Optimization of thermal insulation and moisture absorption properties of knitted fabrics with different fiber compositions

Автор: Jurinskaya I.M., Tashmukhanbetova I.B.

Журнал: Международный журнал гуманитарных и естественных наук @intjournal

Рубрика: Технические науки

Статья в выпуске: 12-3 (99), 2024 года.

Бесплатный доступ

This study examines the optimization of thermal insulation and moisture absorption properties in knitted fabrics with diverse fiber compositions. It evaluates the effects of yarn types, including wool, cotton, polyester, and acrylic, on the thermal and moisture management performance of multi-layered weft-knitted structures. The findings confirm that the selection of raw materials plays a pivotal role in determining air permeability, heat transfer dynamics, and the overall thermo-physiological comfort of fabrics.

Thermal insulation, moisture absorption, knitted fabrics, fiber composition, thermal comfort

Короткий адрес: https://sciup.org/170208919

IDR: 170208919 | DOI: 10.24412/2500-1000-2024-12-3-70-75

Текст научной статьи Optimization of thermal insulation and moisture absorption properties of knitted fabrics with different fiber compositions

Thermal insulation and effective moisture management are essential for the comfort and functionality of textile products, especially when used in sportswear, work uniforms, and protective gear [1, 2]. Knitted fabrics, known for their distinctive structural properties, provide significant opportunities for enhancing these performance attributes. The type of fiber and composition of yarn play a critical role in influencing the thermal and moisture-related behaviors of these fabrics.

Maintaining thermal insulation and controlling humidity are fundamental to ensuring wearer comfort and optimal textile performance, particularly under conditions of physical exertion or extreme climates. Materials capable of retaining heat while efficiently wicking moisture contribute not only to comfort but also to reducing risks of thermal imbalance, such as hypothermia or overheating, which is crucial for both professional and athletic activities [3, 4].

Knitted textiles, with their permeable structure and adaptable knitting densities, offer unique advantages for tailoring thermal and moisture management properties. Their flexibility, coupled with the option to incorporate various fiber types, allows for the development of materials with a broad range of functional characteristics. The choice of fibers and yarns directly affects critical fabric parameters such as thermal conductivity, moisture absorption, and breathability [5].

Among the commonly used fibers in knitted fabric production are wool, cotton, polyester, and acrylic. Wool excels in thermal resistance due to its air-trapping ability, while cotton is favored for its superior moisture absorption. In contrast, polyester and acrylic stand out for their durability, strength, and quick-drying properties, making them suitable for active applications [6].

While many studies have explored the thermal and moisture properties of textiles, limited research systematically addresses the influence of fiber composition and multilayer knitted fabric structures on these characteristics [7, 8]. This study aims to fill this gap by analyzing the effects of fiber composition and fabric construction on the thermophysical properties of knitted textiles. The objective is to identify optimal fiber combinations and knitting configurations that enhance thermal insulation and moisture management, catering to diverse environmental conditions and applications.

Materials and Methods

Yarn Preparation and Fabric Development

To conduct this study, yarn samples were prepared using both carded and rotary spinning techniques. These samples were then knitted on a flat knitting machine, maintaining uniform density settings across all fabric types. The resulting knitted fabrics underwent a combined finishing process, which included thermal fixation and treatment with solutions designed to enhance their moisture absorption and thermal insulation characteristics.

Materials Used for Fabric Layers

The multilayer knitted fabrics were constructed using the following materials for the outer and inner layers, each selected for their unique properties:

-

- Wool: Chosen for its excellent thermal insulation, attributed to its ability to trap air within its structure.

-

- Cotton: Known for its superior moisture absorption and soft texture.

-

- Polyester: Valued for its strength, durability, and resistance to wear.

-

- Acrylic: Selected for its elasticity and rapid drying capability.

Each fabric layer was carefully designed to optimize specific thermophysiological characteristics. The outer layer provided protection against external environmental factors, while the inner layer ensured comfort in direct contact with the skin.

Parameters and Measurement Techniques

-

1 . Thermal Resistance and Conductivity

-

- Measured using a Thermal Resistance Tester in compliance with GOST 32199 standards.

-

- Parameters included:

-

a) Thermal resistance (m²K/W).

-

b) Thermal conductivity (W/mK).

-

- Measurements were conducted at a standard temperature of 20 ± 2 °C.

-

2. Breathability

-

- Tested using an Air Permeability Tester according to the ISO 9237 standard.

-

- Airflow velocity during the test was set at 100 mm/s.

-

- Results were expressed in millimeters per second (mm/s).

-

-

3. Moisture Absorption

-

- Determined by immersing fabric samples in distilled water for 60 minutes.

-

- Moisture absorption was calculated as a percentage increase in the sample's weight relative to its original mass.

-

- The time required for complete drying was measured at room temperature.

-

4. Thermal Absorption

-

- Measured using an Alambeta device to evaluate the initial sensation of warmth or coolness upon skin contact.

-

- Recorded in terms of thermal absorption (W/m²K).

Statistical Analysis

To determine significant differences among the experimental groups, an analysis of variance

(ANOVA) was performed, complemented by a Tukey multiple comparison test . The significance threshold was set at p < 0.05 . All measurements were repeated three times to ensure data reliability.

Fabric Manufacturing Conditions

The production of the fabric samples adhered to the following specifications:

-

- Knitting Machine: Flat knitting, 12-gauge.

-

- Knitting Density: 350 courses per 10 cm.

-

- Sample Dimensions: 30 × 30 cm.

-

- Finishing Treatment: Applied waterrepellent and antibacterial finishes to improve durability.

The collected data were used to investigate the relationship between the thermophysical properties of fabrics and their fiber composition and structure.

Results and Discussion

The findings of the study revealed that both fiber composition and knitting structure play crucial roles in determining the thermal resistance and conductivity of knitted fabrics. Key outcomes include:

-

- Thermal Insulation: The thermal insulation characteristics were quantified using the thermal conductivity coefficient and thermal effusivity, which are critical measures of a fabric’s capacity to retain heat and stabilize body temperature [8].

-

- Thermal Resistance: The highest thermal resistance was observed in the wool/cotton blended fabric, with the cotton/polyester and acryl-ic/polyester blends showing progressively lower values.

-

- Thermal Conductivity: The wool/cotton blend exhibited the lowest thermal conductivity, underscoring its superior heat retention capability when compared to other fiber compositions [9].

These results align with prior research that highlights the crimped structure of wool fibers, which facilitates air entrapment and significantly enhances thermal insulation [2].

-

- Moisture Management: The cotton/polyester blend demonstrated the highest capacity for moisture absorption, retaining 25% more moisture compared to wool/cotton and acryl-ic/polyester fabrics. This property is primarily due to the hydrophilic nature of cotton, which allows it to absorb perspiration effectively.

-

- Breathability: The highest air permeability was recorded in the acrylic/polyester blend, followed by cotton/polyester and wool/cotton

blends. This suggests that acrylic/polyester fabrics are better suited for applications requiring enhanced breathability.

-

- Thermal Absorptivity: The wool/cotton blend showed the lowest thermal absorptivity, indicating a more comfortable and softer feel when in contact with the skin.

These findings corroborate earlier studies that emphasize the potential of multilayer knitted structures to improve both thermal insulation and moisture management performance. Such insights further validate the strategic selection of fiber compositions and knitting structures for designing high-performance fabrics (table 1).

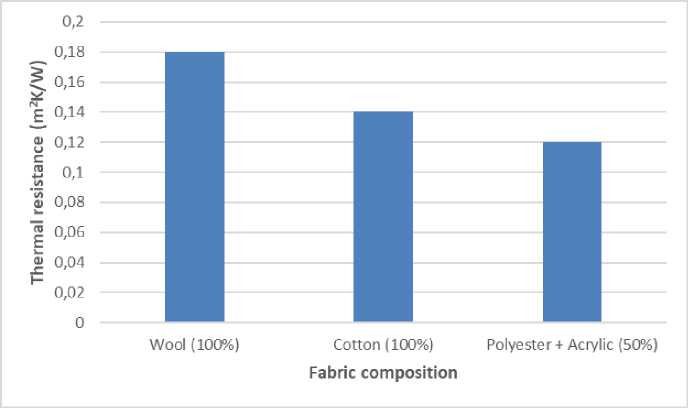

Table 1. Indicators of thermal resistance and thermal conductivity

|

Fabric composition |

Thermal resistance (m2K/W) |

Thermal conductivity (W/mK) |

|

Wool (100%) |

0.18 |

0.045 |

|

Cotton (100%) |

0.14 |

0.060 |

|

Polyester + Acrylic (50%) |

0.12 |

0.080 |

Fabrics composed entirely of wool exhibited the highest thermal resistance, measured at 0.18 m²K/W. This performance is attributed to wool’s porous structure, which effectively traps air, enhancing its insulating properties. Cotton fabrics presented a well-balanced profile, offer- ing moderate levels of both thermal resistance and thermal conductivity. In contrast, polyester and acrylic blends, while exhibiting lower thermal insulation, demonstrated superior mechanical strength and durability (figure 1).

Figure 1. Graph of the dependence of thermal resistance on the composition of the fabric

The breathability of the fabrics was influenced by both binding density and fiber composition. Fabrics made from polyester and acrylic exhibited the highest air permeability, recorded at

220 mm/s. This exceptional breathability makes them particularly well-suited for use in sportswear (table 2).

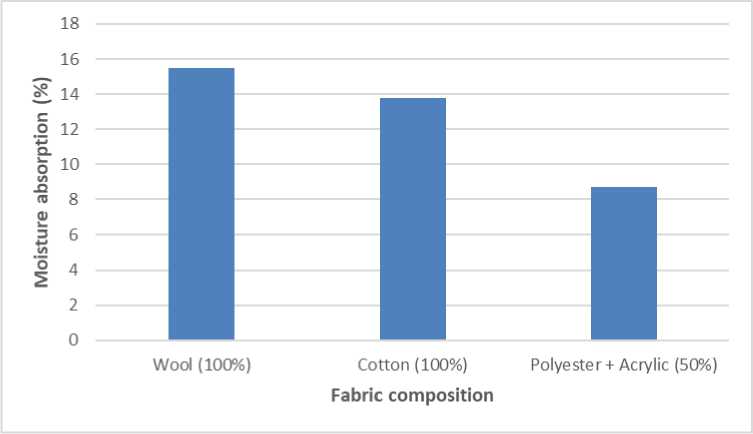

Table 2. Breathability and moisture absorption of fabrics

|

Fabric composition |

Air permeability (mm/s) |

Moisture absorption (%) |

Drying time (min) |

|

Wool (100%) |

180 |

15.5 |

120 |

|

Cotton (100%) |

200 |

13.8 |

100 |

|

Polyester + acrylic (50%) |

220 |

8,7 |

60 |

Wool samples exhibited the highest moisture absorption capacity at 15.5%; however, their extended drying time of 120 minutes poses a limitation for active use. In contrast, polyester and acrylic blends demonstrated significantly faster drying times of 60 minutes, making them more suitable for sportswear applications (figure 2).

Figure 2. Dependence of moisture absorption on the composition of the fabric

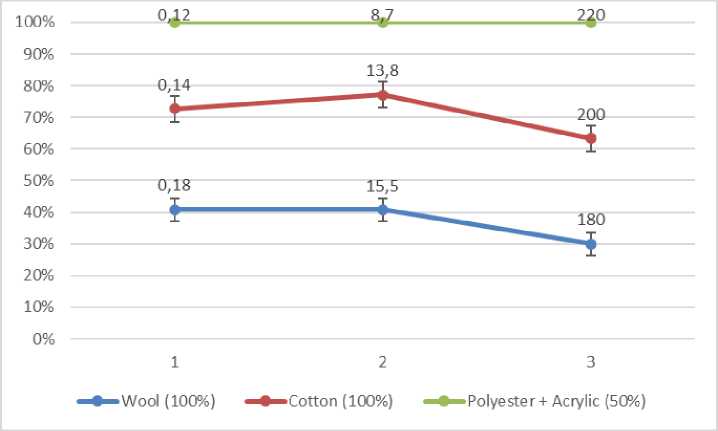

The study results revealed that wool possesses excellent thermal resistance, attributed to its structure that traps air pockets, making it an ideal choice for fabrics designed for cold climates and winter clothing. However, its high moisture absorption and prolonged drying time limit its practicality in humid conditions or during intense physical activity.

Cotton displayed a balanced combination of thermal resistance and breathability, making it suitable for a wide variety of applications. Meanwhile, polyester and acrylic blends, though exhibiting lower thermal resistance, demonstrated superior breathability and faster drying times, characteristics that are particularly beneficial for sportswear and activewear.

These findings align with prior research emphasizing the critical role of fiber composition and fabric structure in optimizing the thermophysical properties of knitted textiles [10]. Future investigations could focus on exploring the combined effects of different fibers in multilayer knitted fabrics to further improve thermal insulation, moisture management, and breathability.

Cotton’s balanced properties, including moderate thermal insulation and effective moisture absorption, underscore its versatility for various types of clothing. Polyester and acrylic mixtures, with their excellent breathability and rapid drying, remain the preferred choice for active and sportswear, where moisture management and durability are key requirements.

The study’s conclusions corroborate earlier findings on the significant influence of fiber composition and fabric structure on thermophys-iological characteristics (figure 3) [11].

Figure 3. The relationship of thermal resistance, moisture absorption and breathability

The findings underscore the importance of selecting the fiber composition and binding parameters to create fabrics with targeted performance attributes. To achieve an optimal equilibrium of thermal insulation, moisture absorption, and breathability, it is crucial to consider the intended use conditions and the needs of the target audience.

Conclusion

The study's findings confirm that the fiber composition and structural design of knitted fabrics play a critical role in their thermal insulation and moisture management properties. Key conclusions include:

-

1. Wool Fabrics: Fabrics made entirely of wool exhibited the highest thermal resistance, making them ideal for cold climates and winter garments. However, their high moisture absorption and prolonged drying time limit their effectiveness in humid or high-activity conditions.

-

2. Cotton Fabrics: Cotton demonstrated balanced characteristics, offering moderate thermal insulation, good moisture absorption (13.8%), and a drying time of 100 minutes. These attributes make cotton suitable for a wide range of applications, including both casual and professional clothing.

-

3. Polyester and Acrylic Fabrics: These blends provided the highest breathability (220

mm/s) and the shortest drying time (60 minutes), making them particularly well-suited for sportswear and outdoor applications where efficient moisture management is crucial.

The practical significance of this research lies in its potential application within the textile industry to design fabrics tailored to various operational needs. By selecting appropriate fiber compositions and knitting structures, manufacturers can create textiles with optimal characteristics for thermal insulation, breathability, and moisture absorption.

For a more comprehensive understanding of textile performance, further research is recommended to:

-

- Investigate the impact of advanced finishing techniques and multilayer fabric designs on thermophysiological properties.

-

- Conduct long-term durability assessments, including wear and repeated washing.

-

- Evaluate additional parameters, such as thermal absorptivity, static electricity behavior, and the environmental sustainability of the materials.

These findings contribute to the development of innovative textile solutions that prioritize functionality, comfort, and durability, paving the way for advancements in high-performance fabrics.

Список литературы Optimization of thermal insulation and moisture absorption properties of knitted fabrics with different fiber compositions

- Buzaite V., Repon Md.R., Milašienė D., Mikučionienė D. "Development of multi-layered weft-knitted fabrics for thermal insulation" Sep. 30, 2019, SAGE Publishing. DOI: 10.1177/1528083719878811

- Legerská J., Ondrušová D., Krmela J. "Evaluation of thermal insulation properties and dynamic moisture transfer of knitted fabrics" Feb. 01, 2020, IOP Publishing. DOI: 10.1088/1757-899x/776/1/012100

- Meng J., Hou C., Zhang C., Zhang Q., Li Y., Wang H. "Thermal and Humidity Management for Next-Generation Textiles". Feb. 28, 2020. - 163 p. DOI: 10.1002/9783527818556.ch7

- Behera B.K., Hari P.K. Assessing the comfort of woven fabrics: thermal properties // Elsevier eBooks, Elsevier BV. - 2010. - 330 p. DOI: 10.1533/9781845697815.4.330

- Kiš A., Brnada S., Kovačević S. "Influence of Fabric Weave on Thermal Radiation Resistance and Water Vapor Permeability" Mar. 01, 2020, Multidisciplinary Digital Publishing Institute. DOI: 10.3390/polym12030525