Phase-structural heterogeneity and activity of the surface of polymineral sand powders

Автор: Morozova M.V., Ayzenshtadt A.M., Akulova M.V., Frolova M.A.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Manufacturing technology for building materials and products

Статья в выпуске: 2 Vol.14, 2022 года.

Бесплатный доступ

Introduction. The value of the specific surface (Ssp), the degree of crystallinity (С, %) and surface activity (ks) plays an important role in creating various compositions. The increase in the size of Ssp is associated with a change in the “С” of rock powders, the value of which characterizes the properties of fillers. The reactivity of the finely dispersed material can be determined by the value of ks, which allows quantifying transition of the potential energy into free surface energy by activating the surface of the raw material. Therefore, determining the functional relationship between the parameters characterizing the reactivity of rock powders is an urgent task. Methods and Materials. Four deposits of polymineral construction sands are selected as raw materials. To obtain fine powders, the samples were ground by dry dispersion. The specific surface area of rock systems was determined by gas sorption. Crystallinity was calculated from the X-ray diffractogram of the samples. Results and Discussion. The certain sizes of specific surfaces for highly dispersed rocks have shown, that deposits “Kenica” and “Nekhtskoye” possess the greatest values Ssp. The study of the phase-structural heterogeneity of the samples, showed a significant increase of the content of the amorphous phase. At the same time, the degree of crystallinity for the sands “Kenica” and “Nekhtskoye” deposits decreases 25%. The functional relationship between the surface activity and the shares of the amorphous component (c) for highly dispersed sands was characterized by mathematical expression ks = 21•10–6•c+0,58•10–6. The identified dependence demonstrates the relationship between the parameters of the phase-structural heterogeneity and ks of fine-dispersed samples. Conclusion. The results obtained showed that mechanical dispersion contributes to the activation of raw materials. This is due to the breakability of the crystal structure of minerals and the texture of the raw materials. These characteristics are reflected in the value of the activity of the surface of finedispersed systems of the rocky rocks.

Polymineral sands, specific surface area, degree of crystallinity, amorphous component, surface activity

Короткий адрес: https://sciup.org/142231190

IDR: 142231190 | DOI: 10.15828/2075-8545-2022-14-2-89-95

Текст научной статьи Phase-structural heterogeneity and activity of the surface of polymineral sand powders

Original article

C urrently, thin-fat mineral powders are of great importance for the building materials industry [1–2], the introduction of which to the production technology makes it possible to improve the quality of building materials. Sizing powders to micro- and nano-dimensional levels of particles leads to a change in a number of physicochemical properties of the systems themselves [3–4]. This approach allows significant improving the quality of composite materials. Strength, wear resistance, thermal and chemical resistance, viscosity of destruction, that

-

is, increase the operating period and the life cycle of the product or construction as a whole [5–9].

The most common and demanded raw materials for the production of building materials are rocks of various genesis. With mechanical dispersion of this raw material, according to the classical principles of thermodynamics, a certain work is spent, as a result of which the energy of the formation of a free surface [10–11] is released from the total energy potential of the breed.

In addition, a number of researchers noted that to create various compositions in composition, the value of the specific surface ( Ssp ), the degree of crystallinity

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS and the activity of the surface (ks) plays an important role.

The preparation of micro- and nanoscale particles in the analyzed systems ensures the transition of part of the potential energy of the entire object due to its structure, composition and texture into excess surface energy. The dominant role in this plan is given by the specific surface, the increase of which helps to strengthen the relationship between raw materials with the composite matrix (more uniform particle size distribution is achieved), which leads to the optimization of its structure and properties [2, 6, 8, 12].

The increase in the size of Ssp is closely related to the degree of crystallinity of rock powders. So, it is known that the degree of crystallinity – is the ratio of the mass of the crystal part of the powder of the test sample to its total mass, expressed as a percentage or fractions. During the dispersion of rocks, the crystal lattice of the material occurs during the ultra-and nanoscale state. As a result, the intake of internal energy and the transformation of a part of the crystal structure into an amorphous phase is an important component to increase the reactivity of composites [13].

Thus, the degree of crystallinity is an indicator of a highly dispersed material, the magnitude of which characterizes the properties of fillers, and as a result, the main finish properties of the concrete composite (density, strength, frost resistance, water resistance).

In turn, as shown by our research, the reactivity of the highly dispersed material can be determined by the activity of the surface ( ks ). It is this parameter that allows you to quantify the transition of potential energy accumulated by the rock in the process of genesis, into free surface energy due to the activation of the surface of the raw material [2, 14, 15].

The definition of the value of KS is based on macroenergy rates of rock. The first is – the atomization energy ( Ea , KJ/mol), which is determined as the sum of the standard enthalpy of the formation of crystals and the heat of the formation of the components of the atoms of chemical elements (values are given in reference literature [16]). The derivatives of this value are the specific mass energy of atomization ( Em , KJ/g) and the specific volumetric energy of atomization ( Ev , KJ/cm3), allowing you to correctly compare rocks by energy parameters. At the same time, the Ev parameter is due to the specifics of its calculation, it allows you to characterize rock rocks for energy content [10–17].

The calculation of the value of the surface activity was carried out using the provisions of [9, 10, 14, 18], according to which this parameter is equal to ks = Es/ Em ratio. Free surface energy (Es, J/kg) was calculated by the product of the values of the surface tension (σk) of the highly dispersed system and its specific surface. For the experimental definition, σk was used the OWRK method (Ounce, Wendt, Rabel, and Kjellble method) [4, 12, 15, 18, 19].

The purpose of the research presented in this work is to determine the possible functional relationship between the parameters characterizing the reactivity of the powders (the degree of crystallinity and the surface activity) of rocks on the example of finely dispersed systems of the polymineral sands of the most widely used fields of the Arkhangelsk and Ivanovo regions.

METHODS AND MATERIALS

Four deposits of polymineral construction sands were chosen as raw materials for the study: the “Krasnoflotsky-Zapad” and “Kenitsy” deposits (Arkhangelsk region), the “Khromtsovskoye” deposit (the village of Khromtsovo, Ivanovo region) and the “Nekhtskoye” deposits (the village of Teterinskoye, Nerekhtsky district). The last two deposits are located in the Ivanovo region.

Before starting the experiments, the sand was washed and dried to a constant weight at 105оC. Sands size modulus and their true density (by picnometric method) were determined according to GOST 8735-88.

To obtain finely dispersed rock powders, samples, raw material, were ground to finely dispersed state by dry dispersion in a “Retsch PM100” planetary ball mill using a carbidwolfram grinding headset. The optimal dispersion conditions were selected by test to obtain a reproducible particle size with a satisfactory polydispersity of the fractions obtained.

The specific surface area of highly dispersed rock systems was determined by gas sorption, according to BET theory, on the analyzer “Autosorb-iQ-MP.”

The degree of crystallinity for rocks in powdered form was calculated based on the X-ray diffractogram of samples using the XRD-7000 XRD-7000 XRD-7000 X-ray diffractometer. Radiographs were recorded in the CCU “Arctic” NArFU.

RESULTS AND DISCUSSION

Selected sand deposits are not significantly different in the size of the size ( Mk ). Three of them belong to the middle, and the sand of the “Krasnoflotsky-West” deposit is small. True densities ( ρreal ) of the breeds under study also have close values and vary in the range from 2500 to 2710 kg/m3 (Table 1).

In the grinding process, several fractions of highly dispersed rocks were obtained, which were characterized by the value of the specific surface (Table 2).

The analysis of the obtained fractions for the rocks presented in Table 2, with 30 minute duration of the grinder, showed that the sand of the “Nekhtskoye” deposit has the highest value of the specific surface. At the same time, the sands “Krasnoflotsky-West” and “Khromtsovs-

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Table 1

Main characteristics of rocks

|

Sand deposit |

Designation |

Mk |

Fineness |

ρreal , kg/m3 |

|

Krasnoflotsky-West |

S1 |

1.70 |

small |

2710 |

|

Kenitsa |

S2 |

2.21 |

average |

2640 |

|

Hromtsovskoye |

S3 |

2.18 |

average |

2500 |

|

Nekhtskoye |

S4 |

2.43 |

average |

2600 |

Table 2

Specific surface area of highly dispersed rock samples

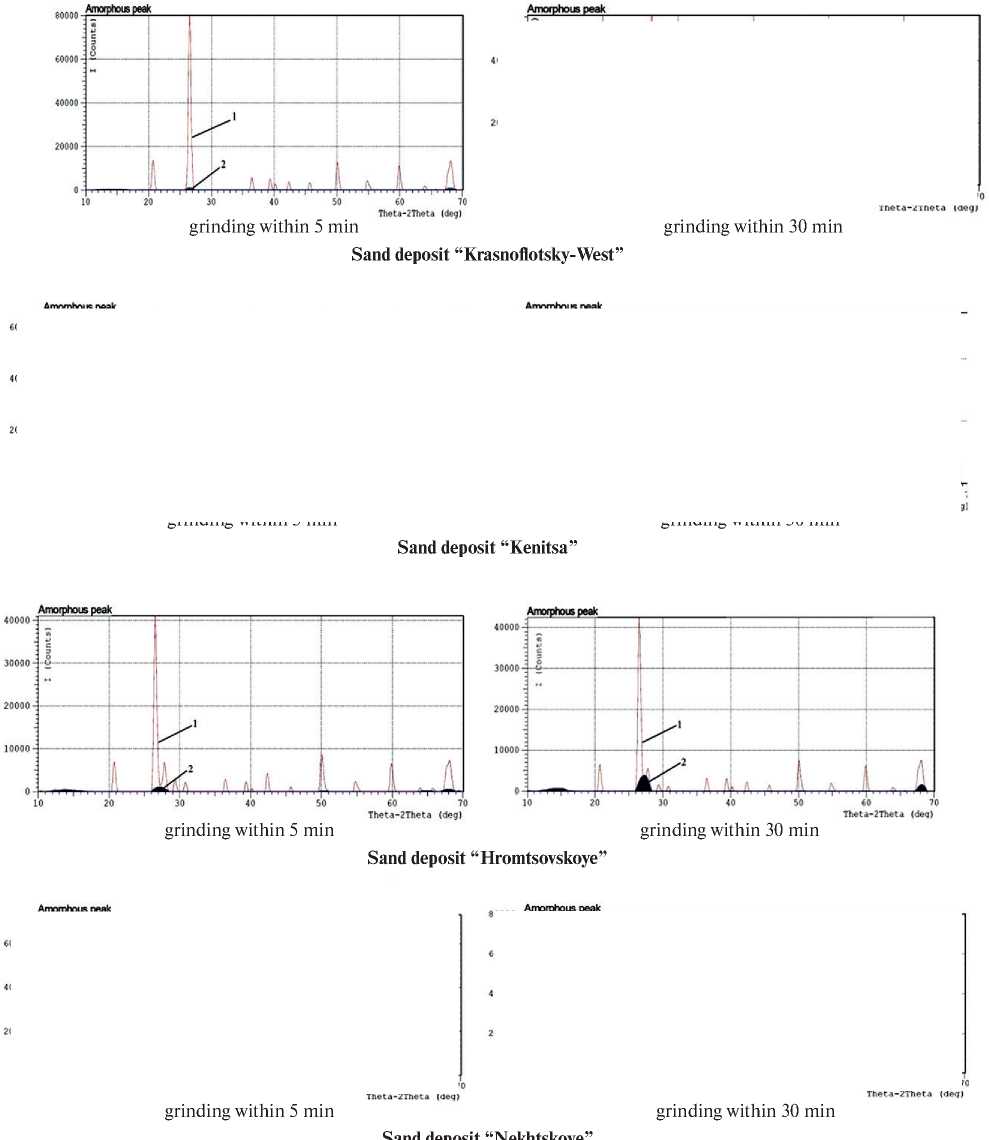

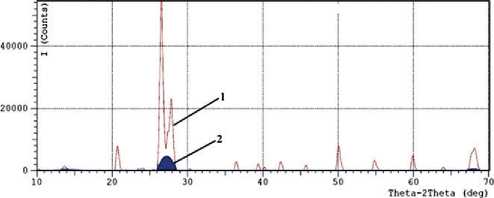

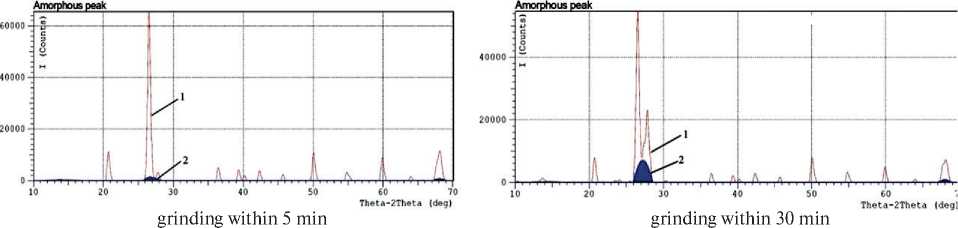

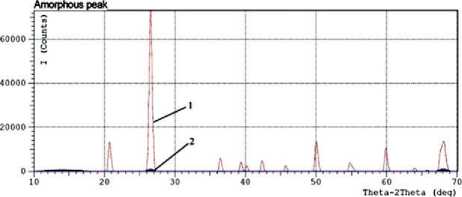

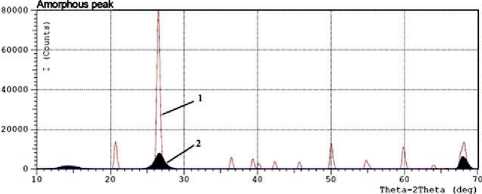

The study of the phase-structural heterogeneity of the samples after different in time (5 and 30 minutes) of the mechanical actuation period (Fig. 1), showed a significant increase in all the studied samples of the amorphous phase.

The change in the degree of crystallinity and the percentage of the amorphous phase in highly dispersed samples after mechanical dispersion is presented in Table 3.

The given data (Table 3) show that the degree of crystallinity for the studied polymineral sands decreases during the grinding of 30 minutes from 14 to 25%. The effect of reducing the degree of crystallinity (increasing the degree of phase-structural heterogeneity) of samples is associated with their structural and textural features.

These facts, based on the ideology of calculating the activity of the surface ( ks ), are reflected in the magnitude of this indicator, the physical nature of which is determined by the structural and textural features of the analyzed objects.

Table 4 shows the values of the indicators (calculated and experimentally defined) used by us to calculate ks (specific mass energy of atomization, Em ; cosine values of the wetting angle with reference liquids, cosθ ; surface tension of prototypes, pressing, σk = σd + σp ; free surface energy, Es and specific surface, Ssp ). It should be noted that according to the OWRK method, the determination of the surface tension of the pressed powders is associated with the calculation of the dispersion ( σd ) and the polarization ( σp ) components.

Table 3

Crystal degree and amorphization of rock surface

|

Sand deposit |

The degree of crystallinity / content of the amorphous phase ( C , %), depending on the time of grinding rocks |

|||

|

5 min |

10 min |

20 min |

30 min |

|

|

S1 |

96.2/3.8 |

94.7/5.3 |

90.5/9.5 |

86.2/13.8 |

|

S2 |

95.4/4.6 |

92.9/7.1 |

80.8/19.2 |

74.2/25.8 |

|

S3 |

93.2/6.8 |

91.8/8.2 |

87.7/12.3 |

83.2/16.8 |

|

S4 |

94.9/5.1 |

94.1/5.9 |

84.7/15.3 |

72.6/27.4 |

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 1. Diffractograms of highly dispersed samples of rocks: 1 – crystal part; 2 – amorphous part

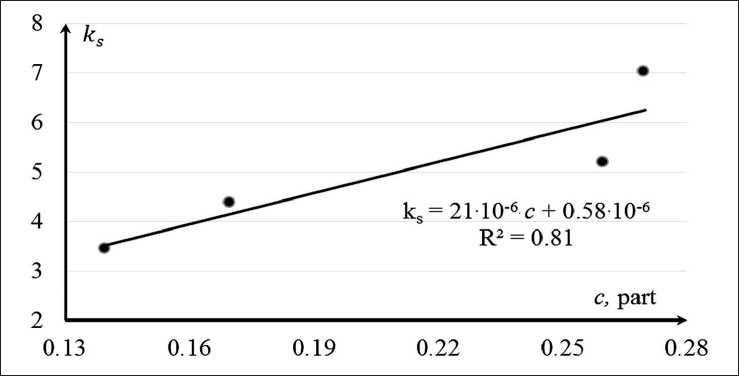

Figure 2 shows the dependence of the surface activity from the share of the amorphous component for highly dispersed sands with a grinding time of 30 minutes (this time was chosen due to the maximum values of “c” – shares of the amorphous component), which is linear in nature with the accuracy ratio of the approximation R2 = 0.81 and subordinate equation:

ks = 21•10–6• c +0.58•10–6. (1)

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Table 4

Energy parameters of sediment rocks

|

Defined parameter |

Sand deposit |

|||||||

|

S1 |

S2 |

S3 |

S4 |

|||||

|

Grinding time, min |

5 |

30 |

5 |

30 |

5 |

30 |

5 |

30 |

|

Specific surface, Ssp , cm2/g |

8241 |

22231 |

7819 |

28603 |

9101 |

23187 |

7783 |

31543 |

|

Surface tension σк , mN/m |

66.97 |

67.58 |

67.06 |

67.81 |

67.51 |

68.11 |

65.22 |

67.51 |

|

Specific mass, Em •103, KJ/kg |

30.44 |

30.41 |

29.12 |

30.67 |

||||

|

Free surface energy Es , J/kg |

67.94 |

104.05 |

66.46 |

157.67 |

61.89 |

126.96 |

50.59 |

214.49 |

|

Surface activity ks •106 |

2.23 |

3.42 |

2.18 |

5.18 |

2.13 |

4.36 |

1.65 |

6.99 |

Fig. 2. Functional dependence of the species ks = f(c) for a grinding time of 30 minutes

CONCLUSION

The obtained experimental results showed that dry mechanical dispersion of the polymineral sands of various fields on the planetary ball mill contributes to the activation of raw materials associated with the destruction of its crystal lattice and the formation of the active amorphous phase. At the same time, the key technological factor of activation is the grinding time, which contributes to a decrease in the degree of crystallinity of the sands at about 0.46% (for S1) to 0.96% (for S4) per minute. This fact is associated with the temperature of the crystal structure of minerals that make up the polymineral prototypes, and the texture of raw materials. These characteristics are reflected in the value of the activity of the surface of fine-dispersed systems of the rocky rocks. The confirmation of this conclusion may be the identified direct proportionality between the parameters of the phase-structural heterogeneity (the proportion of the amorphous phase) and the activity of the surface of the fine-dispersed samples. The functional relationship of these parameters is expressed by a linear equation of the species: ks = 21•10–6•c+0.58•10–6.

Список литературы Phase-structural heterogeneity and activity of the surface of polymineral sand powders

- Tolstoy А.D. Fine-grained high-strength concrete. Construction Materials and Products. 2020; 3(1): 39–43.

- Kozhuhova N.I., Strokova V.V., Chizhov R.V., Kozhuhova М.I. Chemical reactivity assessment method of nanostructured low calcium aluminosilicates. Construction Materials and Products. 2019; 2(3): 5–11.

- Boucedra A., Bederina M., Ghernouti Y. Study of the acoustical and thermo-mechanical properties of dune and river sand concretes containing recycled plastic aggregates. Construction and Building Materials. 2020; (256): 119447.

- Gavshina O.V., Yashkina S.Yu., Yashkin A.N., Doroganov V.A., Moreva I.Yu. Study of the effect of particulate additives on the setting time and microstructure of high-alumina cement. Construction Materials and Products. 2018; 1(4): 30–37.

- Danilov V. E., Ayzenshtadt A.M., Frolova M. A., Tutygin А.S. Dispersion Interactions as Criterion of Optimization of Cementless Composite Binders. Inorganic Materials: Applied Research. 2018; 9(4): 767–771. (In Russian).

- Klyuev S.V., Klyuev A.V., Shorstova E.S. Fiber concrete for 3-D additive technologies. Construction Materials and Products. 2019; 2(4): 14–20.

- Fedyuk R.S., Mochalov A.V. Issues related to management of the structure formation of a composite binder. ALITinform: Cement. Concrete. Dry mixes. 2018; 2(51): 2–10.

- Chernyisheva N.V., Shatalova S.V., Evsyukova A.S., Fisher H.B. Features of the selection of the rational structure of the compositional gips binder. Construction Materials and Products. 2018; 1(2): 45–52.

- Shoshin E.A., Strokova V.V., Kozlov N.A., Gribkov D.S. Improving the efficiency of cement concrete due to the use of a composite binder with silicate calcium dispersion. ALITinform: Cement. Concrete. Dry mixes. 2019; 4(57): 22–29.

- Veshnyakova L.A., Ayzenshtadt A.M., Frolova M.A. Evaluation of surface activity of highly dispersed raw materials for composite building materials. Physics and chemistry processing materials. 2015; (2): 68–72.

- Veshnyakova L.A., Drozdyuk T.A., Ayzenshtadt A.M., Frolova M.A., Tutyigin A.S. Surface activity of silver rocks. Materials Science. 2016; (5): 45–48.

- Grishina A.N., Korolyov E.V. The effectiveness of modification of cement composite-sized hydraulicates of barium. Construction Materials. 2015; (2): 72–76.

- Glezer A.M. Amorphous and nanocrystalline structures similarities, differences, mutual transitions grew. Society of Chemistry named after D.I. Mendeleev. 2002; (5): 57–63.

- Drozdyuk T.A., Ayzenshtadt A.M., Frolova M.A., Rama Shanker Verma. Mineral composite using saponitecontaining mining waste. Construction Materials and Products. 2020; 3(3): 21–27.

- Sokolova Y.V., Ayzenshtadt A.M., Strokova V.V. Evaluation of dispersion interaction in glyoxal-silica organomineral system. Journal of Physics: Conference Series. 2017; 929(1): 012110.

- Binnewies M., Milke E. Thermochemical Data of Elements and Compounds. Hannover: Wiley-VCH; 2002.

- Abramovskaya I.R., Ayzenshtadt A.M., Lesovik V.S., Veshnyakova L.A., Frolova M.A., Kazlitin S.A. Calculation of energy intensity of rocks – as raw materials for the production of building materials. Industrial and Civil Engineering. 2012; (10): 23–25.

- Danilov V.E., Korolev E.V., Ayzenshtadt A.M., Strokova V.V. Features of the calculation of the free energy of the surface based on the model interfacial interaction of the Ounsa–Vendta–Rabelya–Kelble. Construction Materials. 2019; (11): 66–72.

- Morozova M.V., Ayzenshtadt A.M., Akulova M.V., Frolova M.A., Shamanina A.V. Evaluation of the possibility of using powders of polymineral silica-containing sands as a hydrophobic coating. Nanotechnologies in Construction. 2021; 13(4): 222–228. DOI: 10.15828/2075-8545-2021-13-4-222-228.