Methods of introducing a fine additive based on the TiO2–Bi2O3 system into cement compositions. Nanotechnologies in construction

Автор: Kozlova I.V., Dudareva M.O.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 2 Vol.16, 2024 года.

Бесплатный доступ

Introduction. Modification of traditional materials based on mineral binders with fine-dispersed and nano-additives is an essential way to create new functional construction materials with a set of unique characteristics. However, the main difficulty in this process is the method of introducing a finely dispersed component into the cement matrix and the uniformity of its distribution. The homogeneous distribution of the additive particles in the cement composite improves the physical and mechanical characteristics, intensifies the hydration of cement clinker minerals, and is leading to a more durable and dense cement stone structure. The main methods of introducing additives into the cement composition include joint grinding, dry mixing and the introduction of a stabilized suspension of the additive instead of mixing water. Thus, the purpose of this research is to compare the options for the introduction of additives based on the TiO2–Bi2O3 oxide system, which can provide the cement composite with improved physical, mechanical and structural characteristics and the ability to resist mold fouling. The object of this research is the cement compositions modified with an additive based on the TiO2–Bi2O3 system. Materials and methods. The studies were carried out to establish the optimal method of introducing a fine-dispersed additive based on the TiO2–Bi2O3 system. At the first stage, the phase and granulometric composition of the additive was studied, then the additive was introduced into the cement composition in four different ways. The cement stone samples were obtained by dry mixing of the components then mixed with water, by mixing cement powder with water suspension of the additive after ultrasound processing, by mixing a dry mixture of cement and an additive with water-plasticizer solution, and cement powder mixed with water-polymer suspension of the additive after ultrasound processing. After that, the strength characteristics, porosity and ability of the samples to resist fungi fouling were investigated. Results. As a result of the study, the authors concluded that the highest physical and mechanical characteristics of cement stone can be provided by introducing an additive in the form of a stabilized water-polymer suspension. This method contributes to the formation of a more durable and dense structure of cement stone, with an increase in strength of 31; 38 and 44.8% at first day age, 28; 30 and 32% at third day age and 2.4; 9.0 and 14% at 28 days age relative to the control sample containing cement, water and plasticizer. It was found that the highest strength results were shown by a sample containing a stabilized suspension of an additive with a concentration of 50 g/l. The study of the cement stone porosity showed its decrease by 13% at first day age in relation to the control sample with a plasticizer, and by 10% after 28 days of hardening. It was also shown that samples modified with 50 g/l (1.7 wt.%) of the additive demonstrate resistance to bio-fouling. Conclusion. As a result of the research, the authors concluded that the optimal way to introduce a finely dispersed additive based on the TiO2–Bi2O3 system is to mix cement powder with a stabilized water-polymer suspension of the additive, resulting in a more durable and dense structure of cement stone, especially at an early stage of hydration, which can also resist fungi bio-fouling. Thus, the authors came to the conclusion that the cement compositions obtained by this method can be applied as repair compounds and tile grout in damp shaded rooms with favorable conditions for fungi colonization.

Fine additive, TiO2–Bi2O3 system, ultrasonic processing, suspension, dry mixing, plasticizer, strength, fungi fouling resistance

Короткий адрес: https://sciup.org/142240850

IDR: 142240850 | DOI: 10.15828/2075-8545-2024-16-2-90-99

Текст научной статьи Methods of introducing a fine additive based on the TiO2–Bi2O3 system into cement compositions. Nanotechnologies in construction

Original article

Currently the construction material industry has reached a new level, offering new materials with a set of unique characteristics that significantly exceed the properties of conventional building materials. New solutions in the field of science make it possible to create sustainable, environmentally friendly innovative «smart» materials with self-healing and self-cleaning properties with maximum physical and mechanical properties [1–4]. A crucial role in the creation of such materials is assigned to modification. This can involve changing the surface characteristics achieved through various processing methods, influencing the internal morphology of the material by adding fine particles and nanoobjects, or forming new composite systems that advantageously combine different features of the components to create a highly functional material. Concrete and cement-based materials continue to play a leading role both in terms of production and application and by introducing modifying additives into the cement composite innovative materials of a new generation can be created. A large number of scientific papers in Russia and abroad have been devoted to the search, synthesis, and research of methods for the introduction of fine additives of organic and inorganic origin into cement. The effect of ground granulated blast furnace slags [5, 6], fly ash [7, 8], microsilica [9–11], metakaolin [12, 13] as active mineral additives for cement systems allowing to control the hydration process of clinker mineral to obtain a denser and more durable cement stone structure has been studied. The influence of carbon-based nanostructured objects [14, 15], nano- and fine particles of iron, titanium, zinc and aluminum oxides synthesized via sol-gel technology, improving the characteristics of the material [16–18], has been studied. Fine additives are present in the composition of cement composites in quantities not exceeding 1–10% on average, while the method of introducing the additive significantly affects the final properties of the material. The most common options include the method of joint grinding of the additive with cement clinker minerals, dry mixing of the additive with mineral binder powder, and obtaining a stable suspension of additive particles that can be used instead of mixing water. Stabilization of suspensions can be achieved by adding chemicals – organic stabilizers. They have the ability to adsorb on the surface of the additive particles, forming strong thick gel-like films that prevent particles from sticking together and settling, and allow them to remain suspended throughout the dispersion medium. In addition to chemical stabilization, suspensions are often subjected to ultrasonication. This type of mechanical treatment involves additional crushing and grinding of the additive particles as well as intensifies the adsorption process of stabilizer molecules on the active centers on the additive particles. Both chemical and mechanical treatment result in a more uniform distribution of the particles within the suspension and finally within the cement stone structure. However, such method could undoubtedly be considered more difficult and energy-consuming compared, for example, to simple dry mixing of the components, which is an easier, faster, and cheaper option. But this method has its drawbacks, as it is much more difficult to provide uniform distribution of the additive particles throughout the volume of cement powder, and as a result, within the structure of the cement stone. The article [20] discusses various options for introducing perlite into cement systems. The results of this work demonstrate that the maximum increase in strength of samples occurs precisely when the cement is mixed with a stabilized suspension of the additive. However, both methods have their right to exist depending on the purpose and application of the final building material and the type of the additive.

Therefore, the aim of this research was to consider options for introducing a finely dispersed bismuth titanate additive into a cement composition, and an analysis of the the obtained data.

2. MATERIALS AND EXPERIMENTAL METHODS

To obtain cement stone samples, cement CEM 0 LLC “Holsim (Rus) Building Materials” was used in this work, its chemical and mineralogical composition is shown in Tables 1 and 2, an additive based on the TiO2–Bi2O3 system synthesized via solid-state technology, polycar

Table 2

Mineralogical composition of clinker LLC “Holsim (Rus) Building Materials”

|

Mineral content, % |

|||

|

C3S |

C2S |

C3A |

C AF 4 |

|

63.0 |

11.0 |

6.00 |

15.00 |

Table 1

Chemical composition of clinker LLC “Holsim (Rus) Building Materials

|

Components |

Mass loss after calcination, % |

CaO |

SiO2 |

Al2O3 |

Fe2O3 |

MgO |

SO3 |

R2O |

|

Clinker |

1.12 |

63.89 |

20.63 |

5.62 |

5.15 |

3.68 |

0.59 |

1.36 |

CONSTRUCTION MATERIAL SCIENCE

Table 3

Characteristics of the Melflux 5581F plasticizer

The additive was synthesized via solid-state reaction from the corresponding oxides Bi2O3 and TiO2 both analytical grade according to the following reaction:

2Bi2O3+3TiO2 → Bi4Ti3O12. (1)

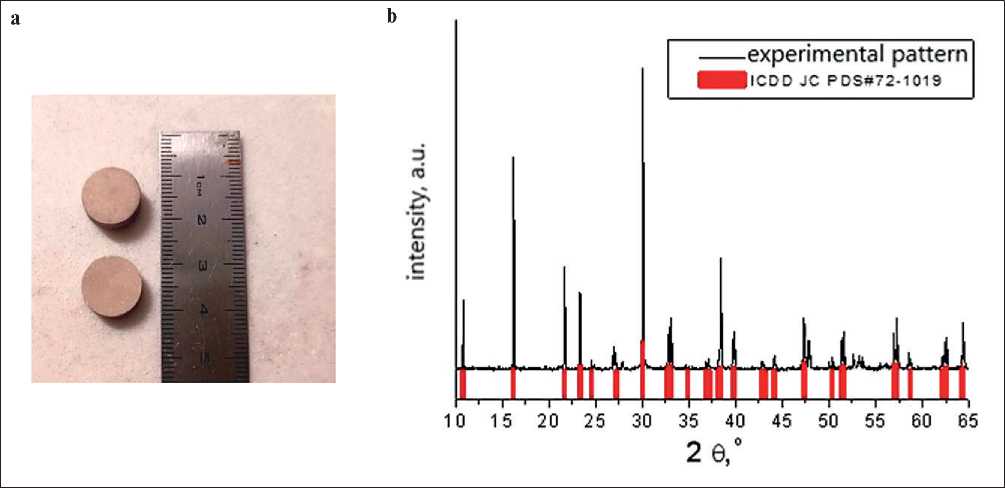

The amounts of substances calculated according to the equation (1) were weighed on analytical scales, ground in an agate mortar with isopropyl alcohol to improve homogenization, pressed into pellets d = 1.0 cm (Fig. 1a) and an- nealed step by step in a muffle furnace in the temperature range 650–800оC, the total annealing time was 15 hours.

The phase composition of the bismuth titanate additive was studied using X–ray diffraction (XRD) phase analysis, which was carried out using an X-ray diffractometer D8 ADVANCE (Bruker AXS, Germany) CuKa radiation (graphite monochromator), λCuKa = 1.54056 Е. an X-ray diffraction pattern of the obtained additive after the final annealing stage is shown in Fig. 1b, which allows us to conclude that the predominant phase is bismuth titanate of the composition Bi4Ti3O12 with presence of small quantities of unidentified phases.

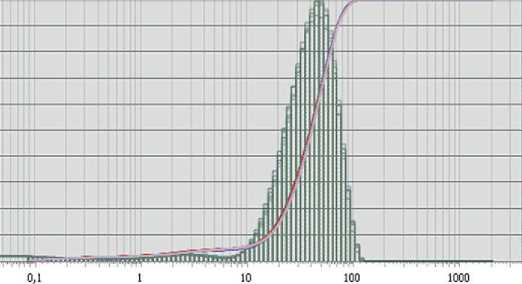

The granulometric composition of the additive was studied using the Analysette 22 NanoTec device (Fritsch,

Fig. 1. a) additive pressed into pellets b) XRD pattern of the additive

CONSTRUCTION MATERIAL SCIENCE о ooooooooo о 98 7 6 5 4-321 容、(3g「UOHnq-匸 s~p u^su ”--«-§-§

particles size, gm

Fig. 2. a) particle size distribution of the additive; b) microphotograph of the additive particles

Germany), the particle size distribution is shown in Fig. 2a. The size and morphology of the additive particles can be evaluated by the microphotograph obtained using the scanning electron microscope “Tescan Vega 3” (Fig. 2b): the particles have an irregular shape with maximum size of 50 microns.

The additive was introduced into the composition of the cement composite in four ways:

-

1) by dry mixing of cement and the additive, followed by mixing with tap water;

-

2) by mixing cement powder with water suspensions of the additive after ultrasonication;

-

3) by dry mixing of cement and additive, followed by mixing with water-plasticizer solution containing 1.2 g/l of plasticizer;

-

4) by mixing the cement powder with water-polymer suspension of the additive stabilized by ultrasonication.

To obtain a dry mixture, an additive of bismuth titanate was introduced in the amount of 0.3; 1.0; 1.7 wt.% in relation to weight of binder. For the preparation of suspensions, an additive of bismuth titanate was used in quantities of 10, 30, 50 g/l, which is equivalent to 0.3; 1.0; 1.7% of the additive during dry mixing.

Ultrasonic processing of suspensions was carried out for 20 minutes at a dispersion temperature of 25 ± 2оC. The choice of a plasticizer concentration of 1.2 g/l is discussed in a previously published work [19].

The properties of cement paste modified with a synthesized additive were studied in accordance with standard methods. To study the mechanical characteristics of the modified cement stone, cubes samples of 2,0×2,0×2,0 cm were prepared and then the compressive strength tests were carried out using Controls laboratory hydraulic press.

The porosity of cement stone samples was determined by the pycnometric method, kerosene oil was used as an inert liquid.

The ability of cement composite modified with the additive to resist to fungi fouling have also been studied. For the study, cube of 3.0×3.0 cm were obtained by mixing cement powder with water suspensions of additives, as well as control unmodified samples. At 28 days age, the samples were sent to the A.N. Severtsov Institute of Ecology and Evolution of the Russian Academy of Sciences. Cement stone samples were tested for resistance to fungi fouling in the Laboratory of tropical technologies in accordance with GOST 9.048-89. The suspension of fungal spores Aspergillus niger van Tieghem, Aspergillus terreus Thom, Aureobasidium pullulans (de Bary) Arnaud, Paecilomyces varioti Bainier, Penicillium funiculosum Thom, Penicillium ochro-chloron Biourge, Scopulariopsis brevicaulis Bainier , Trichoderma viride Pers. Ex Fr. was applied on the surface of the samples, the concentration of fungal spores was 1–2 million/cm3. Then the samples were placed in an open Petri dish in a desiccator and kept in conditions optimal for fungi growth: temperature 27–28оC and humidity 98% for 28 days. At the end of the tests, the stage of fungal development was evaluated according to 6-point scale (GOST 9.048-89).

“0 ” points – absolutely clean samples, absence of conidia and colony development (visually and under a microscope);

“1 ” point – visually clean samples, only small individual mycelium spots are visible under the microscope, there is no fungi sporulation;

“2 ” points – the superficial development of mycelium in the form of numerous spots, there is no fungi sporulation;

“3 ” points – abundant mycelium overgrowth on the surface of the sample, the beginning of fungi sporulation;

“4 ” points – on visual inspection, continuous mycelium growth and sporulation are clearly visible;

“5” points – deep mycelium damage to the entire sample area during intensive fungi sporulation.

3. RESULT AND DISCUSSION

CONSTRUCTION MATERIAL SCIENCE

One of the most important factors to consider when introducing a functional additive into a cement composition is the uniform distribution of its particles in the volume of the cement matrix. As a number of studies [21–23] show, the properties of a cement stone structured with a finely dispersed component may even get worsen compared to a control non-additive sample if this uniform distribution is not achieved. One of the easiest and cheapest ways to introduce additives into cement is dry mixing of the components followed by mixing the dry mixture with water. However, owing excessive surface energy, nano- and fine particles of the additive exhibit a tendency to agglomeration, which prevents the obtaining of a homogeneous mixture of cement and additives. This process can be avoided by the preliminary stage of processing the additive, obtaining its stabilized suspension resistant to particle enlargement and settling. Stability can be achieved by the combined action of two factors: chemical and mechanical. The first is the addition of surfactants to the suspension, which can adsorb on the surface of the additive particles, forming thick gel-like films that do not allow the particles to stick together and settle. The second factor consists in ultrasonic processing of the suspension, which contributes to additional particle crushing and enhances the adsorption of surfactants on the active centers. Together, these methods of suspension processing promote the particles to stay longer in the volume of the dispersion medium, and, as a result, their homogeneous distribution in the cement composition.

Within the framework of this study, four series of cement compositions were obtained, the compositions of which are presented in Table 4.

In accordance with the obtained compositions presented in Table 4, the properties of cement paste were determined (Table 5).

The properties of the cement paste with an additive introduced during the dry mixing of the components demonstrate that there is no significant change in the normal consistency and setting time of the cement paste. For samples with an additive content of 1.0 and 1.7% (samples No. 3–4), the normal consistency increased by 1 and 2%, and a reduction in setting time occurs for a sample with an additive content of 1.7% (sample No. 4).

The mixing of cement with suspensions of additives in concentrations of 10, 30 and 50 g/l (samples No. 6–8) leads to a slight increase in the normal consistency of the cement paste by 1, 5 and 8% relative to the control sample containing only cement and water (sample No. 1). The normal consistency of the cement paste with an additive introduced in the form of a water-polymer suspension remains practically unchanged with respect to the control sample containing only cement and water with a plasticizer (sample No. 5), and decreases by 14% with respect to the sample containing only cement and water (sample No. 1). For the cement paste sample No. 14, there is a slight increase in the value of normal consistency and a reduction in the setting time, which is probably due to the combined presence

Table 4

Cement compositions and methods of their preparation

|

Sample |

Method of obtaining |

Cement |

Concentration of the additive in the mixing water, g/l / % |

Sp |

|

1 |

Cement + water |

+ |

– |

– |

|

2 |

Dry mixture + water |

+ |

10/0.3 |

– |

|

3 |

+ |

30/1.0 |

– |

|

|

4 |

+ |

50/1.7 |

– |

|

|

5 |

Cement + water–plasticizer solution |

+ |

– |

+ |

|

6 |

Cement + water suspension of the additive |

+ |

10/0.3 |

– |

|

7 |

+ |

30/1.0 |

– |

|

|

8 |

+ |

50/1.7 |

– |

|

|

9 |

Dry mixture + water–plasticizer solution |

+ |

10/0.3 |

+ |

|

10 |

+ |

30/1.0 |

+ |

|

|

11 |

+ |

50/1.7 |

+ |

|

|

12 |

Cement + water–polymer suspension of the additive |

+ |

10/0.3 |

+ |

|

13 |

+ |

30/1.0 |

+ |

|

|

14 |

+ |

50/1.7 |

+ |

CONSTRUCTION MATERIAL SCIENCE

Table 5

Construction and technical characteristics of cement dough

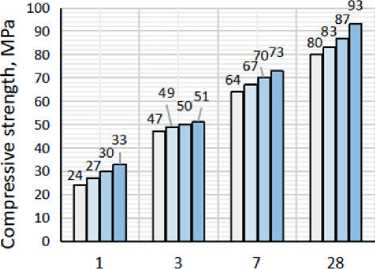

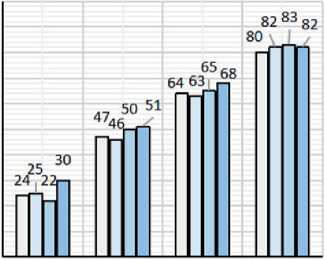

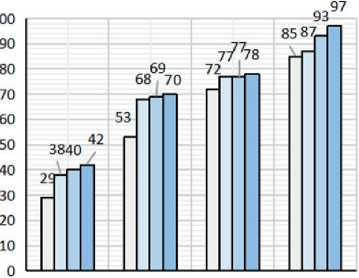

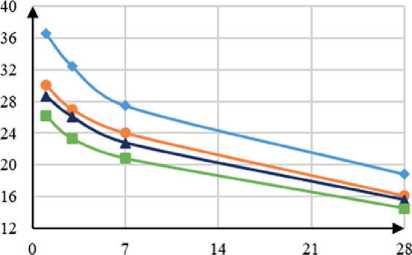

Next, the mechanical characteristics of the modified cement stone samples obtained obtained by four various methods were studied (Fig. 3).

As can be seen from the data shown in Fig. 3, the highest strength characteristics correspond to cement stone samples with the additive introduced in the form of water or water-polymer suspension after ultrasonic processing (Fig. 3 b, d). The samples obtained during dry mixing procedure are characterized by strength values equal to the control sample, as well as an unstable strength set (coefficient of variation exceeds 10% with a confidence probability of 0.95 of 6 definitions), which indirectly indicates to uneven distribution of additive particles in the volume of cement paste and cement composite. In case of introduction of water and water-polymer suspension of the additive an increase in the strength of the modified samples is observed compared to the control sample at all periods of hardening. Thus, the strength increase of the samples according to method II was 12.5; 25 and 37.5% at 1st day age, 4; 6 and 8% at 3rd day age, and 3.8; 8.8 and 16% at 28

days age in relation to the sample containing only cement and water. For samples prepared according to method IV, the strength gain is 31; 38 and 44.8% at first day age, 28; 30 and 32% at third day age and 2.4; 9.0; and 14% at 28 days age relative to the control sample containing cement, water and plasticizer. It can be seen that the maximum increase in strength is observed at the early period of hardening.

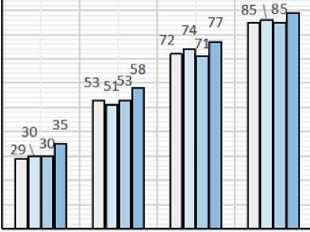

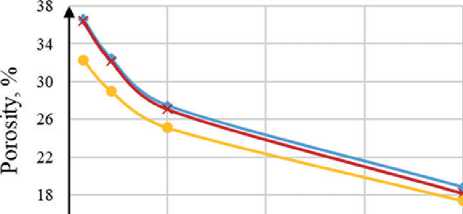

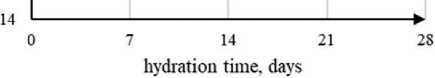

Also, for samples with an additive content of 50 g/l (1.7%) obtained by various methods, porosity values were determined using the pycnometric method (Fig. 4). The results of the studies in Fig. 4a showed that the porosity values of the samples prepared according to method I are equal to those of control sample without plasticizer, and according to method II, a decrease in porosity was noted at first day age by 11.8%, at 28 days age by 7.5%. Fig. 4b shows that the introduction of a stabilized suspension into the cement composition leads to the greatest decrease in porosity both in relation to the control sample with and without a plasticizer.

On the first day, the porosity of the sample prepared according to the IV method decreases by 28.5% and 13% in relation to the control ones; at 28 days age – by 23% and 10%, respectively. It is noticeable that the greatest decrease in porosity is observed precisely at early stages of the sample’s hydration.

This fact allows us to conclude that the combined effect of the plasticizer and ultrasonic processing contributes to the uniform distribution of additive particles in the cement matrix, positively affecting their physico-mechanical properties. This is probably due to a more

CONSTRUCTION MATERIAL SCIENCE

hydration time,days

□ control 口 cement+10 g/l. add.

□ cement+30 g/l. add . 口 cement+50 g/l. add.

b

ooooooooooo 10987654321 edlAI 三甘①匕s ①A-ssaJduJCO

1 3 7 28

hydration time, days

□ control □ cement+10 g/L add.

□ cement+30 g/l. add. □ cement+50 g/L add.

£ІЛ1 ^uc^^ EssalduJ。。

□ control

□ cement+10 g/l add.+Sp

□ cement+30 g/l add.+Sp □ cement+50 g/l add.+Sp

Fig. 3. Compressive strength of the samples depending on the hydration time: a) I – by dry mixing of cement and the additive, followed by mixing with tap water; b) II – by mixing cement powder with water suspensions of the additive after ultrasonication; c) III – by dry mixing of cement and additive, followed by mixing with water-plasticizer solution; d) IV – by mixing the cement powder with water-polymer suspension of the additive stabilized by ultrasonic processing

1 3 7 28

hydration time, days

□ control □ cement+10 g/l add.+Sp

□ cement+30 g/l add.+Sp □ cement*50 g/l add.+Sp

1 3 7 28

hydration tme, days

intensive hydration processes, a more active formation of hydration products, which leads to the formation of a more durable and dense structure of cement stone. Thus, it is preferable to introduce a finely dispersed additive based on the TiO2–Bi2O3 oxide system in the form of a stabilized water-polymer suspension rather than by dry mixing of the initial components, despite the fact that this method is more complicated and requires energy consumption. The maximum increase in strength and reduction of porosity of cement stone at early age allow us to consider these cement compositions obtained by mixing cement with stabilized water-polymer suspensions as repair compounds.

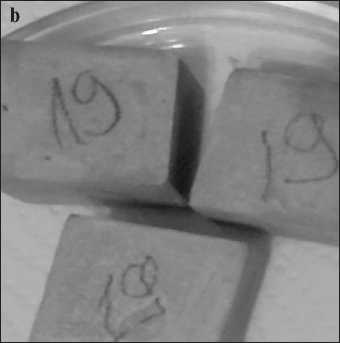

Simultaneously with the study of technical and physi-co-mechanical characteristics of modified cement stone samples, the ability to resist fungi fouling of the cement stone surface of was also studied. For this study, a composition with maximum strength characteristics was selected – 50 g/l of the additive introduced into cement in the form of a stabilized suspension. After 28 days of keeping the samples in an environment favorable for the fungi colonization, there were no signs fungi growth on the surface. However, the surface of cement stone still can be subjected to bio-fouling, although not as fast as it happens in the case of wood-based materials and polymers. The fact that there is no mycelium of fungi on the surface

CONSTRUCTION MATERIAL SCIENCE

b

—♦—conti ol (without Sp) T*— I method sample II method sample

* “msojod

hydration time, days

—♦— control (without Sp) • control (with Sp)

—A1 III method sample ■ IV method sample

Fig. 4. Dependence of porosity of cement stone samples with 50 g/l (1.7%) additive on the hydration time: a) in relation to the control sample without plasticizer; b) in relation to two control samples

Fig. 5. Control (a) and modified (b) cement stone samples after being kept in suspension of fungi spores for 3 months

of the samples may be a consequence of the fact that there are no organic contaminants on the surface of the samples obtained in the laboratory, which are necessary for the nutrition, growth and reproduction of microorganisms. As a result, it was decided to continue keeping the samples in suspensions of fungi spores for another two months in Czapek medium, after which mycelium growth was observed only on the surface of the control samples, mainly Aspergillus niger van Tieghem (Fig. 5).

CONCLUSIONS

Thus, in accordance with the conducted research, the authors of the article concluded that the optimal way to introduce a finely dispersed additive based on the TiO2–Bi2O3 system is to mix cement powder with a stabilized water-polymer suspension of the additive, resulting in a more durable and dense structure of cement stone, especially at early stages of hydration: an increase in the strength of samples with the concentration of 10, 30, 50 g/l is 31.0; 38.0 and 44.8% at first day age, 28.0; 30.0 and 32.0% at third day age and 2.4; 9.0; and 14.0% at 28 days age relative to the control sample containing cement, water and plasticizer. Studies of the porosity of the cement stone containing a stabilized suspension of an additive in the amount of 50 g/l (1.7 wt.%) showed a decrease of 13% at first day age in relation to the control sample with a plasticizer, and by 10% at 28 days age. The conducted studies on the fungi fouling resistance of samples modified with 1.7 wt.% of the additive demonstrate that this composition has not been fouled by fungi. Thus, the authors concluded that the cement compositions obtained by this method can be used as repair compounds and tile grout, which can be used in damp shaded rooms with favorable conditions for the growth and reproduction of fungi.

CONSTRUCTION MATERIAL SCIENCE

The work was carried out within the framework of the 2023 competition in support of graduate student’s research of National Research University Moscow State University of Civil Engineering.

Список литературы Methods of introducing a fine additive based on the TiO2–Bi2O3 system into cement compositions. Nanotechnologies in construction

- Inozemtcev S., Do T., Korolev E. Russian experience of research in the field of building materials with the function of self-healing. Bulletin of Belgorod State Technological University named after V.G. Shukhov. 2022; 7(1): 8-22. https://doi.org/10.34031/2071-7318-2021-7-1-8-22

- Ogurtsova Yu., Antonenko M., Gubareva E., Nerovnaya S., Strokova V.V. Composition and Properties of Finegrained Concrete for Self-cleaning Coatings. E3S Web of Conferencess. 2023; 410(1): 1-7. https://doi.org/10.1051/e3sconf/202341001011

- Şahin H.G., Mardani A. Self-cleaning concrete. Materials of VI Internatioanl European conference on interdisciplinary scientific research. 2022; 215-221.

- Luca B., Panțiru, A., Timu A., Bărbuță M., Diaconu L., Rujanu M., Diaconu A. Eco-concrete for obtaining “green” construction elements. IOP Conference Series: Materials Science and Engineering. 2023; 1283: 1-8. https://doi.org/10.1088/1757-899X/1283/1/012007

- Nicula L., Manea D., Simedru D., Cadar O., Ardelean I., Mihai Liviu D. The Advantages on Using GGBS and ACBFS Aggregate to Obtain an Ecological Road Concrete. Coatings. 2023; 13(8): 1-27. https://doi.org/10.3390/coatings13081368

- Kozlova I., Samchenko S., Zemskova O. Physico-Chemical Substantiation of Obtaining an Effective Cement Composite with Ultrafine GGBS Admixture. Buildings. 2023; 13(4): 1-36. https://doi.org/10.3390/buildings13040925

- Lam T., Dien Vu., Hung N., Bulgakov B., Bazhenova S., Aleksandrova O.V. Stroitel’stvo: nauka i obrazovanie. 2021; 11(2): 17-37. https://doi.org/10.22227/2305-5502.2021.2.2

- Chougule M., Chougule V. Experimental Investigations on the Concrete Mix Design With Fly Ash. International Journal of Innovative Research in Engineering. 2023; 4(1): 106-109.

- Lukpanov R., Dyussembinov D., Altynbekova A., Zhantlesova Zh. Research on the effect of microsilica on the properties of the cement-sand mixture. Technobius. 2022; 2(4): 1-7. https://doi.org/10.54355/tbus/2.4.2022.0027

- Ghafor K., Mahmood W., Sarwar W., Mohammed A. Effect of Particle Size Distribution of Sand on Mechanical Properties of Cement Mortar Modified with Microsilica. Aci Materials Journal. 2019; 117(1): 47-60. https://doi.org/10.14359/51719070

- Abed A., Kamal I., Mojtahedi A. Enhancing Concrete Properties Using Silica Fume: Optimized Mix Design. Journal of Smart Buildings and Construction Technology. 2023; 5(1): 84-91. https://doi.org/10.30564/jsbct.v5i1.5678

- Yehualaw M., Fentie M., Worku B. Effect of Partial Replacement of Cement by Metakaolin on Engineering Properties of Concrete. Advancement of Science and Technology. 2023; 89-101. https://doi.org/10.1007/978-3-031-33610-2_5

- Potapova E.N., Dmitrieva E. A. Vlijanie metakaolina na svojstva cementa. Applied Science of today: Problems and New Approaches: sbornik statej Mezhdunarodnoj nauchno-prakticheskoj konferencii. 2019; 138-142.

- Li Sh., Shen P., Zhou H., Du Sh., Zhang Yu., Yan J. Synergistic effects of CNTs/SiO2 composite fillers on mechanical properties of cement composites. RSC Advances. 2022; 42(12): 27253-27266. https://doi.org/10.1039/D2RA04127H

- Leonovich S., Sadovskaya E. Nanofiber Concrete: Multi-Level Reinforcement. Science & Technique. 2022; 21(5): 392-396. https://doi.org/10.21122/2227-1031-2022-21-5-392-396

- Dahlan A. Smart and Functional Materials Based Nanomaterials in Construction Styles in Nano-Architecture. Silicon. 2019; 11(4): 1949–1953. https://doi.org/0.1007/s12633-018-0015-x

- Bica B., Melo J. Concrete blocks nano-modified with zinc oxide (ZnO) for photocatalytic paving: Performance comparison with titanium dioxide (TiO2). Construction and Building Materials. 2020; 252: 1-12. https://doi.org/10.1016/j.conbuildmat.2020.119120

- Joshaghani A., Balapour M., Mashhadian M., Ozbakkaloglu T. Effects of nano-TiO2, nano-Al2O3, and nano-Fe2O3 on rheology, mechanical and durability properties of self-consolidating concrete (SCC): An experimental study. Construction and Building Materials. 2020; 245. https://doi.org/10.1016/j.conbuildmat.2020.118444

- Samchenko S., Kozlova I., Zemskova O., Dudareva M. Methodological Substantiation of the choice for a stabilizer for bismuth titanate fine particles suspensions. Nanotechnologies in Construction. 2023; 15(2): 97-109. https://doi.org/10.15828/2075-8545-2023-15-2-97-109

- Kozlova I., Zemskova O., Lekanov N., Gavryutin D. Comparative analysis of methods of introducing fine perlite into cement composition. E3S Web of Conferences. 2023; 413: 1-10. https://doi.org/10.1051/e3sconf/202341304001

- Percev V.T., Kozodaev S. P. Himizacija i nanomodificirovanie - sovremennyj put’ sovershenstvovanija tehnologii cementnyh sistem. Himija, fizika i mehanika materialov. 2020; 1(24): 121-130.

- Li G., Wang L., Yu J., Yi B., He Ch., Wang Zh., Leung Ch. Mechanical properties and material characterization of cement mortar incorporating CNT-engineered polyvinyl alcohol latex. Construction and Building Materials. 2022; 345: 1-13. https://doi.org/10.1016/j.conbuildmat.2022.128320

- Kozlova I., Zemskova O., Semenov V., Stepina I. Effect of Nano-Aluminum Component on the Cement Properties. IOP Conference Series: Materials Science and Engineering. 2021; 1079: 1-6. https://doi.org/10.1088/1757-899X/1079/3/032071