Microstructural analysis of strain-resistant cement designed for well construction

Автор: Arman A. Kabdushev, Farit A. Agzamov, Baurzhan Zh. Manapbayev, Zhangazy N. Moldamuratov

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Manufacturing technology for building materials and products

Статья в выпуске: 6 Vol.15, 2023 года.

Бесплатный доступ

Introduction. The efficiency of oil and gas well construction depends largely on the stage of casing cementing and is completed by checking the quality of its fixing by various methods, most often by geophysical methods. The necessity of highquality cementing and ensuring the quality of technical conditions in the subsequent years of oil and gas well operation is the main task. Materials and methods. Microstructural features of cement slurries and cement stone were analyzed with advance methods. The essential technological properties were developed according to the requirements of GOST 1581-96 and API standards (API spec.10B). Class G cement (PCT-I-G) was used for all formulations. Polypropylene fiber and expanding additive СMA were used to increase impact resistance and to ensure tight contact with the confining surfaces of the obtained plugging stone. Microstructural analysis of the obtained cement stones and developed plugging mortars was carried out by X-ray diffraction (XRD) and scanning electron microscope (SEM). Results and discussion. The results of the study showed that the expanding additive in tandem with polypropylene fiber works effectively to ensure the integrity of the cement ring. Conclusion. Microstructural analysis of plugging stones showed a tight bond between polypropylene fiber and cement stone at a concentration of – 0.25%. The expanding additive is fully hydrated and the obtained cement stone has no expansion cracks at 7 days. The developed grouts with a water-cement ratio of 0.44 showed high compressive strength.

Cement slurry, cement stone, deformation, nano-additives, fibers

Короткий адрес: https://sciup.org/142239115

IDR: 142239115 | DOI: 10.15828/2075-8545-2023-15-6-564-573

Текст научной статьи Microstructural analysis of strain-resistant cement designed for well construction

Original article

The efficiency of oil and gas well construction depends largely on the casing cementing stage and is completed by checking the quality of casing cementing by various methods, most often geophysical. Accident-free cementing and ensuring good adhesion of cement stone with casing and geological material are the main tasks of the casing cementing process. The success of several applied technologies, the safety of work in the field, and environmental protection issues regarding reliable isolation of formations proportionally depend on the techni- cal condition of wells [1]. However, various problems appear during good operation, the main cause of which is the violation of cement ring integrity. Therefore, when developing cement slurries, it is necessary to ensure the quality of isolation and durability of the cement ring, which will be effective even after well abandonment [2, 3]. Otherwise, the consequences can be dangerous, and secondary cementing can be a high cost.

Cement ring leakage can have different causes, such as causes related to tectonic movements, which can lead to the failure of not only the integrity of the cement stone but also the casing [4]. Researchers [5] have studied the

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS causes of casing deformation, which may be caused by axial loads due to reservoir drainage. Notwithstanding the causes of deformation, however, quality well cementing that ensures the integrity of the cement plug can prevent or reduce casing distortion [4, 5].

A number of authors in their works [6, 7] state that mainly pressure cycling and temperature changes lead to the occurrence of deformation of the cement plugging stone, with the results being:

– appearance of microcracks in the cement stone;

– damage to the bond between the cement stone and the casing and rock.

The above-mentioned factors should be taken into account when constructing wells under conditions of high pressures and temperatures. However, it should be noted that the factor of pressure influence on cement stone is also associated with the appearance of high loads during hydraulic fracturing and well perforation [8].

A negative effect of high temperatures on cement stone is often associated with the consolidation of steam injection wells, providing steam injection, the temperature of which can reach up to 3000 о C [9]. Therefore, the product of plugging mortar hardening should be heat-resistant, otherwise, due to thermal corrosion can occur destruction of the cement stone [10, 11].

Deformation of the cement stone can also be associated with an exothermic reaction occurring during the solidification of the plugging stone, which releases a large amount of heat that affects the deformation stability of the casing [12]. The result of this reaction can be damage or crumpling of the casing, as well as the appearance of microcracks in certain intervals.

In addition to the above-mentioned causes, the tightness of the well casing is strongly affected by the disruption of the cementing process [13] and gas penetration into the cement structure while waiting wait on cement [14, 15].

Analyzing the above-mentioned reasons, it can be stated that the main factor of well casing tightness preservation is high-quality cementing due to the proper selection of cementing slurry formulation, which ensures the integrity and durability of cement stone.

Various methods are proposed to solve the problems: – application of expanding and reinforcing additives; – the use of nanomaterials;

– use of special additives (e.g., styrene-butadiene rubber latex) to obtain self-healing cements [16, 17, 18].

It is known that the presence of expanding additives, providing optimal expansion in the cement slurry has a positive effect on obtaining a tight contact of the plugging support with the confining surfaces.

The use of fiber has quite a wide application in various branches of construction [19]. Referring to the application of fibers in the oil and gas industry, it should be noted that at the moment quite a few types of fibers such as organic fibers, silicon fibers, and monofilament propylene fibers have been investigated. The studies conducted in [20] showed the effectiveness of polypropylene fibers even under high pressure and temperature conditions. Hybrid fibers, which consist of calcium carbonate of 20–80 nm and carbon fibers of 700–1400 nm, were also investigated. The authors of [21] concluded that all fibers can reduce the corrosion resistance and strength of the plugging stone. However, our studies showed that the use of polypropylene fibers on the contrary increases the compressive and flexural strength of the stone. The use of reinforcing and expanding additives together increases the efficiency of the expansion process, and most importantly increases the impact resistance of the cement stone [10].

The use of nanomaterials to ensure the integrity of the plugging stone has recently been developing dynamically. The paper [6] proposes the use of polymer fibers with shape memory, on which tetraethylorthosilicate nanoparticles were deposited using the sol-gel method. Another interesting work is the reinforcement of cement slurries using polymer nanocomposite. Experimental studies included mini-emulsion polymerization and ultrasonic dispersion [4]. Also, many other studies conducted to improve the formulation of plugging solutions using nanomaterials have been quite well reported in review articles [13, 22]. However, despite the obtained favorable results, according to the authors of [13], the use of nanomaterials to improve the technological qualities of cement slurries is still not cost-effective.

Analyzing various approaches aimed at obtaining impact-resistant cement grout, it was decided to use expanding and reinforcing additives to modify plugging materials.

Regardless of the causes, cement ring failure primarily leads to gas migration, inter-column pressures, and griffin formation, which can lead to good abandonment. At the same time, many cement slurries designed to ensure the integrity of the cement plug under dynamic loads are not always resistant to gas penetration through them while waiting for cement (WOC) to harden. Gas penetration can create channels in the hardening structure of the stone, reducing the strength and impact resistance of the stone.

To solve this problem, a method of well cementing is proposed that provides curing of grouts “from top to bottom” [23, 24]. It is provided by using grouts with differential properties, differing in density and address additives, which take into account the peculiarities of the problem intervals, provide shock resistance of the cement ring, and prevent gas penetration in time of cementing [23, 24].

For experimental studies, plugging compositions were substantiated, which were tested for compliance with the requirements of GOST 1581-96 [25] and 4 formulations were obtained.

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

It should be noted that in many works devoted to the development of plugging systems, there are few studies of plugging stones by electron microscopy and X-ray phase analysis methods. Many researchers and producers limit themselves to checking the basic properties of cement slurries and plugging stones for compliance with the requirements of GOST 1581-96 [25].

However, to fully understand the interaction of cement hydration products with reinforcing and expanding additives, it is necessary to investigate the micro- and nano-structure by electron microscopy.

In this work, the structure, and interaction of the components of the plugging stone were investigated by scanning electron microscope (SEM). X-ray phase analysis (XRPA) was used to identify the crystalline phases of the materials.

MATERIALS AND METHODS

The research methods included scanning electron microscopy and X-ray diffraction analysis of the structure and crystal phase composition of plugging stones. The influence of microstructural characteristics on mechanical properties and deformation stability of materials under conditions typical for well operation was studied.

A large number of tests of the technological properties of cement mortars and the resulting stone were carried out according to GOST 1581-96 [25] and API standards (API spec.10B) [26].

Class G cement (PCT-I-G) was used in all formulations for the studies. Polypropylene fiber and expanding additive CMA produced by LLC «Cement Technologies» (Ufa, Republic of Bashkortostan, Russian Federation) were used to increase impact resistance and ensure tight contact with the confining surfaces of the resulting plugging stone. There were additional additives in the slurry composition, presented in Table 1.

Using the above-mentioned materials according to the developed method of well cementing [23], which provides the use of cement slurries having differential properties, 4 formulations of cement slurries with various properties were substantiated and obtained (Figure 1):

Formulation 1 – W/C – 0,7; EA-CT – 5%; СаСl 2 – 1%; PP fiber – 0,5%; FLoss – 0.2%;

Formulation 2 – W/C – 0,7; EA-CT – 2%; NaСl – 1%; PP fiber – 0,25%;

Formulation 3 – W/C – 0,44; EA-CT – 5%; NMA – 0,01%; PP fiber – 0,25%; Floss – 0,2%;

Formulation 4 – W/C – 0,44; EA-CT – 5%; NMA – 0,05%; PP fiber – 0,25%.

Following the investigation of the main technological properties of cement slurries in accordance with the requirements of GOST 1581-96 and API, the obtained cement stone samples were used for microstructure study. The cement slurry hardening temperature was 22 о С, hardening time was 2 and 7 days. In parallel, 2 samples of each formulation were tested and compared.

The experiments were carried out in the laboratory «Nanotechnology of Cement Systems named after Professors A.F. Polak and N.H. Karimov» of Ufa State Petroleum Technical University.

The samples were examined for microanalysis and morphological analysis of the surface by scanning electron microscope JEOL JSM-6610LV, which was equipped with an attachment energy dispersive spectrometer Oxford Inca Energy.

When studying the contact between the polypropylene fiber and the cement stone matrix, images of the specimens were obtained at magnifications up to 3300x.

The purpose of the investigation on X-ray diffractometer D2PHASER was to obtain a qualitative and quantitative analysis of the composition of curing products. Decoding of the obtained X-ray diffractograms was performed in the programs «Eva.diffrac» and «Topas.diffrac».

Table 1

Chemical reagents used for cement slurry development

|

Additives |

Description |

Functions |

Concentration (of cement weight, %) |

|

PP fiber |

Polypropylene fiber |

Increasing deformation resistance |

0.25; 0.5 |

|

CMA (EA-CT) |

Expanding additive |

Creation of tight contact |

2; 5 |

|

Floss |

Synthetic polymer based on polyacrylamide |

Reduces water release |

0.2 |

|

СаСl 2 |

Calcium chloride |

Hardener |

1% |

|

NaСl |

Sodium chloride |

Hardener |

1% |

|

NMA |

Nitrilotrimethylphosphonic acid |

Structuralizer |

0.01; 0.05 |

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 1. Samples of plugging stones with different properties

RESULTS AND DISCUSSION

Investigations of the effect of water-reducing agents on the strength properties of cement plugging stone with reinforcing and expanding additives have been carried out (Table 2). These data are necessary for comparative evaluation and a complete understanding of microstructure changes in cement stone of the developed 4 formulations.

Table 2 shows that the decrease in the concentration of expanding admixture and the absence of a water-re- ducing agent led to a decrease in the strength properties at W/C = 0.7.

The task of the investigation was, in addition to analyzing the cement structure, the determination of the expanding admixture, and the interaction between the matrix and polypropylene fiber.

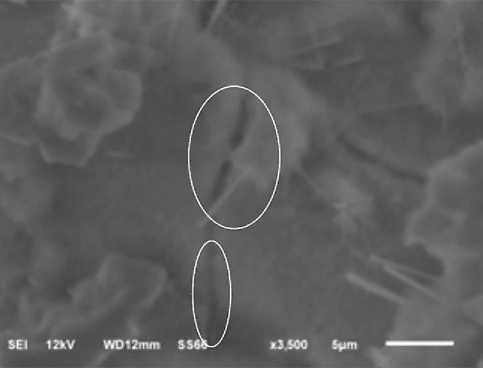

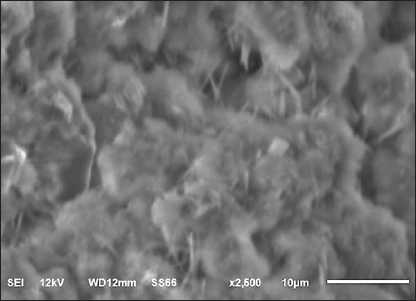

Figure 2 shows the tight contact of polypropylene fiber and the presence of ettringite. The imaging was continued at 2500x and 3500x magnification to clarify the relationship. With a magnification of 3500x, the presence

Table 2

Results of measuring the strength characteristics of cement stone

|

Composition |

W/C |

Bending strength, MPa |

Compressive strength, MPa |

||

|

2 days |

7 days |

2 days |

7 days |

||

|

Additive-free PTC -I-G |

0.44 |

2.9 |

3.8 |

10.8 |

15.4 |

|

Additive-free PTC -I-G |

0.7 |

1.5 |

2.6 |

4.5 |

13.8 |

|

Formulation 1 |

0.7 |

1.97 |

2.95 |

5.53 |

8.7 |

|

Formulation 2 |

0.7 |

3.0 |

4.37 |

6.71 |

12.2 |

|

Formulation 3 |

0.44 |

3.9 |

5.57 |

17.26 |

More than 22 |

|

Formulation 4 |

0.44 |

3.5 |

5.52 |

13.2 |

More than 22 |

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

SEI mV WD12mm SSM

12,600 1Dpm

Fig. 2. Development of ettringite in the cement matrix of formulation 1 during hardening in water for 2 days (×2500 and ×3500)

of cracks can be seen, which could be the reason for the reduction of the strength characteristics of the stone.

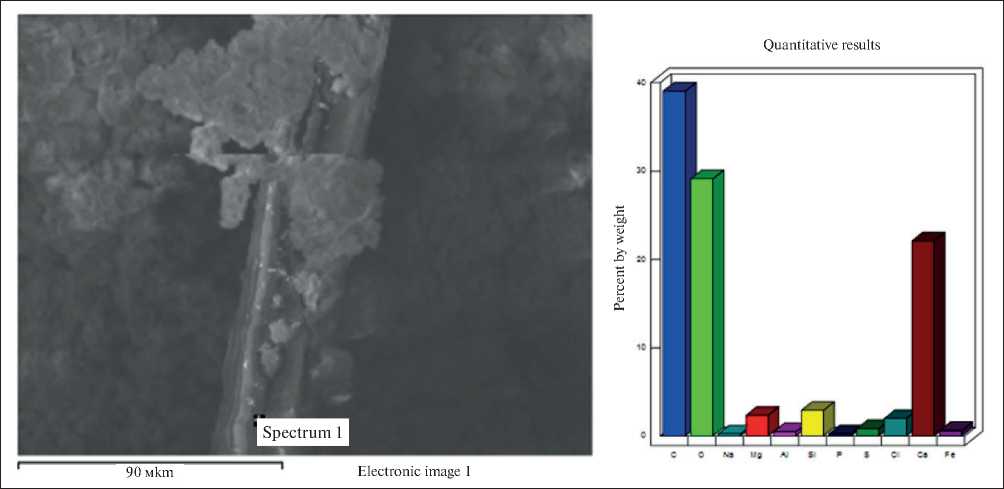

A photo of the fiber shows the interaction between cement and fiber curing products, and quantitative analysis confirms that there are cement (CaO) particles on the fiber surface (Figure 3).

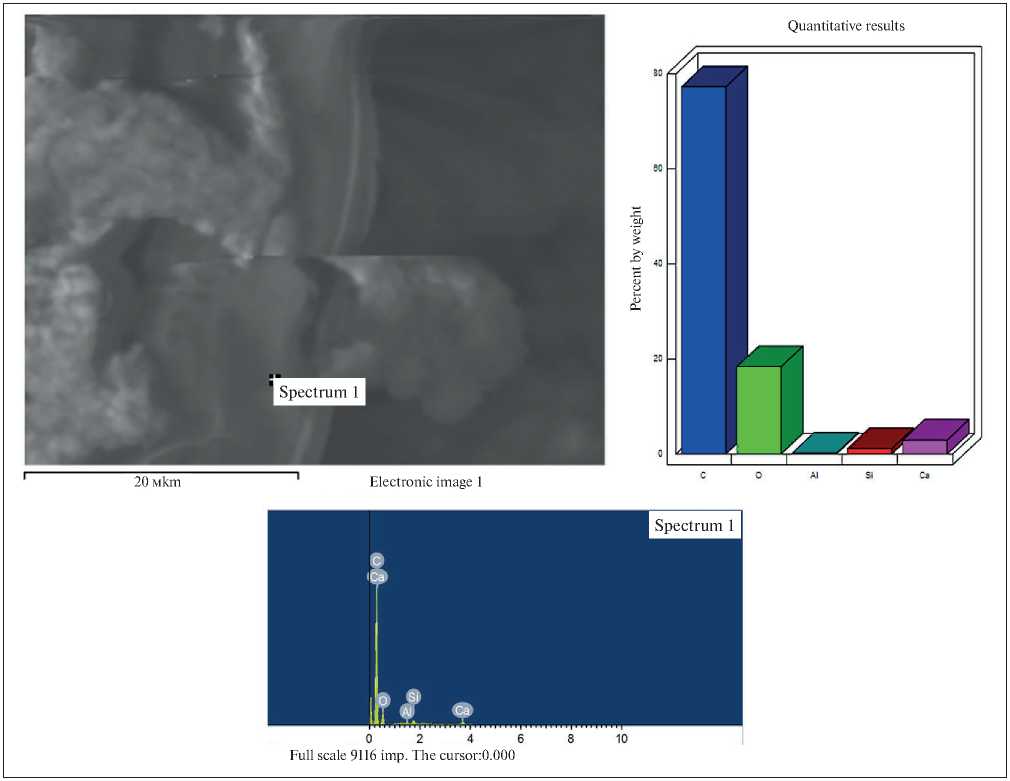

The quantitative analysis of spectrum 1 shows a large amount of carbon content which means the presence of polypropylene fiber (Figure 4).

Late hydration of any expanding additive can lead to the destruction of the cement matrix of the plugging stone, but in all samples such phenomena were not detected.

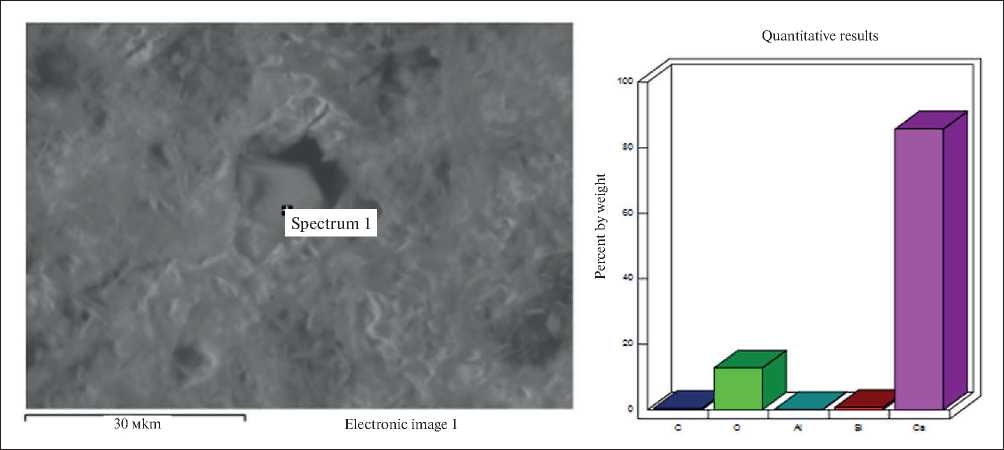

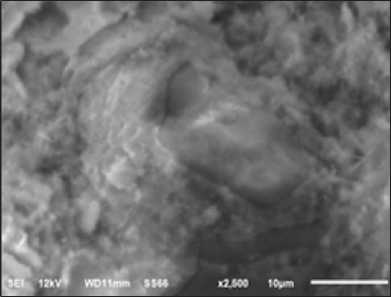

At hardening of 7 days of cement stone of formulation 1, it is possible to note the increase of ettringite. It is also possible to speak about the presence of expanding additives since the core practically contains only calcium. From Figures 5 and 6 it can be concluded that all components are in close contact with each other.

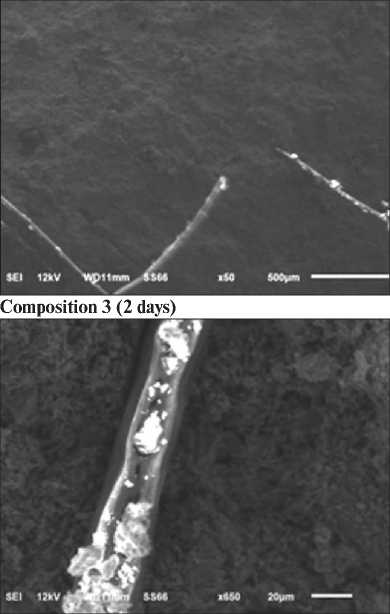

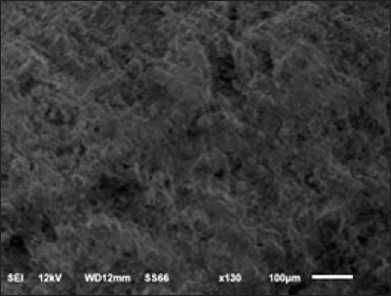

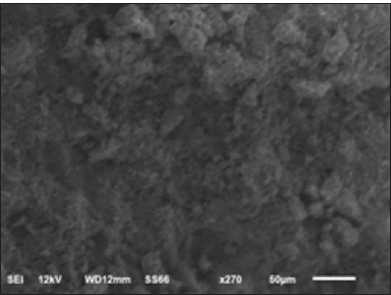

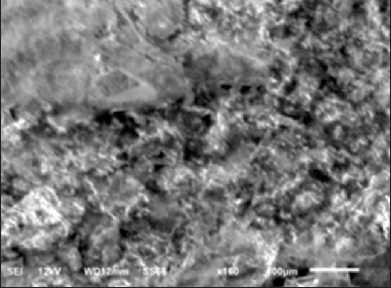

Analysis of the obtained images shows a dense cement stone structure in all formulations (Fig. 7). During an investigation of the formulations (formulation 2) it is necessary to note the absence of holes or channels from polypropylene fiber. This proves that it interacts well with the cement stone, works in tension and after breaking the fibers remain in the cement stone. From the images

Fig. 3. Fiber image (90 µm) and elemental spectrum analysis 1

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 4. Fiber image (scale 20 µm) and elemental analysis of the spectrum 1

Fig. 5. Spectra of chemical elements of the investigated sample and quantitative results of formulation 1 at hardening in water for 2 days (expanding additive – CMA of “Cement Technologies” Ltd.)

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 6. Development of ettringite in cement matrix of formulation 1 during hardening in water for 7 days (×2500)

Composition 2 (2 days)

12*V

Composition 3 (2 days)

Composition 2 (7 days)

Composition 3 (7 days)

Comp os ition 4 (7 day s)

Composition 4 (2 days)

Fig. 7. Cement stone structure of formulations 2, 3, and 4 at hardening in water for 2 and 7 days

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

(formulations 3, 2 days), the surfaces of polypropylene fibers can be seen to have particles of cement hardening products, even after rupture. Studying formulations 2–4 showed that all the expanding admixtures are fully hydrated and have no cracks (e.g. 3 at 7 days hardening).

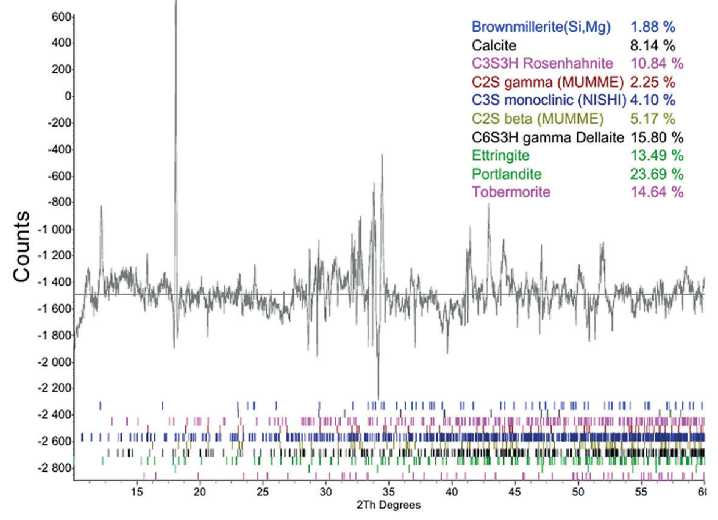

The results of the investigation of the plugging stone by X-ray phase analysis are shown in Figures 8 and 9.

Quantitative analysis of XRD of formulation 1, showed that when the hardening time in the water is increased from 2 days to 7 days, ettringite decreases by 3% and

Fig. 8. Quantitative analysis of radiographs of formulation 1 when hardened in water for 2 days

•*

BrawnrnilerlefS- Mg) 10 18 %

С*1"» Л I

1СЗЙН RoMfiiMhnM^ 2 - 00 % J* CIS gamma tMUWSf6 98 % C3S monoclinic (NISHI) 1812 % C2SbeHiMUMME) 2 46 % C6S3H gamma Deilaite в 97 %

-1 M№

Etomyle Porttendhte Tobermonte

1122% 1677 %

8 27%

1№ IM

>666

4№.

iw iiwjieft ■« Li м ем «OMmeeiieweeMietiwe

■wshpa tr'n4ii ^irimwKMfafiiwihmH

Fig. 9. Quantitative analysis of radiographs of formulation 1 at hardening in water for 7 days

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS amounted to 11.22%, portlandite by 7%, tobermorite by 6.37%. However, braunmillerite increases by 8.3%, calcite by 8.89%, and calcium hydrosilicate by 15.12%.

CONCLUSION

The following conclusions can be drawn based on the results of the completed investigation:

1. In all investigated formulations of cement slurries after hardening a dense contact of polypropylene fibers and cement stone is revealed, confirmed by their adhesion even after cement stone destruction.

-

2. The presence of dense bonds of the cement matrix, fiber, and expanding additive confirmed by electron microscopy shows new possibilities of this method in the investigation of special plugging materials.

-

3. The dense structure of cement stone in formulations 3 and 4 proves the role of polypropylene fiber in increasing the strength of the obtained stone.

-

4. Application of the XRD method allows us to trace the kinetics of hydration and phase formation of cement and modifying additives, which allows a more reasonable approach to the selection of cementing materials for wells with complex mining and geological conditions.

Список литературы Microstructural analysis of strain-resistant cement designed for well construction

- Agzamov F.A., Karimov I.N., Myazhitov R.S. Theoretical bases and practice of production of plugging materials for fastening steam injection wells. Territory Neftegaz. 2016; 9: 26-33.

- Agzamov F.A., Kabdushev A., Tokunova E., Manapbayev B.Z., Kozhageldi B.Z. Magnesia corrosion of grouting materials. PeriodicoTche Quimica. 2020; 17(34): 951-961.

- Tupysev M.K. Deformation of casing strings as a result of technogenic deformation processes during the development of oil and gas fields. Actual problems of oil and gas. 2021; 2(33).

- Buglov N.A., Butakova L.A., Shakirova E.V., Averkina E.V. Use of silicon production wastes as additives improving the process properties of the cement slurries. Bulletin of the Tomsk Polytechnic University, Geo Assets Engineering. 2022: 333(6): 122-130. https://doi.org/10.18799/24131830/2022/6/3428

- Ivanova T.N., Zasadzień M. Technological Capabilities of Well Cementing. Multidisciplinary Aspects of Production Engineering. 2021; 4(1): 465-478. https://doi.org/10.2478/mape-2021-0042

- Agzamov F.A., Ismagilova E.R., Self-healing cements - the key to maintaining well casing tightness. Nanotechnology in construction. 2019; 11(6): 730-742. 10.15828/2075-8545-2019-11-6-730-742

- Moldamuratov Zh.N., Iglikov A.A., Sennikov M.N., Madaliyeva E.B., Turalina M.T. Irrigation channel lining using shotcrete with additives. Nanotechnologies in Construction. 2022; 14(3): 227-240. https://doi.org/10.15828/2075-8545-2022-14-3- 227-240. – EDN: BIEVUB.

- Agzamov F.A., Grigoryev A.Yu. Modification of plugging Portland cement with nanoadditives. Nanotechnology in construction. 2022; 14 (4). https://doi.org/10.15828/2075-8545-2022-14-4-319-327

- Navid Yousuf, Olatunji Olayiwola, BoyuGuo, Ning Liu. A comprehensive review on the loss of wellbore integrity due to cement failure and available remedial methods. Journal of Petroleum Science and Engineering. 2021; 207: 109123. https://doi.org/10.1016/j.petrol.2021.109123

- Christodoulou D., Lokkas P., Droudakis A., Spiliotis X., Kasiteropoulou D., Alamanis N. The Development of Practice in Permeation Grouting by Using Fine-grained Cement Suspensions. Asian Journal of Engineering and Technology. 2021; 9(6). https://doi.org/10.24203/ajet.v9i6.6846

- Liu J., Feng H., Zhang Y., Zheng K. Performance Investigation of Geopolymer Grouting Material with Varied Mix Proportions. Sustainability (Switzerland). 2022; 14(20). https://doi.org/10.3390/su142013046

- Zhu G., Zhang Q., Liu R., Bai J., Li W., Feng X. Experimental and Numerical Study on the Permeation Grouting Diffusion Mechanism Considering Filtration Effects. Geofluids. 2021. https://doi.org/10.1155/2021/6613990

- Jia Q., Wang Y. Study on Calcium Carbonate Deposition of Microorganism Bottom Grouting to Repair Concrete Cracks. Sustainability (Switzerland). 2023: 15(4). https://doi.org/10.3390/su15043723

- Liu X., Wang D., Zhang Y., Jiang A., Fang Q., Zhang R. Analytical solutions on non-Darcy seepage of grouted and lined subsea tunnels under dynamic water levels. Ocean Engineering. 2023; 267. https://doi.org/10.1016/j.oceaneng.2022.113276

- Nima Mohamadian, Mohamadreza Zahedi Ramhormozi, David A. Wood, Rahman Ashena, Reinforcement of oil and gas wellbore cements with a methyl methacrylate/carbon nanotube polymer nanocomposite additive. Cement and Concrete Composites. 2020; 103763. https://doi.org/10.1016/j.cemconcomp. 2020

- Livio S., Arash D.T., Guoqiang L., Nanosilica-treated shape memory polymer fibers to strengthen wellbore cement. Journal of Petroleum Science and Engineering. 2021; 196: 107646. https://doi.org/10.1016/j.petrol.2020.107646

- Shadravan A., Schubert J., Amani M., Teodoriu C. Using Fatigue-Failure Envelope for Cement-Sheath-Integrity Evaluation. SPE Drilling & Completion. 2015; 30(01): 68–75. https://doi.org/10.2118/168321-PA

- Boyun Guo, Liqun Shan, Shuxian Jiang, Gao Li, Jim Lee, The maximum permissible fracturing pressure in shale gas wells for wellbore cement sheath integrity. Journal of Natural Gas Science and Engineering. 2018; 56: 324-332. https://doi.org/10.1016/j.jngse.2018.06.012

- Ramón Victor Alves Ramalho, Salete Martins Alves, Julio Cezar de Oliveira Freitas, Bruno Leonardo de Sena Costa, Ulisses Targino Bezerra. Evaluation of mechanical properties of cement slurries containing SBR latex subjected to high temperatures. Journal of Petroleum Science and Engineering. 2019; 178: 787-794. https://doi.org/10.1016/j.petrol.2019.03.076

- Shivshambhu Kumar, Achinta Bera, Subhash N. Shah. Potential applications of nanomaterials in oil and gas well cementing: Current status, challenges and prospects. Journal of Petroleum Science and Engineering. 2022; 213. 110395. https://doi.org/10.1016/j.petrol.2022.110395

- Zhao L., Li N., Yang J., Wang H., Zheng L., Wang C. Alkali-Resistant and pH-Sensitive Water Absorbent Self-Healing Materials Suitable for Oil Well Cement. Energies. 2022; 15. 7630. https://doi.org/10.3390/en15207630

- Lian J., Yue J., Xing X., Wu Z. Design and Evaluation of the Elastic and Anti-Corrosion Cement Slurry for Carbon Dioxide Storage. Energies. 2023; 16. 435. https://doi.org/10.3390/en16010435

- Moldamuratov Zh.N., Ussenkulov Zh.A., Yeskermessov Zh.E., Shanshabayev N.A., Bapanova Zh.Zh., Nogaibekova M.T., Joldassov S.K. Experimental study of the effect of surfactants and water-cement ratio on abrasion resistance of hydraulic concretes. RASĀYAN Journal of Chemistry. 2023; 16(3): 1116-1126. http://doi.org/10.31788/RJC.2023.1638391

- Moldamuratov Zh.N., Imambayeva R.S., Imambaev N.S., Iglikov A.A., Tattibayev S.Zh. Polymer concrete production technology with improved characteristics based on furfural for use in hydraulic engineering construction. Nanotechnologies in Construction. 2022; 14(4): 306-318. https://doi.org/10.15828/2075-8545-2022-14-4-306-318

- Interstate standard GOST 1581-96 «Portland cement plugging. Technical conditions».

- API spec.10B Recommended Practice for Testing Well Cements.