Modeling of innovation development in machine-building complex

Автор: Guly Ilya Mikhailovich, Dorogovtsev Anatoly Pavlovich

Журнал: Economic and Social Changes: Facts, Trends, Forecast @volnc-esc-en

Статья в выпуске: 4 (8) т.2, 2009 года.

Бесплатный доступ

Innovative level research of the Vologda region and its trades were realized at the article. It was displayed the strengths and weaknesses of outcomes the effectiveness of scientific-and-technological development of regional machinery, its recently meaning and trends. It was suggested multiple-factor innovative models, which furthers to growth the share of new and improved production manufactured by machine-building enterprises.

Innovative development in machine-building branch, multiple-factor regression innovative models

Короткий адрес: https://sciup.org/147223158

IDR: 147223158 | УДК: 338.445:621(470.12)

Текст научной статьи Modeling of innovation development in machine-building complex

UDC 338.445:621(470.12)

Modeling of innovation development in machine-building complex

Innovative level research of the Vologda region and its trades were realized at the article. It was displayed the strengths and weaknesses of outcomes the effectiveness of scientific-and-technological development of regional machinery, its recently meaning and trends. It was suggested multiple-factor innovative models, which furthers to growth the share of new and improved production manufactured by machine-building enterprises.

Innovative development in machine-building branch, multiple-factor regression innovative models.

Ilya M.

GULY

Senior lecturer, Economics and Management Chair,

Vologda State Technical University

Anatoly P.

DOROGOVTSEV

Corresponding member of the Russian Academy of Agricultural Sciences, Head of Economics and Management Chair, Vologda State Technical University

At present Russian economy is at the stage of comprehensive facilities in terms of it’s the most priority way of further strategic development realization – the way of proceeding along the path of innovative economic growth. All branches of economy both high-technology and traditional technology production long for innovative line transition. Innovative way of development is the most effective option of long-term sustainable economy development as well as pledge of the country’s gradual transition to new economic boundaries.

It is universally recognized that among the different economy branches machinery is the main springboard of its innovative reforms and faster technological progress. The branch is one of most science intensive and strategic significant. Necessary rise in production achievement and its competitiveness increase at the expense of transition to higher technical and technological development level depends on the branch’s development dynamic and progressive qualitative and quantitative changes.

The Vologda region machine-building complex includes three main activity categories: machinery and equipment production (more than 80% complex’s aggregate production volume), electrical equipment production, vehicles and equipment production. The share in regional industry dispatched production volume is 4%. There are more than 650 manufactures in the complex. The most major are close corporation “Vologda bearing factory” (frictionless bearings), Co Ltd “CCM-Tyazhmash” (metallurgical equipment maintenance, cast product, forged piece) and public corporation “Vologda optical-and – mechanical plant” (armaments and defense technology production). The major items of production are frictionless bearings, woodworkers, trolleybuses, technological equipment for agro-industrial complex, optical and mechanical, electronic devices, light-gauge construction buildings, enamel tableware as well different equipment maintenance and others.

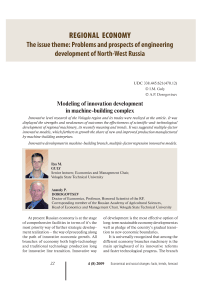

In 2008 physical production volume of the Vologda region machine-building enterprises increased by 12% against the previous year; whereas industrial recession was 4% (negative trends in economy). It should be noted that Russian particularly regional machine-building complex of late years has developed more dynamic then industry in whole.

In 2008 machine-building enterprises dispatched domestic manufactured wares to the amount of 18.4 billion rubles. Electric crane, machinery and equipment for livestock sector, low-voltage electrical equipment, complete transforming stations, chemical equipment and its spares, technological equipment for agricultural sector processing branches, trolleybuses production has increased over this period [1].

With moderate specific weight in production volume of regional industrial production (in 2008 – 5%) 20% of industrial personnel are employed at the branch. Table 1 gives indicators which define machine-building complex importance in regional industry.

Figure 1. Production volume dynamic of the Vologda region machine-building enterprises over 2000 – 2008 [5]

I—I Dispatched domestic manufactured wares volume, million rub.

Physical production volume index, item’s share to previous year

Note. Till 2004 inclusive – according to machinery and metal working branch; from 2005 – summation of three manufactures: machinery and equipment; electrical, electronics and optical equipment; vehicles and equipment.

Table 1. Branch’s share in the Vologda region industry, % [3]

|

Indicators |

Year |

||||||

|

2002 |

2003 |

2004 |

2005 |

2006 |

2007 |

2008 |

|

|

In dispatch of production volume |

6.2 |

6.4 |

5.6 |

5.8 |

4.0 |

5.3 |

5.0 |

|

In export volume |

0.7 |

0.6 |

0.5 |

0.4 |

0.5 |

0.5 |

0.3 |

|

In investment volume |

3.9 |

2.9 |

3.4 |

0.5 |

0.8 |

1.1 |

5.2 |

|

In long term assets |

6.6 |

6.4 |

5.4 |

4.8 |

3.0 |

2.6 |

2.9 |

|

In profit volume |

5.1 |

2.0 |

1.1 |

1.4 |

0.8 |

1.6 |

1.5 |

|

In number of workers |

17.8 |

19.1 |

18.0 |

18.0 |

19.0 |

18.0 |

20.1 |

|

In tax proceeds to all levels budgets |

12.9 |

8.2 |

5.0 |

5.0 |

7.8 |

6.4 |

d/n |

The branch is socially-significant: social stability in the region, personnel potential development, maintenance of a large number of workplaces (one fifth from employed in industry) depend on its welfare.

To realize machine-building complex contribution to innovative motion of the Vologda region it is necessary to analyze generation and know how implementation in regional economy as well as in its branches level state-of-the-art.

The first significant point is regional innovation level research. Regional innovation is the region’s ability to generate and implement innovative developments in its economic environment (on its territory) [4].

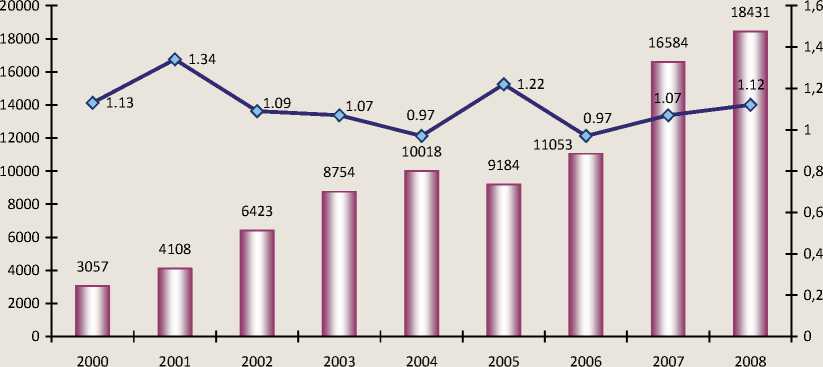

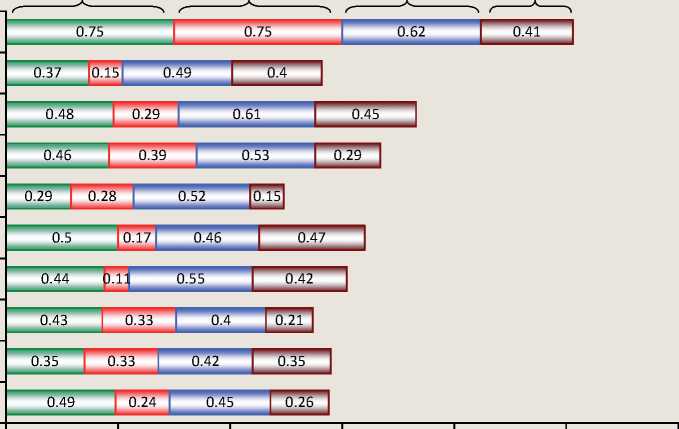

To understand the Vologda region existing positions in terms of innovation relative to other elements of the national economy the innovation development level is calculated by the strategic development Fund “The NorthWest” technique [2]. The technique is based on indicators which maximal reflect the object state, in terms of innovation process main stages attain-mentioned advantages: from human capital preparation to the creation, transfer and knowledge application and, ultimately, innovative products bringing to the consumer (fig. 2) .

Vologda region in terms of innovative development has the average position in the NWFD, ranking the 5th of the 10 regions of the federal district in 2007 and the 47th among the 79

Figure 2. Indicators of regional innovation index * [2]

-

1.1. Graduating postgraduate students and students ratio

-

1.2. Population size with academic degree (for 100 thousand people)

-

1.3. Share of graduating postgraduate students who defended academic degree

-

2.1. Research and development external costs (% in GRP)

-

2.2. Number of organizations carrying R&D (% in the total number of organizations)

-

2.3. Headcount of staff carrying R&D (for 10 thousand people)

(% in GRP)

-

4.1. Dispatched innovative production volume (% in total)

-

4.2. Information and telecommunication technologies costs – ICT(% in GRP)

-

4.3. Advanced manufacturing sciences volume

-

3.1. Number of granted patents

-

3.2. Specific weight of organizations carrying technological innovations

-

3.3. Technological innovations costs

-

1.4 .Share of population with higher education in the number of economically active population

-

1.5 . Employment in the manufacturing activity sector

* Regional innovation index is simple average of 4 innovative development intermediate indicators in every of 4 group. Intermediate indicators are by-turn simple average of formulaic particular innovation indicators: Irij = ( xirj - minxijr) /( max xirj - min xirj ) , where i – particular innovation nnn indicator ( ∑i = 14), j –order number of indicators’ group ( ∑j = 4), r – the region.

2003 2004 2005 2006 2007

Figure 3. The Vologda region innovative development level rating

studied Russian regions (fig. 3). The region has strong positions in the following stages of the innovative process: preparation of human capital, the innovative products output into the market (mainly towards to the relatively high share of innovative products and relatively large number of production technologies used in 2007). As for the other indicators – the phases of the innovation process – the region stands medium (transfer and application of knowledge) and even weaker position (the creation of new knowledge). The latter is a consequence of the fact that the region inferior to the innovation infrastructure development level (research organization, innovation funds, technology transfer centers, etc.).

Figure 4. Innovative development indexes’ value in groups according to innovative process stages in the regions of the NWFD (2007)

1 2 34

St. Petersburg

Pskov region

Novgorod region

Murmansk region

Leningrad region

Kaliningrad region

Vologda region

Arkhangelsk region

Republic of Komi

Republic of Karelia

00,511,522,53

Index’s value in every of 4 groups

-

□ 1. Human capital preparation

-

□ 3. Knowledge transfer and application

-

□ 2. New knowledge creation

-

□ 4. Innovative production marketing

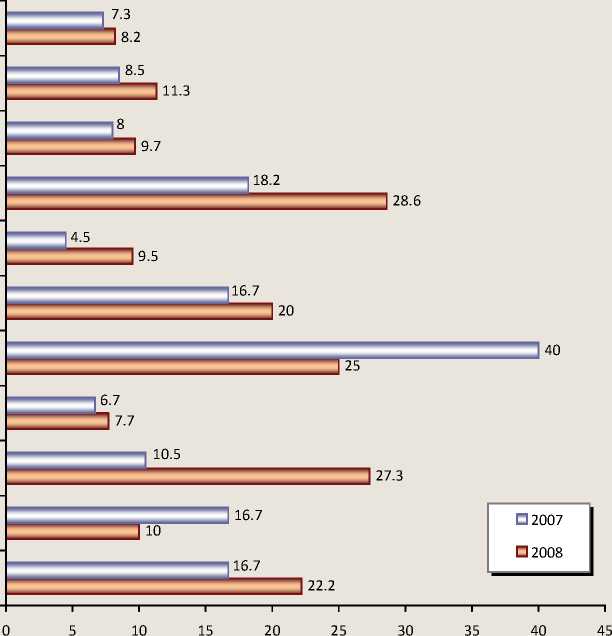

Figure 5. Innovation activity according to manner of manufacture in the Vologda region [7]

Industry, total

Manufacturing activities

Chemical manufacture

Metallurgical manufacture

Metal work manufacture

Textile and clothing manufacture

Other manufactures including furniture production

Wood processing, woodwork manufacture

Machinery and equipment manufacture

Food production including drinks

Computer engineering and IT activity

To identify the innovative growth sources of the studied region currently, innovative activity effectiveness in the manufacturing sector of the Vologda region should be characterized in the article.

The most important indicators used in assessing the intensity of the innovative developments commissioning include:

-

• innovation activity level – the share of enterprises (organizations) which are engaged in innovation, in total number of studied by the sate statistics bodies’ enterprises;

-

• the share of innovative products in total;

-

• technological innovation costs and their share in the dispatched products volume;

-

• number of personnel engaged in research and development;

-

• number of patents’ applications, as well as number of patents granted for the appointed period.

In 2008 the most innovatively active enterprises were textile and clothing manufacture (28.6%), metallurgy (25%) and machinebuilding ones (machinery and equipment production – 27.3%; fig. 5) . Thus the regional machine-building complex is marked by a relatively high level of innovative activity, which is a prerequisite for its transformation into a sustainable innovative point of growth.

In 2008, the innovative products share among the industrial sector organizations was the highest in enterprises producing machinery and equipment, having reached a record value of 33.8% during recent years (fig. 6) . Innovations in and around new types of products were implemented in PC “Trans-Alfa Electro” (articulated trolley bus with low floor production, Euro design), JSC “Vologda Bearing Factory” (bearings for rail trans-port), PC “Vologda Optical – and Mechanical – Plant” (gyros,

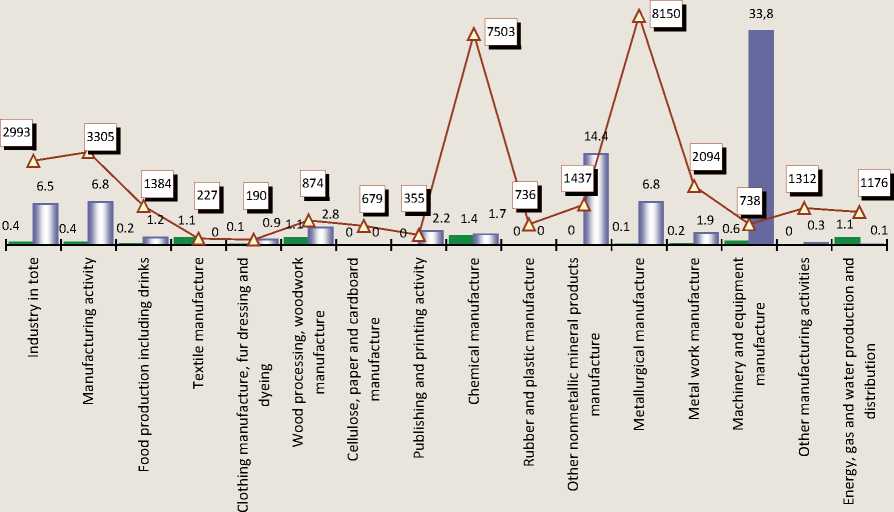

Figure 6. Indicators of productive efficiency and innovative activity in the Vologda region industry in 2008 [7]

^™ Costs on technological innovations, % in annual production volum

I—I Innovative production volume, % in total volume

Labour efficiency in 2008, thousand rubles/ people in a year

a thermal imaging sights), PC “Vologda Machine-Building Factory” (modern urban buses models), PC “Electrotechmash” (furniture and pipe products), JSC “Vologda Electromechanical Plant” (high-voltage electric-parameter equipment) and other enterprises.

Metallurgical production enterprises (6.8%) and other nonmetallic mineral products production (14.4%) have achieved high proportion of innovative products. In particular innovations are intensively implemented in the enterprises manufacturing building materials and structures: modern composite materials

(expanded clay brick, production of foam concrete, polystyrene foam and others; fig. 6) . In 2008 regional industry machine building enterprises had the highest proportion of innovative products (tabl. 2) .

Figure 7 characterizes the degree use of intellectual human capital in the regional industry sectors. Metallurgical industry (the company holding “Severstalgrupp”) and chemical manufacture (vertically-integrated group “Fosagro”) are staffed by technical experts the most significant.

The share of staff engaged in research and development in the machine building field,

Table 2. Innovative product’s proportion, % [7]

|

Economic sectors |

Value |

|

|

2006 – 2008, on average |

2008 |

|

|

Industry |

6.1 |

6.5 |

|

Machine building |

12.3 |

30.4 |

|

In 2008 according to Rosstat data PLC “CCM-Tyazhmash”, PLC “Spetzmontazh”, PC “Domnaremont”, PLC “Prokatmontazh-5”, CC “Firma Stoik”, PC “ Cherepovetz autoequipment plant “Red star”, PC “Cherepovetz foundry” had the most high innovative production volumes. |

||

Figure 7. Number of workers engaged in research and development in the Vologda region and Russia industry in 2007, number of people per 10 thousand employed [134]

Industry, total

Manufacturing activities

Food production including drinks

Textile and clothing manufacture

Wood processing, woodwork manufacture

Cellulose, paper, cardboard manufacture

Publishing and printing activities

Chemical manufacture

Rubber and plastic manufacture

Other nonmetallic mineral products manufacture

Metallurgical manufacture

Metal work manufacture

Machine building (including 3 manufactures)

Other manufacturing activities

Energy, gas and water production and distribution

] 233

0 50 100 150 200 250

□ Vologda region □ Russia in comparison with that one of the country, is behind more than 3 times. This indicates a shortage of highly qualified personnel, designed to strengthen the innovative changes in the regional machine-building business systematically. This problem is caused on many enterprises by systematically involved in research and design development units’ absence, the lack of sectoral research institutes, design offices, laboratories, as well as modern forms of innovation infrastructure: specialized technology parks, centers of technological development, production incubators for small enterprises, subcontracting and support inter-enterprise cooperation centers.

There is a specified correlation between sectoral focus of in-house design patenting with indicators of innovation activity level. Ironworks and machine building enterprises are in the lead by the number of applications for patents (inventions, utility models, and industrial designs; tabl. 3) .

Considering the importance of engineering companies growth innovation model, the key points that will help to strengthen the technological factors in the short and long term should be noted (tabl. 4) .

One of the main tasks to overcome the negative aspects of machine-building complex innovation development is target characteris-

Table 3. Number of patent filed applications in Vologda region industry [7]

|

Types of industrial activity |

Year |

|

|

2007 |

2008 |

|

|

1. Food production |

3 |

- |

|

2. Metallurgical manufacture |

49 |

49 |

|

3. Electrical equipment, electronics and optical equipment manufacture |

27 |

27 |

|

4. Transport vehicles and equipment manufacture |

1 |

2 |

|

5. Energy, gas and water production and distribution |

- |

1 |

|

Total |

80 |

79 |

Table 4. Key points influencing the innovative process by processing factor growth implementing under present-day conditions [2]

|

Factor |

Innovative development items in the past |

Innovative development items at present |

|

1. Locating (territorial aspect) |

According to regions’ sectoral specialization |

According to territory’s opportunity for specific activity |

|

2. Scale |

Big research institutions |

Several manufacturable sectors, high potential of clustering |

|

3. Environment |

Closed, inertial environment of the companies |

Opened and various urban and regional environment. High migration level, many students |

|

4. Personnel training |

Fundamental knowledge orientation |

Cultural policy oriented to technological activity practice |

|

5. Authorities support |

General programmes of innovations’ support |

Stable conditions’ creation for specific innovative activity |

|

6. Infrastructure |

Design departments under the plants, sectoral research institutions, closed administrative and territorial institutions (CATI) |

Techno parks, corporations’ labs, innovative higher education establishments, transfer technology centers, innovative technological development centers (ITDC) |

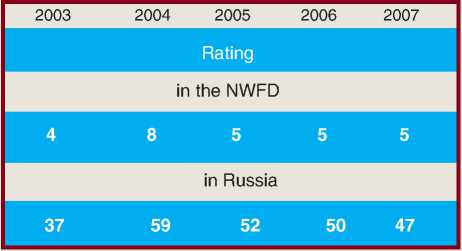

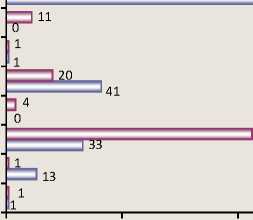

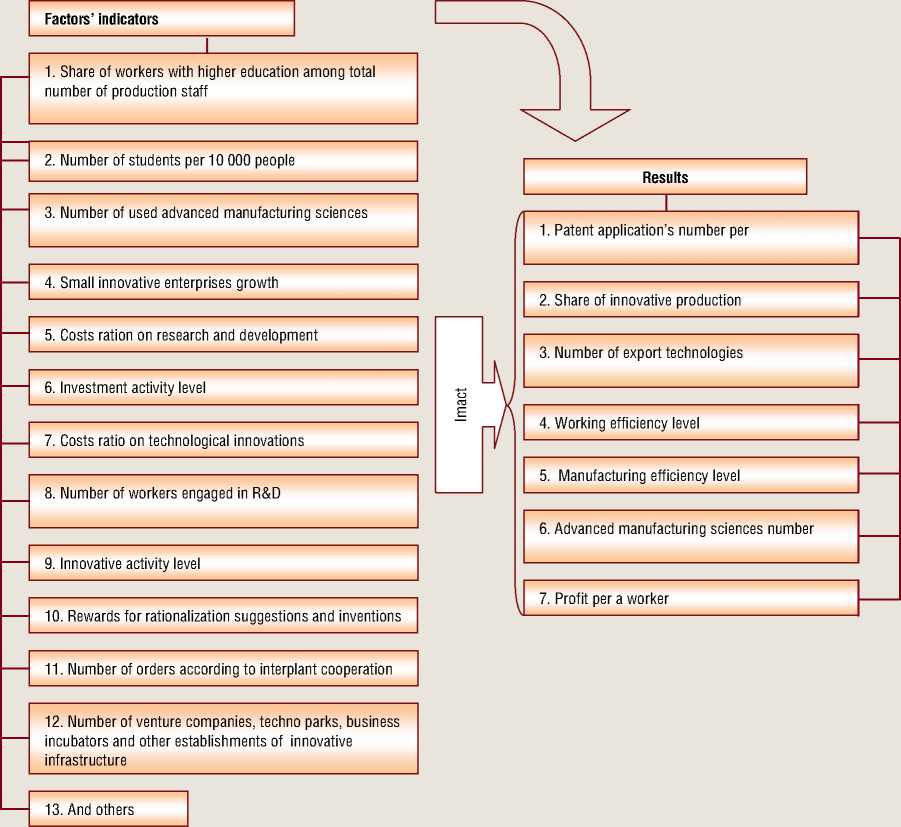

Figure 8. Regression model indicators

tics development, the achievement of which would significantly increase their innovation level. Thereupon the building of economic and mathematical models of engineering industry innovation and technological growth is very important. It is needed to identify cause-and-effect relations revealing the most important result indicator and other factors, which influence the most significantly on it. A particularly important and, at the same time, complex task is to identify the main target innovative landmark and indicators that will have the biggest influence on it. Figure 8 shows the systematization result of factor and dependent variables that will be the starting point the constructed regression model.

By further selection of factors for inclusion into the model, screening of indicators with an implicit correlation, as well as those factors on which there is no statistical database analysis (e.g. the application complexity of indicators such as enterprises’ cooperation, subcontracting relationships, joint R&D), power dependence is proposed, as the most preferable for the preparation of multifactor models of indicators having different quantitative and qualitative content (formula 1) .

y — a• X 1 b 1 • x 2 b 2 • x 3 b 3 • ... x „b ” (1)

where a; b 1 ; b 2 ; b 3 ; ...; b n – multiple regression equation characteristics.

As a criterion function (yx) indicator of innovative product proportion in total capacity of released (shipped) product in machine building complex is selected. Factor variables xi are represented by the following indicators:

x 1 – the number of employees engaged in research and development, per 10 thousand personnel;

x 2 – costs on technological innovation in the comparable prices of 2007 per an average workers on payroll, rub./pers.;

x 3 – organizations’ innovation activity level,%;

x 4 – the proportion of workers with higher education,%;

x 5 – rewards for inventions and rationalization suggestions in the comparable prices of 2007 per an average workers on payroll, rub./pers.

Federal Service state statistics data describing the performance of machine-building complex were the background information [3]. As a result of multiple regression equation characteristics evaluation the following dependence of innovative product share on the above-mentioned factors is yielded (formula 2) :

0.44 0.10 0.05 0.20 0.25

У х — 0.08 X i X 2 X з X 4 X 5 (2)

The found mathematical relationship shows that the share of machine-building complex innovative products can be increased by:

Table 5. Results of machine building complex’s innovative development model solution*

|

Year |

Innovative product specific gravity, % (y) |

Factors’ value, in relevant units |

yx value according to regression equation, % |

||||

|

x 1 |

x 2 |

x 3 |

x 4 |

x 5 |

|||

|

1999 |

7.9 |

77 |

4363.8 |

12.8 |

15.5 |

74 |

7.0 |

|

2000 |

9.0 |

78 |

5504.6 |

17.2 |

16.7 |

70 |

7.3 |

|

2001 |

9.2 |

79 |

8398.3 |

15.2 |

18.6 |

90 |

8.3 |

|

2002 |

6.9 |

81 |

10769.3 |

19.5 |

17.7 |

101 |

8.8 |

|

2003 |

7.6 |

83 |

12929.9 |

20.6 |

18.1 |

120 |

9.6 |

|

2004 |

10.1 |

83 |

11698.9 |

21.3 |

19.2 |

138 |

9.9 |

|

2005 |

12.3 |

103 |

12735.7 |

22.1 |

18.8 |

153 |

11.3 |

|

2006 |

12.0 |

106 |

18438.6 |

22.4 |

19.5 |

117 |

11.2 |

|

2007 |

11.2 |

106 |

16919.4 |

22.6 |

22.4 |

167 |

12.4 |

|

* Russia’s machine building complex performances are included owing to statistics data for stable time series construction. Note: based on [3]. |

|||||||

Table 6. Vologda region machine building complex’s parameters designing according to regression model

|

Indicators |

2007 (fact) |

Plan |

|

Number of workers engaged in R&D per 10 thousand personal |

33 |

200 |

|

Costs on technological innovation in the comparable prices of 2007 per an average workers on payroll, rub./pers . |

1,780 |

25,000 |

|

organizations’ innovation activity level, % |

12.1 |

45 |

|

The proportion of workers with higher education,% |

14.5 |

30 |

|

Rewards for inventions and rationalization suggestions in the comparable prices of 2007 per an average workers on payroll, rub./person |

188 |

500 |

|

Innovative product proportion in total capacity, % (fact and plan value) |

12.3 |

24.8 |

-

♦ increasing proportion of staff engaged in research and development (with its growth by 1% the share of innovative products increases by 0.44%);

-

♦ improving costs’ structure (increasing the unit cost on technological innovations per an employee by 1% leads to a corresponding increase of the innovative products share by 0.1%);

-

♦ increasing the share of workers with higher education, the level of innovative proposals financial motivation, as well as the enterprises’ innovative activity (the share of innovative products with an increase in these factors by 1% increases respectively by 0.20; 0.25 and 0.05%).

Evaluation of regression equation’s parameters importance gives an indication of a sufficiently large degree of relation closeness (coefficient of multiple determinants is 0.9, the value of the Fisher criterion is also high – 6.7).

Using a regression model of machine building complex’s innovation development will formulate proposals and recommendations about future development parameters for an acceptable target level of innovations. Substituting in the model improved values of the variables we can numerically calculate the interventions’ effectiveness focused on the machine building transition to innovation model of economic growth. Table 6 shows the current and target regional machine building development parameters (targets have been selected by comparing the complex’s achievements in 2007 with the average performances of leading regions in the field of innovation development in Russia, as well as developed countries).

According to table 6, the share of regional machine building complex’s innovative products by achieving target values inherent in developed countries – leaders in technological development will increase up to 24.8% according to the forecasts calculated using the obtained model. Currently the number of employees engaged in research and development in machine-building complex of the country is average 106 persons per 10 thousand workers, in Vologda region – 33.

The basis for the industry's transition to the innovative model of development is qualified engineers and technicians attraction efforts and increasing the share of workers with higher education. To increase the volume and share of innovative products it is necessary to change approaches to innovation activity financing in the enterprises. The transition from financing on leftovers accompanied by low level of innovation costs at present to target investment in the f new products development, modernization, new equipment purchase will help to achieve acceptably high level of machine building innovation (tabl. 6) .

Presented in the article an economic model and its further application in practice will help to strengthen the processes of in- novation and technological development and the industry’s modernization, understanding of the investigated factors’ importance in the efficiency increasing by business representa- tives. This will be a factor in strategic stability strengthening and global competitiveness of machine-building business as well as its transition to a sustainable innovation-based growth.

Список литературы Modeling of innovation development in machine-building complex

- Machine building enterprises in Vologda region made production of 16 billion rubles in 2007 . -Mode of access: http://www.mashportal.ru

- Movilly, V. Scientific and technological forsyth of the RF: Regional aspects. Some conclusions of research /V. Movilly//The Russian venture forum, St. Petersburg, October, 10th, 2007. -Mode of access: www.csr-nw.ru

- Federal service of the RF state statistics official data: central registration depository of statistics . -Mode of access:/www.gks.ru

- Republic of Kazakhstan regions’ competitiveness evaluation. Regions’ rating//Investigation report. -Kazakhstan: the Center of marketing and analytical researches, 2006. -22 p.

- Machine and equipment manufacture in Vologda region: coll. of stat./Vologdastat, 2008. -58 p.

- Russia’s regions: social and economic performances. 2008: coll. of stat./Rosstat, 2008. -999 p.

- State statistics monitoring of the Vologda region enterprises and organizations results in 2006, 2007, 2008 at a set standard № 4-innovation “information about organization’s innovative activity”. -Vologda: Vologdastat, 2008.