Nanotechnologies: a review of inventions and utility models. Part I

Автор: Ivanov L.A., Bokova E.S., Muminova S.R., Katuhin L.F.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Review of nanotechnological inventions

Статья в выпуске: 1 Vol.12, 2020 года.

Бесплатный доступ

A brief review of patents is given. The research performed by scientists, engineers and specialists in the area of nanotechnologies and nanomaterials resulted in increased efficiency of construction, housing sector and adjacent fields of economy. For example, the invention «А method to produce titanium carbide nanopowder» refers to inorganic chemistry and nanotechnology and can be used to produce wear-resistant abrasive materials, high-temperature ceramic materials and coatings, high-strength composite materials. The technical result is TiC nanopowder in free-filled condition in the form of particles with average size no less than 30 nm, as well as TiC nanopowder with controlled ratio titanium-carbon. All that boosts technical opportunities for its application. The specialists can also be interested in the following inventions in the area of nanotechnologies: a method to obtain a mixture of micro- and nanoparticles of binary alloys, hydrocatalytic processes of recycling heavy oil fractions with the use of perspective nanosize catalysts, a method to produce graphene oxide, a method to decrease electrization of liquid hydrocarbons when applying them, a method to produce composite material boron-carbon, Modeling of static mixer (oil – water) performance for oil desalting and development test, a method of chromatographic separation of single layer carbon nanotubes by chirality and other.

Nanotechnologies in construction, titanium carbide nanopowder, binary alloy nanoparticles, nanosize catalysts, carbon nanotubes

Короткий адрес: https://sciup.org/142227432

IDR: 142227432 | DOI: 10.15828/2075-8545-2020-12-1-27-33

Текст научной статьи Nanotechnologies: a review of inventions and utility models. Part I

T he practical application of the results achieved by scientists, engineers and specialists can become efficient tool to increase number of import-substituting goods and to rise labor productivity. An invention is known to be a new, with distinctive characteristics technical solution with proved efficiency (new technologies, structures or new substances). The paper reviews the essence, technical result and practical value of some inventions concerning nanotechnologies.

MAIN PART

A method to produce titanium carbide nanopowder (RU 2707596 С2)

The invention refers to inorganic chemistry and nanotechnology and can be used to produce wear-resistant abrasive materials, high-temperature ceramic materials and coatings, high-strength composite materials [1].

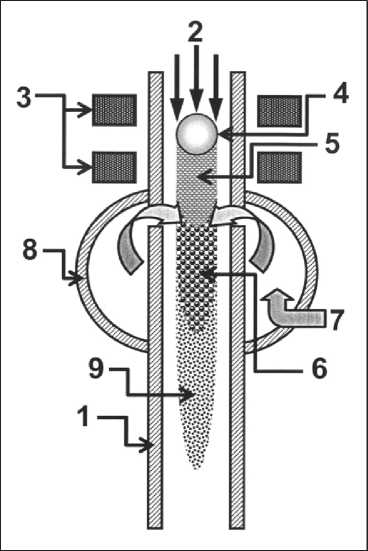

Laminar gas-carrier downflow 2 is supplied to vertical reactor (Fig. 1.) made of thermal-resistant dielectric

REVIEW OF NANOTECHNOLOGICAL INVENTIONS material. On top titanium wire is introduced into reactor, then it is heated in high-frequency field of countercurrent inductor 3 up to melting temperature. A drop of melted titanium 4 is obtained at the end of the wire, after that the drop is hanged without contact between spirals of countercurrent inductor, then evaporation of metal titanium from surface of the drop is provided. The gas-carrier flow 2 continuously takes away titanium vapour from the drop 4, vapour condensation into titanium nanoparticles is performed in condensation zone 5 and then the particles are delivered in reaction zone 6 in which carbon-containing gas-reagent 7 is also supplied from leak 8. Obtained titanium carbide nanoparticles are transferred into cooling zone 9, they are caught with filter and thus final product in the form of titanium carbide nanopowder in free-fill condition is produced. The average size of the particles is no less than 30 nm and the ratio between titanium and carbon without halogen and oxygen is specified. Titanium evaporation from the drop 4 is compensated by continuous supplying titanium wire. A rare gas is used as gas-carrier, and hydrocarbon from alkane, alkylene and alkine class is used as a gas-reagent.

Fig. 1

The technical result is:

– facilitated technological cycle and provision of continuous production process for titanium carbide nanopowders;

– production of TiC nanopowder in free-fill form with the particles which size is no less than 30 nm, production of TiC nanopowder with specified ratio between titanium and carbon. All that boosts technological opportunities and application areas of the nanopowder.

A method to produce ferrum-based composite material strengthened with metal nanopowder oxides (RU 2707686 С1).

The invention refers to the powder metallurgy, in particularly to the designed technology for production of steels strengthened with disperse nanooxides. The invention can be used in manufacture of high-strength constructional parts of railway rolling stock [2].

The technical result is reduced labour intensity, reduced technological process life, 20–30% increase of durability characteristic due to speeded rotation velocity of grinded device (bead mill) up to 3000 rpm, use of monodisperse heat resistant nanooxides obtained through high-energy impact on initial components.

The result described above is achieved due to the method of production of ferrum-based composite material strengthened with metal nanopowder oxides. The stages of the method: mechanical alloying of the mixture prepared from iron oxide powder which is unsteady under deformation and alloy-treated steel powder which is powder of the steel alloyed with yttrium and/or titanium, and/ or wolfram, forming heat-resistant nanooxides.

A method to modify carbon nanotubes for hydrophilic or hydrophobic surfaces (RU 2707930 С1)

The invention refers to physics and nanotechnology and can be used in production of super condensers, filters and sensors [3]. To provide specified value for wetting angle carbon nanotubes are modified by bombarding flows of ions, for example, argon, helium, ferrum, carbon or terbium ions. An array of carbon nanotubes which diameter is 8–250 nm and density is 0,1–3 g/cm3 is used. To obtain carbon nanotubes which wetting angle is 180o a surface of nanotubes is bombarded with ions and value of displacement per atom (DPA) divided by average diameter of carbon nanotubes in the sample up to 0,0075 DPA/nm inclusive is provided at this. To obtain carbon nanotubes which wetting angle is less 90o nanocarbon surface is bombarded with ions and value of displacement per atom (DPA) divided by average diameter of carbon nanotubes in the sample more than 0,025 DPA/nm is provided. The invention makes it possible to control wettability of carbon nanotubes surface and obtain hydrophobic or hydrophilic coatings.

Spherical powder of pseudoalloy based on wolfram and a method to produce it (RU 2707455 C1)

The invention refers to spherical powder of pseudoalloy based on wolfram [4]. Granulation of nanosize

REVIEW OF NANOTECHNOLOGICAL INVENTIONS composite powder is performed. The nanosize composite powder consists of metal particles with size no less than 100 nm and it is obtained as a result of hydrogen reduction in thermal plasma of mixture of wolfram oxide powder with powder chosen from group including Ni, Fe, Со, Сu and Ag or powders of oxides of metal chosen from the given group. Then obtained powder granules are spheroidized by fluxing in thermal plasma. Obtained powder contains 3–50 mass. % of binder of metal chosen from group including Ni, Fe, Со, Сu and Ag or alloy of the metals chosen from the given group. The powder consists of spherical particles with size 20–70 µm, and possessing submicrone structure with evenly distributed wolfram granules which size is no more than1 µm.

The advantage of the proposed method is explained by the opportunity to produce final micropowder of pseudoalloy consisting of spherical particles with sizes 5–100 µm, in which wolfram granules of submicronic size range are evenly distributed in metal binder matrix. This powder can be efficiently used in additive technologies to manufacture products of pseudoalloys with improved performance characteristics.

Thermostating device for conducting nanocalorimetric measurements in controlled atmosphere (RU 2707665 С1)

The claimed thermostating device for conducting nanocalorimetric measurements in controlled atmosphere sets nanocalorimetric sensor in the frame [5]. The device can be integrated into instruments used to measure thermal, physical and structural parameters of the samples. The case of the device can be coupled to connector and it has windows of X-ray transparent material in which nanocalorimetric sensor, Peltier rectangular element, heat removal plate made of thermal conductive material, liquidcooling system embedded in the case are placed. There is a hole on the heat removal plate for radiation transport and a sensor with the studied sample is placed on the plate to provide active part of the sensor within the hole projection. The case is integrated with electric board to couple nanocalorimetric sensors. The technical result: improved applicability of nanocalorimetric methods due to heating the sample up to 450oС and cooling the sample to –20oС, as well as due to creation of controlled atmosphere inside the device (control of humidity and gas mixture content).

A method to produce functional coating based in aluminium-carbon nanotubes (RU 2709688 С1)

The invention refers to the method aimed at production of composite material for manufacturing functional coatings of aluminium and carbon nanofiber alloy and can be used in aircraft, space, shipbuilding and other industries [6]. The method includes following stages: supply of powder by means of two dosing units into supersonic flow of heated gas with formation of heterophase stream and application of powder composition onto article surface. From the first dosing unit powder Al2O3 is introduced into the supersonic flow to process the article until juvenile surface is obtained, then powder composition is consistently applied with gas dynamic cold spray method. To apply the first wear-resistant layer from the second dosing unit composite powder material containing carbon and aluminium is introduced into the supersonic flow; to apply the second one – aluminium powder PA-4; to apply the third hardening layer – composite powder material containing carbon and aluminium; to apply the forth binding layer – aluminium powder PA-4 and to apply the fifth wear-resistant layer – composite powder material containing carbon and aluminium. The carbon content in the first layer is 0,4–0,6 mass. %, Al and inevitable admixtures is the rest; the carbon content in the third layer is 0,5–1 mass. %, Al and inevitable admixtures is the rest; the carbon content in the fifth layer is 0,6–1,6 mass. %, Al and inevitable admixtures is the rest; carbon nanofiber is used as carbon in composite powder material. That provides obtaining of composite material for wear-resistant coating with higher hardness, which is more 1,9 hPa, low friction coefficient up to 0,4, high damage tolerance during performance process and at the same time conservation of low wear, necessary strength and impact toughness.

A method to produce high-strength composite material based on thermoplastic polymer, a modifier for manufacturing composite material and a method to produce modifier for manufacturing composite material (options) (RU 2708583 С1)

The invention refers to the technologies for obtaining a modifier used to produce composite material based on thermoplastic polymer containing carbon, glass or basalt fibers and carbon nanotubes (options) as well as to the methods to produce it and to manufacturing of material containing obtained modifier [7]. According to the first option, the modifier is obtained by mixing thermoplastic polymer (7–15 mass. %), solvent (70– 94 mass. %) and alkali salts (3–15 mass. %) until total polymer resolving. Then nanotubes taken in the quantity up to 5 mass. %. are added into the mixture. A coagulant is introduced into the obtained dispersion. The dispersion is filtered, the precipitation is washed off and dried. According to other options, a modifier for composite material is prepared on the basis of polyamide. Nanotubes are mixed with caprolactam. Dispersion is heated, can be treated with ultra-sound, then caprolactam polymerization catalyst or polymerization activator is added to it. After that the dispersion is heated and dried. To obtain composite material thermoplastic material is mixed with fibers and modifier which contains car-

REVIEW OF NANOTECHNOLOGICAL INVENTIONS bon nanotubes in the quantity from 5 to 33 mass. %. The invention is a solution for creation of high-strength composite material.

A method to produce modified carbon nanotubes (RU 2708596 С1)

The invention refers to nanotechnologies and can be used to strengthen mechanical properties of composite materials based on epoxy resins, to modify mixed glue and to obtain supercondensers [8]. A solution containing carbamide and/or thiocarbamide, water and consentrated mineral inorganic acid is processed in ultra sound concentrator. Then fluoridated carbon nanotubes taken in quantity that provides their concentration 1,2 mg/g in solution are added. Processed solution is diluted and filtered with water washing till neutral acidity. Filtered modified carbon nanotubes are diluted with water, processed in ultra sound bath and diluted with water one more time. The obtained solution are filtered and washed with acetone. The carbon nanotubes modified with carbamide and/ or thiocarbamide are dried. If it is necessary they can be additionally functionalized with water-soluble epoxy resins, for example, DEG-1, TEG-1 or epoxy-hydantoic resin EG-10. That leads to greater final product outcome, decreased energy consumption and reduced time for production modified carbon nanotubes.

A method to process cold-worked titanium of great flow (RU 2709416 С1)

The invention refers to manufacture of nanostructured cold-worked titanium with improved mechanical and corrosion properties and to the methods to process it. The invention can be applied in different engineering areas, including chemical industry [9]. Technical result is a production of cold-worked titanium that combines high values of micro-hardness and high corrosion-resistance: positive steady potential, high capacity to passivation under anodic polarization.

Technical result is achieved due to the following technology: the method to process cold-worked titanium includes great plastic flow deformation by rotation under high hydrostatic pressure no less than 6 hPa under room temperature. According to the invention, the deformation is performed by two rotations and obtained nanostructure of cold-worked titanium consists of 80–85% alpha phase with average size 50–60 nm and 15–20% omega phase. The deformation is performed in Bridgman chamber.

A method to produce coating on the surface of nonferrous metal workpiece (RU 2710094 С1)

The invention refers to mechanical engineering, in particularly to the methods for obtaining coating on the surface of non-ferrous metal workpieces by transferring with high-temperature nanoparticle gas flow [10]. The method includes formation of high-speed atomizing cone of high-temperature gas flow by burning fuel in oxidant in combustion chamber; supply of highspeed atomizing cone of liquid initial material which is a source of nanoparticles formation into combustion chamber; formation, heating and transfer of nanoparticles by means of high-temperature gas flow and precipitation of the nanoparticles on the workpiece surface. At this the material which is a source of nanoparticles formation is simultaneously used as a fuel for high-temperature gas flow formation, and the material is a molecular or colloid solution of organic and/or inorganic compounds in organic solvent or mixture of several solvents. Transfer by means of high-temperature gas flow of nanoparticles and precipitation of them on the workpiece surface is performed jointly with workpiece surface prior processed with electric arch generated between two wolfram electrodes under alternate current 35–45 А, resistance 12–16 V and moving along workpiece surface with the rate of high-speed spray atomized set to spray at the distance between the arch and gas stream woth sprayed powder material 2–4 mm. Technical result of the invention is increased adhesion strength, increased cohesion durability of material coating and reduced porosity of the coating.

A method to purify polluted subsoil water with nanosize ferrum of zero valency ( RU 2709593 С1)

The invention refers to water treatment [11].

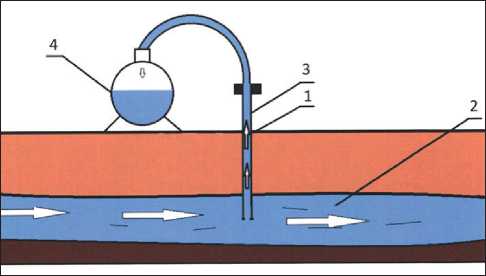

Fig. 2

A method to purify polluted subsoil water includes introduction of suspension of nanosize zero-valent ferrum into drilled hole 1 (Fig. 2) under overpressure exceeding the pressure of purified horizont. Drilling of the hole 1 is performed till the middle of bedding of purified water-bearing strata 2. Underground reservoir 5 is made by means of hydro expanding. Proppant is pumped in the reservoir. Suspension is obtained by mixing nano-

REVIEW OF NANOTECHNOLOGICAL INVENTIONS size zero-valent ferrum with normalized water till values рН 4,5–5,5. Metal guide tube 3 is placed into the hole 1. One pole terminal of alternating-current source with frequency 0,5–5 Hz is coupled to the guide tube, and the second terminal pole is coupled to ground which distance from the hole 1 is two-three depths of the hole 1. The invention makes it possible to increase the value of water treatment and prevent from purification substances loss.

A catalyst of combined hydrotreatment for a mixture of vegetable and oil hydrocarbon stock and a method to prepare it (RU 2707867 С2)

The invention refers to chemistry, in particularly to production of catalysts used for hydrotreatment of vegetable and oil hydrocarbon stock and can be applied in oil refining and petrochemical industries [12]. Technical result is creation of a new catalyst of combined hydrotreatment for a mixture of vegetable and oil hydrocarbon stock. The catalyst possesses increased activity in reactions of sulfur and oxygen removal compared to traditional bimetal systems due to simultaneous employment of two promoting metals (Со и Ni) as promoter. Technical result is achieved due to catalyst of combined hydrotreatment for a mixture of vegetable and oil hydrocarbon stock which contains in calcined under 550oС state: Mо – 9,0–15,0% mass., Со – 0,5–3,5% mass., Ni – 0,5–3,5% mass., the rest – porous carrier with carbon content 0–5% mass.; specific surface of the catalyst is 100–250 m2/g, specific volume of the pores is 0,3–1,1 cm3/g, average diameter of the pores is 4,0–10,0 nm.

These are inventions in nanotechnological area that can be interesting for specialists:

CONCLUSION

It is known that it is precisely the popularization and introduction of inventions that is an important factor for the success of many successful companies. For example, General Electric, which entered world history as one of the most innovative companies of the 20th century, is a company that was originally listed in the Dow Jones index in 1896 and is still there. Therefore, we hope that the information published in this section will be in demand and useful for specialists. Confirmation that articles from the «Invention Review» column are particularly popular is information on the number of views of materials, for example, in the full-text database of open access scientific journals Open Academic Journals Index OAJI (USA), link – journal-detail. html? number = 6931.

Список литературы Nanotechnologies: a review of inventions and utility models. Part I

- Zhigach A.N., Lejpunskij I.O., Berezkina N.G. et al. Sposob poluchenija nanoporoshka karbida titana [A method to produce titanium carbide nanopowder]. Patent RF 2707596 C2. 2019. Bul. № 34.

- Ljovin B.A., Pashinin V.A., Nedorchuk B.L. et al. Sposob poluchenija uprochnjaemogo oksidami nanoporoshkov metallov kompozicionnogo materiala na osnove zheleza [A method to produce ferrum-based composite material strengthened with metal nanopowder oxides]. Patent RF 2707686 C1. 2019. Bul. № 34.

- Shemuhin A.A., Kushkina K.D., Vorob’eva E.A. et al. Sposob modifikacii uglerodnyh nanotrubok dlja poluchenija gidrofil’nyh ili gidrofobnyh poverhnostej [A method to modify carbon nanotubes for hydrophilic or hydrophobic surfaces]. Patent RF 2707930 C1. 2019. Bul. № 34.

- Samohin A.V., Fadeev A.A., Alekseev N.V. et al. Sfericheskij poroshok psevdosplava na osnove vol’frama i sposob ego poluchenija [Spherical powder of pseudoalloy based on wolfram and a method to produce it]. Patent RF 2707455 C1. 2019. Bul. № 33.

- Rychkov A.A., Ivanov D.A. Termostatirujushhee ustrojstvo dlja provedenija nanokalorimetricheskih izmerenij v kontroliruemoj atmosphere [Thermostating device for conducting nanocalorimetric measurements in controlled atmosphere]. Patent RF 2707665 C1. 2019. Bul. № 34.

- Skvorcova A.N., Farmakovskij B.V., Gerashhenkov D.A. et al. Sposob poluchenija funkcional’nogo pokrytija na osnove aljuminij-uglerodnyh nanovolokon [A method to produce functional coating based in aluminium-carbon nanotubes]. Patent RF 2709688 C1.2019. Bul. № 35.

- Predtechenskij M.R., Sajk V.O., Bezrodnyj A.E.. et al. Sposob poluchenija vysokoprochnogo kompozicionnogo materiala na osnove termoplastichnogo polimera, modifikator dlja prigotovlenija kompozicionnogo materiala i sposob poluchenija modifikatora dlja prigotovlenija kompozicionnogo materiala (varianty) [A method to produce high-strength composite material based on thermoplastic polymer, a modifier for manufacturing composite material and a method to produce modifier for manufacturing composite material (options)]. Patent RF 2708583 C1. 2019. Bul. № 34.

- Krestinin A.V., Marchenko A.P., Radugin A.V. Sposob poluchenija modificirovannyh uglerodnyh nanotrubok [A method to produce modified carbon nanotubes]. Patent RF 2708596 C1. 2019. Bul. № 34.

- Glezer A.M., Shurygina N.A., Rakoch A.G. et al. Sposob obrabotki tehnicheski chistogo titana bol’shoj plasticheskoj deformaciej [A method to process cold-worked titanium of great flow]. Patent RF 2709416 C1. 2019. Bul. № 35.

- Balaev Je.Ju.O., Eliseev V.N.. Sposob poluchenija pokrytija na poverhnosti detali iz cvetnyh metallov [A method to produce coating on the surface of non-ferrous metal workpiece]. Patent RF 2710094 C1. 2019. Bul. № 36.

- Sementsov R.N. Sposob ochistki zagrjaznennyh gruntovyh vod s ispol’zovaniem nanorazmernogo zheleza nulevoj valentnosti [A method to purify polluted subsoil water with nanosize ferrum of zero valency]. Patent RF 2709593 C1. 2019. Bul. № 35.

- Kokljuhin A.S., Ishutenko D.I., Sal’nikov V.A. et al. Katalizator sovmestnoj gidroochistki smesi rastitel’nogo i neftjanogo uglevodorodnogo syr’ja i sposob ego prigotovlenija [A catalyst of combined hydrotreatment for a mixture of vegetable and oil hydrocarbon stock and a method to prepare it]. Patent RF 2707867 C2. 2019. Bul. № 34.

- Ivanov LA., Razumeev K.E., Bokova E.S., Muminova S.R. The inventions in nanotechnologies as practical solutions. Part V. Nanotehnologii v stroitel’stve = Nanotechnologies in Construction. 2019, Vol. 11, no. 6, pp. 719–729. DOI: 10.15828/2075- 8545-2019-11-6-719-729.

- Pervikov A.V., Glazkova E.A., Muzhetskaja S.Ju. Sposob poluchenija smesi mikro- i nanochastic binarnyh splavov [A method to obtain a mixture of micro- and nanoparticles of binary alloys]. Patent RF 2709304 C1. 2019. Bul. № 35.

- Mustafin I.A., Sidorov G.M., Stankevich K.E. et al. Gidrokataliticheskie processy pererabotki tjazhelyh neftjanyh frakcij s ispol’zovaniem perspektivnyh nanorazmernyh katalizatorov [Hydrocatalytic processes of recycling heavy oil fractions with the use of perspective nanosize catalysts]. Fundamental’nye issledovanija [Fundamental Research]. 2018. № 7. P. 22–28.

- Tkachev A.G., Melezhik A.V., Osipov A.A. et al. Sposob poluchenija oksida grafena [A method to produce graphene oxide]. Patent RF 2709594 C1. 2019. Bul. № 35.

- Ivanov L.A., Demenev A.V., Muminova S.R. The inventions in nanotechnologies as practical solutions. Part II. Nanotehnologii v stroitel’stve = Nanotechnologies in Construction. 2019, Vol. 11, no. 2, pp. 175–185. DOI: 10.15828/2075-8545- 2019-11-2-175-185.

- Ivanov A.V., Miftahutdinova A.A., Sorokin A.Ju. et al. Sposob snizhenija jelektrizacii zhidkih uglevodorodov pri obrashhenii s nimi [A method to decrease electrization of liquid hydrocarbons when applying them]. Patent RF 2709609 C1. 2019. Bul. № 35.

- Bagramov R.H., Serebrjanaja N.R., Blank V.D. Sposob poluchenija kompozicionnogo materiala bor-uglerod [A method to produce composite material boron-carbon]. Patent RF 2709885 C1.2019. Bul. № 36.

- Predtechenskij M.R., Muradjan V.E. Uprochnennyj stekljannyj sosud (varianty) i sposob uprochnenija stekljannogo sosuda [Strengthened glass jar (options) and a method to strengthen glass jar]. Patent RF 2707612 C1. 2019. Bul. № 34.

- Ivanov LA., Prokopiev P.S. The inventions in nanotechnologies as practical solutions. Part IV. Nanotehnologii v stroitel’stve = Nanotechnologies in Construction. 2019, Vol. 11, no. 4, pp. 447–457. DOI: 10.15828/2075-8545-2019-11-4-447-457.

- Sidorov G.M., Jahin B.A., Ahmetov R.F. Modelirovanie raboty staticheskogo smesitelja (neft’ - voda) dlja obessolivanija nefti i opytno-promyshlennoe ispytanie [Modeling of static mixer (oil–water) performance for oil desalting and development test]. Uspehi sovremennogo estestvoznanija [Achievements of the modern natural science]. 2017. № 2. P. 152–156.

- Ustinovich K.B., Gol’dt A.E., Shul’ga E.V. et al. Sposob hromatograficheskogo razdelenija odnoslojnyh uglerodnyh nanotrubok po hiral’nosti [A method of chromatographic separation of single layer carbon nanotubes by chirality]. Patent RF 2709890 C1. 2019. Bul. № 36.

- Malkin P. Wastewater treatment system based on nanomodified natural sorbents. Nanotehnologii v stroitel’stve = Nanotechnologies in Construction. 2018, Vol. 10, no. 5, pp. 56–72. DOI: dx.doi.org/10.15828/2075-8545-2018-10-5-56-72.

- Podzorova L.I., Il’ichjova A.A., Kutuzova V.E. et al. Keramicheskij kompozicionnyj material [Ceramic composite material]. Patent RF 2710648 C1. 2019. Bul. № 1.