Means for studying the stability of the characteristics of an automated brake drive

Автор: Dygalo V.G., Diakov A.S., Golubchik T.V., Smorchkov A.E., Zhukov I.S., Zakirov R.A.

Рубрика: Контроль и испытания

Статья в выпуске: 2 т.22, 2022 года.

Бесплатный доступ

A brake drive is a set of mechanisms that are used to transfer energy from a source to stop devices. In addition, the brake drive is responsible for controlling this energy during its transmission to implement braking. Brake drivers are classified into simple (using human muscular strength) and automated (using additional mechanisms that enhance the muscular strength of the driver or completely replace it). During vehicle use, changes occur in the braking system, which are the result of the impact on the braking system of operational factors: the beating of the surface of the brake disc, a change in the mass of the brake pad, a decrease in the radial stiffness of the hose walls, etc. The occurrence of these factors affects the stability of the characteristics of the elements of the chain “modulator ABS - brake mechanism”. The instability of the braking system characteristics is one of the reasons for the decrease in the braking efficiency of the car and the safety of the vehicle, as it has a direct impact on the quality of the control commands. Improving the operational properties of vehicles with automated braking systems is an urgent scientific and technical problem. To study and improve the operational properties of the vehicle, a laboratory semi-natural stand of an automated car braking system was designed and assembled. It allows simulating the operating processes of the drive, as well as assigning any operating modes of the braking system The article studies the possibility of applying the method of the virtual-physical modeling method when researching and improving operational properties of automotive brake automated systems on model stands, which makes it possible to successfully identify the instability of existing brake systems, and also lays the foundation for the effective creation of elements of unmanned vehicles.

Transport vehicle, brake drive, brake system, automated braking systems, virtual-physical modeling, unmanned vehicle

Короткий адрес: https://sciup.org/147238123

IDR: 147238123 | УДК: 62-592 | DOI: 10.14529/engin220207

Текст научной статьи Means for studying the stability of the characteristics of an automated brake drive

It is always important to improve the performance of vehicles with automated braking systems.

However, as practice shows, during operation, changes occur in the vehicle's braking system caused by various factors.

These factors affect the stability of the brake drive performance.

With the beginning of the automation of brake systems and the use of relatively precision elements, such as valves, the relevance of assessing the influence of the instability of the characteristics of the elements of the chain “ABS modulator - brake mechanism” of car wheels on the quality of control commands increases.

Since the deterioration in the quality of management leads to a decrease in road safety.

When solving problems of this kind, problems of reproducibility of the experiment may arise, in order to isolate the influence of a particular factor by the nature of manifestation and magnitude.

One of the latest developments to ensure reproducibility is a virtual-physical technology for testing automated automobile brake systems [1, 2]. The accumulated experience and knowledge make it possible to continue research in a given scientific direction and to solve urgent problems of modern automotive industry.

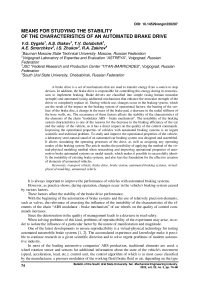

In most of the leading automotive companies' ABS production, traditional elements are used: a wheel rotation sensor and sensors for additional information about the state of the vehicle's movement (speed, acceleration, load, etc.); control unit, the control algorithm of which is in most cases classified by the manufacturer; a pressure modulator of the working fluid (brake fluid or air, depending on the type of brake drive of the car), which is transmitted through the lines to the brake cylinders of the wheels. The commands generated by the ABS control (fig. 1) unit based on the sensor signals are transmitted to the modulator solenoids, with the help of which the necessary (in accordance with the state of the brake wheel) pressure of the working fluid is formed. The latter is transmitted through the highways and enters the working brake cylinders of the wheels, activating the brake pads.

Fig. 1. ABS control loop: 1 – solenoid valve; 2 – the main brake cylinder; 3 – wheel brake cylinder; 4 – electronic control unit; 5 – wheel speed sensor

Modern ABS control units work according to algorithms that use multiphase regulation and holding time when controlling the duration of the phases. When choosing a control phase, the logic block takes into account the angular velocity, acceleration (deceleration), and the derivative of acceleration. The latter creates increased requirements for the quality of control commands arriving at the input of the logic block, therefore, it requires the most detailed study of the effect on them of unstable elements of the circuit “ABS modulator - brake mechanism”.

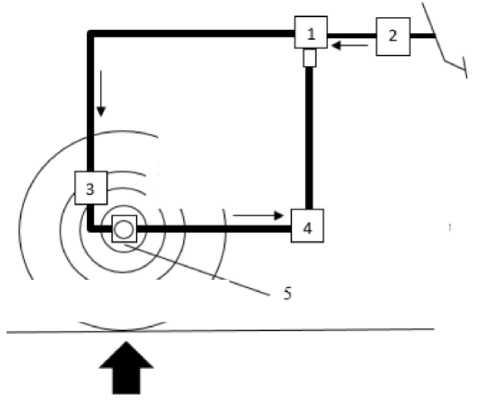

In fig. 2 graphically shows the characteristics of a hydraulic brake drive with two-phase and three-phase ABS (the dotted line indicates one of the possible types of cyclogram when one of the hydraulic parameters deviates). Legend: with two-phase ABS (Fig. 2A) F1 – automatic release phase; F2 – automatic braking phase; Fv – phase of inhibition; with three-phase ABS (Fig. 2B) F1 – automatic release phase; F2 – holding phase; Ф3 – automatic braking phase; Fv – phase of inhibition; T is the pulse period; tn is the duration of the phase Фn, p is the pressure of the working fluid.

Fig. 2. Graphs of pressure dependence in a hydraulic brake actuator with two-phase and three-phase ABS

The instability of the characteristics of the chain elements is caused by various operational factors, for example, such as the beating of the surface of the brake disc, a change in the mass of the brake pad, a decrease in the radial stiffness of the hose walls, microcracks in the hoses, pipe bends, a change in the length or diameter of the pipeline, as well as a blockage can have a significant effect on adequacy the operation of the logical unit and the accuracy of its commands, which ultimately affects the braking efficiency of the car and traffic safety.

In addition, the use of high-speed automated braking systems (at a high frequency of operation) can lead to a high degree of heating of the actuators, and, accordingly, to the danger of fading effect [3–20].

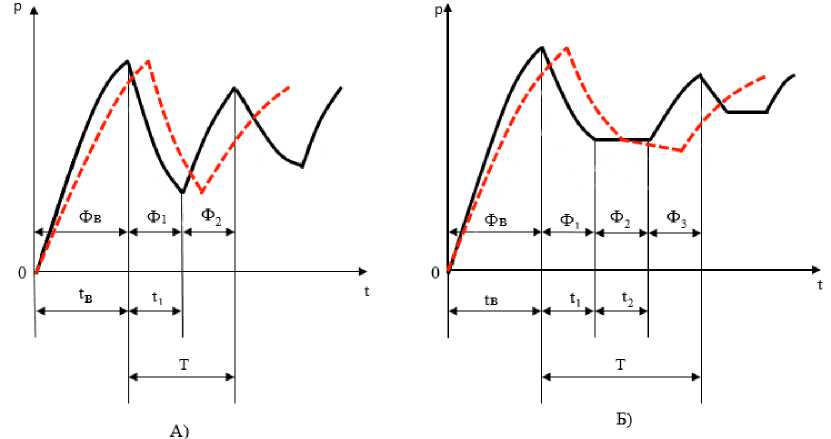

a) b)

Fig. 3. Laboratory stand model of the automated brake system

To assess the instability of the parameters of the signal transmission circuits in the automated braking system for the quality of control of work processes, as well as to assess the response speed of such systems, a laboratory stand model of the automated brake system of the Lada Kalina car was designed and assembled (Fig. 3a, 3b)

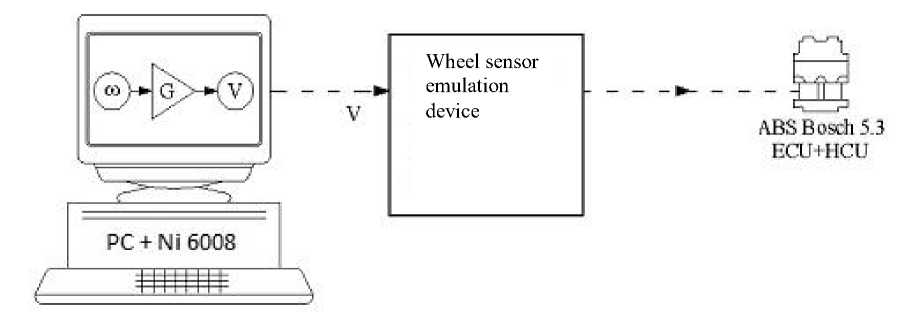

The semi-natural model makes it possible to simulate the work processes of the drive of the automated braking system of a car (fig. 4). The unit is interfaced with a computer via a cable for transmitting relay control signals, with an ABS device using electrical wires soldered to the terminals of the solenoids and the electric motor. To operate the solenoid, the computer sends a control signal to the relay, which activates the internal diode and allows power to be supplied to the controlled solenoid.

Direct control of solenoids and emulation of signals from wheel speed sensors allow simulating any operating modes of the braking system.

Fig. 4. Communication of the device with a PC with a connected USD and ABS

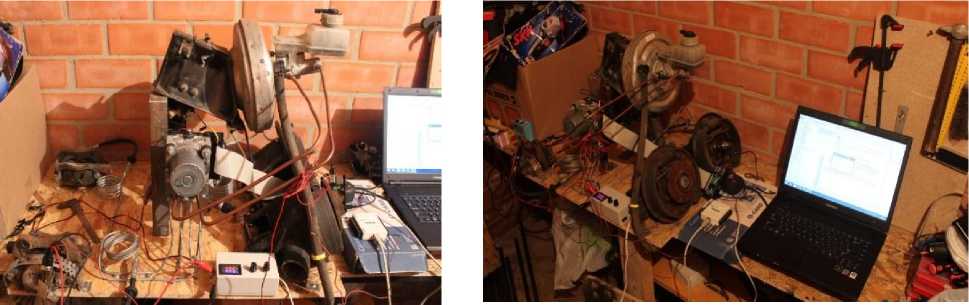

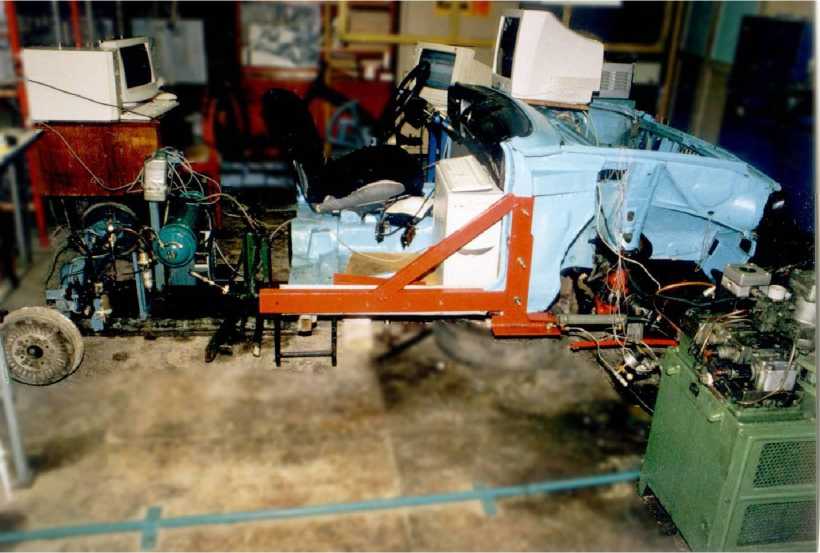

The use of a bench full-size model (fig. 5) of the braking system, instead of a car, allows simulating various malfunctions of the automated braking system and studying the corresponding deviations of work processes without any risk to the safety of the driver / operator [4]. The technique for constructing such stands is described in the works [1, 2].

Fig. 5. Stand with a full-size brake system

Prospects for the development of modern automotive industry are directed towards automation, including full automation of vehicle control. The emergence of unmanned vehicles on public roads today is only a matter of time. Domestic projects, such as the unmanned Shuttle bus from NAMI together with KAMAZ, the unmanned KAMAZ truck, MATRЁSHKA from Volgabus, and Yandex unmanned taxis are already quite successfully running around closed areas and training grounds, observing the speed limit, recognizing signs and traffic lights. However, the real traffic situation is very different from the closed landfill, primarily in the speed of traffic. In an urban environment, in a dense stream of other cars, drones will have to receive / read and process a huge amount of information about the surrounding reality. Based on the collected and data in accordance with the algorithm, control signals are generated, including the brake system. In emergencies, the driver often instinctively presses the brake pedal without having time to think about making this decision. To ensure the safety of unmanned vehicles, the speed of response of a drone to an emergency should not exceed the speed of reaction of a modern average driver. Only in this case, the automated braking systems integrated into the general control system of the unmanned vehicle will keep the braking efficiency at the current level. At the same time, insufficient speed of automated braking systems, as well as inaccuracies in the processing of commands of the logical unit (due to the instability of the parameters of signal transmission circuits) will not allow unmanned vehicles to be certified as safe and to start operating them. Thus, the direction of research indicated in the article is one of the urgent problems of the modern automotive industry.

Acknowledgements

The work is financially supported by the Ministry of Science and Higher Education of the Russian Federation as part of a comprehensive project to create high-tech production “Creation of high-tech production of an unified family of vehicles “Arctic Bus” to organize the safe transportation of passengers and mobile points of the social sphere in the regions of the Far North in conditions of low temperatures (up to minus 50 °C) to ensure the connectivity of the territories of the Arctic zone of the Russian Federation” under the agreement № 075-11-2021-058 dated 06/25/2021 (Government Contract ID 000000S407521QLY0002).

Список литературы Means for studying the stability of the characteristics of an automated brake drive

- Kotiev G.O., Diakov A.S. Advanced development and testing of off-road vehicle. DEStech Transactions on computer science and engineering., 2017, pp. 464-467. DOI 10.12783/dtcse/cmee2017/20021.

- Kotiev G.O., Padalkin B.V., Kartashov A.B., Dyakov A.S. Designs and development of Russian scientific schools in the field of cross-country ground vehicles building. ARPN Journal of Engineering and Applied Sciences. 2017, vol. 12, no. 4, pp. 1064-1071.

- Dygalo V.G., Zhukov I., Diakov A., Chutkov K. Experimental evaluation of the effect of cryogenic treatment of brake discs of the vehicle on the performance characteristics. IOP Conference Series: Materials Science and Engineering. 2020, vol. 820, Number article 012004. DOI: https://doi.org/10.1088/1757-899X/820/1Z012004.

- Dygalo V.G., Lyashenko M.V., Potapov P.V. Ways for Improving Efficiency of Computer Vision for Autonomous Vehicles and Driver Assistance Systems. International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), 2019, pp. 1-5, doi: 10.1109/ICIEAM.2019.8743060.

- Yang J., Dang R., Luo T., Liu J. The development status and trends of unmanned ground vehicle control system. IEEE Int. Conf. on Cyber Technology in Automation Control and Intelligent Systems, 2015, pp. 1946-1952. doi: 10.1109/CYBER.2015.7288245.

- Park J., Lee J-H., Son S.H. A Survey of Obstacle Detection Using Vision Sensor for Autonomous Vehicles, Int. Conf. on Embedded and Real-Time Computing Systems and Applications, 2016, pp. 264-264. doi: 10.1109/RTCSA.2016.54.

- Ranft B., Stiller C. The Role of Machine Vision for Intelligent Vehicles. IEEE Transactions on Intelligent Vehicles, 2016, vol. 1, no. 1, pp. 8-19.

- Bengler K., Dietmayer K., Färber B., Maurer M. Three decades of driver assistance systems -review and future perspectives. IEEEIntell. Transp. Syst. Mag., 2014, vol. 6, no. 4, pp. 6-22.

- Yoshimura T., Takagi A. Pneumatic active suspension system for a one-wheel car model using fuzzy reasoning and a disturbance observer Journal of Zhejiang University SCIENCE, 2004, vol. 5, pp.1060-1068.

- Howard D., Dai D. Public Perceptions of Self-Driving Cars: The Case of Berkeley, California. Transportation Research Board 93rd Annual Meeting, Washington DC, 2014, pp. 1-16.

- Payre W., Cestac J., Delhomme P. Intention to use a fully automated car: attitudes and a priori acceptability. Transport. Res. F: Traffic Psychol. Behav. 2014, vol. 27, pp. 252-263.

- Albatlan S. Automotive brake pipes characteristics and their effects on brake performance. Ain Shams Engineering Journal, 2012, vol. 3, pp. 279-287.

- Segal L. Diagnostic method for vehicle brakes. Ndt & E International, 1999, vol. 32, pp.369-373.

- Chen H., Gong X., Hu Y., Liu Q., Gao B., Guo H. Automotive control: The state of the art and perspective. Acta Autom. Sin. 2013, vol. 39, pp. 322-346.

- He R., Feng H. Research and development of autonomous emergency brake (AEB) technology. J. Automot. Saf. Energy, 2019, vol. 10, pp. 1-5.

- Nakata D., Okano T., Fukasawa T. Brake Apparatus Brake Control Unit and Brake Control Method. U.S. Patent 8303046B2, 2012, 13 p.

- Shen C., Wang J., Lin Y. Study on brake actuator of electro-mechanical braking system. Trans. Chin. Soc. Agric. Mach. 2007, vol.38, pp. 30-33.

- Li J., Yang K., Tan S. The Electro-Mechanical Brake Actuator of Using in Vehicle. CN Patent 201212535Y, 2009.

- Hu D., He R., Xu X., Yi F. Analysis on influencing factors of energy consumption characteristics of electronic hydraulic braking system. J. Beijing Inst. Technol. 2018, vol. 38, pp. 261-266.

- Lin H., Zhuo G. Electro-hydraulic brake system model identification. J. Jilin Univ. Eng. Technol. Ed. 2011, vol. 41, pp. 70-73.