On the сreation and de-velopment of specialized shipyard “Arctic – Shelf”

Автор: Valeriy V. Borodin, Nikolay N. Vas’kov, Nikolay Y. Kalistratov, Andrey V. Larionov, Vladimir S. Nikitin, Vyacheslav M. Popov, Andrey V. Rusanov

Журнал: Arctic and North @arctic-and-north

Рубрика: Social Sciences. Politology. Economics

Статья в выпуске: 17, 2014 года.

Бесплатный доступ

The article proposes the concept of a specialized shipyard business project, geographically dispersed within the boundaries of the Arkhangelsk agglomeration, which aims to develop production cooperation, existing competencies and technologies in the creation of the Arctic marine equipment and vessels.

Arctic, shelf, vessels, sea platforms, topside facilities, modular units, expertise, special shipyard, technologies, shipbuilding

Короткий адрес: https://sciup.org/148319802

IDR: 148319802 | УДК: 338.984/338.4

Текст научной статьи On the сreation and de-velopment of specialized shipyard “Arctic – Shelf”

Russia has entered the time of hydrocarbons’ development on the Arctic shelf. In a relatively short time it is essential to solve difficult engineer, organizational, managing and other challenges. A complex of such challenges is considered to be a strategic state problem for current century. In the nearest ten years a practical exploitation of the Arctic region’s values sets a mission of creation and development of industrial infrastructure, which could be able to provide full functioning of the Northern sea route and ecologically safe conduct of operations on prospecting and exploitation of mineral resources in coastal areas and offshore zones including those at great depth and even under ice. These challenges face not only Russia, but also other countries of circumpolar basin.

Reclamation of the Russian Arctic shelf

Nowadays the main Russian companies who work on the Russian continental shelf are considered to be OJSC «Gazprom», JSC «Rosneft’» and private company JSC «Lukoil». The company «Lukoil», which at the proper time created a sleet-proof oil terminal «Varandei» in the Pechora sea, nowadays works mostly on shelves of the Baltic and Caspian seas, and it would like to back to large-scale projects in the Arctic. Oil production license is now achieved by «Rosneft’» and «Gaz-prom». Also foreign states show interest and actively prepare themselves for Arctic values’ exploitation, but only those states, who are parties of the Arctic Council.

According to the national approach, a question was escalated about coordination of work for all the interested companies, regions’ administration, scientific establishments, industrial and other enterprises and organizations of the country; the main issue concerned practical exploitation of the Arctic shelf, including ways of state-private partnership.

Current circumstances speaking about exploitation of the shelf is alike a situation which took place in the USSR at the end of the 60s — beginning of the 70s when working on direction «oil-and-gas exploration in the sea». A picked up direction was supervised by three relevant ministries: Mingeology, Minnefteprom and Mingasprom. By 1975-78 retardation of the USSR from other countries in this field became evident. In 1978 a «Glavmorneftegas» (Head office on exploita- tion and development of sea oil and gas resources) was founded within Mingasprom. By the middle of 80s in «Glavmorneftegas» there were more than 30 enterprises, which had more than 500 floating equipments. A program of platform and other technical equipment creation for shelf was dedicated to realize to shipbuilders of Viborg and Astrakhan, and project works — to CDB «Korall» (Sevastopol). Herewith procurements of ships and marine techniques were made in Poland, Yugoslavia and Finland. Results were not low to arrive. During the period 1978-1989 deposits in the Barents, Pechora, Baltic seas and on the shelf of the Sakhalin Island were discovered.

Demand in marine facilities and ships for shelf exploitation

Nowadays there are different estimates of demands in ships and marine facilities when exploitation of the Russian shelf on both from the part of different expert societies and energetic companies by way of adopted proper investment programs. This is one side of the coin, the other side is considered to be those territories, grounds and production capacities, where orders for creation of the arctic marine facilities must be placed, as well as marine ships for exploitation of the shelf.

Main problems of the Russian shipbuilding are known well: lack of shipyards’ specialization, necessity of new technologies’ implementation, unstable during period of time (from the beginning of development to the end of works) funding, for example during creation of MLSP «Priraz-lomnaya» and SPBU «Arkticheskaya», insufficient inter-branch and interplant cooperation, faint localization of allied productions in Russia, etc.

JSC «Rosneft’» estimates a demand in marine ships and facilities when exploitation of its license places in the Kara sea for 30 perspective structures in 106 items of production platforms and in 500 items of various intended purposes ships, platforms and other facilities2. On the 30th of August 2013 in Vladivostok during the leaded by Russian president meeting on perspectives of Russian commercial shipbuilding, it was mentioned that backlogs of orders in shipbuilding program of such companies as «Gazprom», «Rosneft’» and «Sovkomflot» up to the year 2030 assemble 512 ships, which will be required for exploitation of the shelf and year round run of the Northern sea route. When speaking about all the segments of commercial shipbuilding for the same period of time (up to the year 2030), demand of companies will compose 2200 items of marine facilities. On the meeting which took place on the 13th of November 2014 on issues of shipbuilding complex creation at the premises of JSC «Far-East factory «Zvezda», V.V.Putin pointed out that it is «necessary to use the practice and groundworks of Russian shipbuilders in production of drilling platforms, geological prospecting ships and supply agents, ice-class vessels. These competitive positions must be materialized into real and economically effective projects» 3.

Production unloading of shipyards, diversification and construction of platforms for Arctic

Power supply of JSC «USC» is mostly specialized in enforcement of Defense Procurement and Acquisition (DPA) and are fully busy. But speaking about enterprises of ship-industrial complex in Severodvinsk, from the middle of 90s of the past ages and to the current times, these enterprises, except DPA, at the same period executed orders in both building of marine techniques, commercial shipbuilding and military and technical cooperation (MTC) with other countries. Let’s suppose, that such summary of process utilizations was practically 100%. Than it becomes evident that implementation of just SDO for the short-term and especially after 2020 will not provide acceptable on socio-economic grounds loading of shipyards. It is well-known that shipbuilding has long-term and flexuous (spasmodic) production cycles: it is subject to both usage of shipbuilding platforms and production charge of providing workshops.

For shipyards in Severodvinsk orientation on production of just arms production poses risks which could again lead to failure which already took place in Severodvinsk territorial-production complex in 90s of the 20th century. Famous shipbuilders D.G.Pashayev and G.L.Prosyankin who leaded Severodvinsk productions in the recent past, told that for sustainable development and non-admission of great social problems appearance, «Plants had to have both two and better three feet on the floor». It means that in addition to SDO, a program of non-military production release for energetic branch as well as MTC production must be formed [1].

It is enough to put in remembrance that during building of OIFP «Prirazlomnaya» and SEFDR «Arkticheskaya» in 2009-11 there was noticed a peak recruitment of labor forces — it composed more than 10 thousand workers and specialists of SevMash, «Zvezdochka» and SVE «Arktika», exclusive of partners. It is known that according to technical complexity, measure of labor intensity, production lead time, research intensity and also to variety of specialists and workers, who are engaged in creation of new marine arctic techniques, these objects don’t relinquish to the most difficult ships of Navy - nuclear submarines and aircraft carriers.

Against the background of JSC «OSK» development concept, modern realities set a mission of a state level before our country: to find an optimal way of development of state shipbuilding’s different segments and other branches to start exploitation of the shelf in existing conditions, thus to «strike a happy medium, not to lose but to enrich». Such buildup reflects necessity of searching of new opportunities and ways of development on the assumption of current situation understanding and practice of Severodvinsk shipyards productions’ diversification, received from 90s of the XXth century up to modern times.

The nearest to Arctic fully and productively working shipyards are considered to be plants in Severodvinsk: JSC «PA «Sevmash», JSC «Center of ship repairing «Zvezdochka» and JSC «SVE «Arktika». Because of strategic initiative of RAS academician E.P.Velikhov and Hero ofRussia D.G.Pashayev historically by the end of 80s — beginning of 90s of the 20th century these greatest plants in Severodvinsk worked at ground zero of offshore industry in the European North of Russia. Nowadays they are considered to be leaders in this branch of national industry.

Completed construction of platforms «Prirazlomnaya» and «Arkticheskaya» - are real practical results in creation of national marine techniques for Arctic shelf. Realization of these projects was connected with great difficulties and when bringing them over, the above mentioned productions achieved unique competence of non-military shipbuilding and marine techniques manufacturing cycles, such as: management of difficult engineer projects; active participation in development of constructions and technologies of these objects’ creation; equipment and materials procurement, including foreign producers; production; specialists’ education and training; practice of unique marine operations actualization, including technologies of under-water weldout.

In 2005—09 JSC «PA «Sevmash» built two all-purpose supporting bases with free doublehulled flat for semisubmersible mounting of the 5th generation «Moss CS-50». The weight of the base composes 15 thousand tones with sizes 118×70×40 meters and its flat is ready to support constructions of topside facilities with weight up to 20 thousand tones. Depending on procurement, «Moss CS-50» could be used at the depth of 80-2500 meters. A Norwegian company Moss Maritime AS appeared to be customers [1].

When building new technologies in designing and construction of non-military objects were captured. A system CAD installation «Foran» was implemented for operational 3D simulation and submission issue. Full 3D model of a work-in-progress construction project let to shorten Vendor documents launch time and to create piping systems without labour-intensive process of pipework routing on-site. A technology of assembly of foundations in bulk right afloat with usage of jointly coastal cranage crampons and marine crane load-carrying ability 300 tones. If when for construction of the first foundation there were bought in extensive transition elements of connections between pontoons and columns, then for the second foundation they were created on JSC «PA «Sevmash», what could pull in fair financial resources.

A successful construction of all-purpose supporting bases for semisubmersible marine platforms upon the foreign class project, standards and demands of Norwegian Maritime Registrar DNV showed a high adaptiveness of existing production and engineer-technical staff for further production of marine techniques. Gained experience of construction for foreign customer will be useful for future construction of marine techniques for exploitation of the Russian Arctic shelf.

By 2009—11 the result of Severodvinsk production-industrial complex’s work in creation of marine techniques became development and exploitation of production technologies of three platform types: 1) stationary gravity (OIFP — offshore ice-resistant fixed platform) for drilling, mining, storage and export of oil; 2) self-elevating floating drilling rig (SEFDR) for purposes of development and exploitation drilling; 3) broad-based semisubmersible mounting (SSM of the fifth generation) for deep depth with opportunity to arrange different ways of superstructures, defined by prescriptions and conditions of exploitation.

Modern exploitation of the Russian shelf

From the 12th of June 1990 (since adoption of Declaration of State Sovereignty of the Russian Federation) to August 2014 on shelfs of various Russian seas there appeared seven stationary and one complex platforms for oil-and-gas production, one deposit is exploited with the application of offshore subsea solutions.

In contemporary history of Russia the first stationary platform was fixed in September 1998 on the shelf in Sakhalin Island, the sea of Okhotsk — this platform «Molikpak» is a project «Sakha-lin-2». On the 27th of June 2014 a platform «Berkut» was formed on the deposit Arkutun-Dagi in the sea of Okhotsk within the project Sakhalin-1: the upper structure of platform, created in the

South Korea, was pointed and strengthened on the gravity-based structure, fixed in 2012 on the deposit.

Since 2012 till today in Astrakhan continues production and construction of the complex, which consists of nine platforms for deposits named after Filanovsky in the Northern sector of Caspian sea (ice stationary platforms, living quarter platforms, central processing platforms, riser block, wellhead platforms, etc.).

When analyzing completed projects of platforms’ construction, we can emphasize three basic approaches to their creation (see table):

-

1. In-depth modernization of platforms, which were already exploited.

-

2. Creation of high-technology superstructures beyond Russia, and less constructable supporting bases — in the Russian Federation.

-

3. Creation of platforms in cooperation of shipyards on the territory of the RF with the involvement of both Russian and foreign subcontractors.

2.3

«Lunskaya-А» (Lun-А)

Lunskoye

2006

USP — SHI, South Korea; GBS — PMC «Vos-tochny»

2.4

OIRFP D-6

Baltic sea

Kravzovskoye

«Lukoil»

2004

USP and GBS — «KLIEVER»

2.5

Complex of platforms (IRFP-1, IRFP-2, transit bridge)

Caspian sea

named after Korchagin

«Lukoil»

2009

IRFP-1, IRFP-2 of Astrakhan SPO

2.6

Complex of platforms (IRFP-1,2, LQP-1,2, CTP, RB, WhP 1,2,3 transit bridges)

named after Filanovsky

beginning 2012

General contractor — GSE

2.7

OIRFP «Prirazlomnaya»

Pechora sea

Prirazlomnoye

«Gazprom neft’ shelf» («Gaz-prom neft’»)

2011

JSC «PA «SevMash» LQ, UM — JSC «Viborg SSZ»

The first and the second approaches were used for construction of objects for island Sakhalin’s shelf (projects «Sakhalin-1, 2»). The third approach was and is used when realization of platforms’ construction for deposits in the Northern Caspian, Baltic and the Barents sea.

Table 1

|

№ |

Name |

Place of installation |

Deposit |

Project / operator |

Year of installation on the deposit |

Participants of construction, contractors |

|

1 |

Upgraded platforms |

|||||

|

1.1 |

«Molikpak» (PA-А) |

the sea of Okhotsk |

Piltun-Astohskoye |

«Sakhalin-2» / Sakhalin energy |

1998 |

ASP (ОО for drilling rig) |

|

1.2 |

«Orlan» |

Chaivo |

«Sakhalin-1» / «Eckson neftegaz Ltd.» |

2005 |

ASP (EPCI contract for modernization of a platform), HHI since June 2004 — completion |

|

|

2 |

Platforms of full-cycle construction |

|||||

|

2.1 |

«Berkut» |

the sea of Okhotsk |

Arkutun-Dagi |

«Sakhalin-1» / «Eckson Neftegaz Ltd.» |

2012 – ОГТ 2014 — ВС |

USP — DSME, GBS — PMC «Vostoch-ny» |

|

2.2 |

«Piltun-Ashotskoye—B» (PА-B) |

Piltun-Astohskoye |

«Sakhalin-2» / «Sakhalin energy» |

2007 |

USP — SHI, South Korea; GBS — PMC «Vostoch-ny» |

|

Comments:

OIRFP — offshore ice-resistant fixed platform

IRFP — ice-resistant fixed platform

LQP — living quarter platform

CPP — central processing platform

RB — raiser block

WhP — wellhead platform

USP — upper structure of platform

GBS — gravity-base structure (bullet-proof)

FP — foot of pile (metal)

SB - supporting base

LQ — living quarters

UM — utility module

HHI — Hyundai Heavy Industries (South Korea)

DSME — (South Korea)

SHI — Samsung Heavy Industries (South Korea)

«Kliever» — JSC «Kliever», Kaliningrad (till Sept. 2012-plant on construction of metal structures LUKOIL-Kaliningradmorneft’)

ASY — Amur shipbuilding yard

ЗPMC «Vostochny» — Plant of marine constructions «Vos-tochny», Nahodka

Astrakhan SPO - production plant of group of companies «Caspian energy»

GSE — JSC «Globalstroy-Engineering»

Each deposit on the shelf possesses its unique characteristics and parameters, which define eventually the choice of technological scheme of deposit’s development, according to economic, technical and technological practicability. Arrangement and exploitation of Russian shelfs’ deposits with the help of fixed platforms is applicable for mainly depth up to 100—150 meters. For achieving and gaining of shelf exploitation experience «Gazprom» in the year 2013 brought into opera- tion Kirinsk deposit of the project «Sakhalin-3», in which subsea production complexes for the marine part of the project is used. This was the first practical step for new technologies of submarine oil-and-gas production to appear in Russia. But we should notice that nowadays Russia doesn’t possess all the competences, «Know-how» and technologies to localize construction and production of such systems in our country; dependence on foreign technologies and equipment is still preserved.

The first fixed platform, fixed on the 28th of August 2011 on the shelf in the Arctic region, was OIRFP «Prirazlomnaya». Construction of the platform and production of its components was created by mostly with Russian participation, which didn’t exclude attraction of foreign parties there, where it was needful.

Plans of «Rosneft» and sanctions aspects

Coming of I.I. Sechin in OJSC «Rosneft» otherwise in May 2012 opened a new page in the history of the company and gave an extra pulse in native Arctic projects. The company really projects to place a supporting shore base for providing western Arctic shelf projects in urban-type settlement Roslyakovo (Murmansk region) over an area of JSC «82nd shipyard» (82 SY). For putting this plan into practice 82 SY is planned to relocate in JSC «35th shipyard» (35 SY) situated in the region Rost in Murmansk. At that, on the territory of SY 35 there will be repair of naval forces ships in dock-ship PD-50 with a lifting capacity of 80 00 tones prior to initial operation of modern dry dock. Concerning Murmansk «Rosneft» also plans to locate plants on production of underwater fittings, concrete blocks, helicopter airdrome, logistic base for warehousing and transshipment of cargoes, and also to create the center of Arctic competence as part of Murmansk State technical university for staff training.

Decision of interdepartmental challenges containing detachment of secure territories based on example of 82 SY is possible at the state level. For solving state challenges it is real to cover and solve urgent problems of bureaucratic interests of Ministry for Industry and Trade, Ministry of Defense, JSC «United Shipbuilding Corporation», JSC «Rosneft» and other parties concerned.

Realization of construction of large-capacity shipyard complex «Zvezda» on the Far East shows how difficult and thorny the way is. Nowadays approximate actual deadline of the project is 2009—16 (instead of initial period of accomplishment — 2021). Later consortium Closely-Held Stock Company «Sovremenniye Technologii Sudostroyeniya» (Modern technologies of shipbuilding) is planning to construct on the Far East not only non-military orders, but also provide SDO works under output obtained into ownership from JSC «Dalnevostochny center sudostroyeniya i remonta» (Far-East center of shipbuilding and repairing) which earlier entered JSC «United Shipbuilding Corporation». In such a way, for consortium «STS» appeared difficult questions of managing incidental shipbuilding costs with high potential of diversification. Nevertheless, future works on reorientation of 82 SY means the necessity to solve the same challenges, which were solved during reconstruction of the Far East «Zvezda» — but now taking into account climate conditions of North of the Arctic circle, actual physical position of chief funds, new major construction work, managing challenges, political, economic risks of global international relations’ crisis.

We consider the program of ships’ and marine techniques’ construction for exploitation of the Arctic shelf to be more reasonable to possess in number of platforms in Russia , including European north of the country. It is determined with historic practice of development of number deposits in the western Arctic in 80s of the 20th century. Introducing of sectoral economic sanctions against Russia, imposed by the policy of foreign countries, makes actual such a logic. It is mostly probable that sanctions transform from short-term into long-term. This risk determine for Russia necessity of reorientation, reconstruction, development and creation of specialized mights for goals of shelf exploitation. A production cooperation and strong collaborative partnership of such platforms when reasonable coordination of production processes would help as a whole solve challenges of double quick exploitation of the Arctic shelf and development of native technologies for Arctic conditions.

An apportioned shipyard and its localization

There has formed such a situation on enterprises of Severodvinsk production-industrial complex, that there are no equivalent orders such as «Prirazlomnaya» and «Arkticheskaya» in the coming years. It leads to loss of qualified and experienced personnel, which was involved when construction of platforms. Specialists, who have got through the school of both projects’ realization, are considered to be carriers of unique gained knowledge, information and competence (know-hows). Gained competence are becoming less demanded and could to a large extend be lost.

In the current situation, taking into account state interests, it is necessary to preserve and develop the available intellectual, production and technological potentials of the Severodvinsk enterprises in the branch of construction of marine oil-and-gas assets. Backgrounds for such an activity and creation of Specialized Apportioned Shipyard on the European north of the RF in Arkhangelsk agglomeration are following:

-

a) an increased global competition for Arctic resources;

-

b) the longest Arctic maritime boundary of the RF;

-

c) geographic proximity to the Arctic region;

-

d) true output to the basin of the Arctic ocean;

-

e) historical maritime traditions;

-

f) Russian arctic vector being declared as top-priority;

-

g) Northern Sea Route, which needs qualified technical supply, development and fitted out with marine technique and ice-proof offshore structures;

-

h) United Shipbuilding Corporation flexible strategy (multi-variety of development in a number of basic scenarios);

-

i) necessity and real opportunities of science-research and educational fulfillment of the Northern Arctic federal university named after M.V.Lomonosov (NArFU);

-

j) achieved competence while realization of non-military shipbuilding and marine techniques projects.

It is supposed to solve this challenge by means of creation of a Specialized Shipyard (SS) of apportioned type «Arctic-shelf» (operating name). Arkhangelsk SS will be oriented on production and output of difficult and unique marine techniques, modules, upper structures of platforms, marine constructions of various profiles and ships for exploitation of the Arctic shelf and Northern sea route. The shipyard could be consisted of number of different platforms, which would be united by the same production-technological process. SS «Arctic-shelf» would let to use high potential of Arkhangelsk and Severodvinsk enterprises by means of production cooperation and development of related branches in regions of oil existence.

There is a practice of apportioned shipyard in Russia since Soviet times. Such production platform and even nowadays is considered to be «Astrakhan Shipbuilding Production Association» (ASPA) — subdivision of production division of asset management company «Group Caspian Ener-gy». ASPA itself consists of three platforms: ASPA Leading Yard and ASPA Platform №3, which are situated in Astrakhan, and the plant ASPA «Lotos», situated in Narimanov town, 45 km from Astrakhan.

A production line of ASPA includes opportunities of mobile drilling rig systems’ construction (SEFDR, semisubmersible drilling rigs, drilling barges), winning technological platforms, construction ships (crane boats, pipe layers, barges), special ships (supply, anchor handling tugs, fire- protections, harbor fleet), transport ships (bulk, dry-cargo, passenger) and steel constructions of marine infrastructure.

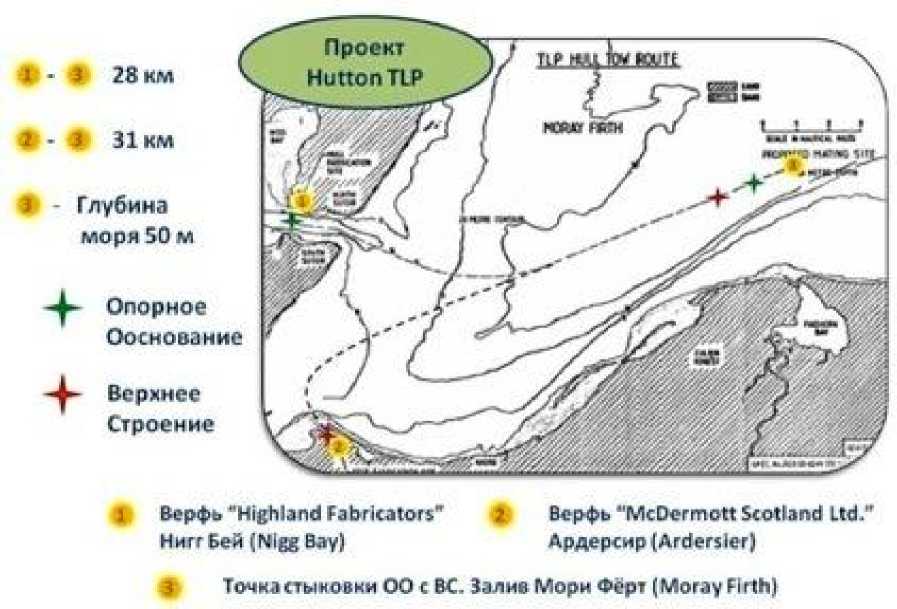

Picture 1. Hutton TLP Platform (the North Sea)

The practice of foreign shipyards which created marine platforms for exploitation and production of oil and gas exists. For example, the first platform in the world of TLP type (Tension Legs Platform) was constructed for Hutton deposit in the North Sea on two worksites in Scotland at the beginning of 1980s. Construction of integrated superstructures was put through on shipyard «McDermott Scotland Ltd.» in Ardersir City and supporting base was created dry dock of «High-land Fabricators» shipyard in city Nigg Bay. Platform was accumulated in summer 1984 in Mory Fert bay in the North sea narrowly spaced from shipyards — connection point was 25—30 km. During construction of this platform an approach was implemented, which was put in definition of apportioned shipyard.

New native shipyard (Arkhangelsk CS) could fulfill a function of the united centre of the offshore industry competence with localization of its basic platforms in Northern Dvina River estuary — in Arkhangelsk, Severodvinsk and their neighborhood. A possibility of territorial localization of production platforms in North-Western region is not excluded. A variant of production cooperation, distribution of platforms in Murmansk and other geographical points is also possible. It is suggested to organize an operational activity of such a shipyard through the managing centre

Арктика и Север. 2014. № 17 (company) which will provide integration of all the production processes throughout the life cycle of marine Arctic technique.

At any way, all the existing shipyards of Severodvinsk will remain centers of military direction competence in future. And while management centers of both competences a direction and specialization of shipyards will be taken into account: military or non-military, what doesn’t exclude their strong production cooperation. Such an approach will let to combine both military and non-military components in working processes of shipyards and to minimize the conflict of interests.

Speaking about potential of CS localization in the region Arkhangelsk-Severodvinsk, we could overview following ways of its distribution: 1) on the right, firstly, and probably on the left shore of the Northern Dvina river; 2) on the right side of M-8 route in Arkhangelsk-Severodvinsk segment; 3) platforms of closed/stand-by plants in Arkhangelsk-Severodvinsk agglomeration; 4) other alternative platforms within the so-called «Big Arkhangelsk». Platforms for SC must take into account access to water areas; it is more preferable to place them geared to the left (Nikol’sky) distributary of the Northern Dvina River (along the prolonged federal M-8 route).

Nowadays within the Arkhangelsk city carries out production and business activities LLC «MRTS Terminal». Territory of the enterprise is situated right in front of sea-and-river station in Arkhangelsk and currently it is in stage of remedial works, arrangement and major construction work. Earlier, during 2009-2011 JSC «Mezhregiontruboprovodstroy» (JSC «MRTS»)4 carried on searching of ground in the northern regions of Russia for construction of its production-logistic resting base for participation in the Arctic projects. As a result, the appropriate platform was found in Arkhangelsk region and since 2012 LLC «MRTS» is presented in Arkhangelsk. By the end of 2013 its "sister" subsidiary LLC «MRTS Terminal» was founded. Today LLC «MRTS» is involved in projects on Yamal peninsula exploration — it takes part in construction of new port installation in Obsk-Tazovsk bay (port Sabetta) as part of project realization «Yamal SPG». Development of production-logistic base in Arkhangelsk and its final molding is provided by the strategy of associated company development by the year 2020.

Appearance of new platform CS «Arctic-shelf» within the Arkhangelsk—Severodvinsk agglomeration would let to fulfill the potential of cooperation in shipbuilding industry of the region in a new way and create a serious capacity for placement of big orders, connected with exploitation of the Russian Arctic resources. In an appropriate well-balanced approach connected with material matter and technical decommission of main funds, such a base platform for CS «Arctic-shelf» could become dockyard «Krasnaya Kuznica» — branch of JSC «CS «Zvezdochka» in Arkhangelsk, which are situated on the islands Solombala and Moseev, where in 1693 native military shipbuilding started.

Allied challenges, solved during construction of apportioned shipyard

When providing the future team work of all the production complexes and shipyards of the region and solving of questions of import substitution a challenge appears, which is connected with possible localization in Arkhangelsk—Severodvinsk agglomeration of allied productions, necessary for sustainable functioning of marine subjects in the Arctic zone of the RF. For example, these allied enterprises could be oriented on creation of some component parts and equipment, including for shelf projects, for technical provision of Northern sea route service bases and for working oil-and-gas complexes (marine techniques, equipment for underwater mining, duplicate parts and service kits for ships, etc.). Justification of such statement of work is following: in nonmilitary shipbuilding population of ship equipment is 60%, while for stationary platform — about 70%. Construction of CS «Arctic-shelf» would let to form a specialized niche in innovation territorial shipbuilding cluster of the Arkhangelsk region through the efficient cooperation and development of allied enterprises. It is well-known that multiplicative effect of investments in shelf projects from allied branches arranges about 1 to 7. As a result for our region we could achieve the extra pulse to development of regional economy and its future clustering.

When using a complex approach, CS «Arctic-shelf» could also become the instrument for decision of a number of accompanied practical challenges, which we are formulated at the state level of the Arctic region exploitation. Firstly, they are:

-

I. Service and post-guarantee maintenance of actual Arctic platforms.

-

II. Construction of a number of logistic bases in delta of the Northern Dvina River (reference point — development of the port «Ekonomiya» in Arkhangelsk on services of shelf projects, NSR subjects and expansion of new service bases - mother-ships, docks and storage areas through the NSR.

-

III. Training of specialists of beginners, medium and higher professional levels in NArFU named after M.V.Lomonosov and other educational establishments.

-

IV. Exploitation of Arctic and NSR through joint specialized domestic enterprises in cooperation with foreign companies.

Suggestions on creation of Arkhangelsk apportioned shipyard

Engaging in the project of Arkhangelsk CS construction of eventual buyers (investors) could let to divide existing and potential risks. When developing the investment potential of the region, it is needful to organize a long-term prospective work. Engaged investors must be considered not only as partners for both joint participation and co-managers of future Arctic projects, but also as participants of the working process, involved in management of key risks during realization of projects, including observing discipline on project life and budget, as well as quality of works [3]. When realizing such an approach it is possible to engage such investors as OAO «Gazprom» / OAO «Gazpromneft», JSC «Rosneft», JSC «Lukoil», in the long term — JSC «Noril’skiy nikel», JSC «NO-VATEK», JSC «Zarubezhneft», JSC «Sovkomflot» and other Arctic stakeholders.

Accelerated reclamation of the Russian Arctic shelf is possible. This challenge is solved with the help of existing mights and capacities with synchronous technological development of domestic industry and construction of new industrial locations. Quickness of construction and erection of objects on the shelf directly depend on greatest possible unification of constructions. Unification of space structures is necessary for upper structures of platforms (integrated decks, superblocks, block-modules, etc.), as well as for shallow waters substructures (depth up to 20 meters), platforms for depth up to 50—100 meters and more, and also for ships and other marine technique including technique for underwater mining. For example, for creation of new generation of substructures for Arctic, usage of technological capacity and development from the branch of underwater shipbuilding is possible.

Construction of superstructures performed by block-modules and integrated decks for marine platforms is absolutely real to carry out in Ship-Repair yard «Krasnaya Kuznica» - Arkhangelsk branch of JSC «CS «Zvezdochka». By that way, in practice, perfection of technological potential of the production with some limited financial expenses will be required. Series-produced creation of integrated multifunctional structures and constructions of various profiles for Arctic is also possible in JSC «CS «Zvezdochka». Automated flow line of installation and welding of plain sections (designer, constructor and supplier is JSC «Centre of Shipbuilding and Ship repairing Technologies» Saint-Petersburg)5, which is estimated for arrangement in AB Ship-repair yard «Krasnaya Kuznica», could let to cut labor intensity, time and cost of production of superstructure steel constructions and solid modular constructions of various profiles (manufactures). High accuracy of section di- mensions created in flow lines could let to cut number of works on adjustments and corrections of constructions when final formation of products «in bulk». Production spaces and capacity of a plant afford to organize future filling of manufactures with technical equipment and construction of the object «key ready». Position of a plant in the central part of Arkhangelsk and hydrologic characteristics of the Northern Dvina River in the area of the plant give an opportunity to ship off all the finished items directly to carriers and special barges.

We suppose, that development of potentials for taking-part in Arctic projects is efficiently to organize in cooperation with Severodvinsk productions. The way of diversification of shipyards’ productions, which was defined in 80s of the 20th century, appeared to be right and successful. According to practice, presence of commercial jobs on shipyards favorably influences socioeconomic situation in the region and considers to be the driver of not only Arkhangelsk region development, but also of the regions, which are included in North-western federal area (for example, Murmansk and Vologda regions, Saint-Petersburg). Construction of CS «Arctic-shelf» could give a qualified impulse of oil-and-gas production development in the region for decades. International practice shows that such a positive experience already exists. As an example we could give practice of Stavanger development — oil-and-gas capital of Norway, Aberdin (Scotland) and Houston (the USA).

A forecast becomes evident, that in recent years in Russia there will be an explosive growth and development of industry of Arctic shelf orientation [3]. Arkhangelsk region could and must make efforts for preservation and accruement of its leader positions, conquered since 90s of the XXth century. Otherwise, recovery of give grounds will worth great pain, resources and will expand for years.

Based on analysis of the situation and solving the denoted challenges, Arkhangelsk region has the possibility to form industrial oil-and-gas complex CS «Arctic-shelf», which will be considered to be an active element of Shipbuilding innovation territorial cluster of the Arkhangelsk region [5]. Such a complex could actively work in with science-research and project-technological

Pic. 2. Platform «Prirazlomnaya»

organizations of Saint-Petersburg, where scientific and experimental basis of shipbuilding branch is concentrated, and also of other productions of oil-and-gas industry, including foreign participants as it was during constructions of platforms

«Prirazlomnaya» (Pic.2) and «Arkticheskaya» (Pic.3). Taking into account vast extension of Russian sea borders , we suppose that sustainable development of the shelf in the long-term is possible involving a number of centers of the offshore competences.

Acquisition of such competences on bulk shipbuilding and construction of marine objects

for North-Eastern Arctic shelf by productions, located in the regions of Vladivostok, will be implemented in recent years under common guidance of asset management company UAB «Sovremenniye Technology Sudostroyeniya» («Modern Technologies of Shipbuild-ing») on Far East.

To our mind, marine sleet-proof oil-and-gas structures, including technique for subsea/subice works in extreme ice conditions and also ships and other objects of marine techniques for the Western sector of Arctic is more reasonable to construct right in the area of Arkhangelsk - in closebodied cooperation with Severodvinsk enterprises. Right here for the first time in native shipbuilding practice appeared the idea and was collected a unique practice of marine objects’ construction with usage of module-aggregate method of constructions, mechanisms, equipment, complicated structures and complexes. Here as economically as possible could be successfully implemented innovation solutions, concerned creation of unified module constructions of substructures and superstructures of ice-resistant platforms, which could help to reduce its construction price if we would use a proven practice project-technological solutions of submarine shipbuilding.

Conclusion

We suppose that the stated concept of specialized apportioned shipyard project’s business idea is necessary to capture in strategic documents of different levels’ development: of the RF Arctic zone, USC, socio-economic development of the Arkhangelsk region, Federal special purpose program, General Outlay and others. On the regional level for purposes of future business planning we suggest this concept to include in plan of actions in realization of regional legislation on industrial policy and in plan of innovation territorial shipbuilding cluster development [5].

In such a way, construction of industrial complex CS «Arctic-shelf» in Arkhangelsk region, which is oriented on production and output of unique marine techniques, structures and ships for exploitation of the shelf and for technical equipment of marine and offshore control stations of the Northern sea route, is considered to be current, advanced and economically feasible taking into account already gathered experience by enterprises, which are included in the structure of

Arkhangelsk innovation shipbuilding cluster.

Список литературы On the сreation and de-velopment of specialized shipyard “Arctic – Shelf”

- Borodin V.V., Vas’kov N.N., Kalistratov N.Y., Larionov A.V., Nikitin V.S., Popov V.M., Rusanov A.V. Analiz sozdaniya neftegazovyh platform «Moss CS-50», «Arkticheskaya», «Prirazlomnaya» i dal’neyshiye perspektivy stroitel’stva morskih sooruzheniy v Arkhangel’skom regione [Analysis of construction of oil-and-gas platforms «Moss CS-50», «Arkticheskaya», «Prirazlomnaya» and further prospects of marine structures construction in Arkhangelsk region]. Arkhangelsk, September-November 2014. URL: http://narfu.ru/upload/medialibrary/b9a/analiz_persp_y-mngs_-ao_06_noya_2014_arkh_ais.pdf (accessed: 10.11.2014).

- Rogozin D.O. Zaglyanem v bezdnu [Let’s look into abyss]. Rossiyskaya gazeta — Russian newspaper, March 14th, 2014, no 6331. URL: http://www.rg.ru/2014/03/14/rogozin.html (accessed: 14.10.2014).

- Timofeev Oleg: interview zamestitelya general’nogo direktora Krilovskogo GNC: «Zakazchiku nuzhni ne tol’ko technicheskiye resheniya, no i finansoviye» [Timofeev Oleg: interview with deputy director general of Krylov SSC: «Customer needs not only technical solutions, but also financial»]. Informacionno-analiticheskoye agentstvo «Portnews» — Informationanalytical agency «PortNews», April 11th, 2014. URL: http://portnews.ru/comments/1774/ (accessed: 16.10.2014).

- «Razvitiye proizvodstvennogo potenciala Arkhangel’skoy oblasti dlya osvoyeniya Rossiyskoy Arktiki: projektniye predlozheniya»: krugliy stol [«Development of Arkhangelsk region production potential: project suggestions» the Round Table]. June 18th, 2014. URL: http://сафу.рф/aan/news.php?ELEMENT_ID=161913 (accessed 30.10.2014).