Microstructural study of medieval crucible steels from archaeological sites in Central and Northwest Asia: identifying the bulat

Автор: Zinyakov N.M.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 3 т.52, 2024 года.

Бесплатный доступ

The microstructure of 9th–15th century artifacts made of crucible steel, found at sites in Central and Northwest Asia, is described. Metallographic study of items from settlements and burials with precise data on chronology, location, and accompanying artifacts is important for reconstructing the history of bulat steel and the technology of melting and processing ultra-high-carbon crucible steel. The study of the macro- and microstructure, and the chemical analysis of such items indicate an extremely high content of carbon—1.7–2.1 %. The characteristic feature of their microstructure is a dark matrix with white inclusions of ledeburite and iron carbides. The combination of structural components is reflected in the patterned structure of the metal. These properties suggest that such metal is identical to bulat steel. Findings of macrostructural analysis extend our knowledge of the varieties of this metal, its structural features, phase composition of separate groups of ultra-high-carbon crucible steel, smelting technology, plastic and thermal treatment, and physical properties.

Короткий адрес: https://sciup.org/145147220

IDR: 145147220 | DOI: 10.17746/1563-0110.2024.52.3.082-090

Текст научной статьи Microstructural study of medieval crucible steels from archaeological sites in Central and Northwest Asia: identifying the bulat

Until the mid-18th century, crucible cast steel, which was long considered the summit of metallurgical technology, was produced exclusively by artisans from the East. In the Middle Ages, it was used for making the best saber blades that possessed legendary properties. Items made of crucible steel were distinguished by high elasticity and exceptional compressive strength. Their qualities were not inferior to items made of modern tool steel.

According to information from the Central Asian encyclopedist and scholar Abu Rayhan al-Biruni contained in his treatise on mineralogy, two types of crucible steel were known in the East. The first type, without visual distinguishing features, was used to produce tools. The second type demonstrated a sharp heterogeneity of composition resulting in a specific pattern (firind) on the surface of the items, visible to the naked eye. This steel was called fulaz (“bulat” in Russian) and was used primarily for manufacturing bladed weaponry (Biruni, 1963: 235).

The first attempts to study cast bulat steel were undertaken by physicists and metallurgists in Western Europe in the early 19th century, which was triggered by the need for new types of tool materials for the developing industry. At that time, scholars came to contradictory conclusions about the chemical composition, quality of bulat steel, and reasons for emergence of patterns on its surface. The general recognition was that the unusual properties of bulat steel resulted from additives such as aluminum, platinum, silver, chromium, and other elements (Gurevich, 1985: 67–68).

In 1828, the Russian engineer P.P. Anosov began to study bulat steel and carry out metallurgical experiments. The results of his work were published in Gorny Zhurnal (“Mining Journal”) in 1841 under the title “On bulat steel”. In this work, Anosov not only described the course of metal smelting experiments, but also made a number of interesting observations and conclusions. The most important was the conclusion that “Bulat steel is not a mixture of steel with some metal, but the mixture of iron and carbon, as with steel”, and that “the reason for the emergence of large patterns should be most closely sought in the method of combining iron and carbon” (Anosov, 1954: 129). A comparison of various bulat alloys showed that the larger the patterns were, “the harder the bulat steel was and, consequently, the more carbon it contained” (Ibid.: 135). Thus, the most important law of metal science—dependence of the properties of metal on its crystalline structure—was discovered.

In the 20th century, studies on the problems of bulat steel were published both in Russia and internationally. The overwhelming majority of these studies were carried out by metallurgical engineers. In Russia, research aimed at identifying and theoretically substantiating the technology for producing alloy steels intensified in the 1950s, causing a surge of interest in bulat steel. The most famous study was done by the team from the Zlatoust Metallurgical Plant, supervised by I.N. Golikov, who elaborated his own theory of bulat steel and its production. He claimed that “the reason for the bulat pattern and specific properties of bulat steel is preservation of suspended, under-melted particles with lower carbon content in the volume of liquid metal during steel smelting” (Golikov, 1958: 25). Y.G. Gurevich, the author of many scholarly works on metal production technology, including studies on the problems of bulat steel (Gurevich, 2006; Gurevich, Papakhristu, 1992a, b), effectively worked on Golikov’s team. His publications on two medieval items—a tool of the 9th–13th centuries from the Akhsiket (Fergana) fortified settlement and a chainmail ring from the same period from Samarkand (Gurevich, Papakhristu, 1992a, b)—are of particular interest from an archaeological point of view. These items were heavily corroded, which was typical of Central Asia, but the author managed to find metal particles in them that could be studied under a microscope. The condition of the samples precluded an objective description of microstructure of the steel. The conclusions drawn were largely hypothetical (“it can be assumed”, “the dark gray component could represent”) (Ibid.), and therefore seem unconvincing.

In the 1960s–1990s, international metallurgists who studied modern ultra-high-carbon steels became interested in producing and processing crucible bulat steel. Research teams from Stanford University headed by O. Sherby and from Iowa State University headed by D. Verhoeven deserve special attention. Both groups claimed to have rediscovered the process of producing bulat steel. Sherby proposed and defended his theory on the origin of the bulat pattern, called the “Wadsworth-Sherby Mechanism” (Wadsworth, Sherby, 1992). His team also identified the superplastic behavior of ultra-high-carbon steels with increasing temperature, and discovered high-strength materials, opening up great prospects for their use in modern industry (Sherby, Wadsworth, 1995). During the experiments of Verhoeven’s team, a technique for reproducing surface patterns and the internal microstructure of bulat steel blades, based on adding a small amount of carbide-forming elements such as vanadium, molybdenum, and chromium into the metal, was elaborated (Verhoeven, Peterson, 1992; Verhoeven, Pendray, Wagstaff, 2018). The authors clarified the mechanism of carbide formation during smelting and its arrangement into a row-like structure (Verhoeven, Pendray, 1993), determined the temperature conditions for plastic processing of metal, and proposed the main characteristics of bulat steel (Verhoeven, Peterson, 1992).

In present-day Russia, metallurgists are still quite interested in bulat steel, as can be seen from the publications of scholars (Gurevich, 2005, 2006, 2008, 2010; Sukhanov, Arkhangelsky, 2015; Sukhanov et al., 2019; Taganov, Ivanov, Nechaev, 2007) and practitioners (Arkhangelsky, 2007). Their motives are not only scientific, but also applied, such as creation of a resourcesaving technology for producing cutting tools.

There are only a few metallographic studies of items made of crucible bulat steel that have archaeological context. These studies yielded three finds from the 1st and 5th centuries AD from Taxila (Punjab), a Sassanid sword from the 6th–7th centuries from Iran, a sword from Nishapur (late 8th–9th centuries), four blades from the Alanian and Khazar burials in the North Caucasus (Feuerbach, 2005: 28–29), a blade of the 12th–13th centuries made of hypercarbon steel with cementite network and excess cementite in the form of needles, found in a collective burial in the city of Yaroslavl (Zavyalov, Engovatova, 2020), and a sword made of ultra-high-carbon steel from an Iron Age megalithic burial in Telunganur (India) (Park, Rajan, Ramesh, 2020).

Thus, there is substantial historiographic literature on the topic, including studies on crucible steels of the Middle Ages. However, many problems of bulat steel remain controversial to this day. Authors disagree on the chemical composition of bulat steels, their microstructural components, cooling rate of melts, nature of formation of carbide layers in the metal, and conditions for the emergence of the bulat pattern. The common drawback of studies of medieval metal items is usually the lack of accurate dating, dubious location of finds, and ambiguity of their origin.

This article presents the results of microstructural analysis of archaeological evidence from sites in Central Asia (Southern Kazakhstan) and Western Siberia. Advantages of this study include the origin of evidence from settlements and burial complexes that have a precisely established chronology, location, and set of artifacts, which is of great importance for identifying the history of the available metal, and establishing the technology of its smelting and mechanical processing.

Material and methods

This study focuses on items made of ultra-high-carbon crucible steel (according to the AISI classification) that were discovered at medieval archaeological sites in Central and Northwest Asia. It is important to mention that these items constitute an insignificant part of the overall collection of artisanal items studied: no more than 1 % in Semirechye (out of 400 forged items) and no more than 0.16 % in Western Siberia (out of 2400 items). Macro- and microstructural analysis was carried out on: a pair of scissors and blacksmith’s chisel from the Talgar fortified settlement (Northeastern Semirechye), dating to the 9th–13th centuries; a fragment of a saber of the 10th– 13th centuries from the Kipo-Kulary fortified settlement (Omsk Irtysh region); two sabers of the 12th–14th centuries from the burial ground at the mouth of the Malaya Kirgizka River (Tomsk region of the Ob); and one saber of the 14th–15th centuries from the Ust-Balyk burial ground (Yugansk region of the Ob). Judging by the microstructure and known sources, these finds from Western Siberia were imported items, most likely produced in the nearest urban artisanal centers of Central Asia.

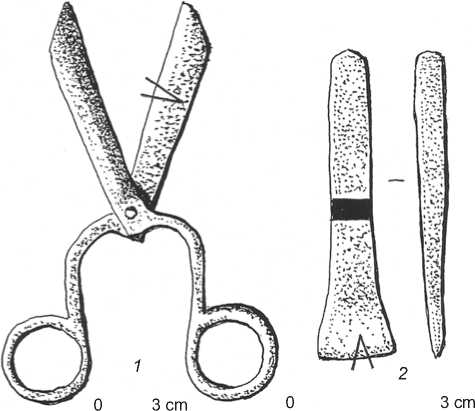

Fig. 1 . Scissors ( 1 ) and chisel ( 2 ) from the Talgar fortified settlement.

This study has followed the methods of metallographic analysis, including studying the macro- and microstructure of the samples and measuring the microhardness of metal. The microstructures will be described using the standard terminology of metallography.

Study results and discussion

Metallographic and chemical analysis of the items has revealed an extremely high concentration of carbon (1.7– 2.1 %) in the metal. In Russian metal science, such ironcarbon alloys are called high- or supercarbon steels, in international science ultra-high-carbon or hypercarbon steels. According to the structural classification, these belong to the ledeburite and carbide classes. The microstructure of the studied alloys shows the presence of ledeburite (structural component of white and mottled cast iron) and iron carbides (Fe3C).

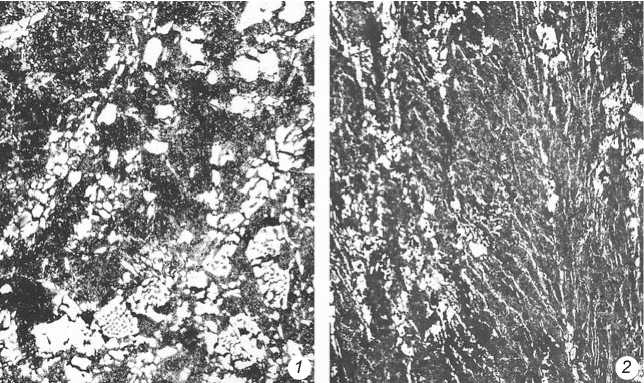

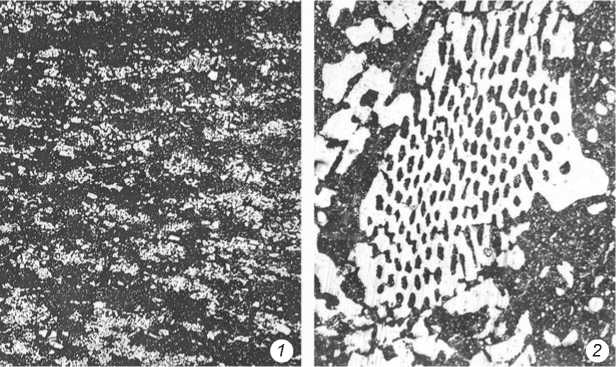

Items made of steel belonging to the ledeburite class included the hinged scissors, two saber blades, and small blacksmith’s chisel. The hinged scissors were quite large; their design was similar to modern scissors (Fig. 1, 1 ). Macro- and microstructural analysis of the cross-section of the working blade showed that the item was forged from ultra-high-carbon crucible steel of the ledeburite class and hardened in cold water. The striated microstructure of the metal consisted of a martensite matrix, inclusions of iron carbides (in the form of elongated grains, less often individual needles), and zones of ledeburite eutectic (Fig. 2). Individual rows were formed by alternating particles of carbides and ledeburite inclusions, and were elongated towards the blade. Their thickness was uneven. To study the pattern on the external surface, one of the blades of the scissors was polished to a mirror shine, etched with a chemical reagent (4 % solution of nitric acid in alcohol), and subjected to microscopic analysis. Since different structural components of the metal reacted differently to the action of acid, etching clearly revealed the patterned structure of the steel consisting of a combination of the dark matrix (martensite), light carbide inclusions in the form of netlike (needle-like) branches, large and small clusters of angular and rounded shapes, as well as zones of ledeburite eutectic (Fig. 2, 2 ). The location of carbide particles and ledeburite zones had a dendrite nature.

For establishing the composition of the steel, a sample from the scissors was subjected to chemical analysis, revealing an iron-carbon alloy with extremely high carbon content (2.1 %). According to this indicator, it was in the border zone between cast iron and steel, and, according to international terminology, it belonged to the category of ultra-high- or hypercarbon steels. However, chemical analysis showed the absence of the main carbide-forming elements, such as vanadium, tungsten, molybdenum, and titanium, and an extremely low concentration of chromium (0.01 %). It is known that manganese is an essential carbide-forming element, yet its content in the studied alloy was relatively small (0.62 %). Manganese becomes an alloying agent and is able to impart special properties to steel only at concentrations over 1 % (Blanter, 1963: 252). Nevertheless, such a manganese content also positively affects the steel elasticity (Ibid.: 288). All of this indicates that the formation of carbides and ledeburite eutectic in the alloy under study resulted not from the addition of metals, but from increased carbon concentration.

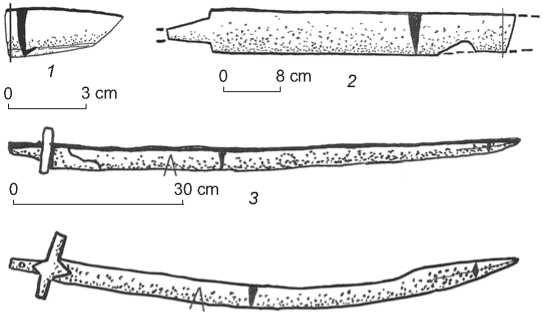

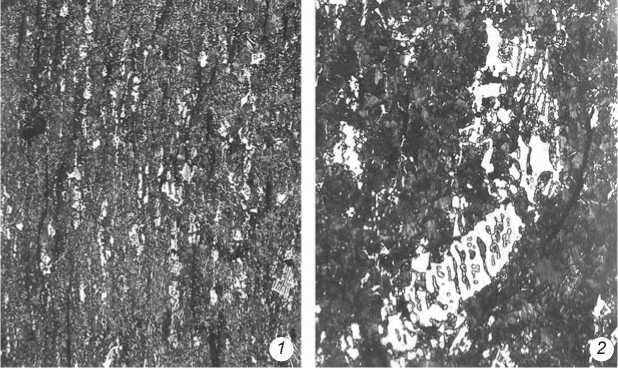

Two specimens of saber blades were of particular interest. The first one was the fragment of a saber (the end of a blade) found at the Kipo-Kulary fortified settlement. External examination of the item showed obvious traces of reforging, which ended in failure possibly due to the blacksmith’s lack of experience in handling such materials (Fig. 3, 1 ). Numerous cracks visible under a microscope clearly confirmed this. A study of the sample’s microstructure showed that the blade was made of crucible steel with a large amount of carbon. Such iron-carbon alloys are on the border between steel and cast iron in terms of carbon concentration (according to the ironcarbon phase diagram). For this reason, such metal was difficult to forge at traditional metal heating temperatures. The alloy structure consisted of finely dispersed pearlite, a cementite net, and a substantial amount of both individual and grouped ledeburite zones (Fig. 4). Significant differences in the size and shape of ledeburite particles and their uneven distribution across the crosssection of the sample were observed.

The second saber was found in grave 2, burial mound 63 at the medieval cemetery located at the mouth of the Malaya Kirgizka River, near Tomsk (see Fig. 3, 2 ). The item

Fig. 2 . Microstructure of the scissors’ surface, at ×250 ( 1 ) and ×50 ( 2 ) magnification.

30 cm

Fig. 3 . Sabers.

1 – Kipo-Kulary; 2 – Malaya Kirgizka, burial mound 63, grave 2; 3 – Malaya Kirgizka, burial mound 62, grave 2; 4 – Ust-Balyk, grave 214.

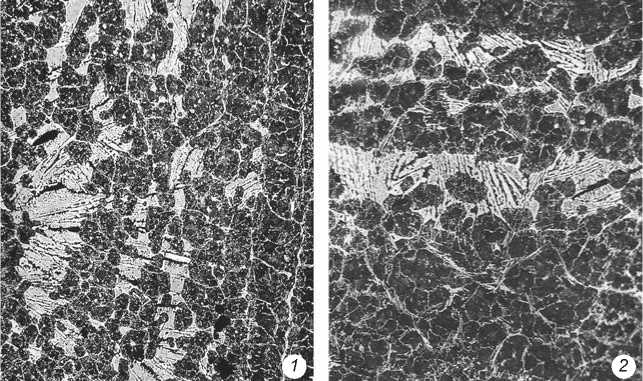

Fig. 4 . Microstructures of a saber from the Kipo-Kulary fortified settlement. 1 – cross-section, ×100; 2 – surface, ×200.

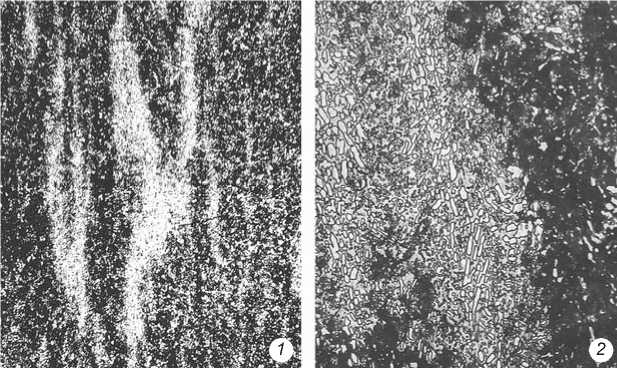

Fig. 5 . Microstructure of the longitudinal cross-section of a saber from grave 2, burial mound 63 of the Malaya Kirgizka cemetery, at ×25 ( 1 ) and ×400 ( 2 ) magnification.

Fig. 6 . Microstructure of the transverse cross-section of a chisel from the Talgar fortified settlement, at ×100 ( 1 ) and ×500 ( 2 ) magnification.

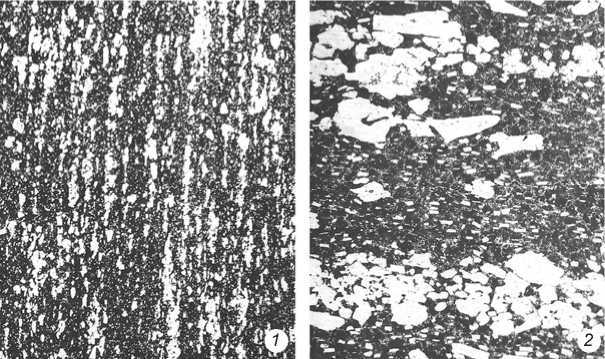

Fig. 7 . Microstructure of the transverse cross-section of a saber from the Ust-Balyk cemetery, at ×100 ( 1 ) and ×500 ( 2 ) magnification.

has survived in fragments. The blade was slightly curved. Its total length was 96 cm; the width was 3 cm. Metallographic analysis revealed a microstructure of troostite with carbide precipitation in the form of small and large inclusions of round and angular shapes, as well as individual zones of ledeburite (Fig. 5). Distribution of carbides over crosssections was uneven. It was uniform in the transverse cross-section, while the arrangement of carbide particles was row-like in the longitudinal cross-section (Fig. 5, 1 ). The structural components had the following microhardness: troostite – 376–397 kg/mm2, carbides – 1170– 1290 kg/mm2, and ledeburite – 762 kg/mm2.

Finally, the last item made of steel of the ledeburite class was a small chisel for cutting metal (see Fig. 1, 2 ). Metallographic examination showed that it was forged from ultra-high-carbon steel and was subjected to thermal hardening (quenching). The microstructure of the metal consisted of troostite, inclusions of iron carbides (Fe3C), and ledeburite eutectic. In the cross-section, the carbide inclusions and zones of ledeburite were grouped into clusters and were extended along the forging line (Fig. 6). The microhardness of the troostite was 412–457 kg/mm2 and of the ledeburite was 946– 1225 kg/mm2.

The group of ultra-high-carbon crucible steel of the carbide class was represented by saber blades. This article will discuss two of them in some detail. One blade came from the late medieval grave 214 at the Ust-Balyk cemetery (see Fig. 3, 4 ). The saber band was curved and ended with a double-edged yelman (false edge). The handle grip was inclined towards the blade. The crossguard was straight. The total length of the blade was 92 cm; the width was 3 cm, and the length of the handle grip was 8.2 cm. Metallographic analysis revealed a troostite structure and carbide inclusions in the form of individual grains and light areas of clusters located in a row along the plane of the polished section (Fig. 7). The density of particles in the clusters was extremely high

(Fig. 7, 2 ). Carbide inclusions had rounded outlines. Areas with martensite structure were observed at the edge of the blade. Judging by the microstructure, the concentration of carbon in the metal was about 2 %. The finished item was hardened. Microhardness of the troostite was 367–466 kg/mm2, and that of the carbide phase was 1006 kg/mm2.

Another saber was found in grave 2, burial mound 62 at the medieval cemetery located at the mouth of the Malaya Kirgizka River (see Fig. 3, 3 ). The length of the saber was 91 cm; the length of the handle was 5.8 cm. The blade was slightly and evenly curved along its entire length. The handle was slightly bent toward the blade. The crossguard was straight. The band beneath it had a non-ferrous, metal

Fig. 8 . Microstructure of the transverse cross-section of a saber from grave 2, burial mound 62 of the Malaya Kirgizka cemetery, at ×50 ( 1 ) and ×320 ( 2 ) magnification.

fitting. Microstructural analysis of a polished section taken from the cross-section of the blade revealed the structure of the ultra-high-carbon steel, which consisted of sorbite and carbide inclusions in discontinuous rows and clusters. The width of the rows varied from three or four to eight or nine cementite particles. The carbide particles had rounded outlines (Fig. 8). The carbon content was about 1.7 %. The microhardness of the sorbite was 367 kg/mm2, and that of the carbides was 946– 1144 kg/mm2.

In addition to the above two main and distinct groups of ultra-high-carbon steel (the ledeburite and carbide classes), a so-called intermediate group can also be identified. In addition to a predominance of carbides, its metal structure showed rare zones of ledeburite eutectic.

The results of macro- and microstructural analysis, as well as data from historical sources and publications of previous experiments, have made it possible to reconstruct the process of producing and processing ultra-high-carbon crucible steels in the pre-industrial period. A special source among other historical sources is the treatise of the Khorezm encyclopedist of the 11th century, Abu Rayhan Biruni (1963). In the chapter “Iron”, he presented his ideas about ferrous metal and carbon alloys, described recipes for smelting crucible steel and individual technological operations for manufacturing tools and bladed weaponry. In accordance with the classification of ferrous metal he followed, al-Biruni distinguished between natural (“noncomposite”) and “composite” iron (Ibid.: 231, 235). “Noncomposite” iron was divided into two varieties: soft (iron proper) – narmakhan , called female, and hard (steel) – shaburkan , called male. The latter iron demonstrated increased hardness, could undergo hardening, and did not yield to even the slightest bending (Ibid.: 231). In fact, this description includes the most important properties of pure iron (softness and associated plasticity) and steel

(hardness, reponsiveness to hardening in order to increase hardness while simultaneously increasing the brittleness of the metal).

According to al-Biruni, “composite” iron included two components— narmakhan and daus (cast iron), and was called fulaz (bulat steel) (Ibid.: 235). The author wrote that daus was “a hard [metal], white with a silvery tint” (Ibid.: 231). This description of cast iron is quite accurate, since in modern metal science, when visually assessing an iron-carbon alloy of this type, the criterion of the color of the metal fracture is used. White cast iron corresponds to a light, white color of fracture. Metallographic studies of ferrous metal carried out by the author of this article in Semirechye and Southern Kazakhstan indicate its widespread distribution in the Central Asian region during the Middle Ages (Zinyakov, Savelieva, Voyakin, 2013: 32–34).

In describing the technology for obtaining “composite” iron (crucible steel or bulat steel), al-Biruni mentioned that its production consisted of the joint smelting of soft iron and cast iron in a clay crucible. Depending on the technological mode of smelting, steel of different compositions, possessing different physical properties, was obtained. “The method of obtaining steel [of different] composition is twofold: either narmakhan [‘pure iron’ – N.Z. ] and its water [ daus , ‘cast iron’ – N.Z. ] are smelted in a crucible over a calm fire, and both of them are combined in such a way that they are indistinguishable from each other, and such steel is suitable for files and the like… Or they are smelted in a crucible sequentially, and there is no complete fusion between the two, but the particles of both are located alternately, so each separately is clearly visible from their two shades; [this pattern] is called firind (from the Persian word pirind , ‘silk patterned fabric’)” (Ibid.: 235). “ Firind in Khorasan [historical region that included Northeastern Iran, the Merv Oasis, Southern

Turkmenistan, Northern and Northwestern Afghanistan, and a part of Uzbekistan – N.Z. ] is called dzhaukhar ” (Ibid.: 236).

Thus, al-Biruni described two technological processes used for obtaining crucible steel in the Middle Ages. According to the first process, the combined long-term smelting of narmakhan (‘soft iron’, which can mean both plain iron and low-carbon steel, which has similar properties) and daus (cast iron introduced in the form of powder or dust) led to complete dissolution of the latter in liquid metal and formation of a relatively homogeneous high- or ultra-high-carbon steel (depending on the quantity and quality of cast iron introduced), consisting of pearlite and cementite. According to the second technological process, smelting of the charge components was done sequentially. Cast iron that was introduced into the melt, dissolved only partially. During smelting and timely stopping of the metallurgical process, one part of the daus underwent carburization and became dissolved, while the other part was preserved in the ingot in the form of individual ledeburite inclusions, with their size and shape depending primarily on the duration of the smelting process and the size of the cast iron chips. In this regard, one of al-Biruni’s statements cited in his treatise, is quite indicative: “A man who had visited Sindh told me that [once] he was sitting and watching the work at a blacksmith’s while the latter was making swords; the iron for them was from narmakhan ; he sprinkled it with some kind of medicinal product in the form of a fine powder of a reddish color… and I realized that this was daus which he mixed with the narmakhan … just as ovoid blooms are made from it by smelting in Herat” (Ibid.: 240).

In modern metal science, iron-carbon alloys formed under such conditions belong to the carbide and ledeburite classes, in accordance with their structure. A distinctive feature of these steels is the presence of a large number of carbides in the structure of metal in the former case, and particles of ledeburite eutectic in addition to numerous carbide inclusions in the latter case. Microhardness of carbides is 1144–1413 kg/mm2 and that of ledeburite 946–1314 kg/mm2. Thus, the resulting steel is a threedimensional combination of heterogeneous components: a solid metal base in the form of pearlite, sorbite, troostite, or martensite, with even harder carbides and ledeburite, having different physical and mechanical properties, being dispersed in the solid metal.

An important feature of fulaz (bulat) steel is the pattern (firind) on its external surface, which results from color contrast of the constituent parts of the iron-carbon alloy—the metal matrix, carbides, and ledeburite—after exposure to plant juice, acid, or other chemicals. When acid is applied to the polished surface, the metal matrix of such steel becomes black, while carbides and ledeburite inclusions remain white and shiny. Heterogeneity of the metal due to a three-dimensional assortment of grains, nodules, clusters, areas of carbides, as well as small and large inclusions of ledeburite, produced an intricate pattern. According to al-Biruni, “the [pattern] of firind is not obtained according to a set purpose when manufacturing [the sword] and does not emerge according to someone’s will, for it is random” (Ibid.: 237). In practice, this led to the appearance of items with a wide variety of patterns. First of all, they differed in the ratio of white and black colors. “The best of its varieties

Metallographic analysis of ultra-high-carbon crucible steel, which revealed the presence of a large number of white carbides grouped into rows, conglomerates, clusters, etc., and ledeburite eutectic, show these structures as the basis for the pattern formed on the external surface of metal due to the special arrangement of light components against a general dark background. Carbide and ledeburite inclusions in the original bloom were arranged by special forging techniques that were known to individual artisans and were kept in secret. One such technique was described in the treatise of al-Biruni: “…The bloom is forged not along its length, but starting from its head until it flattens like a plate, then it is cut in a spiral, after which its roundness is leveled into a plane; swords are forged from this and end up being with dzhaukhar mukhawwas [‘decorated with sparkles’ – N.Z. ]” (Ibid.: 238).

Some types of patterns (loop-shaped or rosette-like) could have been obtained by notching and cutting out the metal on the blank of a saber band. The use of such a technology of plastic steel processing by Eastern artisans was confirmed by experiments on reconstructing bulat steel production (Verhoeven, Pendray, 1993). Scholars discovered that if ultra-high-carbon steel was forged at sufficiently low temperatures (from 800 to 600 °C), the carbide fibers moved and a pattern was formed. According to experimental data, intense forging was required to obtain a beautiful pattern. For example, Verhoeven pointed out that even with 27 forging cycles the distribution of carbides in steel appeared random, whereas after 70 its geometry in the metal appeared to be quite well formed (Verhoeven, Pendray, Wagstaff, 2018).

The pattern and primer were the main indicators of the quality of bulat steel, as was repeatedly mentioned by al-Biruni and the medieval authors he cited. The Russian metallurgist of the mid-19th century P.P. Anosov, who operated with later information, wrote: “Asians know the quality of bulat steel from the pattern, the color of the primer, or the gaps between the patterns, and from the sheen of the surface under indirect rays of light. Asians believe: the larger and clearer the pattern, the higher the quality of the metal” (Anosov, 1954: 122). The size and clarity of the patterns, in his opinion, were determined by the amount of carbon in the steel, and their different arrangement could be explained by different degrees of perfection in the combination of the carbon and iron (Ibid.: 143). A comparison of various patterns of bulat steel items showed that the larger the patterns, “the harder the bulat steel was, and consequently, the more carbon it contained” (Ibid.: 135). Following up on this idea, Anosov divided the known bulat steels into hard and soft, and made one very important observation during the forging process: if the blank is heated to white-hot (1200– 1400 °C, the initial forging temperature for ordinary carbon steels), then “in the case of hard bulat steel it loses its malleability and crumbles, and in the case of soft steel it loses its patterns” (Ibid.: 147).

The observations and suppositions of Anosov have been confirmed and substantiated by modern microstructural studies. Large patterns can be associated primarily with a fairly high concentration of ledeburite inclusions, and small ones with carbide inclusions. Structural and chemical analysis indicates that crucible steel of the ledeburite class contains more carbon than steel of the carbide class. Consequently, the former can be identified with hard bulat steel, and the latter with soft steel. The metal structure revealed during the study of archaeological evidence also explains the behavior of hard bulat steel when heated to a high temperature. Relatively low-melting inclusions of ledeburite melt when heated to white heat, resulting in metal destruction in the case of its deformation.

As studies have shown, hardening of the finished product was one of the most important technological operations in manufacturing items of crucible steel, both for tools and bladed weaponry. Microstructural analysis of the metal indicates that in order to obtain the needed set of mechanical properties, medieval artisans used hardening modes that corresponded to the purpose of their products.

Conclusions

Macro- and microstructural study of items made of iron and iron-carbon alloys from medieval sites in Central and Northwest Asia clearly demonstrates the use of crucible ultra-high-carbon steel by the local population. Carbon content in the metal of individual samples was 1.7–2.1 %. Chemical analysis did not reveal sufficient amounts of carbide-forming elements, such as vanadium, tungsten, molybdenum, titanium, chromium, and manganese. The nearest crucible steel production facilities were located in Central Asian urban artisanal centers. The identified groups of iron-carbon alloys of the carbide and ledeburite classes have specific features of their macro- and microstructure, consisting of a dark matrix (depending on the nature of heat treatment, this can be pearlite, sorbite, troostite, or martensite), with white inclusions of ledeburite eutectic and cementite. Such steel may have been obtained by joint smelting of bloomery iron and cast iron. Two possible technological processes of the crucible metallurgical production have been described above, but clearly, there existed also other processes.

The presence of carbide and ledeburite clusters in the form of rows, areas, and conglomerates, which manifested itself in the patterned structure of the steel, together with an extremely high concentration of carbon, gives grounds to identify the studied metal as being identical to Eastern bulat steel from which weaponry, as well as chopping and cutting tools, was made. The pattern of the crucible steel was determined by the technology of metal production and processes of its plastic deformation. Numerous finds of crucible steel with ledeburite heterogeneity show that medieval metallurgists used special methods of metal smelting, which ensured preservation of ledeburite in its structure.

This research expands our knowledge on the existing varieties of bulat steel, structural features and phase composition of individual groups of ultra-high-carbon crucible steel, reflecting the technology of crucible smelting, plastic processing, and physical properties of iron-carbon alloys.