Nanomodification is an effective method for forming the structure of the weld metal. Part II. Increasing the efficiency of nanoinoculators in the welding bath

Автор: Boldyrev A.M., Sizintsev S.V., Sannikov V.G., Pershin V.F.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanotechnologies and nanomaterials

Статья в выпуске: 4 Vol.12, 2020 года.

Бесплатный доступ

The short-term existence of the melt in the weld pool and its overheating, a large temperature gradient near the interface and two-dimensional crystallization centers, in the form of fused grains at the weld pool boundary, reduce the probability and rate of formation of crystallization centers in the liquid phase. This leads to the formation of a coarse-grained columnar structure of the weld metal, which, in combination with defects arising during crystallization, is less ductile than the fine-grained rolled metal being welded, and often causes brittle fracture of the structure. Therefore, obtaining a fine-grained structure of the weld metal is a constant problem in the welding industry. It is now generally accepted that the most effective way to obtain a fine-grained weld metal structure is to modify the weld pool. At the same time, micro- or nanoparticles of refractory metals or their chemical compounds (inoculators) are introduced into the weld pool from the outside, as ready-made crystallization centers. In a superheated melt, the rate of formation of crystallization centers, due to the deactivation of particles, decreases. It can be increased in two ways: by slowing down the decontamination process and by increasing the number of modifying particles introduced into the weld pool. The paper analyzes the factors that determine the modifying activity of inoculators and methods for maintaining this activity in the weld pool. To ensure high activity of the inoculator, it is necessary to reduce the time of its residence in the hightemperature zone of the weld pool; the material of the inoculator should have high values of temperature and heats of fusion, but lower values of thermal and thermal diffusivity. A decrease in the rate of heating and melting of the inoculator particles is achieved by introducing them into the weld pool, by passing the arc column and the high-temperature zone of the bath, in combination with metal particulates that act as microcoolers and means of transporting the inoculator to the tail of the bath. Nanoscale inoculators have a high thermodynamic potential and the associated high nucleating activity. Inclusions of oxides, carbides and nitrides, on the basis of which crystallization centers are formed, in the solidified metal have strong interatomic bonds with the matrix, and due to the fact that the coefficients of their thermal expansion are an order of magnitude lower than those of the matrix, after cooling the metal, they experience all-round compression. Therefore, such inclusions are not dangerous, are not concentrators of tensile stresses and centers of crack initiation. It is experimentally shown in this work that the introduction of carbon nanotubes with a specific surface area of more than 270 m2/g into the weld pool contributes to the formation of a fine-grained structure of the weld metal.

Nanomodification of the weld metal, preservation of the modifying activity of inoculators in the weld pool, modification with nanocarbon tubes

Короткий адрес: https://sciup.org/142226966

IDR: 142226966 | DOI: 10.15828/2075-8545-2020-12-4-197-203

Текст научной статьи Nanomodification is an effective method for forming the structure of the weld metal. Part II. Increasing the efficiency of nanoinoculators in the welding bath

F eatures of the conditions of crystallization of the weld pool: overheating of the melt, a large temperature gradient near the interface and two-dimensional crystallization centers, in the form of semi-melted grains at the pool boundary, reduce the probability of the formation of crystallization centers in the liquid phase, and cause the formation of a coarse-grained columnar structure in the weld metal. Such a structure in combination with defects arising during crystallization is less ductile than the fine-grained rolled metal being welded and, often, is the cause of brittle fracture of structures. Therefore, obtaining a fine-grained structure of the weld metal is a constant problem in the welding industry. It is now generally accepted that the most effective and economical way to obtain a fine-grained weld metal structure is to modify the weld pool [1].

Modification is the process of introducing into the weld pool a small amount of modifiers-substances that, without changing the chemical composition, slow down the growth of crystals (inhibitors), or, as readymade crystallization centers, increase the rate of nucleation (inoculators).

Inhibitors – surfactants (sfs), being deposited on the faces of a growing crystal, slow down or stop its growth for some time, during which, due to continuous heat removal, supercooling of the melt and spontaneous endogenous nucleation of new crystals occur. Modification of the weld pool with inhibitors has not yet found application in the welding industry because of the danger of hot cracks in the adsorbed intergranular layers. Therefore, to obtain a fine-grained metal structure under conditions of fusion welding (arc, electronbeam, laser), refractory inoculators are mainly used. However, due to the specific conditions of solidification of the weld pool, the modification of the metal in this case turned out to be less effective than during casting. This is due to the fact that when casting, the melt is usually overheated before pouring by only 5–8% above the liquidus temperature. And the theory of modification and the practice of foundry production have shown that with an increase in the overheating of the melt, a larger grain is formed in the casting, because the inoculators introduced into the melt lose their nucleating ability (deactivate) with increasing temperature [2, 3]. Under welding conditions, overheating of the melt in the weld pool is 2–3 times higher than during casting (16–20% of the liquidus temperature). In this re-gard, one of the main problems of obtaining a fine-grained structure of the weld is the problem of maintaining the modifying activity of inoculators in the weld pool.

Factors determining activity of the inoculator in the welding bath

Not all inoculant particles introduced into the weld pool become crystallization centers. It depends on the temperature of the weld pool, the residence time of the particle in the hazardous high-temperature zone, the degree of structural and dimensional conformity of its crystallizing metal. Therefore, a probabilistic approach is required to the question of the nucleation of new grains when introducing inoculators into the melt.

If N particles of the inoculator are introduced per unit volume of the melt per second, and the probability that they can become the nuclei of new grains is equal to P N , then the rate of nucleation n in this case will be equal to the product of these quantities [1/m3•s]:

n = N • P N . (1)

Hence it follows that the rate of nucleation in the weld pool can be increased in two ways:

1 – an increase in the number of modifying particles N , introduced, for example, in 1 second into the bath; 2 – increasing or maintaining the modifying activity of these particles, i.e. increased likelihood P N (0 ≤ P N ≤1).

The modification of the crystallizing metal, in contrast to alloying, does not change the chemical composition of the crystallizing alloy. Therefore, in order to increase the number of modifying particles N while the chemical composition of the alloy remains unchanged, it is necessary to reduce their size. In this case, not only the number of possible crystallization centers per unit volume of the liquid phase increases, but also due to an increase in the specific surface area of the particle, the probability P N that the particle becomes an active germ of a new grain. For example, when ceramic particles with a radius of 0.05 µm (50 nm) are introduced into the melt in steel castings, a grain is obtained that is 1.5–2 times finer than in castings without a modifier. And the use of particles with a radius of the order of 0.005 microns (5 nm) provides structure refinement by 4–8 times [4].

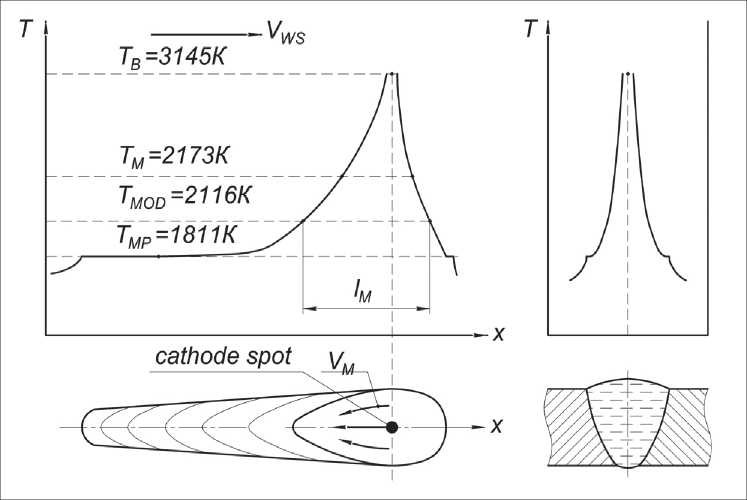

The modifying particle on its way to the crystallization zone, moving from the head of the bath with melt flows, passes through sections with different temperatures. For a while τ MOD , it is in the danger zone l M , where the melt temperature exceeds the melting temperature of the particle Т MOD and where deactivation processes proceed vigorously, as a result of which the surface energy of the particle decreases. When the particle is completely melted, the interface disappears and its modifying role is completely lost. Time τ MOD determined by the length l M , the rate of melt flows from the head of the bath to the tail V M and welding speed V WS (fig.)

τ MOD = l M / V WS + V M . (2)

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS

Particle deactivation time τ D can be simplified as the sum of three successive processes [1]:

τ D = τ 1 + τ 2 + τ 3,

where τ 1 – heating time of the modifying particle from the initial temperature T 0 to the melting point of the in-oculator Т MOD ; τ 2 and τ 3 – time of its melting and dissolution in the melt.

Obviously, in order to preserve the modifying activity of a particle, it is necessary that the time of its stay in the hazardous zone τ MOD is less than the deactivation time τ D :

of fusion, density, thermal and thermal diffusivity, initial temperature and overheating of the modifier; С C and С S – concentration and limiting solubility of the modifier in the melt.

If we assume that the particle is insoluble in the melt, and the initial tem-perature of the particle Т 0 = 0, then condition (4) takes the following form:

lM

V „+У

WS M

< r 2 • ( k 1 • TMOD + k 2 • L MOD " P MOD ) (6)

α MOD ⋅ ∆ T MOD ∆ T MOD ⋅ λ MOD

τ MOD < τ D .

Based on the analysis of the heating, melting and dissolution time of a spherical modifying particle with a radius r in the melt with temperature Т M , the particle deactivation time can be expressed as follows:

τ D

k 1 " r " ( TMOD T0 ) + k 2 " r " L MOD " P MOD α MOD ⋅ ∆ T MOD ∆ T MOD ⋅ λ MOD

+

+

k 3 • r1 • CC

D ⋅ CS

where k 1, k 2, k 3 – dimensionless coefficients; L MOD , ρ MOD , λ MOD , α MOD , Т 0 and ∆ Т MOD – respectively – heat

It follows from inequality (6) that the activity of the modifying particle in the weld pool depends on the technological parameters of the welding process (left side) and on its natural properties (right side of the inequality). To increase the activity of the modifier in the weld pool, it is necessary to strive to reduce the left and increase the right parts of the inequality.

The technological parameters that can be used to reduce the residence time of the particle in the hazardous zone of the melt include: the speed of welding and the movement of the particle into the tail part V WS and V M ; length of dangerous overheated zone l M and melt temperature Т M , determining the amount of overheating ∆ Т MOD = Т M – Т MOD . From inequality (6) it follows that to reduce the residence time of the inoculator particle in the overheated zone, it is necessary to weld at maximum speed and take measures to reduce the length l M and overheating ∆ Т MOD .

Fig. Change in the temperature of the melt along the axis of the weld pool during welding of low-carbon steel with a metal-chemical ad-ditive (modifier TiO2) TB , ТM , ТMOD and ТMP – boiling point of base metal, average melt temperature, melting point of modifier and melting point of base metal. lM – modifier overheat zone length

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS

Particle speed with melt flows V M increases proportional to the welding speed, in addition, it can be increased by external action on the weld pool (current ripple, external magnetic field, arc oscillations, etc.).

Zone length l M with a temperature exceeding the melting point of the particle depends on the method and point of introduction of the particle into the bath. The introduction of an inoculator into the tail of the weld pool, bypassing the arc column, minimizes the value of l M and the time of its stay in the danger zone τ MOD .

It was noted above that a decrease in the size of a particle, and the associated increase in the thermodynamic potential, sharply increases its nucleation activity. But, on the other hand, the time of heating and melting of a particle, according to (5), is proportional to the square of the size of this particle. And this means that the finer the particle, the higher the rate of its heating and melting, the faster the probability of the appearance of a new crystallization center in the melt will disappear. In addition, the high surface energy of fine particles contributes to clumping, and the low specific gravity characteristic of oxides, carbides and nitrides used in the modification of steels leads to their floatation and prevents their uniform distribution in the melt. Therefore, the direct introduction of the inoculator into the weld pool is ineffective.

To ensure high modifying activity of the inoculator particles, it is proposed to introduce them into the weld pool in combination with macroparticles made of metal of the same or similar composition as the metal being welded. Such particulates act as microcoolers, serve as a means of delivering the inoculant to the crystallization zone, lower the melt temperature, and prevent clumping and floating of modifying nanoparticles [5]. This idea was developed and applied in practice in submerged-arc welding with the so-called metal-chemical additive (MHP) [6]. MHP is a granular additive made from wire chips (granulate), which passed mechanosynthesis together with the particles of the inoculator in a high-energy planetary mill. As a result of such processing, the proportion of particles of nanoscale order increases, and due to strong chemical bonds, heat transfer to granules improves. Welding of butt seams is carried out along the MHP layer, poured into the joint gap, which ensures the introduction of modifying particles into the weld pool, bypassing the arc column.

Good results in the modification of the weld metal were obtained when the inoculator was introduced through an additional hot wire (DHW) into the tail part of the weld pool [7].

Methods for introducing inoculators, bypassing the arc column, although they allow obtaining welded joints with high indicators of plasticity and toughness of the weld metal, have a number of disadvantages. Welding on the MHP layer cannot be performed in other spatial positions, except for the lower one, and the introduction of inoculators through the DGP requires two sources of electrical energy and two wire feeders. In addition, for high accuracy, the point of entry of additional wire into the pool, high synchronization of the wire feed mechanisms and the movement of the welding head is required. Mismatching will lead to burning or «freezing» of the wire.

In our opinion, further research should be focused on finding ways to modify the weld metal through an electrode wire. One of the promising directions in solving this problem is the use of modern digital inverter power supplies with ample opportunities to control the process of transferring electrode metal and preserve the modifying activity of inoculators. The program of operation of such sources allows one to drop from the electrode single or a series of drops of a given size, at specified time intervals, to regulate the temperature and residence time of drops on the electrode, the speed and time of their flight through the arc, etc. [8].

The natural properties of the modifier determine the time of retention of its activity in the weld pool. They must be taken into account when choosing a modifier. First of all, there should be an isomorphism between the crystal lattices of the modifier and the base metal (Dankov’s rule on structural and dimensional compliance). Modifiers with the same type and close size parameters of the lattices have an advantage. In addition, the criteria for the suitability of the modifier should be its thermophysical properties. Modifiers with high values of temperature and heat of fusion, but with lower thermal conductivity and thermal diffusivity, retain their modifying activity in the weld pool longer and, therefore, are preferable.

The inoculators introduced into the weld pool, being the centers of crystallization, remain in the weld in the form of non-metallic inclusions, which, from the point of view of fracture mechanics, are stress concentrators and centers of crack initiation. Therefore, all foreign inclusions in the seam, until recently, were considered harmful. Currently, the assessment of the role of inclusions in the metal is approached selectively.

Of course, inclusions that violate the continuity of the metal (slag particles, gas cavities and pores), or reduce the forces of interatomic bonds at grain boundaries, such as S and P, are harmful. And inclusions - centers of crystallization, are currently considered as one of the control levers for the formation of the optimal microstructure of crystallizing metal [9, 10]. First, due to the small size of the inoculant particles, inclusions formed on their basis are less dangerous as stress concentrators. Secondly, the isomorphism of their crystal lattices with the matrix provides a high level of interaction forces at the interface. And due to the fact that the coefficient of thermal shrinkage of oxides, carbides, nitrides and other nonmetallic

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS inclusions is several times less than that of the matrix in the cooled metal, they will experience all-round compression. Therefore, under tensile stresses, a rupture at the interface is less likely.

Prospects for nanomodification of welded joints with carbon nanotubes

Nanomodification of the weld pool with carbon nanotubes (CNTs) can become a new direction of oxide metallurgy in the fight against brittle fractures of building metal structures. The unique properties of CNTs, such as a fantastically huge specific surface area (up to 2000 m2/g), testifies to their colossal adsorption capacity and refractoriness (up to 3000–4000oС), providing the presence of a CNT-melt interface [11], suggest the possibility of using CNTs as active inoculators in the weld pool.

At present, at the State Technical Universities of Voronezh (VSTU) and Tambov (TSTU), joint research is being conducted on modifying the weld metal with carbon nanotubes in arc welding of steels. Carbon nanotubes of the Taunit-M series (outer and inner diameters, respectively, 10–30 and 5–15 nm, length ≥2 µm, specific surface area ≥270 m2/g) were used as inoculators, developed and produced at OOO NanoTechCenter at TSTU, bulk density 0.025–0.06 g/cm3).

The modifying activity of Taunit-M CNTs was compared with the activity of known inoculators used in welding steels: TiO2 – average particle size 374 nm, melting temperature 1843oC, density 4.05 g/cm3 and Al2O3 – average particle size 141.8 nm, temperature melting point 2050oC, density 4.23 g/cm3.

Specimens 300×250×10 mm of steel 09G2S were butt-welded in one pass by automatic submerged arc welding AN-47. Plates were collected with a gap 6+2 mm. A granular metallochemical additive (MHP) from wire chips was poured into the gap ∅ 2,5×1,5 and the investigational inoculant synthesized in a planetary mill. Welding modes: constant welding current, reverse polarity –

650–750 A; arc voltage 36–38 V; welding speed 18 m/h; wire feed speed Sv08GA ∅ 4 mm – 85 m/hr.

Evaluation of the effectiveness of inoculators in grinding grain was given on the basis of counting the number of grains in photographs of the metal microstructure in the center of the cross-section of the weld. The counting of grains was carried out in accordance with STST 5639-82 on the area of the section bounded by a circle ∅ 0,798 mm, which at ×100 magnification in the photograph corresponded to a circle ∅ 79,8 mm. Count the number of whole grains inside the circle n 1 and crossed by its border n 2. The total number of grains in the controlled area was calculated n ∑ = n 1+ n 2/2; average grain size da and the relative values of grain grinding in the seam by the amount n ∑/ n 0 and medium size d a / d 0 grains ( n 0 and d 0 – the number of grains and their average size in a seam made without a modifier).

The results of measurements and calculations are presented in the table.

The results obtained indicate that TiO2, Al2O3 and Taunit-M, introduced into the weld pool, are active modifiers, which almost doubled the number of crystallization centers. The greatest modifying effect was obtained when Al2O3 was introduced into the weld pool. Taunit-M and titanium dioxide showed approximately the same results in terms of modifying activity.

It should be noted that the given comparative quantitative assessment of the activity of inoculators is very rough, since the equality of the conditions of their interaction with the melt (inequality of particle sizes and concentration, adhesion forces with the granulate, etc.) is not maintained. This experiment searches, allowing to confirm or disprove the possibility of CNTs to influence the process of crystallization and formation of the weld metal structure. The experimental results allow us to conclude that the introduction of carbon nanotubes into the weld pool contributes to the formation of a fine-grained structure of the weld metal, and research in the field of using such nanoparticles to improve the structure and properties of welded joints is relevant and promising.

Table

|

Inoculator |

Number of grains, pcs |

Grain size, mm |

Relative fineness |

|||

|

n1 |

n2 |

n∑ |

d a |

n∑/n0 |

da/d0 |

|

|

without inocul. |

148 |

49 |

173 |

0.054 |

1 |

1 |

|

TiO2 |

307 |

49 |

332 |

0.039 |

1.81 |

1.38 |

|

Al 2 O 3 |

372 |

54 |

399 |

0.035 |

2.2 |

1.54 |

|

Taunite-М |

308 |

64 |

340 |

0.038 |

1.85 |

1.42 |

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS

CONCLUSIONS

-

1. Nanomodification of the weld pool, today, is the most effective way to obtain a fine-grained structure of the welded seam during factory and assembly welding of large-sized structures that are not subjected to subsequent heat treatment.

-

2. To maintain the modifying activity of the inoculator particles, it is necessary to reduce the time of their stay in the high-temperature zone, and the material of the particles must have high values of temperature and heats of fusion, but lower thermal conductivity and thermal diffusivity.

-

3. Inclusions of oxides, carbides and nitrides, on the basis of which crystallization centers are formed, in the solidified metal have strong interatomic bonds with the matrix, and due to the fact that the coefficients of their thermal expansion are an order of magnitude lower than those of the matrix, after cooling the metal, they undergo a comprehensive compression. Therefore, such inclusions are not dangerous, they are not tensile stress concentrates and crack initiation sites.

-

4. It has been shown experimentally that the introduction of CNTs into the weld pool as inoculators promotes the formation of a fine-grained structure of the weld metal.

Part I of the paper «Nanomodification is an effective method for forming the structure of the weld metal» by Boldyrev A.M., Sizintsev S.V., Sannikov V.G., Pershin V.F. has been published in the issue 3/2020 of the journal «Nanotechnologies in Construction».

Список литературы Nanomodification is an effective method for forming the structure of the weld metal. Part II. Increasing the efficiency of nanoinoculators in the welding bath

- Boldyrev A.M., Grigorash V.V. Problems of micro- and nano-modification of seams during welding of building metal structures. Nanotechnologies in Сonstruction. 2011; 3(3): 42-52. Available from: http://nanobuild.ru/ru_RU/journal/Nanobuild_3_2011_RUS.pdf [Accessed 14th August 2020]. (In Russian).

- Balandin G.F. Formation of the crystal structure of castings. Moscow: Mechanical engineering; 1973. (In Russian).

- Dankov P.A. Crystal-chemical mechanism of interaction of the crystal surface with foreign ele-mentary particles. Physical chemistry. 1946;8: 853-867. (In Russian).

- Kalinina A.P., Cherepanov A.N., Poluboyarov V.A., Korotaeva Z.A. Mathematical model of nu-cleation in liquid metals on ultradispersed ceramic particles. Journal of Physical Chemistry. 2001; 75(2): 275-281. (In Russian).

- Boldyrev A.M., Petrov A.S., Dorofeev E.B. Method of electric arc welding. Invention certificate USSR No. 584996 Cl V 23 K 9/00, 17.04.76. (In Russian).

- Boldyrev A.M., Grigorash V.V., Gushchin D.A., Grebenchuk V.G. Investigation of the adhesion strength of particles in a modifying additive for submerged arc welding of bridge structures. Nano-technologies in Сonstruction. 2012;4(2): 56–69. Available from: http://nanobuild.ru/ru_RU/journal/Nanobuild_2_2012_RUS.pdf. [Accessed 14th August 2020]. (In Russian).

- Aleshin N.P., Yakushin B.F., Kobernik N.V., Kilev V.S. Improvement of the process of cold-resistant steels by optimizing the balance of thermal energy of an arc source. Welding production. 2018;10: 3-13. (In Russian).

- Fedyukin S.V., Karasev M.V., Kolodyazhny D.Yu., Zhuk V.V. A new generation of industrial import-substituting inverter welding machines for mechanized gas-shielded metal electrode welding of a standard type and with separation of the arc and short circuit phase control. Welding and Diag-nostics. 2017;5: 49-53. (In Russian).

- Golovko V.V., Boldyrev A.M., Gushchin D.A., Kuznetsov V.D., Fomichev S.K., Smirnov I.V. Peculiarities of distribution and the role of non-metallic inclusions in the weld metal when nano-oxides are introduced into the weld pool. Welding and diagnostics. 2015;6: 25-29. (In Russian).

- Ma, Z.T., Janke D. Oxide metallurgy-its purposes and practical approaches. Acta Metall. 1998;11(2): 79-86.

- Davydov S.V. Nanomodifier as a tool for genetic engineering of the structural state of cast iron melt. Collection of reports of the Foundry Council No. 1 ≪Modification as an effective tool for im-proving the quality of cast iron and steels≫. Chelyabinsk: Chelyabinsk House of Press; 2006. (In Russian).