New data on iron-smelting sites in the Kuektanar and Turgun valleys, Southeastern Altai

Автор: Agatova A.R., Nepop R.K., Slyusarenko I.Y., Panov V.S.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 2 т.46, 2018 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145145370

IDR: 145145370 | DOI: 10.17746/1563-0110.2018.46.2.090-099

Текст обзорной статьи New data on iron-smelting sites in the Kuektanar and Turgun valleys, Southeastern Altai

On the basis of archaeological studies conducted in 1970s within the high-mountain southeastern part of the Russian (Gorny) Altai, N.M. Zinyakov distinguished the Chuya-Kurai metallurgical province (1988: 31). The region has yielded 29 out of 32 currently known

Altai ferrous metallurgy sites, including a special type of iron-smelting furnace (or “bloomer”) known as the Kosh-Agach type. Analysis of accompanying artifacts, as well as the typological similarity to furnaces of other archaeological cultures dated to the second half of the 1st millennium AD, allow these features to be inferentially linked to the 6th to 10th centuries AD (Ibid.: 51).

During geological and geomorphological studies aimed at reconstruction of hydrological transformations in the Kurai and Chuya basins in the Late Pleistocene and Holocene (Agatova et al., 2016; Agatova, Nepop, Slyusarenko, 2017), we also investigated ferrous metallurgy sites in the mouth of the Kuektanar River (specifically, in the Chuya valley between Chuya and Kurai basins) and in the Turgun valley (the western part of the Kurai basin). These sites are Kuektanar-1 and -2 and Turgun-1, sites originally described by Zinyakov (1988: 36–37, 46–49). Despite the fact that charcoal fragments were found in exterior depressions and furnace fill, only one radiocarbon date (1775 ± 35 BP (SOAN-5040) (Gutak, Rusanov, 2013)) was available for the site of Kuektanar-2, located in the Chuya valley near the mouth of the Kuektanar River. On the basis of this non-calibrated date, researchers concluded that the site was active during the Hun-Sarmatian period. Flakes of a variety of hematite (specular hematite) found near the smelting location also led to the assumption that ore mining for iron-smelting production took place in the Sailugem ridge (Ibid.), i.e. at a distance of about 100–150 km from the mouth of the Kuektanar, at the opposite edge of the Chuya basin. Unlike the Late Paleolithic surface finds, which bear traces of redeposition (Agatova, Nepop, Slyusarenko, 2017), these iron-smelting furnaces constructed on river terraces are in situ sites. Thus, they can be used to help estimate the upper age limit of deposits and topography formation processes, and geologic inquiry can also identify the nearest sources of combustibles and raw materials for the iron-smelting production in the past.

This article outlines the following: 1) the results of new radiocarbon dating, including that with the use of accelerator mass-spectrometry (AMS), of charcoal fragments from the furnaces of Kuektanar-1 and -2 and Turgun-1, including analysis of species composition of tree vegetation that was used for smelting; 2) assessment of the retreat rate of slopes of the river terraces after construction of the furnaces; 3) analysis of possible sources of mineral raw materials and combustibles for arrangement of iron-smelting production in the Kuektanar and Turgun valleys.

Materials and methods

Bark and charcoal fragments from the filling of furnaces and slag pieces were selected as materials for traditional, scintillation based radiocarbon dating and Acceleratory Mass Spectrometry (AMS). Radiocarbon dating by the scintillation method was conducted in the Cenozoic Geochronology Center (Novosibirsk, SB RAS) and Laboratory of Radiocarbon Dating and Electron Microscopy (Moscow, Institute of Geography RAS) following the standard procedure outlined by Arslanov (1987). Determination of the residual activity of carbon in both laboratories was performed using the QUANTULUS-1220 unit. AMS-dating was conducted in the Arizona State University (USA), and sample preparation in the Cenozoic Geochronology Center (NSKA). A half-life of 14С equal to 5570 years was used to calculate the age. Radiocarbon dates were calibrated using the CALIB Rev 5.0 program (Stuiver, Reimer, 1993), using the IntCal09 calibration database (Reimer et al., 2009).

In order to obtain material for radiocarbon dating from sites near the mouth of the Kuektanar, we conducted new archaeological and geomorphological investigations at Kuektanar-1 and -2 in 2013 and 2014 (for a detailed geomorphological description of this area, and location of the sites in the relief, see (Agatova et al., 2014, 2016)).

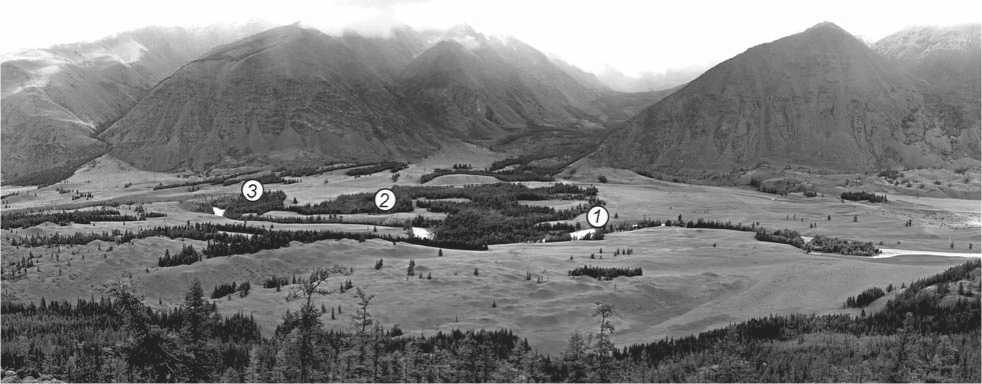

Kuektanar-1 (50º08′ N, 88º18′ E, 1721 m a.s.l.) is situated on the right bank of the Chuya River, upstream of the mouth of the Kuektanar (Fig. 1). It consists of two ancient furnaces, eroded due to retreat of the river bank. In this area, the Chuya cuts through boulderheavy glacial moraine deposits of the Kuektanar glacier, overlain by wind-blown thin lacustrine sands (the traces of a landslide-moraine-dammed paleolake). The river makes a sharp turn at the site, and this bend produces high-intensity bank erosion. Judging by the series of shallow ravines cut into the beach scarp, the number of furnaces may originally have been greater; however, only two of them were recorded when the site was originally noted (Zinyakov, 1988: 46). The ground around the remains of furnaces has been colored red through calcination.

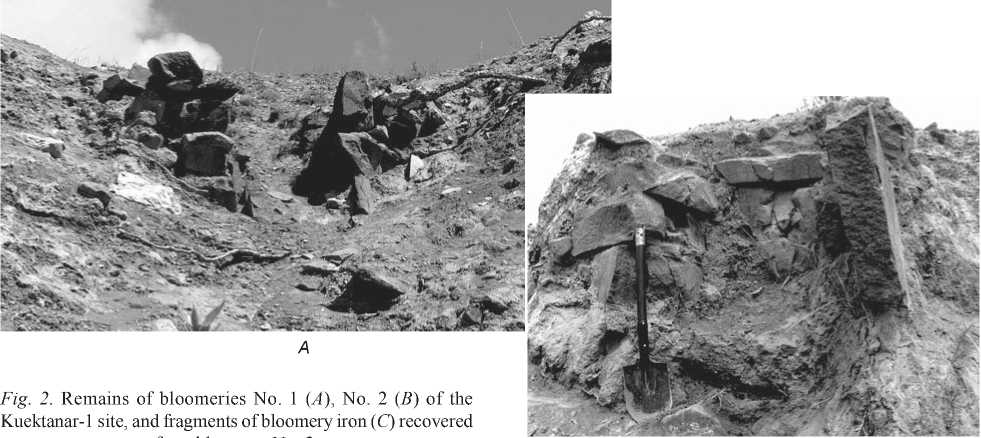

In 2013, only small fragments of structural stone slabs with remains of “puddleclay” lining used in smelting were preserved from upstream bloomery (No. 1). The flat stone floor, which was originally 15 cm thick (according to description made by Zinyakov (Ibid.)), had completely collapsed by the time of our visit, along with the rear wall (Fig. 2, A ).

The rear structural slab wall and adjacent fragments of the lateral furnace slab walls, overhanging the cliff, are preserved from downstream bloomery No. 2 (Fig. 2, B ). The associated exterior depression and the adjoining slag offtake channel, along with the front wall (originally composed of two vertical stone slabs placed at a shallow angle relative to each

Fig. 1 . Area of the Chuya valley between the Chuya and Kurai basins, near the Kuektanar mouth, with indication of locations of ferrous metallurgy sites.

1 – Kuektanar-1; 2 – Kuektanar-2; 3 – earlier unknown locality.

other, a portion of a side wall, and a flat-slab floor 6–10 cm thick, according to Zinyakov (Ibid.: 47)) are now totally lost. The three-layer fill of interior chamber, whose lower layer consisted of mixture of slag and charcoal, did not survive either (Ibid.). Nevertheless, we recovered pieces of uncharred bark, charcoal, and small fragments of slag and ore (hematite with quartz) from under the base of the rear slab (Fig. 2, C ).

X-ray spectrum microanalysis conducted by A.V. Korsakov (V.S. Sobolev Institute of Geology and Mineralogy SB RAS) using a scanning microscope MIRA 3 LMU (Tescan), with the microanalysis system Inca Energy 450 XMax 80 (Oxford Instruments) demonstrates that the slag composition is dominated by wustite (FeO) and fayalite (Fe2SiO4), both iron-bearing minerals (for more detailed information about the mineralogy of slags and the metallurgical process see (Agatova, Nepop, Korsakov, 2017)). Having studied several charcoal fragments, V.S. Myglan (Siberian Federal University) and N.I. Bykov (Altai State University) determined that they belong to Siberian larch species. A radiocarbon date of 1250 ± 65 BP (SOAN-9091) was obtained for the recovered layer of charcoal chips, and a piece of uncharred conifer bark was dated to 1368 ± 42 (NSKA-00832) with the AMS technique.

Kuektanar-2 (50º09′ N, 88º18′ E, 1738 m a.s.l.) is situated on the surface of 2-meter right-bank terrace of the Kuektanar right branch. Here, Zinyakov discovered a well-preserved bloomery (Ibid.: 48). According to his description, the major part of the furnace shaft was constructed in a pit approximately 150 cm deep. The side and rear walls were composed of flat stone slabs ~80 cm high, while the front wall was made of small stone pieces with an opening for flushing of slag. The furnace chamber above the stone foundation was made of clay. The furnace chamber fill consisted of an 80-centimeter layer of burnt earth and clay fragments, which overlapped large pieces of slag and charcoal. In 2014, when examining this place (now overgrown with a young larch forest), we discovered a half-filled pit, with walls that had been burnt to a red color. By the time of our visit, only fragments of furnace masonry were preserved; the upper part of the shaft made of clay had already degraded. A lot of large slag pieces, with large charcoal fragments included therein (sometimes in a single charred piece), were scattered around on the surface (Fig. 3). To produce iron using the bloomery method, as in bloomery No. 2 at Kuektanar-1, species analysis suggests that the site’s occupants used larchwood (definitions by V.S. Myglan and N.I. Bykov). Wood was used along with ore in the ratio of approximately 4 : 1. A date of 1515 ± 33 BP (NSKA-00833) was obtained by means of Accelerator Mass Spectrometry, using an interior portion of the large charcoal fragments recovered from within the slag.

Previously unknown furnace locality (50º09′ N, 88º17′ E, 1730 m a.s.l.). This site was discovered during our geological and geomorphological survey of the Kuektanar mouth area. A series of ravines, on the sides of which the ground had been calcined to red, was discovered at the cliff edge of the upper 25-meter right-bank terrace of the Chuya, downstream of the mouth of the Kuektanar (see Fig. 1). Here, a bend

А

Fig. 2. Remains of bloomeries No. 1 ( A ), No. 2 ( B ) of the Kuektanar-1 site, and fragments of bloomery iron ( C ) recovered

in the Chuya has exposed the sediments in the bank (from bottom to top): bedrock, Tertiary carbonous fluvio-lacustrine sediments, large-boulder moraine loams, lacustrine sands and loams, and finally subaerial (aeolian lacustrine) sands with paleosol horizons, the lower of which was formed not later than 8 ka BP (Agatova et al., 2016). As in the case of Kuektanar-1, a number of bloomery furnaces existed here before the retreat and ultimate collapse of a considerable part of the embankment. After destruction of furnaces, small ravines formed at the former shaft locations.

In 2015, in the northwestern part of the Kurai basin (the Turgun valley, another right-bank tributary of the Chuya), we explored one of two previously known

C

0 3 cm

bloomery localities to select samples for radiocarbon dating (Zinyakov, 1988: 36).

The Turgun-1 site (50º15′ N, 87º53′ E, 1621 m a.s.l.) is located on the slope of right-bank terrace, which is actively slumping. The exact number of iron-smelting furnaces was not clear, owing to the erosion of the river bank. However, the distribution of a large quantity of slag fragments enabled Zinyakov to suggest that at least three furnaces were originally present (Ibid.). During excavations, he discovered one underground/overground

Fig. 3. Slag with large charcoal inclusions at the location of the iron-smelting furnace at Kuektanar-2.

furnace; slag and charcoal were recorded in its shaft filling and in an adjacent depression. Estimating the date of the smelter’s use was beyond the scope of our research goals, so no test excavations were undertaken. Nevertheless, in order to determine the upper age limit of formation of the first Turgun fluvial terrace, we dated the charcoal included in one of the large slag fragments littering the surface of the terrace (1270 ± 70 BP) (IGAN-5012).

Discussion

Age of furnaces. Despite the abundance of charcoal in the furnaces and associated depressions, radiocarbon dating was not undertaken during initial investigations of Altai metallurgy during 1980s, and conclusions about the age of sites were drawn only based on the typological characteristics of furnaces and presence of rare artifacts. Though bloomeries of the Chuya-Kurai metallurgical province do not have direct analogs in adjoining territories, comparison of individual structural elements enabled Zinyakov (1988: 50–51, 74) to draw parallels with sites of the 6th–9th centuries AD found in the Khakass-Minusinsk Basin (Sunchugashev, 1975: 93–100), and with the Saltovo type of furnaces of the 8th–9th centuries AD (Afanasiev, Nikolaenko, 1982). Furthermore, a fragment of a ceramic vessel rim, decorated with thumbnail depressions and pits in the upper portion, was discovered in the filling of the working chamber of bloomery No. 2 at Kuektanar-1 (Zinyakov, 1988: 50–51). Ceramics with similar decorations are known in the Altai region from assemblages dated to the 6th–7th centuries AD from Kudyrge burial ground (Gavrilova, 1965: 36) and in the complexes of the 7th–9th centuries AD (Stepi…, 1981: 41). On the basis of these comparisons, Zinyakov dated bloomeries of the southeastern Altai to between the 6th–10th centuries AD (1988: 51).

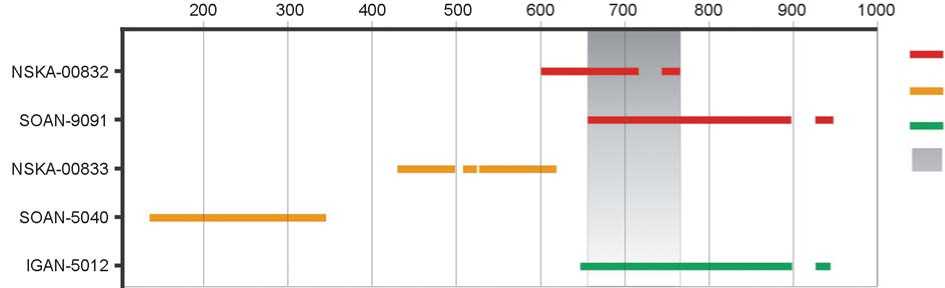

After calibration (at a 2-sigma confidence interval), our new radiocarbon dates for charcoal from the furnaces of three sites (Kuektanar-1, -2, and Turgun-1) fall across a wide interval spanning the 5th through first half of the 10th century AD (see Table , Fig. 4). In general, dates on charcoal will tend to represent an earlier age than the actual time of smelting, as their radiocarbon signature will reflect the age of the wood itself. Wood pieces recovered from furnaces at the investigated sites showed approximately 25 annual rings each, and represented trees whose wood growth had already become stable; i.e. it can be stated with a high degree of confidence that the trees used for smelting had reached an age of 100 years or more. Larches in the Chuya valley can reach the age of 400–450 years (it is difficult to assess the diameter of trunks of such trees, but according to Myglan they can vary from 25 to 50 cm wide in the similar presentday landscape). Thus, a difference up to 300 years and more in radiocarbon ages of charcoals may result from the fact that the samples represent different parts of tree trunk.

Charcoal from the furnace at Kuektanar-2 proved to be older than those from Kuektanar-1 and Turgun-1, dating to between 428–617 AD (2 sigma calibrated range, see Table , Fig. 4). An even more ancient date for charcoals from this locality was obtained by Y.M. Gutak and G.G. Rusanov (2013)— 1775 ± 35 BP (SOAN-5040), or ca 134–344 AD (2 sigma calibrated range). Taking into consideration the old wood effect, we propose that the latter of these dates (428–617 AD) is closer to the time of furnace functioning. Accordingly, we reason that the hypothesized construction of the furnace from Kuektanar-2 in the Hun-Sarmatian epoch (the

Radiocarbon dates

|

Archaeological site |

Material |

Lab code |

Radiocarbon age |

Intervals of calibrated values (2σ), years AD |

|

Kuektanar-1 |

Fragment of bark |

NSKA-00832 |

1368 ± 42 |

599–716, 743–765 |

|

Small charcoal pieces |

SOAN-9091 |

1250 ± 65 |

655–897 and 925–944 * |

|

|

Kuektanar-2 |

Fragment of charcoal |

NSKA-00833 |

1515 ± 33 |

428–497, 506–523, 526–617 |

|

Charcoal pieces ** |

SOAN-5040 |

1775 ± 35 ** |

134–344 |

|

|

Turgun-1 |

Charcoal |

IGAN-5012 |

1270 ± 70 |

644–897 and 925–943 |

Note. The dates having SOAN and IGAN lab codes have been obtained by the scintillation method, those with NSKA code with the use of accelerator mass-spectrometry (AMS).

*An interval that is not valid (see explanations in the text).

**After (Gutak, Rusanov, 2013).

Fig. 4. Calibrated (2σ) radiocarbon dates for coals from the iron-smelting furnaces.

a – Kuektanar-1; b – Kuektanar-2; c – Turgun-1; d – the interval during which the last smelting occurred in bloomery No. 2 of Kuektanar-1.

2nd century BC to the first half of the 5th century AD), as was proposed by Gutak and Rusanov (Ibid.), is hardly probable. Based on our analyses, it is much more likely that the feature was used during the Old Turkic epoch. Nonetheless, while the number of dates is small, the difference between date estimates from the three sites (even taking into account the old wood effect) suggests that the Kuektanar-2 furnace was constructed earlier than the other features. The period of operation of these Chuya valley smelting sites, both upstream and downstream of the Kuektanar mouth, may not have overlapped in time, despite the fact that the bloomeries appear to have been used and reused many times: the feature fill of the associated exterior depression of bloomery No. 2 at Kuektanar-1 consisted of seven charcoal and slag layers, separated by layers of calcined ground (Zinyakov, 1988: 46).

A radiocarbon date (NSKA-00832) on uncharred conifer bark, a fragment of which was found in bloomery No. 2 at Kuektanar-1, falls in the interval of 599 to 765 AD (2 sigma calibrated range), i.e. the 7th–8thcenturies AD. This find is unique. Because of its position at the exterior of the tree, the radiocarbon age of bark corresponds to the age of tree felling, and with great probability to the time of last smelting. This unambiguously indicates that from two possible calibrated date ranges comprising the 2-sigma (95 %) confidence interval for another radiocarbon date (SOAN-9091) from the same furnace (655–897 and 925–944 AD), the first one contains the true value. Thus, the NSKA-00832 and SOAN-9091 dates suggest that the last smelting was probably performed between 655 and 765 AD (according to the intervals of calibrated values, from 655 to 716 or from 743 to 765 AD), i.e. in the middle of the 7th to the middle of the 8th centuries AD (Fig. 4). The accuracy of radiocarbon analysis makes it impossible to narrow this 100-year interval; however, the obtained results refine the typological dating (based on artifacts) and place construction of bloomery No. 2 furnace at Kuektanar-1 during Old Turkic epoch. In spite of the fact that Kyrgyz culture artifacts were found near the mouth of the Kuektanar, in sandy deposits not far from this site (Hudiakov, 1990), they thus appear to be unrelated to the iron-smelting furnaces on the Chuya bank.

The IGAN-5012 radiocarbon date from a charcoal fragment taken from slag found at Turgun-1 also appears to coincide with the SOAN-9991 date from Kuektanar-1. The results of its calibration show two probability intervals (together comprising a 2-sigma confidence interval), 644–897 and 925–943 BP (Fig. 4). However, unlike Kuektanar-1, there is no convincing selection criterion to favor one of these date ranges. Therefore it can only be hypothesized that the furnaces both at the Kuektanar mouth and in the Turgun valley, situated at a distance of more than 30 km from each other, were used during the same interval.

In general, the common style of furnaces at all three study sites points to their construction within the same cultural period. Even if a change of metallurgical practices took place following the erection of the oldest of these three structures (Kuektanar-2), the new artisans appear to have fully adopted previous traditions of bloomery construction.

A series radiocarbon dates for the Old Turkic sites in the Chuya basin has been previously published (Kubarev G.V., 2005: 139; Kubarev G.V., Orlova, 2006). The earliest one is the burial of mound 10 at the Ulandryk I cemetery (ca 539–657 AD), which makes it possible to assign it to the Kudyrge stage, at least on chronological terms (following the classification by

A.A. Gavrilova (1965: 58–61)). However, this mound is a marked contrast to the Kudyrge burials with respect to the associated artifacts (Kubarev G.V., Orlova, 2006: 140–141). Monumental structures as the enclosure at the Kyzyl-Shin site, at the lower course of the Chagan-Uzun River (407–645 AD) (Ibid.: 140), and enclosures with statues from Apshiyakta I, at the lower course of the Chuya River (429–652 AD) (Kubarev G.V., 2017: 101), belong to the beginning of the epoch. Mound 2 of the Kalbak-Tash cemetery (886–987 AD) and the funerary enclosures in the Yustyd valley (897–1019 AD) and on the Dyer-Tobe hill (981–1029 AD), in contrast, belong to the late Old Turkic period (Kubarev G.V., Orlova, 2006: 140).

Thus, the dates for coal recovered from the iron-smelting furnaces of Kuektanar-1, -2, and Turgun-1 align with the documented chronology for Old Turkic culture in southeastern Altai that was determined using the radiocarbon dating method.

Retreat rate of the Chuya River bank since construction of furnaces. Reconstructions of the initial sizes of bloomeries and adjacent features (Zinyakov, 1988: 46–48), as well as estimated dates for termination of site activity, allow us to estimate the slope retreat rate of terraces, on which iron-smelting furnaces were constructed. During the study of the Kuektanar-1 site by Zinyakov, the length of the remaining portion of the working chamber of bloomery No. 1 reached 80 cm. Retreat of the bank over a period of almost 50 years came to at least 50 cm. By the time of our survey in 2013, only portions of side walls facing the slope were preserved (see Fig. 2, A ).

The initial furnace length reconstructed by the outlines of chamber walls could have reached 130 cm, and a sufficiently hard-sized working space before a furnace of this type is about 5 m (Ibid.: 31–49). Consequently, we estimated that the slope retreated by at least 6 m since the time of furnace construction. Assuming that bloomeries No. 1 and No. 2, located 50 m from each other, are of similar age, and taking into account the obtained data on the time of last smelting in bloomery No. 2 (placing its final use between 655–765 AD), the average rate of the Chuya cliff retreat at this place during the last 1500 years can be assessed at approximately 0.5 cm per year.

By the time of examination of bloomery No. 2 by Zinyakov, the length of its working chamber was 125 cm, the length of the slag offtake channel 55 cm, and the length of the remnant depression at the forefront of the bloomery was 155 cm. Thus, at that time, the distance from the existing rear wall of the furnace (see Fig. 2, B) to the river escarpment was about 335 cm. This represents the extent slope retreat at this place over a time period of no more than 50 years. The collapse of a large block was probably caused by disturbance of slope substrate cohesiveness due to undercutting of the furnace, slag offtake channel, and associated depression. It is not improbable that intensification of the slope collapse was also facilitated by archaeological excavations conducted by Zinyakov. Taking into account the data on the time of last smelting and sufficiently hardsized furnaces and working spaces in front of them, the approximate average retreat rate of the Chuya cliff over the last ~1500 years, as with bloomery No. 1, appears to be around 0.5 cm per year.

Despite the fact that the original distance between furnaces and the terrace edge is not reliably known, our numeric evaluation gives a general idea of the average retreat rate of the Chuya bank near the Kuektanar-1 site since its construction. Apparently, at the location of the sharp bend the Chuya River bed downstream of the Kuektanar, it was even higher—at present, a series of furnaces here can only be inferred on the basis of remnant erosional rills showing traces of thermal action on their slopes. Obviously, the river-cut cliff retreat has not been uniform across time and space. Intervals of a relatively stable state of the slope appear to have alternated with catastrophic detachments and landslides of large blocks of substrate formed by boulder and pebble moraine loams. This resulted in almost full destruction of iron-smelting sites on the Chuya cliff.

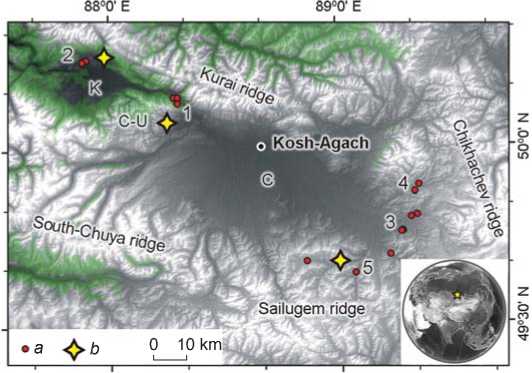

Possible sources of ore and combustibles. Development of iron-smelting production in southeastern Altai was facilitated by favorable combination of accessible crude ore and forest resources. At present, owing to aridization of climate to the southeast, the forest vegetation within the Kurai-Chuya intermountain basins system is confined mainly to its southern edge. Forest vegetation thus forms a single belt in the Kurai basin, with only isolated occurrence in the western part of the Chuya basin, and forests are absent in its eastern part (Fig. 5). However, the presence of a vast number of mounds comprised of massive wooden funeral structures in the eastern portion of the basin (Kubarev V.D., 1987, 1991; Bykov, Bykova, Slyusarenko, 2005; Kubarev V.D., Shulga, 2007), as well as pottery kilns and iron-smelting furnaces (the largest ones in southeastern Altai) in the Yustyd, Bar-Burgazy, and Ulandryk valleys (Zinyakov, 1988: 38–42, 213– 218; Kubarev V.D., Zhuravleva, 1986), suggests a former forest coverage of this area, including the

Fig. 5. Locations of the iron-smelting furnaces, sources of raw materials and fuel in the territory of the Chuya-Kurai basins.

a – iron-smelting sites: 1 – in the Kuektanar mouth, 2 – in the Turgun valley, 3 – in the Yustyd valley, 4 – in the Bar-Burgazy River basin, 5 – in the Ulandryk River basin; b – iron-ore deposits and ore manifestations discussed in the article. C – the Chuya basin, K – the Kurai basin, C-U – the Chagan-Uzun massif. Forest vegetation is shown in green.

period of interest (6th–10th centuries AD). In general, enhancement in climate aridization, along with accompanying changes in the forest vegetation area of the Chuya basin, is demonstrated by several climate proxies across the last 1.5 thousand years (Agatova et al., 2014, 2016). Therefore, the interpretation that Kuektanar area was chosen as an area for iron smelting due to its proximity to Sailugem (Gutak, Rusanov, 2013), is highly questionable, from our point of view. This perspective ignores the changes in climate and landscapes and conflates environmental conditions of the 1st millennium AD with modern ones.

Most probably, ore was delivered to the Kuektanar mouth from places closer than the Rudny Log deposit, which is located around 100 km away, in the southeastern part of the Chuya region, in the Bolshie Shibety River valley (Fig. 5). Iron-smelting furnaces discovered by Zinyakov (at the sites of Buraty, Koch-Korbas) in the immediate vicinity of this deposit point not only to the availability of necessary fuel in the eastern part of the Chuya basin during the period of their construction and use, but also suggest that ancient metallurgists placed their production facilities near the iron ore sources (Zinyakov, 1988: 200, 210). Hematite ore manifestations are known in the vicinity of the Kurai village, at a distance of only 30–40 km from the Kuektanar and, moreover, on the right bank of the Chuya (Ibid.: 201). Here, use could also have been made of local hematite and siderite ores, deposits of which are recorded not far from the Chagan-Uzun village, on the eastern slope of the Chagan-Uzun massif (separating the Chuya and Kurai basins). They are located on the left bank of the Chuya, but much nearer to the center of metallurgical activity at Kuektanar. In September to the first half of October, the water level in the Chuya drops dramatically, which makes it possible to wade across the river on horseback or camelback. The river freezes over in October–November. In January–February, the ice is the strongest and, if necessary, the frozen surface can be used to move large ore volumes in order to build up supplies for the warm season. Besides, in order to smelt enough iron to satisfy the economic needs of nomads, it was not necessary to have an entire hematite deposit, but a smaller ore outcrop or source, which could have been located even closer (and later mined out completely).

Thus, we argue that the concentration of a large number of furnaces in the Kuektanar mouth was due not only to abundance of forest trees (which were considerably reduced by ancient metallurgists), but also to close location of a number of ore deposits and occurrences (which, however, does not rule out delivery of rich ore from other places, including Sailugem). In addition, horizons and lenses of the Neogene brown coals, which could also be used as combustibles for smelting, were also unearthed here in the Chuya River escarpment. A similar combination of favorable conditions also probably resulted in the formation of another large center of iron-smelting production in the Turgun valley.

Conclusions

The results of radiocarbon dating of charcoal from the bloomeries of the Kuektanar-1 and -2, and Turgun-1, part of the Chuya-Kurai metallurgical province of the Russian (Gorny) Altai, suggest the use of forests that grew in this region between the 5th and 10th centuriesAD as fuel for metallurgical production. Mature larchwood as old as 100 years or more was used as raw material for fuel. Since larches in the Chuya valley can reach the age of 400–450, the observed difference up to 300 years or more between our dated samples may result from the “old wood” effect, wherein different portions of the tree may produce different radiocarbon ages.

Recovery of uncharred bark samples under the rear wall of bloomery No. 2 at Kuektanar-1 has made it possible to determine, for the first time, that the last smelting at this structure probably occurred between the interval of 655–765 AD. A similar age was estimated for Turgun-1 site based on archaeological charcoal. Even taking into account the own age of trees that were used as fuel, it is likely that Kuektanar-2 predates the other localities. Nevertheless, all studied bloomeries are of the same type, and the dates for coals taken from them fit the known chronology for the Old Turkic culture in the southeastern Altai, based on radiocarbon dates from archaeological sites. The concentration of a large number of furnaces in the Kuektanar mouth and the Turgun valley was probably related to the presence of sufficient forest fuel and the close location of hematite deposits and ore outcrops.

Many ancient metallurgy sites from Russian Altai, including such well-known ones as the iron-smelting furnaces in the Kuektanar mouth, are on the verge of destruction, or are already destroyed due to slumping of riverbanks along the terraces where they were originally constructed. The Chuya bank, where the Kuektanar-1 bloomeries were situated, has retreated by approximately 6–7 m since time of site formation, at an average rate of approximately 0.5 cm per year. In view of inevitable disappearance of these sites in the near future, it is necessary to dedicate urgent and careful scholarly attention to their study.

Acknowledgements

The study was performed under Public Contract (Project No. 0330-2016-0015); archaeological studies were supported by the Russian Science Foundation (Project No. 14-50-00036), geological and geomorphological studies, including radiocarbon dating, were supported by the Russian Foundation for Basic Research (Project No. 16-05-01035).

The authors express appreciation to V.S. Myglan (Siberian Federal University, Krasnoyarsk) and N.I. Bykov (Altai State University, Barnaul) for consultation and for determination of the species composition of tree vegetation that was used for charring, and to A.V. Korsakov (V.S. Sobolev Institute of Geology and Mineralogy SB RAS, Novosibirsk) for determination of the mineral composition of slags.