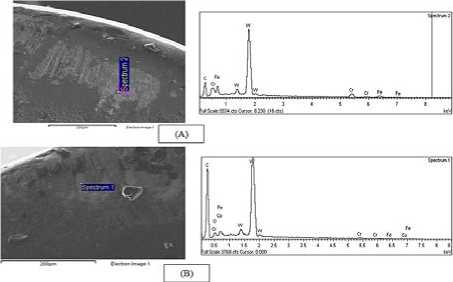

On the other hand, crater wear which was formed due to the coating material loss, indicated that the flank face was affected by less loading than the rake face [10]. Fig. 5 represents the SEM and EDS analyses of the coated carbide tool flank. The SEM images shows the flank wear at low condition of cutting speed and feed (100m/min and 0.16 mm/rev) for dray and both lubrication methods (air-oil-mist and nitrogen-oil-mist). It can be noticed that the cutting tool tested in the medium of nitrogen-oil-mist served for longer time. In this case, the tool was failed by abrasion wear mechanism, while the tool tested in air-oil-mist medium failed by diffusion wear mechanism. This explains for the higher percentage of adhered workpice material that detected by EDS on the tool surface. In addition, the damage of coating substrate was found to be less under nitrogen-oil-mist compared to air-oil mist conditions as shown in Figures 5А and 5В .

Figure 5. SEM of rake face and EDS analysis of typical area: (A) air oil mist (B) nitrogen-oil mist at 100 m/min, 0.16 mm/rev

Surface Roughness

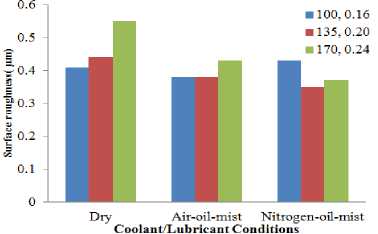

Table 3 p resents the values of surface roughness for dry and both lubricant methods. In general, the surface roughness values for dry machining were higher than the air-oil-mist and nitrogen-oil-mist lubricants. Nitrogen-oil-mist machining medium showed better surface finish than air-oil-mist one at condition of high speed and feed. This is attributed to the good penetration and better cooling effect of the lubrication method [11], and the less contact area between the tool and chip interface. Thus, it enabled the nitrogen to reduce the friction at the interface between the tool and the chip [12]. Furthermore, the high nitrogen gas pressure led to improve the surface quality of the machined workpiece and prolong the tool life when it was used with the oil-mist [13, 14]. This could be due to the fast cleaning of metal residual left on the surface of the workpiec by the chip during machining. Figure 6 shows the variation in surface roughness measured during turning STAVAX ESR by coated carbide cutting tools under dry and the two lubrication methods at different cutting parameters. It can be concluded that the smoother surface finish of the machine surface was obtained by using nitrogen-oil-mist lubrication medium at high condition of cutting speed and feed.

Table 3.

|

Results of dry, air-oil-mist and N 2 -oil-mist conditionsin terms of surface roughness |

||||

|

Cutting speed (m/min) |

Feed (mm/rev) |

Surface roughness (μm) |

||

|

Dry |

Air-oil-mist |

Nitrogenoil-mist |

||

|

100 |

0,16 |

0,41 |

0,38 |

0,43 |

|

135 |

0,20 |

0,44 |

0,38 |

0,35 |

|

170 |

0,24 |

0,55 |

0,43 |

0,37 |

Figure 6. Histogram of surface roughness for air-oil mist and nitrogen oil mist at different cutting parameters

Cutting Forces

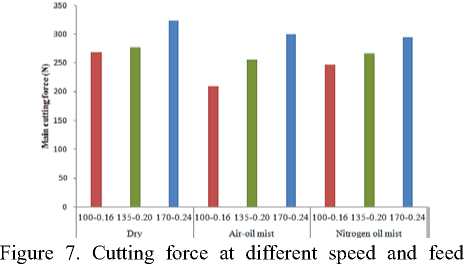

The measured main cutting force when turning hardened tool steel (48НRС) under the dry, air-oil-mist and nitrogen oil mist conditions was illustrated in Fig. 7. It is in the ranges of (269–323N) for dry, (210–300N) for air-oil-mist and (247–294N) for nitrogen-oil mist machining conditions. It is evident that mean cutting force increased when cutting speed and feed were increased for all three machining conditions. However, the main cutting force is higher in dry machining at all cutting conditions of speed and feed. When the two lubricant methods were used, the cutting force was reduced for all employed cutting parameters. This is due to the lower rate of tool wear when lubricants were used and thus, reduced the cutting force. However, the main cutting force at low speed and feed was lower under air-oil-mist condition. This could be due to the low temperature generated at the cutting zone, and the ability of oil film to penetrate to the cutting area in contact. Whereas at high speed, cutting force is slightly lower under nitrogen-oil-mist condition. This is probably due to the evaporation of the oil film in the case of air-oil-mist lubricant because of temperature rise at higher cutting speed, and thus this lubrication method became less effective. The situation is different when machining was performed using nitrogen-oil-mist lubrication method at high condition of cutting speed and feed. Although the developed high temperature led to evaporate the oil film, the nitrogen stood alone to perform the cooling action at the cutting zone [11].

under dry, air-oil-mist and nitrogen-oil-mist conditions

Conclusion

Hardened AISI 420 stainless steel (48 HRC) was turned under dry, air-oil-mist and nitrogen-oil-mist conditions using wiper-coated carbide cutting tools at various cutting speed and feed rate. The tool life under nitrogen-oil-mist machining condition was appreciably prolonged compared to dry and air-oil-mist cutting conditions. Flank and crater wear are the dominant failure modes when hard turning STAVAX ESR. Nitrogen reduced oxidation wear on tool faces and provides better cooling effect compared to air-oil-mist condition. Nitrogen-oil-mist machining condition showed better surface roughness than air-oil-mist one. At high speed, cutting force is slightly lower under nitrogenoil-mist condition. Therefore, it can be suitable lubricant/cooling medium for machining the stainless tool steel material at high removable rate.

Acknowledgement

The authors wish to thank the Ministry of Higher Education, Malaysia (MOHE), Universiti

Teknologi Malaysia (UTM) and Research Management Center, UTM for their financial support to this work through the Long Term Research Grant Scheme (LRGS) funding number 4L804. The authors also wish to thank staff of Production Laboratory, UTM for their technical support.

Список литературы Machinability of stainless tool steel using nitrogen oil-mist coalant

- Elmunafi M. H., Kurniawan D., Noordin M. Y. Use of castor oil as cutting fluid in machining of hardened stainless steel with minimum quantity of lubricant. Procedia CIRP. 2015. vol. 26. pp. 408-411.

- Rahim E. A. Ibrahim M. R., Rahim A. A., Aziz S. et al. Experimental investigation of minimum quantity lubrication (MQL) as a sustainable cooling technique. Procedia CIRP. 2015. vol. 26. pp. 351-354.

- Sreejith P. Machining of 6061 aluminum alloy with MQL, dry and flooded lubricant conditions. Materials letters. 2008. vol. 62. pp. 276-278

- Zhang S., Li J.F., Wang Y.W. Tool life and cutting forces in end milling Inconel 718 under dry and minimum quantity cooling lubrication cutting conditions. Journal of Cleaner Production. 2012. vol. 32. pp. 81-87.

- Sharma J., Balwinder S. S. Investigation of effects of dry and near dry machining on AISI D2 steel using vegetable oil. Journal of Cleaner Production. 2014. vol. 66. pp. 619-623.

- Handawi M., Elshwain A.E., Noordin M. Y., Redzuan N. et al. Comparison between Nitrogen-Oil-Mist and Air-Oil-Mist Condition when Turning of Hardened Tool Stainless Steel. Applied Mechanics and Materials. 2014. vol. 660. pp. 18-22.

- Shizuka H., Sakai K., Suzuki Y. The Assist Effect of Nitrogen Atmosphere on MQL Cutting Performance. Key Engineering Materials. 2009. vol. 407. pp. 321-324

- Shaw M. C. Metal cutting principles. Clarendon press Oxford. 2005. pp. 30-90

- Gillibrand D., Sarwar M., Pierce C. The economic benefit of finish turning with coated carbide. Surface and Coatings Technology. 1996. vol. 86. pp. 809-813

- Noordin M. Y., Kurniawan D., Sharif S. Hard turning of stainless steel using wiper coated carbide tool. In-ternational Journal of Precision Technology. 2007. vol. 2007. pp. 75-84

- Çakır O., Kıyak M., Altan E. Comparison of gases applications to wet and dry cuttings in turning. Journal of Materials Processing Technology. 2004. vol. 153. pp. 35-41

- Zhao W., He N., Li L. Effect Mechanism of Nitrogen Gas on Chip Formation in High Speed Cutting of Ti6Al4V Alloy Based on FEM Simulation. Materials Science Forum. 2009. pp. 177-182

- Chandrasekaran V. V., Payton L. N., Hunko W. S. Performance of Nitrogen and Liquid Nitrogen as Cool-ants in Orthogonal Machining of AISI 1020 Steel Alloy With Uncoated Carbide Tools. In ASME International Me-chanical Engineering Congress and Exposition, American Society of Mechanical Engineers. 2014. pp. V02BT02A036-V02BT02A036.

- Diniz A.E., Machado Á. R., Corrêa J. G. Tool wear mechanisms in the machining of steels and stainless steels. The International Journal of Advanced Manufacturing Technology. 2016. vol. 87. pp. 3157-3168..