Nanostructured foam ceramics for building purposes: production technology and applications

Автор: D.A. Sinitsin, U.Sh. Shayakhmetov, O.N. Rakhimova, R.M. Khalikov, I.V. Nedoseko

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in building

Статья в выпуске: 4 Vol.13, 2021 года.

Бесплатный доступ

Introduction. Foam-ceramic heat-insulating building materials have the greatest stability of the demanded technological characteristics due to their unique physical and technical properties. Increasing the large-capacity production of nanostructured foam-ceramic products and developing educational programs for advanced training of process engineers remains an urgent task. Methods and materials. A technological method for manufacturing nanostructured foam ceramics is the method of direct foaming: ceramic foams are created by involving atmospheric air in a suspension. Further, the consolidated foams are carefully dried and sintered for 12 hours by heat treatment (950–1100оC) to obtain sufficiently high-strength foam ceramics for building purposes. The most important raw materials for the production of construction foam ceramics are clays, diatomites, siliceous minerals, zeolite rocks, etc., as well as ceramic and slag waste, and the like. Results. The technology of production of foam-ceramic materials for building purposes based on clay raw materials has been developed. As a result of physical and chemical transformations in the production cycle, including firing, uniformly closed micropores of foam ceramics with a diameter of up to 120 microns are formed, and the wall thickness varies from 1.8 microns to 6.3 microns. The compressive strength of the obtained nanostructured construction foam-ceramic products with an average density of 450–850 kg/m3 is 3–8 MPa, thermal conductivity is 0.12–0.15 W / (m●оC), frost resistance is at least 50 cycles. Discussion. In large-scale technological production, bubbles mass (three-phase foam) can be obtained by mixing nanostructured foam with a highly dispersed mineral powder. By controlled sintering, a dried foam mass is produced with the required technological characteristics due to the crystal bond of a solid-phase mullite based on cluster microparticles with dimensions of 15–200 nm, and the walls of micropores and nodal joints of nanostructured foam ceramics provide high mechanical strength, hydrophobicity and chemical resistance. Conclusions. Nanostructured foam ceramics for building purposes is sufficiently moisture-resistant, since it has a microstructure of closed ultramicropores; it is resistant to chemical and physical effects and therefore is the optimal thermal insulation material.

Nanostructured foam ceramics, manufacturing technology, foam-ceramic building materials, educational programs

Короткий адрес: https://sciup.org/142227311

IDR: 142227311 | DOI: 10.15828/2075-8545-2021-13-4-213-221

Текст научной статьи Nanostructured foam ceramics for building purposes: production technology and applications

When construction residential buildings, industrial modern buildings, one of the important aspects in the selection of materials is the increased heat and sound insulation characteristics; therefore, building materials that simultaneously combine lightness, low thermal conductivity with sufficient structural strength should be considered as the most promising for the energy-saving construction industry. Currently, these requirements are most fully met by highly porous silicate foams: foam ceramics, cellular concretes, foam glass, foam concrete based on porous aggregates. Due to the unique physical and technical characteristics, foam-ceramic heat-insulating building materials and products have the greatest stability of technological parameters: bio-and corrosionresistant, durable, fireproof and the like [1–4]. Foam ceramics in granules as an innovative insulation can be used in direct contact with cement-containing plasters, screeds etc. The solution of the problem of increasing

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN BUILDING the large-capacity production of nanostructured foamceramic building materials with the production of a highly porous microstructure and the development of educational programs for advanced training of technological engineers is an urgent task.

The purpose of this article is to consider the features of the technology for obtaining nanoporous ceramics for building purposes.

METHODS AND MATERIALS

Foam ceramics is a sintered solid-phase energysaving building material with low thermal conductivity (0.05–0.1 15 W/(m•оC) with closed (insulated) micropores with diameters from 7 nm to 8 microns. The necessary microstructure of foam-ceramic products is obtained by introducing various pore-forming agents, burn-out additives, porous fillers, etc. into the clay suspension [5–7]. A practical method of manufacturing nanostructured foam ceramics is a method of direct foaming: ceramic foams are created by including air in a suspension or liquid-phase medium. The porosity and size distribution of closed cellular micropores can be controlled by changing the viscosity of the ceramic foam and the foaming technology. Further, in the technological production, the consolidated foams are carefully dried and sintered by heat treatment (950–1100оC) for 10–12 hours to obtain high-strength foam ceramics for building purposes.

The firing rate of foam ceramic products, which results in a durable and water-resistant mullite, should be controlled to avoid the appearance of defective cracks. Foaming of raw ceramic suspensions includes gas dispersion in the form of micro-bubbles: inclusion of atmospheric air by mechanical foaming (or injection of a gas stream) or gas release in situ [8, 9]. In the case of gas release in situ , the foaming agents disintegrate under the action of heat or a chemical reaction with the formation of gas micropores inside the ceramic nanosuspension. To stabilize the gas nanobubbles formed in the suspension, the surface tension of the gas-liquid interface must be reduced, so in most cases, surfactants are added.

Nanostructured foam ceramics for construction purposes are also made by the replica method [10–12] (duplication): a three-dimensional mesh precursor based on polyurethane foam or other suitable macromolecules with open pores is immersed in a ceramic suspension. Then the excess suspension is removed, the organic components are pyrolyzed, then the porous nanoceramics is sintered to achieve the necessary mechanical strength. Porous building ceramics are obtained at a fairly low cost on the basis of available local clay raw materials, and for the formation of pores, sawdust, peat, straw, polystyrene foam granules, carbon waste, fuel slag, etc. are most often used as burnout additives.

Ceramic foam is a metastable dispersion, so it is important to “fix” the macrostructure of the foam in order to preserve the cellular nanostructure during the further heating procedure. Low-temperature foaming [13], as well as modified sol-gel methods are used to consolidate ceramic foams without any other nanoadditives. The microstructure of nanostructured foam ceramics is a solidphase building material filled with micropores of gaseous air. A sharp decrease in bending strength and an increase in the water permeability of foam ceramics for building purposes is interpreted by an increase in the number of open micropores.

The main raw materials for the production of building foam ceramics are mineral raw materials – clays, diatomites, siliceous minerals, alkaline geopolymers, zeolite rocks and the like, as well as slag waste, river silt, ceramic waste, shale, etc. As a result of physical and chemical transformations in the production process, including firing, the necessary number of evenly closed micropores is formed, rhythmically distributed throughout the entire volume of the building material.

To date, the possibility of technological production of innovative foam-ceramic building products based on low-melting clays, which allow forming a stable foam structure, intensifying the process of defect-free drying and subsequent sintering, has been theoretically substantiated and experimentally confirmed. For multi-tonnage production and use of nanostructured foam ceramics for construction purposes, it is necessary to take into account the influence of the component composition of foam ceramic masses on the physical and technical properties of products [14], as well as the optimal parameters of the preparation of raw materials, porization of the ceramic mass by foaming, which is implemented at existing enterprises, drying and technological firing.

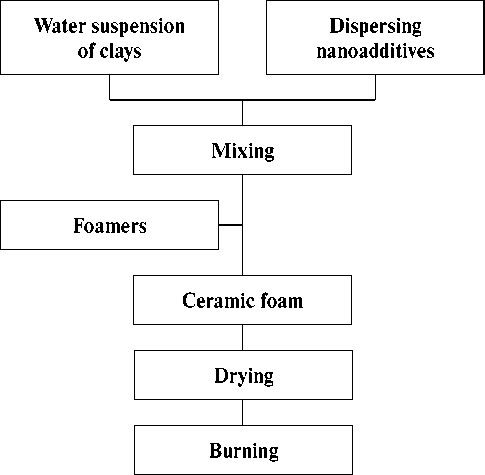

The technology of production of nanostructured construction foam ceramics at a relatively low cost includes the preparation of clay raw materials, intensive mixing with dispersing components (Fig. 1) and foaming agents.

A more uniform volume distribution of micropores in the foam-ceramic dispersion after the addition of foaming agents (frothers) contributes to the formation of a cellular ultramicrostructure of construction nanostructured foam ceramics. The preferential use of cheap local raw materials and artificial waste [15, 16] in the technological cycle can significantly reduce the cost of nanopenoceramic building materials.

When manufacturing construction foam ceramics with an average density below 1000 kg/m3 using the traditional method of burn-out additives, many problems arise in the technological cycle. The technology of foam ceramics is being developed by foaming a clay suspension stabilized with sodium pyrophosphate with a high-speed mixer of a slip mass. Enhanced mechanical activation [17]

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN BUILDING

Fig. 1. Technological scheme of traditional production of building nanostructured foam ceramics of aqueous clay suspensions in the presence of diluting nanoadditives-electrolytes allows achieving homogeneity of ceramic foam. The use of electrolyte additives, for example, aqueous solutions of sodium silicates, significantly reduces the viscosity of the clay slip, thereby optimizing the porization of the ceramic mass.

The introduction of a highly dispersed mineral powder into the ceramic foam, which is wetted with the liquid phase, leads to the formation of a three-phase foam mass during mixing. Then the resulting ceramic foam is formed, dried and subjected to heat treatment; when the ceramic foam is dried, liquid-phase water evaporates and a nanostructured foam ceramic is formed [18]. For hardening of foam-ceramic building materials, adjustable firing is used, during which decomposition (transformation of dispersing nanoadditives) and sintering occur. It should be noted that in real conditions of large-capacity production, obtaining nanoporous ceramics, which simultaneously combines lightness, thermal insulation properties and high strength, is fraught with difficulties.

Along with the average density of nanostructured foam ceramics, the determination of the compressive strength, thermal conductivity and water absorption are the determining parameters of highly porous ceramics for construction purposes. In nanostructured foam ceramics, heat transfer is determined by the thermal conductivity, which consists of the thermal conductivity of a ceramic building material, as well as by heat transfer in micropores [19]. It should be noted that the thermal conductivity of porous ceramics (aerogel) is influenced by the characteristics of the air filling the pores; humidity and the diameter of the micropores.

Among the innovative building materials, there is an without firing aluminosilicate foam ceramic, which has a foam-cell nanostructure (density 230–550 kg/m3), which gives it some advantages compared to other analogues in terms of water resistance and operating temperature up to 1200оC. The author [20] has developed an energy-and resource-saving non-burning technology for manufacturing foam-ceramic materials, the advantages of which are lightness, low thermal conductivity, sufficient constructional strength.

Micrographs of nanostructured foam ceramics were obtained using a JEOL JSM-6610LV scanning electron microscope [21] by scanning surface layers with a resolution of 3–4 nm. The ITP-MG4 “100” device was used to determine the thermal conductivity coefficient of foam-ceramic samples. The principle of operation of the ITP-MG4 device is based on the creation of a stationary heat flow passing through a foam-ceramic sample, measuring the thickness of the sample, the density of the heat flow and temperature. The range of thermal conductivity measurement by the thermal probe method was 0.03–1 W/(m•оC), the limit of the relative error in determining the thermal conductivity coefficient was ±7.

RESULTS

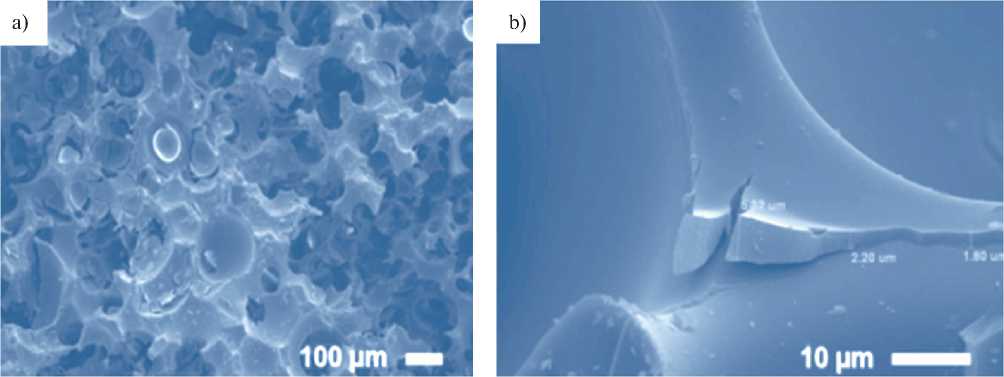

Figure 2 shows the microstructure of the cut surface of a sample of nanostructured foam ceramics for construction purposes, which were obtained by foaming low-melting clay. The micrograph clearly shows isolated micropores of foam ceramics with a diameter of up to 120 microns, and the wall thickness varies from 1.8 microns to 6.3 microns.

Refractory foam ceramics with an operating temperature of at least 1580оC are often used as the lining of high-temperature furnaces for firing porous building nanoceramics. The production of glass-crystal nanostructured foam ceramics for construction purposes is based on the use of 50–88 wt.% of pyrophyllite [22] (Kul-Yurt-Tau deposits), 11–49 wt.% of low-melting clays (Alekseevs-koye deposit of the Republic of Bashkortostan) and gasforming nanoadditives – 0.5–1 wt.% titanium carbide.

The manufacture line for the production of heatinsulating building materials from glass-crystalline foam ceramics [23] is organized by the method of foaming during firing of an amorphous-crystalline matrix with the formation of a cellular microstructure of inorganic foam, in which almost all ultramicropores are isolated from each other. The porous structure of foam ceramics was created using an energy-efficient technology of low-temperature 120–150оC foaming of porous ceramic masses during gas release.

A comparative analysis of the main types of porous heat-resistant materials was carried out in [24] on: high temperature struggle, refractoriness, heat resistance.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN BUILDING

Fig. 2. Micrograph of the surface of the foam ceramic saw (a); with an increase for measuring the thickness of solid-phase walls (b)

A comparison of various compositions with the highest thermal stability and fire resistance made it possible to select objects based on aluminum oxides and silicon oxide that are most suitable for creating appropriate porous heat-resistant inorganic composite materials.

The main technological characteristics of highly porous foam ceramics are porosity, pore size distribution, and specific surface area. Glass-crystal foam ceramics for construction purposes had the following physical and technical characteristics: compressive strength-at least 3.5 MPa; heat resistance (200оC) at least 50 cycles; use temperature from –45 to +60оC; density 350–600 kg/m3; low thermal conductivity (0.12–0.14 W / (m•оC). A nonignition technology for the production of nanopenoc-eramic materials for construction purposes using phosphate binders [25] based on clay local raw materials has been developed. The compressive strength of the obtained nanostructured construction products with an average density of 450–850 kg/m3 is 3–8 MPa, thermal conductivity is 0.12–0.15 W/(m•оC), frost resistance is at least 50 cycles.

In 2014–2015, the workers of the Department of “Building Constructions” of the Architectural and Building Institute of the Ufa State Petroleum Technical University, together with the Bashkir State University, completed the demanded work on the project of the Fund for Infrastructure and Educational Programs of “RUSNANO”. A professional development program was developed in the field of advance and production of highly porous nanostructured foam ceramics for building purposes [26]. The creation of educational programs for advanced training of specialists in the field of using nanostructured foam-ceramic products for construction purposes is designed to form the professional competencies of process engineers [27, 28].

The process of forming the competencies of technologists of production and application of nanopenoceramics at different stages of training is correctly described within the framework of the fractal concept of structure formation and hardening of accepted composite building materials [29]. Nodes are allocated in the hierarchical structure of educational programs for advanced training, and the branched fractal university system acts as a central link of advanced training of technologists of the production of nanostructured foam ceramics.

For the implementation of national projects of the Russian Federation, an educational program for retraining and advanced training of engineering specialists in the field of production of nanostructured foam-ceramic products for building purposes has been created. The educational program is designed to provide the regional construction industry with in-demand technologists for the production and use of nanopenoceramic products that replace the import of foreign analogues.

The program of retraining and advanced training of engineers of the production of nanostructured foamceramic building products contains three professional modules and one interdisciplinary course that is mandatory for all target groups. The curriculum for advanced training and retraining of qualifications provides for the implementation of the final certification work with testing in production conditions. The educational program (table 1) it is intended to provide the personnel potential of competitive, high-tech, domestic production of products made of highly porous nanostructured multifunctional building foam ceramics.

DISCUSSION

Among the innovative building thermal insulation materials, it is necessary to separately highlight the nonfired aluminosilicate nanostructured foam ceramics. This sintered innovative material based on available clays has a

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN BUILDING

Table 1

Educational results of the advanced training program for technologists in the field of development and production of highly porous nanostructured foam ceramics for building purposes

Physicochemical reactions [30] of the formation of a ceramic foam material occurs on the basis of liquid foams and highly dispersed mineral powders: the dispersion medium in them is a liquid-phase nanosuspension, and the dispersion phase is a gas in the form of microbubbles, which are separated from each other by films of an aqueous film. In large-scale technological production, foam mass (three-phase foam) can be obtained by mixing nanostructured foam with a highly dispersed mineral powder. In the production process, solid clay microparticles are distributed in liquid-phase films, and ultramicrobubbles are surrounded by two-phase shells.

Then comes the next stage of creating foam ceramics in construction – drying: the liquid phase evaporates from the foam mass, as a result of which a solid (two-phase) foam is formed. As a result of sintering, a dried foam mass with the required mechanical strength is obtained, due to the crystalline bond of solid-phase mullite, which forms a foam-cellular framework between the amorphous components of the foam ceramics. The silica airgel has a stochastic fractal [31] nanostructure based on cluster microparticles 15–200 nm in size, aggregated by strong covalent bonds.

To make construction foam ceramics more durable, trivial firing is used, leading to pyrolysis (decomposition) of organic components, that is, liquid foam stabilizers. In the course of heat treatment, nanostructured foam ceramics are sintered while maintaining micropores. It should be noted that the ratio between the solid and gas phases and the size of micropores in nanostructured foamed ceramics for building purposes can vary within wide limits.

Phosphate compositions, which are used as non-annealing binders [32] of porous ceramics, show the ability inherent in geopolymer inorganic [33] macromolecular nanostructures-when heated, they exhibit the property of plastic flow. During the heat treatment, the amorphous phase of colloidal phosphate nanocompositions moistens the surface of the mullite filler particles, thereby determining the adhesive characteristics. The heat transfer of nanostructured foam ceramics is caused by the thermal conductivity of solid-phase porous ceramics of the building material and gas permeability due to the multifractal diffusion [34] of the walls of micropores.

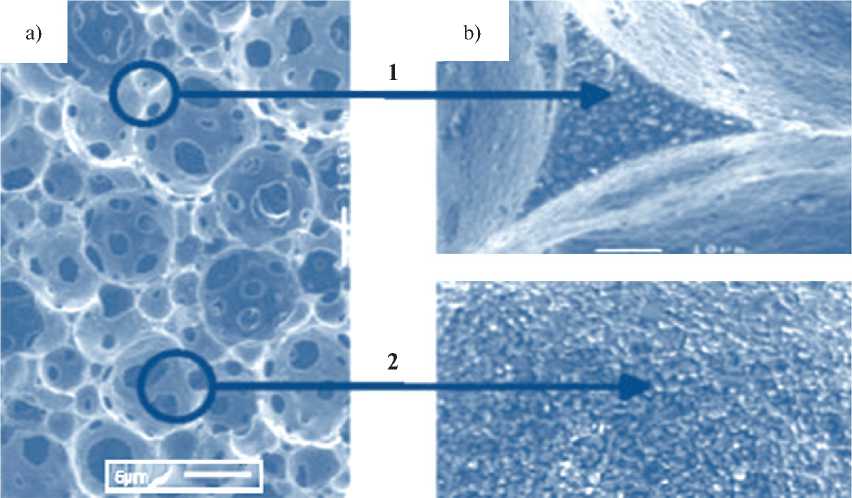

Therefore, it is possible to achieve the necessary technological characteristics when clay minerals are based on the industrial technology of nanostructured foam ceramics, by changing the ratio of phases (solid, liquid and gaseous) in the foam mass and regulating the phase composition. It should also be noted that the walls of micropores (Fig. 3) and the nodal joints of nanostructured foam ceramics are solid-phase and completely dense, and this provides high mechanical strength, hydrophobicity and chemical resistance.

Porous nanoceramics are characterized by relatively high compressive strength and low bending strength, good heat and sound insulation, air and vapor permeability, low water absorption compared to light concretes (however, waterproofing and a facing layer are recommended), high frost resistance, incombustibility, biostability, low nailability, environmental friendliness, average geometry accuracy and mechanical processing ability. For example, the developed nanostructured foam-ceramic kerpen [35] with a density of 300 kg/m3 has a frost resistance of

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN BUILDING

Fig. 3. Microstructure of porous nanostructured ceramics (a); with an increase in nodal joints (b) (1 – nodal joints; 2 – walls)

more than 25 cycles, a compressive strength of 3–4 MPa, a thermal conductivity of 0.15–0.2 W / (m•оC).

Currently, nanostructured foam ceramics for building purposes are used as a facade finishing material, heat-protective wall panel, etc. The thermal conductivity of construction foam ceramics depends on its density, composition, type and size of pores and it increases sharply with increasing humidity. The vapor permeability of nanopenoceramics is not regulated by the current state standards and technical conditions; however, in some cases, it affects the durability of building structures: low permeability to water vapor of heat-insulating building materials can cause the formation of condensate.

The use of nanostructured foam ceramics in building provides the required heat and sound insulation, fire protection of interstory floors without increasing the load on the building's enclosing structures. One of the ways to eliminate the emerging disadvantages of porous ceramics – a decrease in strength and an increase in water absorption under uncontrolled conditions of large-scale production is liquid-phase sintering with the formation of a glaze layer on the surface of products (translates most of the open pores into closed ones). Due to the use of nano-additives that increase the corrosion resistance of multifunctional nanocomposite building materials [36], a glass-crystalline (partially amorphous) high-strength solid phase is formed during firing.

The technological flaw of a nanostructured foamceramic product for building purposes – fragility can be overcome by reinforcement. The production of wall and heat-insulating ceramic products without firing, despite their high thermal protection properties, has not received proper distribution. The reason is the lack of a theoretical justification for the nano-porization of the ceramic mass, the developed technology and appropriate equipment, and competent personnel. The energy efficiency of buildings and structures within the framework of the concept of sustainable development becomes the main parameter determining the consumer value of a heated construction object. For the implementation of the tasks of national projects of Russia, the economic efficiency due to reducing the density of wall foam ceramics from 1600–1800 kg/m3 to 90–1100 kg/m3 of enclosing structures is characterized by the following figures according to various data:

– fuel consumption in the production of nanostructured foam ceramic products for building purposes can be reduced by 20%, and the material consumption of the production of highly porous foam ceramics is reduced by 1.5 times;

– due to innovative technologies, the energy costs for the construction of 1 m2 of an external wall are reduced by 1.8 times;

– the heat transfer resistance of buildings and structures increases, depending on the thickness of enclosing structures adopted in the region, etc.

Evaluating the properties of nanostructured foam ceramics, we can expect that its use can be especially effective as a wall material in the construction of monolithic houses. At the same time, the efficiency of using foam-aluminum-silicate ceramic blocks in the walls of monolithic houses will primarily be provided by saving

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN BUILDING

Fig. 4. Foam-ceramic building blocks building materials due to the best thermal characteristics of nanopenoceramics, and its lower density with a sufficiently high strength. Resource-saving use of cheap local low-melting clays, industrial waste (secondary concrete, cullet, blast furnace slags, etc.) [37, 38] can reduce the energy consumption of large-scale production of highly porous building foam ceramics (Fig. 4).

The wider industrial use of nanostructured foam ceramics in the building industry provides the necessary sound and thermal insulation, fire protection of floor-to-floor ceilings without increasing the load on the supporting structures and foundations of buildings and structures.

CONCLUSION

In recent decades, the progress of innovative technological production routes has contributed to the potential large use of building foam ceramics. Methods of foaming nanosuspensions are rapidly developing, which give ceramic foams with different micromorphology, and therefore with different thermal insulation characteristics, which ensures the adaptation of building structures to specific consumer requirements. Nanostructured foam ceramics for building purposes are sufficiently moistureresistant, since they have a microstructure of closed, capillary-free nanopores; it is resistant to chemical and physical effects (it is chemically sufficiently inert) and therefore is the optimal thermal insulation material. The use of low-temperature foaming technology ensures the achievement of the strength of the nanostructure of foam ceramics for construction purposes with short solidification periods (30–60 minutes) and a high rate of strength gain. A professional development program has been developed in the field of development and production of highly porous nanostructured foam ceramics for construction purposes under a project with the Fund for Infrastructure and Educational Programs of RUSNANO.

Список литературы Nanostructured foam ceramics for building purposes: production technology and applications

- Zavadsky V.F., Putro N.B. Porized building ceramics. Novosibirsk: Sibstrin; 2005.

- Shayakhmetov U.Sh., Fakhretdinov I.A., Chudinov V.V., Khalikov R.M., Latypov V.M., Latypova T.V. Highly porous nanostructured foam ceramics for building purposes. Features. Research methods. Ufa: Publ. BashSU; 2015.

- Ivanov LA., Kapustin I.A., Borisova O.N., Pisarenko Zh.V. Nanotechnologies: a review of inventions and utility models. Part II. Nanotechnologies in Construction. 2020; 12(2): 71–76. Available from: doi: 10.15828/2075-8545- 2020-12-2-71-76.

- Kudryavtsev P.G. Main routes of the porous composite materials creation. Nanotechnologies in Construction. 2020;12(5): 256–269. Available from: doi: 10.15828/2075-8545-2020-12-5-256-269.

- Gorlov Yu.P., Merkin A.P., Ustenko A.A. Technology of thermal insulation materials. Moscow: Stroyizdat; 1980.

- Baikov I.R., Smorodova O.V., Trofimov A.Yu., Kuznetcova E.V. Experimental study of heat-insulating aerogelbased nanomaterials. Nanotechnologies in Construction. 2019; 11(4): 462–477. Available from: doi: 10.15828/2075- 8545-2019-11-4-462-477.

- Selivanov Yu.V., Shiltsina A.D., Selivanov V.M., Loginova E.V., Korolkova N.N. Compositions and properties of ceramic heat-insulating building materials from low-temperature foaming masses based on clay raw materials. Engineering and Construction Journal. 2012; 3: 35–40.

- Hammel E.C., Ighodaro O.L.R., Okoli O.I. Processing and properties of advanced porous ceramics: An application based review. Ceramics International. 2014; 40(10): 15351–15370. Available from: doi: 10.1016/j.ceramint. 2014.06.095.

- Li H., Li C., Wu L. et al. In-situ synthesis and properties of porous cordierite ceramics with adjustable pore structure. Ceramics International. 2020; 46(10): 14808–14815. Available from: doi: 10.1016/j.ceramint.2020.03.005.

- Luyten J., Mullens S., Cooymans J. et al. Different methods to synthesize ceramic foams. J. Eur. Ceram. Soc. 2009; 29(5): 829–832. Available from: doi: 10.1016/j.jeurceramsoc.2008.07.039.

- Khalikov R.M., Akhmetshina G.G., Batrshina G.S., Kulanbayeva Z.M. Formation of a three-dimensional nanoset of a composite based on polyacrylamide gel. In: Collect. of III All-Russian Conference. “Modern technologies of composite materials”. Ufa: Publ. BashSU; 2018. p. 238–242.

- Ketov P.A. Development of an environmentally safe, energy-efficient cellular construction material corresponding to the principles of green construction. Bulletin of the Moscow State University of Civil Engineering. 2018; 13(3): 368–377.

- Fomina O.A., Stolboushkin A.Y. Firing of cellular ceramics from granulated foam-glass. Materials Science Forum. 2020; 992 MSF: 265–270. Available from: doi: 10.4028/www.scientific.net/MSF.992.265.

- Dmitriev K.S. Features of designing the composition of foam-ceramic products. Bulletin of Civil Engineers. 2015; 4(51): 112–116.

- Suvorova O.V., Manakova N.K. Utilization of mining waste of the Kola Peninsula with the production of granular porous material. Ecology of Industrial Production. 2014; 1: 2–5.

- Nushtaeva A.V., Shumkina A.A., Kruglyakov P.M. Structure formation in a dispersion medium of emulsions stabilized by solid microparticles. Regional Architecture and Construction. 2010; 2: 31–37.

- Bezborodov V.G., Medentsov L.F., Medentsova N.L. Influence of mechanical activation of the raw mixture and the degree of dispersion of the fluxing component on the structure and properties of foam ceramics based on loam. News of higher educational institutions. Building. 2014; 27: 26–30.

- Kuksa P.B., Akberov A.A. Highly porous ceramic products obtained by an unconventional method. Building materials. 2004; 2: 34–35.

- Tolstova Yu.I., Shumilov R.N. Fundamentals of building thermophysics. Yekaterinburg: Publ. Ural Univ.; 2014.

- Baranov I.M. Properties and production of non-cooked foam ceramics. Building materials. 2011; 10: 74–76.

- Shayakhmetov U.Sh., Larkina A.A., Khalikov R.M., Sinitsin D.A., Nedoseko I.V. Methodological tools for university transfer of high-demand nanotechnologies to the regional building industry. Nanotechnologies in Construction. 2021; 13(1): 12–17. Available from: doi: 10.15828/2075-8545-2021-13-1-12-17.

- Shayakhmetov U.Sh., Khalikov R.M., Vdovenko N.N., Akhmetshina G.G., Chudinov V.V., Bikbulatov M.R., Gazizova A.T. Structure formation in composites based on pyrophyllite. Bulletin of the Bashkir University. 2018; 23(2): 346–353.

- Shayakhmetov U.Sh., Murzakova A.R., Vasin K.A., Bagautdinov N.Ya., Yumabaev Yu.S., Shayakhmetov R.U., Bakunov V.S., Yakupova L.V., Nedoseko I.V. A line for the manufacture of products made of glass-crystal foam ceramics. Patent RU 120418 U1. Publ. 20.09.2012.

- Kudryavtsev P.G. Composition and structure of porous heat-resistant inorganic composite materials. Nanotechnologies in Construction. 2018; 10(4): 75–100. Available from: doi: 10.15828/2075-8545-2018-10-4-75-100.

- Khalikov R.M., Shayakhmetov U.Sh., Galyautdinov A.G. Chemistry and structure of compositions based on phosphates. Ufa: Publ. BashSU; 2012.

- Shayakhmetov U.Sh., Khalikov R.M., Latypova T.V., Chudinov V.V. From the experience of developing an educational program for advanced training in the field of research and production of nanostructured foam ceramics for building purposes. In: Collect. of the II All-Russian Conference. “Modern technologies of composite materials”. Ufa: Publ. BashSU; 2016. p. 371–376.

- Shayakhmetov U.Sh., Fakhretdinov I.A., Khalikov R.M., Ivanova O.V., Chudinov V.V., Goncharenko E.A. The process of formation of professional competencies of bachelor-material scientists in the field of heat-resistant nanostructured composites. Bulletin of the Bashkir University. 2014; 19(1): 248–252.

- Averyanova E.V., Rakhimova O.N., Chernoglazova G.G. Innovative design in the preparation of a competitive bachelor-builder. European Social Science Journal. 2018; 6: 124–129.

- Khalikov R.M., Sinitsina E.A., Silantyeva E.I., Pudovkin A.V., Nedoseko I.V. Modifying intensification of the hardening of extruded construction gypsum nanocomposites. Nanotechnologies in Construction. 2019; 11(5): 549– 560. Available from: doi: 10.15828/2075-8545-2019-11-5-549-560.

- Kazantseva L.K., Rashchenko S.V. Chemical processes during energy-saving preparation of lightweight ceramics. J. Am. Ceram. Soc. 2014; 97: 1743–1749.

- Baikov I.R., Smorodova O.V., Trofimov A.Yu., Kuznetcova E.V. Experimental study of heat-insulating aerogelbased nanomaterials. Nanotechnologies in Construction. 2019; 11(4): 462–477. Available from: doi: 10.15828/2075- 8545-2019-11-4-462-477.

- Bakunov V.S., Khalikov R.M., Shayakhmetov A.U., Khaidarshin E.A., Shayakhmetov A.K. Hardening of an alumophosphate composition during heating. Refractories and Technical Ceramics. 2016; 3: 24–27.

- Saifullin R.S. Physical chemistry of inorganic polymer and composite materials. Moscow: Chemistry; 1990.

- Khalikov R.M., Kozlov G.V. Multifractal model of gas diffusion in polymers. Polymer Science. Series B. 2006; 48(4): 699–703.

- Bakunov V.S., Kochetkov V.A., Naddenny A.V., Cherepanov B.S., Shchelkov E.M. Multifunctional ceramic building material – kerpen. Building materials. 2004; 11: 10–11.

- Sinitsin D.A., Khalikov R.M., Bulatov B.G., Galitskov K.S., Nedoseko I.V. Technological approaches to directed structure formation of construction nanocomposites with increased corrosion resistance. Nanotechnologies in Construction. 2019; 11 (2): 153–164. Available from: doi: 10.15828/2075-8545-2019-11-2-153-164.

- Lotov V.A. Obtaining foam glass based on natural and technogenic aluminosilicates. Glass and Ceramics. 2011; 9: 34–37.

- Gusev B.V., Kudryavtseva V.D., Potapova V.A. Concretes with nanoadditive of fired recycled concrete. Nanotechnologies in Construction. 2020; 12(5): 245–249. Available from: doi: 10.15828/2075-8545-2020-12-5-245-249.