Plastic Drainage Slabs with low-temperature nanosintering of granules

Автор: Lyapidevskaya O.B.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Development of new materials

Статья в выпуске: 5 Vol.17, 2025 года.

Бесплатный доступ

Introduction. Currently, the construction industry is developing rapidly. New residential and industrial buildings and structures appear both in megalopolises and small towns. In this regard, an active development of the underground space continually gains in scope: basements and buried facilities, multistorey structures, underpasses and parking lots, shopping malls and many other structures are being built. In order to create reliable and durable structures much attention should be paid to the protection of underground parts of buildings from the destructive effects of groundwater. Waterproofing and drainage materials currently used do not always meet the necessary requirements. The paper discusses the development of a new material for wall drainage in order to provide reliable protection for underground buildings against the damaging influence of groundwater. Methods and materials. The article presents a detailed analysis of existing methods and materials that are used in the installation of wall drainage systems. Plastic slabs made of filtration expanded polystyrene have been proposed as an effective drainage material. The technology of filtration material with high water transmission capacity is presented. This methodology is based on the low-temperature nanosintering of polystyrene granules. The main structural characteristics of filtration polystyrene, including characteristic pore diameter and intergranular porosity, and its physical and mechanical properties were determined. Results and discussion. The results of research on the structure of filtration expanded polystyrene with different grain-size compositions are given. It is shown that due to the process of nanosintering of granules it is possible to form varies types of drainage slab structures, which are necessary to obtain required characteristics. In addition, the experimental results of the water transmission capacity of drainage slabs, depending on the structural characteristics of the material, are also presented. Based on the tests conducted, an empirical formula has been developed to calculate the filtration coefficient of the plastic drainage slabs. Recommendations have been developed for selecting the grain composition of material when working on cohesive and non-cohesive soils. Conclusion. The results of our study show that filtration expanded polystyrene slabs have a high-water transmission capacity and sufficient compressive strength and can be used to protect the underground parts of buildings based on different soil types.

Underground structures, wall drainage, filtration expanded polystyrene, nanosintering, plastic slabs, water transmission capacity, filtration coefficient

Короткий адрес: https://sciup.org/142246074

IDR: 142246074 | DOI: 10.15828/2075-8545-2025-17-5-538-546

Текст научной статьи Plastic Drainage Slabs with low-temperature nanosintering of granules

Original article

Ляпидевская О.Б. Пластиковые дренажные плиты с низкотемпературным наноспеканием гранул. Нанотехнологии в строительстве. 2025;17(5):538–546. – EDN: IIWXTI.

The most widespread methods for protecting underground parts of buildings from the damaging influence of groundwater are the use of various waterproofing rolled or mastic materials made from bitumen, combined with a drainage gravel-sand backfill. However, these methods are rather labor-intensive, and the quality of the waterproofing protection for underground structures does not meet the necessary requirements. Due to this, frequent flooding of underground and buried parts of buildings can be observed. Such occasions not only degrade favorable thermal and humidity conditions of underground premises operation but also can cause destruction of concrete structures [1–8].

There are several directions for developing wall drainage systems. These include rolled bulk polymer meshes combined with geotextiles, synthetic mats with loose mineral or polymer fillings, coarse-porous polymer plates with geotextiles, and more [9–13].

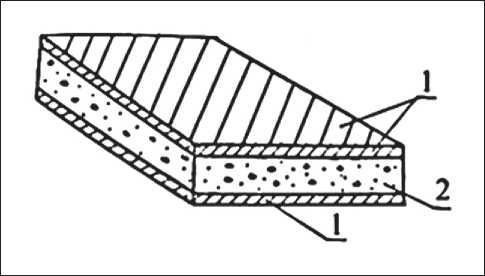

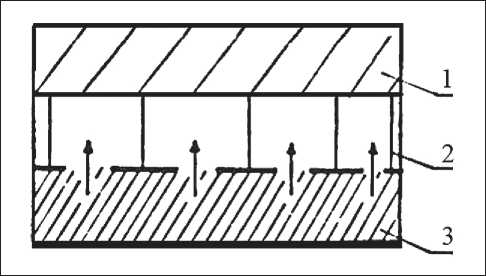

Some of examples of multilayered systems are presented in Figures 1–4. A three-layer structure consisting of two layers of geotextile coverings, between which small pieces of synthetic rubber are evenly distributed, glued together at the contact points, is shown in Figure 1. The disadvantage of this structure is its low corrosion resistance and the unreliability of the adhesives used. The next example of a drainage system consists of two slabs, one of which is perforated and contacts with the soil. These two slabs are held together by spacers, which also serve as a water culvert channel (Fig. 2). The main drawback of this system is its complexity and lack of study of its filtration characteristics.

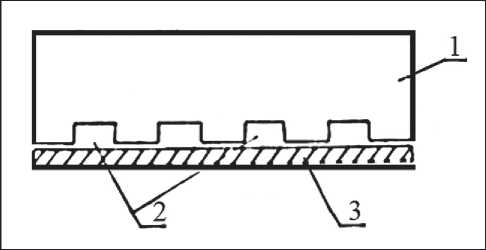

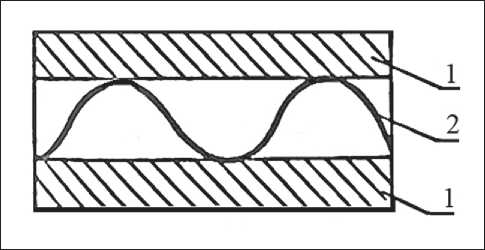

An isolation plastic panel with special cutouts for water removal, protected from soil clogging by geotextile cloth, is shown in Figure 3. Another example of a drainage slab is a corrugated sheet made from synthetic resin, with geosynthetic material attached to both sides (Fig. 4). These two examples are also more difficult to produce, and they cannot be used below a depth of 5 meters.

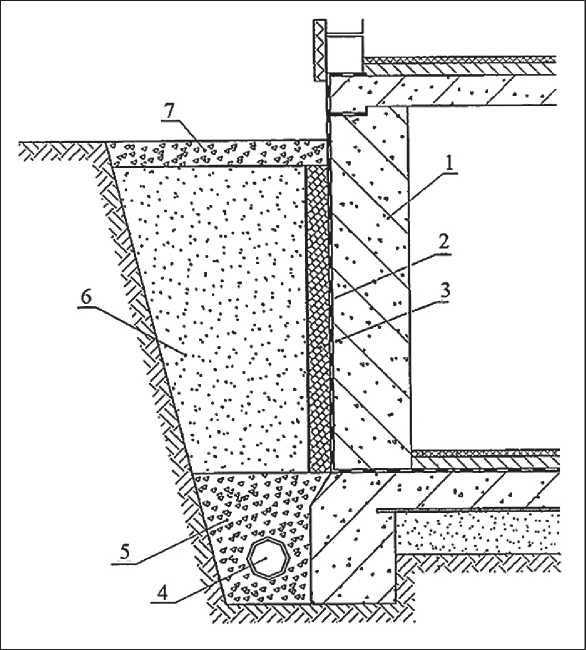

To improve the protection of structures from ground water and increase the durability of underground constructions, new methods have been developed, including prefabricated rigid filtering wall slabs (Fig. 5).

The first prefabricated rigid drainage wall slabs were made from filtering coarse-poured concrete. These slabs have rather appropriate water permeability (0.3–1.0 cm/s) and a high compressive strength (2.5–10 MPa) [14, 15].

DEVELOPMENT OF NEW MATERIALS

Fig. 1. Drainage structure: 1 – a geotextile covering; 2 – glued together pieces of synthetic rubber

Fig. 2. Drainage system: 1 – a wall; 2 – two slabs (lower slab is perforated); 3 – soil

Fig. 3. Drainage item: 1 – a plastic panel; 2 – cutouts for water removal; 3 – geotextile cloth

Fig. 4. Drainage slab: 1 – a geotextile covering; 2 – a corrugated synthetic sheet

Fig. 5. Underground construction with filtering wall slabs:

1 – an underground part of wall;

2 – a waterproofing covering;

3 – filtering wall slabs;

4 – a drainage pipe;

5 – gravel mix;

6 – soil;

7 – gravel

DEVELOPMENT OF NEW MATERIALS

However, concrete slabs do have some disadvantages. They have a large mass, which makes them difficult to transport and install. Additionally, they have low resistance to various types of corrosion and cannot be used in areas with aggressive groundwater [16].

In recent years, multilayer polyethylene roll sheets with rounded protrusions and protective layers made from geotextile coatings have become widely used as wall drainage elements. These materials have a high strength and resistance to aggressive environments, and they can withstand the pressure of the ground up to 0.05 MPa. Despite several advantages over protective materials made from bitumen, polyethylene sheets do have some disadvantages. Due to the high rigidity of plastic, it is quite difficult to perform overlapping seams efficiently, which requires the use of special mastics [17–20]. The quality of the work sometimes does not meet the necessary standards, and over time, the joints become damaged, leading to leaks and a loss of waterproofing.

So, the review of materials used for drainage systems has shown the need to develop new and effective materials to protect underground structures that would be free from the drawbacks mentioned above.

METHODS AND MATERIALS

In order to create an effective and durable drainage system with high water transmission capacity and resistance to aggressive environments, we have made an attempt to develop plastic slabs with an open coarse-porous structure. This slabs structure has been created by sintering spherical polystyrene foam granules at the contact points with the formation of an open (intergranular) porosity in the spaces between them. In this case the sintering process itself occurs at the nanoscale. As a result intermolecular interactions create a strong adhesion between granules in the proposed conditions. This process can be called nanosintering.

The development of technology has been based on research of the influence of various factors, such as the foaming and sintering time and temperature, as well as the granular size, on the main properties of the drainage polystyrene foam material: water transmission capacity, intergranular porosity, and compressive strength, among others [21, 22].

As discussed in our previous research [21–23], the foaming time of granules depends on their size and ranges from 200 to 300 seconds. Nanosintering of the granules occurs at the temperature of 98°C and the duration of the sintering process is 60 seconds. A further increase in temperature or sintering time can lead to granular deformations. As well as this we have determined the following physical and mechanical properties of the material: average density – 18 kg/m3 and compressive strength – 0.09–0.11 MPa. In order to provide proper protection for underground structures from groundwater and to create a thermal and humidity regime for the operation of buildings, the following dimensions of drainage slabs are recommended: 1000×500×100 mm [23].

In the course of the work, the structural characteristics of the plastic slabs made of filtration expanded polystyrene were determined: the characteristic pore diameter and intergranular porosity. For this purpose, we produced test batches of samples with various granulometric compositions and obtained flat sections of the porous material (slices). These slices were then subjected to computer processing. The characteristic pore size of the filtration expanded polystyrene is the pore size that corresponds to 70% of its content in the material ( D70 ).

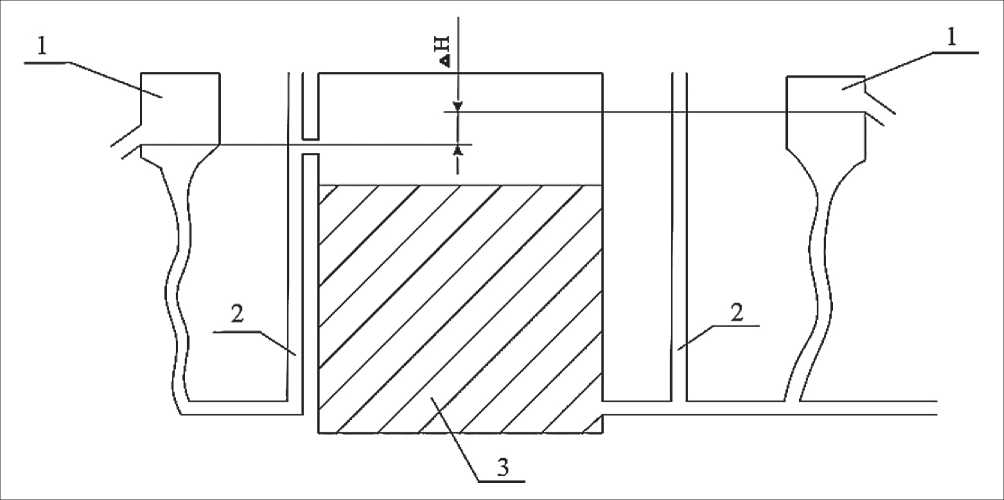

The water transmission capacity of materials with different granulometric compositions was determined using cylinder samples with a diameter and height of 10 cm. Before testing the sides of the samples were covered with a sealing material. The device shown in Figure 6 was used to measure the water transmission through a sample at different pressure gradients. In order to reduce the impact of air colmatation, the filling of the samples was done slowly, and the filtration flow was directed from the bottom to the top.

To control the pressure, two spillway tanks with a constant water level were used. Spillway tanks were moved vertically in every 10 minutes. The pressure loss in the samples was measured as the difference between the piezometer readings. While measuring the water levels in the piezometers, we also determined the water consumption at gradients ranging from 0.05 to 1.0.

The pressure gradient ( J ) was calculated using the Formula 1.

J = ∆ H / l , (1)

where ∆ H – the pressure loss in the sample, cm; l – a sample height, cm.

The filtration rate ( V ) was calculated using the Formula 2.

V = Q / A , (2)

where Q – water consumption, cm3/s; A – a crosssectional area of the sample, cm2.

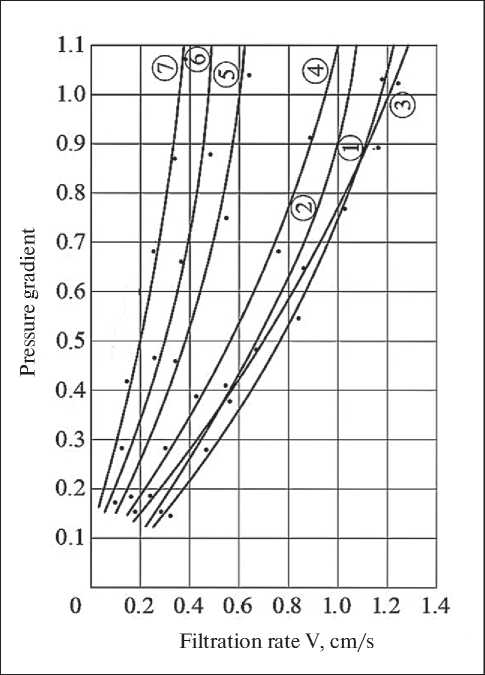

Based on the results obtained, we plotted filtration rate V as a function of pressure gradient J and determined the relationship between the materials’ water transmission capacity and the pressure gradient.

As have been discussed in our previous research [22, 23], in the laminar flow regime and at low water flow rates, there is a linear relationship between the filtration rate and the pressure gradient in a finely porous medium. In this case, the Darcy’s law can be applied (Formula 3).

DEVELOPMENT OF NEW MATERIALS

Fig. 6. Device for measuring the water permeability of samples: 1 – spillway tanks; 2 – piezometers; 3 – a sample; ∆ H – the pressure loss in the sample

V = Cf • J , (3)

where Cf – filtration coefficient, cm/s; J – pressure gradient.

In highly porous medium, the water flow rate can change significantly depending on the value and direction, even with low pressure gradients. In such cases, the linear law no longer works and the Proni formula (a polynomial of the second degree) should be used (Formula 4).

J = aV + bV 2, (4)

where J – pressure gradient; a – an empirical coefficient that characterizes the water permeability of the material; b – an empirical coefficient of inertial resistance; V – filtration rate, cm/s.

Using a polynomial of the second degree, an empirical formula was derived for calculating the filtration coefficient of filtration expanded polystyrene ( Cf , cm/s) (Formula 5).

V

Cf-J^ +

0.O1P-2’3

0.6758D2o - 2.7873D70 + 3.3023 ^ , (5)

where P – intergranular porosity, fractions of a unit; J – pressure gradient; V – filtration rate, cm/s; D70 – characteristic pore diameter, cm.

One of the most important conditions for ensuring the stability of a drainage system is its resistance to clogging by backfill soil particles, i.e. resistance to colmatation.

For researching the colmatation of plastic drainage slabs made of filtration expanded polystyrene by con- tact of various types of soils we used the device shown in Figure 2. Test methodology was as follows: a 1.0 cm thick layer of soil was poured onto the sample, and then water was supplied to the device from above. Water level changes were measured using piezometers every 2 hours. After the colmatation of the intergranular voids of filtration expanded polystyrene with soil until a constant flow of water was reached, we measured the filtration coefficient.

RESULTS

As a result of the research conducted, the following indicators of the drainage plastic plates made of filtration expanded polystyrene were determined: structural characteristics (grain composition of foamed granules, characteristic pore diameter, intergranular porosity) and filtration coefficient. The data obtained are presented in Table 1.

The results presented in Table 1 show that the water transmission capacity of the material is significantly affected by its structural features. Thus, depending on the granulometric composition, the characteristic pore diameter, and intergranular porosity, the values of the filtration coefficient vary widely, ranging from 2.30 to 0.44 cm/s.

The dependence of the filtration rate on the pressure gradient has been established for the samples with different grain compositions (Figure 7).

Analyzing the obtained data, we can conclude that even with small pressure differences, the linear relationship between filtration rate V and pressure gradient J does

DEVELOPMENT OF NEW MATERIALS

Table 1. Structural characteristics and filtration coefficient of the filtration polystyrene

|

Sample batch No. |

Grain composition of foamed granules |

Characteristic pore diameter ( D 70), mm |

Intergranular voidness, % |

Filtration coefficient, cm/s |

|

|

mm |

% |

||||

|

1 |

7–8 |

100 |

2.2 |

22.0 |

2.30 |

|

2 |

7–8 |

50 |

1.71 |

18.9 |

1.90 |

|

5–7 |

50 |

||||

|

3 |

5–7 |

100 |

1.55 |

31.0 |

1.60 |

|

4 |

5–7 |

50 |

1.23 |

27.9 |

1,10 |

|

3–6 |

50 |

||||

|

5 |

7–8 |

33 |

1.12 |

15.8 |

0.88 |

|

3–6 |

33 |

||||

|

2–3 |

33 |

||||

|

6 |

2–3 |

100 |

0.64 |

19.7 |

0.59 |

|

7 |

7–8 |

25 |

0.43 |

9.5 |

0.44 |

|

5–7 |

25 |

||||

|

3–6 |

25 |

||||

|

2–3 |

25 |

||||

Fig. 7. The dependence of the filtration rate on the pressure gradient: 1–7 – sample batch numbers

not observed. The filtration rate increases as the granule diameter and pore size increase.

In the course of the work, suffusion studies were also carried out in order to develop recommendations for selecting the granulometric composition of filtration expanded polystyrene when operating plastic drainage plates in various soils.

Analyzing the data presented in Table 1 and using the results of our previous experiments [21–23], the following conclusions can be drawn.

For wall drainage systems that work in contact with cohesive soils we recommend using plastic slabs of all tested compositions of filtration polystyrene (No. 1–No. 7) with a granule size ranging from 2.0 to 8.0 mm. In this case additional protection made of geotextiles coverings is not needed. Thus, one-layer plastic slabs consisting of filtration polystyrene compositions (No. 1–No. 7) are recommended to use in the following types of soil: clays with a plasticity index PI > 17, loams with PI ≤ 17 and sandy loam with PI < 7. Compositions No. 5–No. 7 are possible to use in cohesive silty soils. For wall drainage systems that work in contact with non-cohesive soils such as coarse-grained and medium-grained sand we recommend using one-layer drainage slabs made of composition No.1.

In addition, in our work we have also considered options for applying two-layer slabs. Two-layer structures are efficiently used in silty sands with particle size more than 0.03 mm: the layer adjacent to soil should be made of compositions No. 4–No. 7, while the layer adjacent

DEVELOPMENT OF NEW MATERIALS to the protected surface should be made of compositions No. 1–No. 3. For systems that are in contact with finegrained sands two-layer slabs are also recommended. The layer adjacent to soil should be made of compositions No. 2–No. 7, while the layer adjacent to the protected surface should be made of the composition No. 1. In silty sands with a granular size of less than 0.03 mm one-layer slabs of any composition may be used. However, in this case it is necessary to apply geotextile protective coverings. The width of a one-layer slab is 100 mm, while the width of each layer in a two-layer slab is 50 mm for each layer.

The compositions of filtration slabs recommended for use for one-layer and two-layer drainage structures in various soils are given in Table 2.

Research of the colmatation effect of soils on the filtration expanded polystyrene slabs were conducted using four types of soil: coarse-grained sand, fine-grained sand, sandy loam, and loam. The values obtained are presented in Table 3.

During the experiment, the initial and final (after 90 days) filtration coefficient of a sample of expanded polystyrene in contact with various types of soils was determined.

Based on the results, shown in Table 3, due to the partial colmatation of intergranular voidness of the filtration slabs the water transmission capacity of the samples decreases by up to 30–80% depending on the type of a soil compared to the initial filtration coefficient. At the same time, the final filtration coefficient is 70 times higher compared to the filtration coefficient of the backfill soil. This result meets the necessary requirements for drainage effect in all real conditions of drainage system operation.

CONCLUSION

The results of the research we conducted allow us to draw some conclusions. The filtration properties of the plastic drainage slabs depend largely on the structural characteristics of the material, such as the grain composition, the characteristic pore diameter, and the intergranular porosity. The variation of these factors in the production process can be achieved using low-temperature nanosintering technology, which will make it possible to obtain filtration polystyrene with a different macroporous stable structure.

Table 2. Recommended compositions for one-layer and two-layer drainage structures

|

Type of structure |

Cohesive soils |

Non-cohesive soils |

|||||

|

Clay, loam, sandy loam |

Cohesive silty soil |

Coarse-, medium grained sands |

Fine-grained sands |

Silty sands with particles > 0,03 mm |

Silty sands with particles < 0,03 mm |

||

|

One-layer slabs |

Compositions No. 1–No. 7 |

Compositions No. 5–No. 7 |

Composition No. 1 |

– |

– |

Compositions No. 1–No. 7 with geotextile protective coverings |

|

|

Two-layer slabs |

The layer adjacent to soil |

– |

– |

– |

Compositions No. 2–No. 7 |

Compositions No. 4–No. 7 |

– |

|

The layer adjacent to the protected surface |

– |

– |

– |

Composition No. 1 |

Compositions No. 1–No. 3 |

– |

|

Table 3. The values of the filtration coefficient of drainage slabs made of filtration expanded polystyrene, depending on the type of filling soil

|

Sample batch number |

Initial filtration coefficient, cm/s |

Filtration coefficient, cm/s, after testing on different types of soil during 90 days |

|||

|

Coarse-grained sand Cf = 0,058 cm/s |

Fine-grained sand Cf = 0.006 cm/s |

Sandy loam Cf = 0.0007 cm/s |

Loam Cf = 0.0001 cm/s |

||

|

2 |

1.9 |

1.49 |

1.33 |

0.82 |

0.44 |

|

5 |

0.88 |

0.78 |

0.59 |

0.45 |

0.27 |

|

7 |

0.44 |

0.33 |

0.30 |

0.22 |

0.12 |

DEVELOPMENT OF NEW MATERIALS

Based on the data obtained, it can be concluded that as a result of the partial colmatation of the pores of the filtration expanded polystyrene by the filling soil, the water transmission capacity of the samples decreased by 1.5 to 4.5 times compared to the initial filtration coefficient, depending on the type of filling soil used. At the same time the value of the final filtration coefficient allows using the

filtration expanded polystyrene slabs in contact both with cohesive and non-cohesive soils.

Thus, plastic drainage slabs made of filtering polystyrene, using low-temperature nanosintering of granules, have a high filtration coefficient, sufficient strength and chemical resistance and can be used as effective wall drainage of buildings and structures.