Nanotechnologies for testing and diagnostics of materials, constructions and elements of engineering systems of buildings from them with fire retardant coatings. Part 2

Автор: Belozerov V.V., Belozerov Vl.V., Golubov A.I., Kalchenko I.E., Prus Yu.V.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Problems of using nanomaterials and nanotechnology in construction

Статья в выпуске: 4 Vol.12, 2020 года.

Бесплатный доступ

Introduction. To determine the effectiveness of fire-retardant coatings (FRC), a system of methods for fire and high-temperature testing of fire-retardant materials and structures made of themis being used. However, there are no methods and means that could provide current effectiveness of fire protection, and existing methods cannot be applied to determine fire resistance of building structures with fire protection, they set only a group of the effectiveness of the flame retardants. Therefore, to assess the quality and durability of the FRC, in case they provide the parameters of thermal stability of the protected materials, structures and elements of the engineering systems of the objects, it was necessary to develop a quickmethod and a portable diagnostic complex of fire-retardant coatings (PDC FRC). Methods, models and tools. Based on a system analysis of the existing fire protection technologies for building materials from wood, metals, rubber and polymers, a rapid analysis methodology and PDC for thermo-electro-acoustic (TEA) sensing of FRCs using thermo-acoustic methods have been developed. That made it possible to determine thermal conductivity, the ultrasound speed and its absorption coefficient in the FRC, as well as to conduct a comparative analysis of the «FRC image» obtained on a BETA-analyzer with measured characteristics, based on which to calculate the time of its operability. Results and discussion. The PDC of FRC consists of a case with a laptop, with the immitance meter and a two-channel oscillographic attachment connected to the laptop, to the inputs of which a TEA-zonding unit is pressed, pressed to the FRC of the tested object (structure, material, cable), by thermal, electrical and acoustic signals from which the laptop software identifies the properties and stages of operational stability of the FRC. The PDC of the FRC and the proposed approach allowed us to synthesize a model of the Internet system of TEA - diagnosis of FRC and of the monitoring of the operational stability of the protected materials. The novelty of the study is protected by patents of the Russian Federation. Conclusion. The proposed approach and the PDC of the FRC made it possible to implement a quickanalysis of the FRC at the facility and to synthesize a model of the Internet system of TEA-diagnostics of FRC, which can become the basis of the national supervision system for the given area.

Fire retardant coatings, degree of fire resistance, materials and structures, quality of fire retardant coatings, durability of fire retardant coatings, thermo-electro-acoustic method, heat conductivity, thermal diffusivity, heat capacity, aging of fire retardant coatings, dangerous factors of fire

Короткий адрес: https://sciup.org/142226969

IDR: 142226969 | DOI: 10.15828/2075-8545-2020-12-4-216-222

Текст научной статьи Nanotechnologies for testing and diagnostics of materials, constructions and elements of engineering systems of buildings from them with fire retardant coatings. Part 2

To determine the effectiveness of fire-retardant coat- temperature testing of fire-retardant materials and struc- ings (FRC), a system of methods for fire and high- tures made of them is being used [1, 2]. However, there

PROBLEMS OF USING NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION are no methods and means that could provide current effectiveness of fire protection, and the existing assessment methodology divides the FRC into seven groups, depending on the time of heating up to 500оC of an I-section steel column of profile No. 20 or profile No. 20B1 with a height of 1700 mm, coated with FRC [3]:

1st group – at least 150 minutes;

2nd group – at least 120 minutes;

3rd group – at least 90 minutes;

4th group – at least 60 minutes;

5th group – at least 45 minutes;

6th group – at least 30 minutes;

7th group – at least 15 minutes.

Thus,the latent form of assessing the effectiveness of the FRC is again evident: not by the thermal stability of the material being protected, but by the indirect characteristics of the FRC itself [6].

That is why, in order to assess the quality and durability of the applied FRC, in case they provide parameters of resistance to the impact of the protected materials, structures and elements of engineering systems of objects (buildings, structures), it was necessary to develop a quickmethod and portable diagnostic complex of fire retardant coatings (PDC FRC).

METHODS, MODELS AND TOOLS

Based on a system analysis of the existing fire protection technologies for building materials from wood, metals, rubber and polymers, a rapid analysis methodology and a portable diagnostic complex (PDC) for thermo-electro-acoustic (TEA) sounding of FRC using thermo-acoustic methods were developed, which allowed determine the thermal conductivity, ultrasound speed and its absorption coefficient in the FRC at the facility, and also conduct a comparative analysis of the «FRC-image», including its operational aging, obtained on a BETAanalyzer, with the measured characteristics at the facility during the test, by which to calculate its working time [6–10].

The developed method of thermo-electro-acoustic (TEA) sounding uses not only the method of acoustic emission (AE), but also the method of molecular acoustic analysis (MA), which allows you to determine the speed – with (T) and frequency – ω (T) of ultrasound in the FRC, then calculate the absorption coefficient α c and check the value of the E – Young’s modulus obtained on the BETA-analyzer [9–11]:

« c

to 4 11

2pc ^ 3 n+S+V^ - - C- j

where l в is the length of the acoustic waveguide, d is the diameter of the sample, τг is the time the first sensor excites the pulse from the reference generator, τп is the time the second sensor receives the pulse from the reference generator, ρ is the density of the sample, с is the speed of sound in the sample, ω is the circular frequency sound wave, η is the shear viscosity coefficient, ε is the bulk viscosity coefficient, λ is the heat conductivity coefficient, CV is the heat capacity at a constant volume, CP is the heat capacity at a constant pressure.

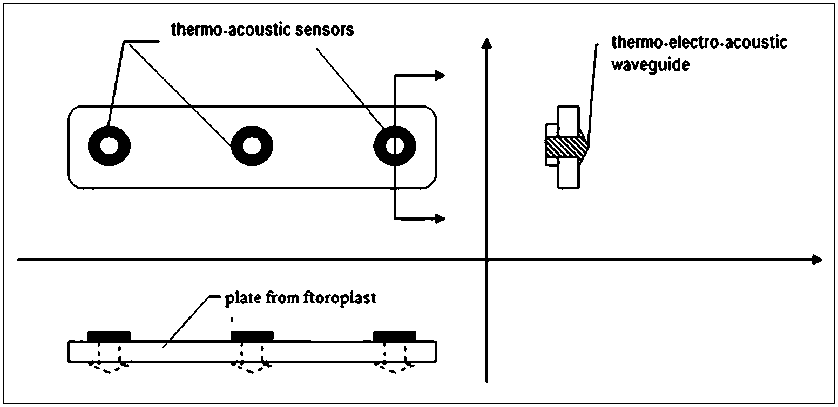

TEA sounding is carried out using a special board (Fig. 1), which contains three metal probes mounted on the plate from ftoroplast in a straight line at fixed distances, each of which has an acoustic sensor. The extreme sensors are connected to the individual inputs of the oscillographic set-top box through preamplifiers, registering acoustic signals, and the central one – to the output of its reference generator through a controlled electronic key, operating as an emitter of ultrasonic signals [7, 9].

On each of the three probes, one thermal sensor is installed, connected to the input of the emittance meter through a managed switch, measuring the temperature (by changing their resistances). Each of the three probes represents a pointed thermo-electro-acoustic molybdenum waveguide, connected to the input of the emittance meter via a controlled switch, for measuring the electrical and thermal parameters of the FRC between the probes, and to an oscillographic prefix for measuring acoustic signals [9].

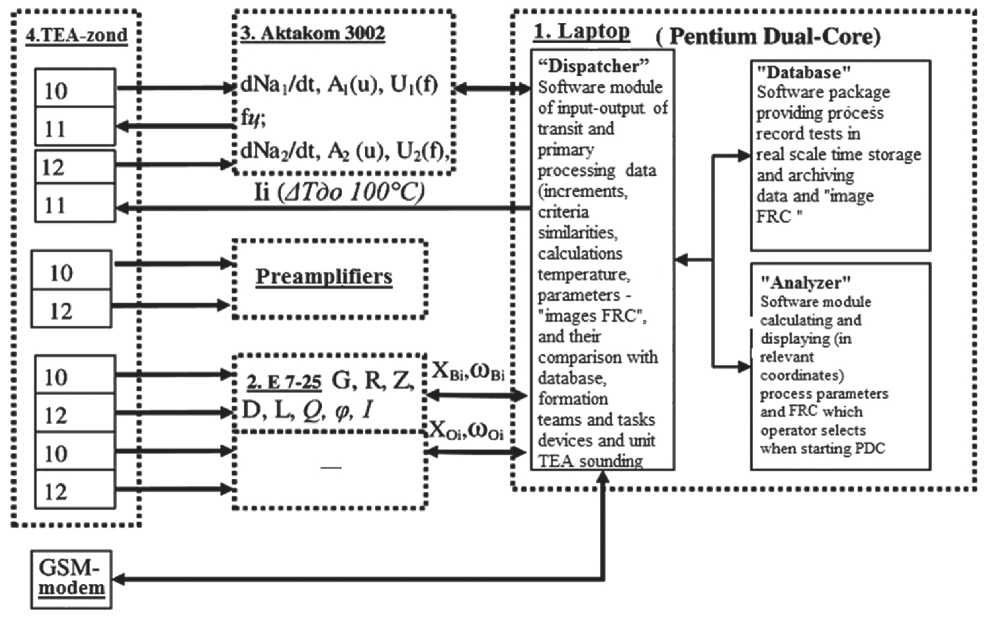

When calibrating according to known parameters of the body wall of the PDCFRC of an aluminum alloy: density (ρ), heat capacity (Cp) and bulk modulus (K = 1/β), as well as calibrated distances between probes (lц and lк), special software ( Fig. 2) controls the PDCFRC and determines the following parameters [9, 12]:

– mechanical – Young’s modulus (E = ρС2), shear modulus (G = 3E/(9-E/K) and Poisson’s ratio (ν = E/2G–1);

– thermal – surface temperatures (Tc and Tk), thermal conductivity (λ) and thermal diffusivity (а = λ/ (ρ•Ср);

– electrical – resistance (R), conductivity (G), impedance (Z), loss tangent (tgσ), dielectric (ε) and magnetic permeability (µ), solving the characteristic (surface according to Leontovich) impedance equation (Z = (µ/ε)1/2);

– acoustical – the intensities of the flow (quantity per unit time) of acoustic emission (AE) events dNa/ dt, their total amount of Na, amplitude A and spectral composition of radiation U(f), as well as sound speed (C).

PROBLEMS OF USING NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 1. TEA soundingboard

Fig. 2. Block diagram of special software

RESULTS AND DISCUSSION

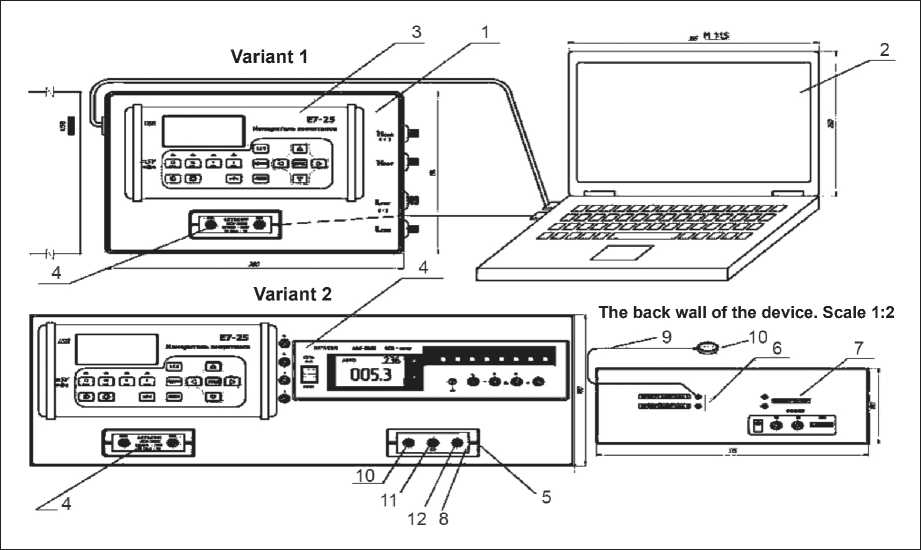

During the calibration, all measuring channels are tuned to the parameters of the «case-shunt» made of aluminum alloy (Fig. 3), by calculating the corresponding errors of the electric (∆e), temperature (∆t) and acoustic (∆a) measuring channels and their correction.

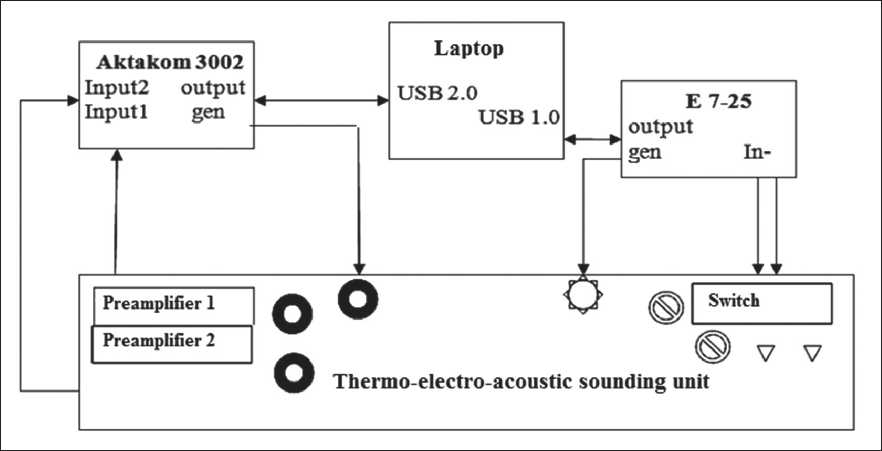

PDCFRC consists of a housing (1) with a laptop (2), with an imitance meter (3) and a two-channel oscillographic set-top box (4) connected to the laptop, the inputs of which are connected with the appropri-

PROBLEMS OF USING NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 3. General view of the PDCFRC with options for execution

ate cables to the thermo-electro-acoustic (TEA) sensing unit (5), pressed to the FRC of the tested object (structure, material, cable), by thermal, electrical and acoustic signals from which, the special software of the laptop identifies the properties and stages of operational stability of the FRC. In this case, the oscillographic set-top box is connected and powered by the USB port of the laptop (Fig. 4), and the imitance meter is powered by the built-in battery and connected to another USB port. The TEA sensing unit is part of a portable complex, consists of two preamplifiers (6), a switch (7), a multi-core connecting cable (9) and a TEA probe board (8), on which a reference probe (10), a central measuring probe (11) are installed ) and the extreme

Fig. 4. Block diagram of a portable diagnostic complex

PROBLEMS OF USING NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION measuring probe (12). The reference probe contains an acoustic sensor emitting an ultrasonic pulse, a thermal sensor-heater of the molybdenum probe to a temperature of 100оC. The central and extreme measuring probes are the same and are pointed metal rods that act as thermo-electro-acoustic waveguide probes on which thermal and acoustic sensors are mounted. To measure the temperature and resistance of the FRC between the probes, an imitance meter with a switch is used, and sensors that record acoustic signals are connected to an oscillographic prefix [9, 12].

A laptop can be any two-processor computer with at least 4 GB of RAM and Windows 7 OS, the software (software) of which, in addition to the software module packages (SMP) of the imitance meter and two-channel oscillographic set-top box, includes special software (SSW), which synchronizes the operation of all these components of the PC and, processing the obtained TEA data, calculates the current parameters of the FRC, which identifies the stages of its operational stability and determines the effectiveness of protection [9, 12].

E7-25 with autonomous power supply was used as an emittance meter, and the oscillographic set-top box should be two-channel (for example, Aktakom 3002) with the function of a spectrum analyzer and powered by a laptop’s USB connector (Fig. 4).

PDCFRCis activated by turning on the laptop and the emittance meter with the choice of the «calibration» procedure from the «menu», after which the TEA-sensing unit is removed from the PC case and pressed to the object under test with the FRC (structure, cable, material), after which the mode starts «Diagnosis of FRC» using the same special software (Fig. 2). Moreover, to identify the state of the FRC, i.e. stages of its operational aging, in the PC database there should be an «FRC image», which is its life cycle vector function in the temperature range from minus 55оС to plus 65оС, obtained on a BETA analyzer, by which the stability stage is determined and calculates the update time of the FRC [12, 13].

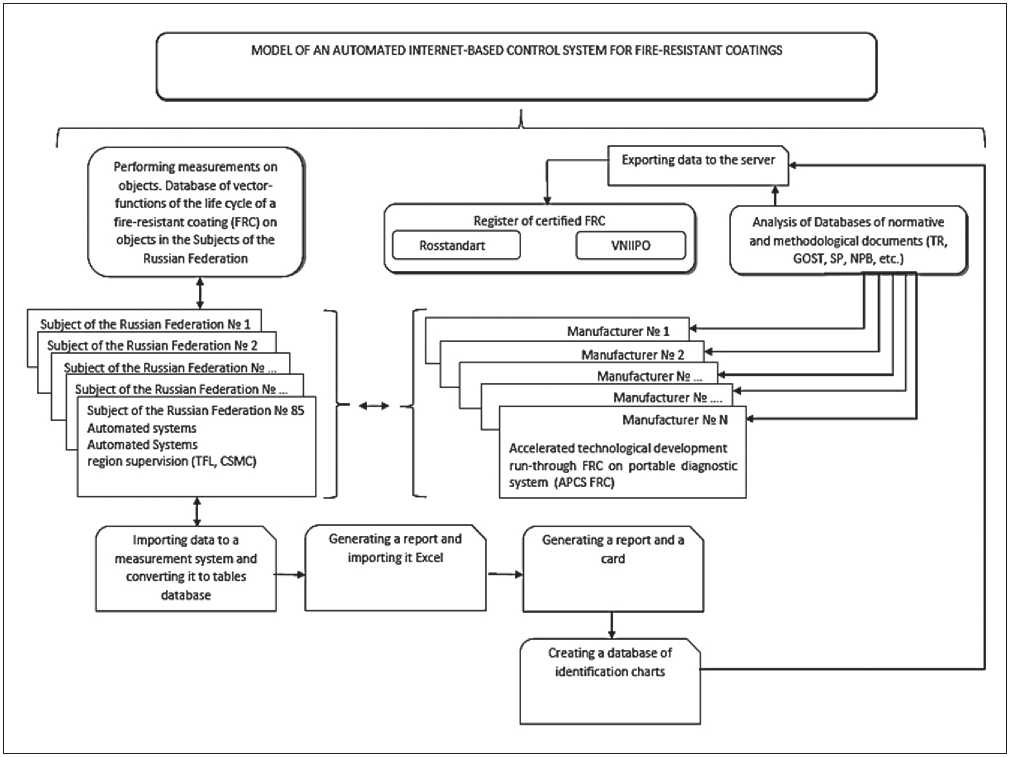

PDCFRCand the proposed approach made it possible to systematically synthesize a model of the Internet system for thermo-electro-acoustic diagnostics of FRC and

Fig. 5. General view of the information exchange scheme

PROBLEMS OF USING NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION operational stability of the protected materials (structures and elements of engineering systems), which can become the basis of the national surveillance system in this subject area [12, 14].

Such a national surveillance macro-system is an automated laboratory-operational Internet system (Fig. 5), consisting of 3 separate, but functionally connected systems – test, control and information [14].

Testing system – should consist of BETA analyzers with the proposed adaptation, which should be equipped with all regional forensic institutions Testing Fire Laboratories (TFL) EMERCOM of Russia and Centers for Standardization, Metrology and Certification (CSMC) of the Federal Agency for Technical Regulation and Metrology (Rosstandart) [10, 15, 16].

The control system consists of the PDCFRC, which with the help of TEA probes will allow to measure, process and carry out diagnostics by the specialists of these test divisions of the condition of the protected materials and the FRC in the conditions of operation at the facilities [8, 12, 14].

The information system (Fig. 5) will consist of servers and sites of Rosstandart and VNIIPO EMERCOM of Russia, with a bank of TEA-data of FRC and protected materials filled by FMC and VNIIPO (FSBI SEU FPS IPL) EMERCOM of Russia, as well as a database of the current TEA-diagnostics FRC on the objects filled in

«on-line» mode through the specified sites by bodies for certification of products, objects and bodies of supervision [14].

The solution of tasks in the information system can be carried out using the available Internet portals [12, 14]: – FSBI VNIIPO EMERCOM of Russia (http://www.

– Rosstandart .

CONCLUSION

The proposed approach and PDCFRCimplement a quick analysis of the FRC at the facility, complementing the known methods for determining fire retardant efficiency, which are reflected in the relevant regulatory documents [1, 3–5] and research [6–8], including thermal [17] and thermo-electro-acoustic analysis [18, 19], creating a «FRC image» for the subsequent identification of the stages of its «aging», and, therefore, for determining the actual time of its updating at any objects of supervision [12, 14, 15].

The proposed approach and PDCFRCallowed synthesizing a model of the Internet system of thermo-electro-acoustic diagnostics of FRC and operational stability of the protected materials (structures and elements of engineering systems), which can become the basis of the national surveillance system in this subject area [14].

Part I of the paper «Nanotechnologies for testing and diagnostics of materials, constructions and elements of engineering systems of buildings from them with fire retardant coatings» has been published in the issue 3/2020 of the journal «Nanotechnologies in Construction».

Список литературы Nanotechnologies for testing and diagnostics of materials, constructions and elements of engineering systems of buildings from them with fire retardant coatings. Part 2

- GUGPS of the Ministry of Internal Affairs of Russia. NPB 236-97. Fire retardants for steel structures. General requirements. Method for determining fire-retardant efficiency. Collection of guiding documents of the State Fire Service, Part 6. Moscow: 1997. (In Russian).

- GOST R 53292-2009.Fire retardant compositions and substances for wood and materials based on it. General requirements. Test Methods. Moscow: Standartinform; 2009. (In Russian).

- GOST R 53295-2009. Fire protection for steel structures. General requirements. Method for the determination of fire-retardant effectiveness. Moscow: Standartinform; 2009.(In Russian).

- GOST R 53311-2009. Fireproof cable coatings. Methods for determining flame retardant efficiency. Moscow: Standartinform; 2009. (In Russian).

- GOST R 53293-2009. Fire hazard of substances and materials. Materials, substances and means of fire protection. Identification by methods of thermal analysis. Moscow: Standartinform; 2009. (In Russian).

- Kalchenko I.E. An analysis of the objectivity of assessing fire resistance and the effectiveness of fire protection of structures of infrastructure for various purposes.Theoretical and applied aspects of modern science. 2014; 3-1: 64–72. (In Russian).

- Belozerov V.V., Kalchenko I.E., Prus Yu.V. The system of thermoelectroacoustic diagnostics of fire resistance of objects. Annual international scientific and technical conference Security Systems – SB-2013. Moscow: Academy of the State Fire Service of the Ministry of Emergencies of Russia. 2013. Pp. 224–227. (In Russian).

- Kalchenko I.E. Simulation methods for assessing the quality of fire retardant coatings.Technosphere Safety Technologies. 2015;1(59). URL: http://academygps.ru/ttb. (In Russian).

- Kalchenko I.E. A portable diagnostic system for fire retardant coatings – utility model. Patent RF No. 157151. Bull. No. 32. 11/20/2015.

- Belozerov V.V., Marchenko A.V., Prus Yu.V. BETA-analysis in the diagnostics of safety and strength of structural materials. In: Annual international scientific and technical conference Security systems. SB 2008:Proceedings of the 17th Int. Conf. Moscow: AGPS of the Ministry of Emergencies of the Russian Federation, 2008. Pp. 54–57. (In Russian).

- Belozerov V.V. Automated system for testing materials of the electrical and electronic industries with control of their fire hazard. Abstract of PhD thesis. Moscow: AGPS of the Ministry of Emergencies of the Russian Federation, 2008. (In Russian).

- Prus Yu.V., Golubov A.I., Kalchenko I.E. Thermo-electro-acoustic method and system for diagnosing the quality and durability of fire-retardant coatings.Electronics and Electrical Engineering. 2016; 1: 146-160. Available from: DOI:10.7256/2453-8884.2016.1.21075. (In Russian).

- Belozerov V.V. The vector-function of the life cycle of materials. In:≪Fundamental and applied aspects of new highly efficient materials≫: proceedings of the II All-Russian Scientific Internet Conference with International Participation. Kazan: IP Sinyaev D.N., 2014. Pp. 11–13. (In Russian).

- Belozerov V.V., Kalchenko I.E., Prus Yu.V. The model of the Internet system of thermo-electro-acoustic diagnostics of materials and fire retardant coatings.Modern problems of science and education. 2014;1. Available from:http://www.science-education.ru/115-11952. [Accessed 13th August 2020]. (In Russian).

- Belozerov V.V., Golubov A.I., Kalchenko I.E., Nguyen T.A., Topolsky N.G. Nanotechnology testing and diagnostics of materials, structures and elements of engineering systems of buildings with fire retardant coatings. Part 1. Nanotechnology in construction. 2020; 12 (3): 174–184. Available from: DOI: 10.15828/2075-8545-2020-12-3-174-184.

- Belozerov V.V., Nguyen Tuan A., Belozerov Vl.V. Improvement of BETA-analysis for viscous media, flammable liqvids and flame-retardant coatings.Physics and Mechanics of New Materials and Their Applications (PHENMA 2019). 2019; 52–54.

- STB 1333.2-2002. Polymeric products for construction. A method for determining the durability of polymer pipes for engineering systems (at a nominal value of the activation energy of thermo-oxidative degradation). Available from: http://www.nestor.minsk.by/sn/2003/06/sn30606.html. [Accessed 13th August 2020]. (In Russian).

- Belozerov V.V., Golubov A.I., Kalchenko I.E. About unification of diagnostics and tests of solid and liquid materials and fireproof coverings. In:7th International Scientific and Practical Conference ≪Science and Society≫, 2015, 23–30 March, London, Great Britain. 2015. Pp. 31–41.

- Bosy S.I., Builo S.I. About synchronization of thermal analysis with acoustic emission and electrometry.Electronics and Electrical Engineering.2016;1:1-20.Available from: DOI:10.7256/2453-8884.2016.1.21026. (In Russian).