Pottery traditions among the carriers of the Novosibirsk variant of the Kulaika culture: a multidisciplinary study

Автор: Selin D.V., Maksimova A.A., Fedorova Z.A.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 1 т.52, 2024 года.

Бесплатный доступ

This article presents the findings of a multidisciplinary analysis of pottery belonging to the Novosibirsk variant of the Kulaika culture. Technological (traceological), petrographic, X-ray phase, and thermal analyses were carried out, providing a basis for an objective reconstruction of the pottery technology. Raw material used at two sites, Kamenny Mys and Dubrovinsky Borok-3, originated from a single region, but from different mines. Three types of clay were used at the former site, and two at the latter, evidencing several groups of potters using various types of clay. Correlation between the types of clay and composition of the paste supports this idea. The clays used at Kamenny Mys are quite different from those used at Dubrovinsky Borok-3 in terms of mineral composition, as shown by petrographic and X-ray phase analyses. According to the thermo-gravimetric analysis, the samples fall into groups differing in the quality of firing. Certain vessels were subjected to more intense firing than others.

Короткий адрес: https://sciup.org/145146981

IDR: 145146981 | DOI: 10.17746/1563-0110.2024.52.1.070-079

Текст научной статьи Pottery traditions among the carriers of the Novosibirsk variant of the Kulaika culture: a multidisciplinary study

The Kulaika cultural and historical community existed in Western Siberia in the Early Iron Age. Scholars have identified several of its variants in different areas. Currently, over 25 archaeological sites attributed to the Kulaika culture are located in the Novosibirsk Ob region. Extensive research at the sites belonging to this culture by the Novosibirsk Archaeological Expedition headed by T.N. Troitskaya have identified a special Novosibirsk variant (Troitskaya, 1979).

Pottery is the most common category of finds at the Kulaika sites. The study of the pottery technology makes it possible to analyze the manufacture of ceramic dishware and to reconstruct some historical and cultural processes that took place among specific populations in different ancient periods (see, e.g., (Bobrinsky, 1978, 1999; Tsetlin, 2012; Zhushchikhovskaya, Mylnikova,

2020; Molodin et al., 2020)). Modern archaeology has widely used scientific methods of research. When studying ancient pottery, these methods have been used to identify the mineral composition of the original raw materials, natural and artificial impurities, ceramic coating (glazes, engobes, etc.), isotopic composition of deposits, and the firing regime of dishware (see, e.g., (Fiziko-khimicheskoye issledovaniye…, 2006; Drebushchak V.A., Mylnikova, Drebushchak T.N., 2018; Molodin et al., 2019; Zhushchikhovskaya, 2022)). Digital technologies, in particular 3D modeling, have also been actively used in the study of stone and pottery (Karasik, Harush, Smilansky, 2020; Chistyakov, Bocharova, Kolobova, 2021). However, less than all scholars clearly delineate the potential for various scientific methods and their use in solving individual focused problems. In our opinion, the integrated use of technical/technological, scientific, and digital methods of studying ancient pottery makes it possible to produce results that do not contradict each other, but rather complement each other, because each method has its own boundaries. This may be achieved by setting a clearly defined research problem and correctly interpreting formal physical, technological, and metric parameters of pottery. This article is intended to reconstruct and compare individual pottery traditions at various sites of the Novosibirsk variant of the Kulaika culture.

Material and methods

The sources used in the research were pottery assemblages of the Novosibirsk variant of the Kulaika culture from the cemetery of Kamenny Mys, the fortified settlements of Dubrovinsky Borok-3 and -4, and the settlement of Ordynskoye-9. It was particularly interesting to compare the technological features of pottery-making from Kamenny Mys and from Dubrovinsky Borok-3 located 1 km southeast of it. Troitskaya observed some similarities in the ornamentation and shapes of vessels from these sites (1979: 29–30) which, according to her, belonged to different periods. The cemetery of Kamenny Mys was dated to the late 3rd century BC, while the fortified settlement to the 1st century BC (Ibid.: 48–49).

This study was based on the interdisciplinary synthesis. The technical/technological analysis followed the methodology proposed by A.A. Bobrinsky in accordance with the natural structure of production (1978, 1999). Techniques of pottery manufacturing were identified by binocular microscopy (Leica

M51) of the surfaces of items and fractures of shards, followed by comparison of the technological traces with the collection of experimental samples. Vessels from Kamenny Mys ( n =49), Dubrovinsky Borok-3 ( n =25) and -4 ( n =12), and Ordynskoe-9 ( n =10) were examined.

Mineralogical and petrographic analysis of thin sections involved polarization microscopy (Zeiss Axio Scope A1) to determine the composition of initial raw materials and artificial additives. The mineral phases of the initial raw material were determined by X-ray phase analysis using a Stadi MP (Stoe) X-ray powder diffractometer*. Thermogravimetric analysis, using a Netzsch TG-209 thermal weighing unit in the temperature range from 20 to 850 °C, was carried out to establish specific features of pottery firing and to compare its quality. Samples were analyzed in a 546 mg gold crucible with a heating rate of 20 °C/min, in pure argon. The sample mass was measured after each heating, using an electronic weighing unit with a scale of 1 g and division value of 0.001 mg. Petrographic and X-ray phase analysis was used for the pottery from Kamenny Mys ( n =30) and Dubrovinsky Borok-3 ( n =10). Thermal analysis was used for the same vessels and for the pottery from Dubrovinsky Borok-4 ( n =4) and Ordynskoye-9 ( n =6).

Notably, the results of technical/technological analysis of the pottery from the Kamenny Mys cemetery and settlements have been published (Selin, 2021). This article focuses on the data obtained using scientific methods and their correlation with the results of technical/ technological analysis of the pottery.

Geological structure of the sites’ area

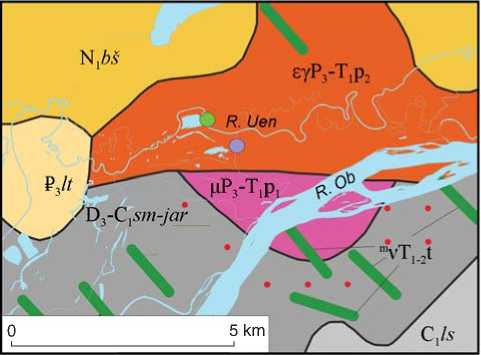

Geologically, the sites under discussion are located in the area confined to the Kolyvan-Tomsk fold system, which includes the Novosibirsk fold zone. The latter comprises the Yeltsovka-Basandaika synclinorium composed mainly of aleurolite, argillite, shale, and sandstone. Its deposits are intensely foliated, with formation of clayey and silty-clayey shale rocks intruded by Late Paleozoic-Early Mesozoic granitoids of the Ob P3–T1 and Barlak T1–2complexes. They are associated with the occurrence of mafic dikes of the Tashara gabbro-dolerite complex T1–2 (Gosudarstvennaya geologicheskaya karta…, 2015). The areas of Dubrovinsky Borok-3 and Kamenny Mys are associated with outcrops of the Ob complex of granitoids (Fig. 1), more precisely

B

C

Fig. 1 . Location of the sites on the maps of Eurasia ( A ) and Novosibirsk Region ( B ), and geological map of the area of the Kamenny Mys and Dubrovinsky Borok-3 sites ( C ).

1 – Beshcheulskaya formation (N1 bš ); 2 – Lagernotovskaya formation (₽3 lt ); 3 – Lagernosadskaya formation (C1 ls ); 4 – Salamatovskaya and Yarskaya poorly defined formations (D3-C1 sm-jar ); 5 – gabbro-dolerite dikes; 6 – the second phase: monzogranites, granosyenites, granites, and amphibole-biotite and biotite medium-grained granodiorites (εγP3-T1 p 2); 7 – the first phase: monzodiorites, diorites, quartz monodiorites and quartz diorites (μP3-T1 p 1); 8 – contact metamorphism, hornfels; 9 – Kamenny Mys; 10 – Dubrovinsky Borok-3.

with the second phase of its injection. Monzogranites, granosyenites, granites, as well as amphibole-biotites and biotite medium-grained granodiorites, occur in the area under study.

Results and discussion

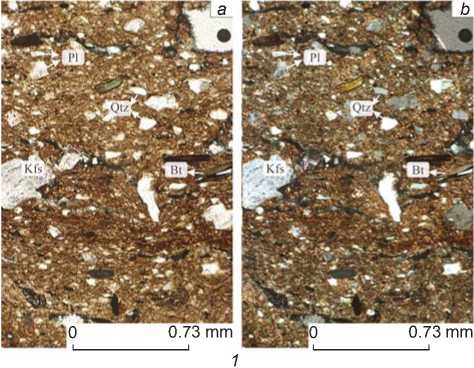

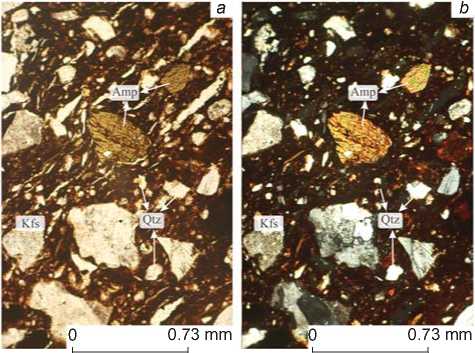

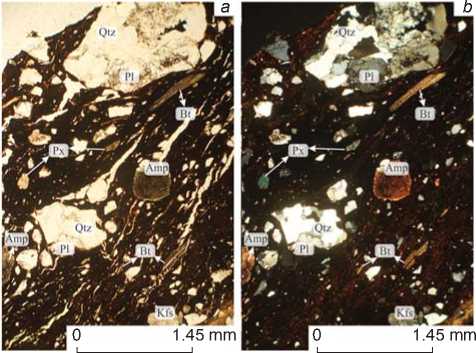

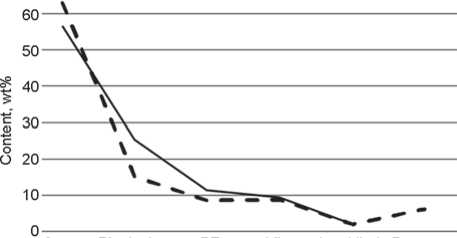

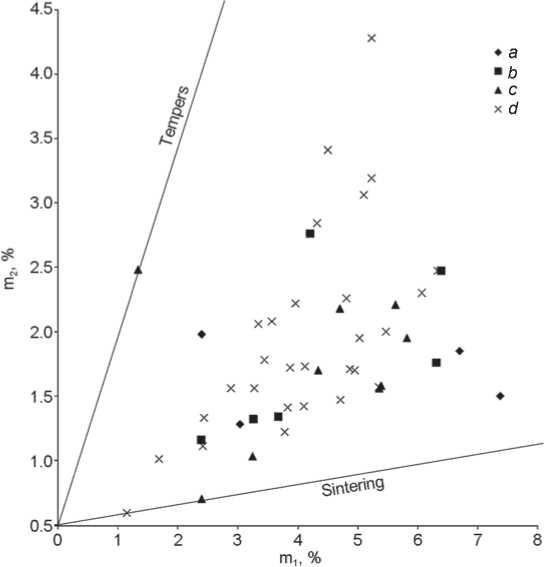

Petrographic and X-ray phase analysis (Fig. 2–4). For pottery production, an initial plastic clay-like raw material (hereafter IPRM) was selected. In almost all the samples from Kamenny Mys, either the predominance of cement (60–70 %) over clastic material (30–40 %), or their equal ratio has been observed. The clastic material includes mainly potassium feldspar, plagioclase, biotite, and amphibole. Pyroxenes and fragments of what is presumed to be granite have also been observed. The cement is predominantly micaceous, with fragments of plagioclase, potassium feldspar, and grains of muscovite, biotite, and pyroxene. The grog contains fragments of plagioclase, potassium feldspar, and muscovite. The obtained data, which were also confirmed by X-ray phase analysis (see Fig. 4, 1 ), make it possible to distinguish three types of IPRM, which differ in mineral composition in the pottery assemblage from Kamenny Mys.

IPRM 1 (see Fig. 2, 1 ) shows increased content of natural biotite inclusions (11–14 wt%). The clastic material includes quartz (47–65 wt%), potassium feldspar (7–22 wt%), and plagioclase (13–17 wt%).

IPRM 2 (see Fig. 2, 2 ) consists mainly of salic minerals, such as quartz (41–90 wt%), potassium feldspar (2–20 wt%), and plagioclase (3–46 wt%).

IPRM 3 (see Fig. 2, 3 ) is distinguished by a relatively large amount of natural dark-colored minerals: pyroxenes (1–20 wt%) and amphiboles (2–6 wt%). The clastic material includes quartz (37–90 wt%), potassium feldspar (1–41 wt%), and plagioclase (1–32 wt%).

Nevertheless, all of the raw materials were procured from one granitoid massif in the same area. The diversity of their composition is probably associated with different stages of crystallization of the massif, during which monzogranites, granosyenites, granites, as well as amphibole-biotite and biotite mediumgrained granodiorites, were formed. When granitoids were weathered, terrigenous deposits of the same composition emerged in their place.

Technical/technological analysis of pottery from Kamenny Mys has revealed six recipes of paste: 1) clay + + grus (68 %); 2) clay + grus + grog (14 %); 3) clay + + grog (10 %); 4) clay + grog + organic solution (2 %); 5) clay + grus + grog + organic solution (4 %), and 6) clay + organic solution (2 %). When comparing the identified types of clay with the paste, it was possible to determine that IPRM 2 had a larger quantity of mixed paste with the addition of grus and grog, and IPRM 3 had a two-component paste with grog. This indicates the coexistence of at least three groups of potters with different skills in selecting raw materials.

An interesting fact is that vessels made of different clays were found together in the same burial mounds and graves. This may imply that a mixed population left behind the Kamenny Mys cemetery, and that the funeral practice of offering ceramic vessels to the deceased came from different groups of potters.

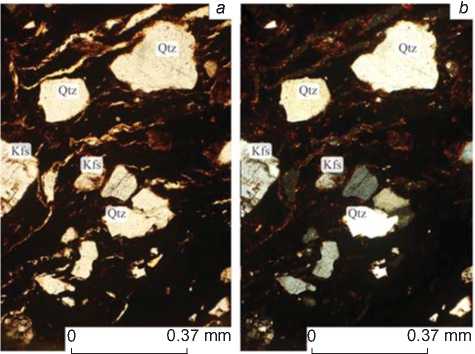

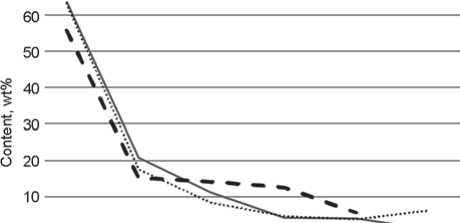

In all samples from the Dubrovinsky Borok-3 fortified settlement, the predominance of cement (60–70 %) over clastic material (25–35 %, mostly potassium feldspar, plagioclase, muscovite and biotite) was detected. The cement was predominantly micaceous, with fragments of plagioclase, potassium feldspar, muscovite, and biotite. According to the

Fig. 2 . Thin sections of pottery from the Kamenny Mys cemetery.

1 – IPRM 1; 2 – IPRM 2; 3 – IPRM 3. a – in polarized light; b – in transmitted light. Qtz – quartz; Pl – plagioclase; Kfs – potassium feldspar; Bt – biotite; Amp – amphibole.

|KS

0.37 mm

0.37 mm

Fig. 3 . Thin sections of pottery from the Dubrovinsky Borok-3 site.

1 – IPRM 1; 2 – IPRM 2.

a – in polarized light; b – in transmitted light.

Qtz – quartz; Pl – plagioclase; Kfs – potassium feldspar; Ms – muscovite; Ap – apatite; Bt – biotite; Px – pyroxene; Amp – amphibole.

0 --------=-

Quartz Plagioclase PF Mica Amphibole Pyroxenes

Quartz Plagioclase PF Mica Amphibole Pyroxenes

Quartz Plagioclase PF Mica Amphibole Pyroxenes

KM. IPRM 2 — - DB, IPRM 1

IPRM 1 -- iprm 2

Quartz Plagioclase PF Mica Amphibole Pyroxenes

KM. IPRM3 — -DB, IPRM2

Fig. 4 . Results of X-ray phase analysis.

1 , 2 – average composition of IPRM mineral phases for pottery from Kamenny Mys ( 1 ) and from Dubrovinsky Borok-3 ( 2 ); 3 , 4 – comparison of the average compositions of mineral phases in different types of IPRM for pottery from these sites. PF – potassium feldspar, KM – Kamenny

Mys, DB – Dubrovinsky Borok-3.

petrographic and X-ray phase analysis (see Fig. 3; 4 , 2 ), two types of IPRM can be distinguished.

IPRM 1 (see Fig. 3, 1 ) shows an increased content of natural mica inclusions (3–14 wt%). It consists mainly of quartz (47–74 wt%), potassium feldspar (9– 16 wt%), and plagioclase (7–14 wt%).

IPRM 2 (see Fig. 3, 2 ) contains a relatively large amount of natural pyroxenes (3–11 wt%).

Six pastes were identified after technical/ technological analysis of the pottery: 1) clay + grus (40 %); 2) clay + grus + organic solution (32 %); 3) clay + organic solution (4 %); 4) clay + grog + organic solution (4 %); 5) clay + grus + manure of ruminants (8 %); 6) clay + grus + grog + manure of ruminants (12 %). The correlation of the identified types of clays with pastes has shown that manure was more often introduced into IPRM 2, which suggests two groups of potters who used different clays and were carriers of different traditions of paste composition.

The comparison of IPRM in the pottery from two sites (Table 1) demonstrates that clays differing in mineral composition were used for making vessels from Dubrovinsky Borok-3 and Kamenny Mys. Clastic material in the pottery from Dubrovinsky Borok-3 contains mostly feldspars, muscovite, and biotite; cement in the pottery mainly consists of micas with grains of these minerals, but of a smaller fraction. Samples from Kamenny Mys are distinguished by a more famic composition (the IPRM contains more dark-colored minerals) of fragments and cement, as well as the presence of grog and granite fragments, which is not typical for the pottery from Dubrovinsky Borok-3. Two possible explanations can be suggested: 1) the population of Dubrovinsky Borok-3 did not leave behind the Kamenny Mys cemetery, which was the necropolis of another group; 2) when one site functioned, the other already ceased to exist.

X-ray phase analysis has shown that clay composition in the samples from both sites includes mineral phases that appear in granite rocks occurring in the area confined to the Kolyvan-Tom fold system. Their content, which is two or more times larger in the pottery from the burials of Kamenny Mys, indicates a smaller proportion of cement than clastic material in the IPRM, as compared to the samples from Dubrovinsky Borok-3. The X-ray phase analysis has confirmed the types of IPRM identified. They show clear differences in the content of mineral phases (see Fig. 4, 1 , 2 ). The clay in pottery from Kamenny Mys and Dubrovinsky Borok-3 also differs (see Fig. 4, 3 , 4 ).

Thermal analysis. According to technical/ technological and petrographic analysis, most of the pottery samples analyzed had approximately the same concentration of artificially added tempers (grus, grog), which is 1:4–5. Instances when the concentration deviates from the average values are described below. All study samples were taken from the same part of the vessel (the outer part of the rim), which ensured validity of comparative analysis of thermal transformations in pottery obtained from different sites. The quality of pottery firing can be assessed from the ratio of weight loss in a sample at the stages of dehydration and dehydroxylation (Fiziko-khimicheskoye issledovaniye…, 2006: 24– 29; Drebushchak V.A., Mylnikova, Drebushchak T.N., 2018; Molodin et al., 2019), which occur in different temperature ranges of 30–350 °C and 350–600 °C, respectively.

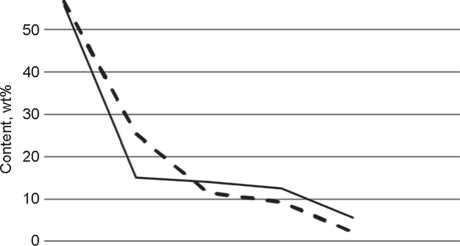

Samples of pottery from Dubrovinsky Borok-4 (DBR) can be divided into two series: 1) DBR1 and DBR11, and 2) DBR2 and DBR6. They differ significantly in the total weight loss upon heating up to 900 °C (Table 2), most of which occur at the dehydration stage (in the range of 30–350 °C). This indicates different degrees of porosity of pottery in these series. In the range of 350–600 °C, mass loss varies between 1.28 and 1.98 %. It can be concluded that samples from series 1 were subjected to more intense exposure to high temperatures or longer firing than those from series 2.

Samples of pottery from the Ordynskoye-9 (OR) settlement can also be conventionally divided into two series, which differ significantly in weight loss upon heating up to 900 °C: 1) OR6, OR7, and OR9; 2) OR2, OR4, and OR5 (Table 3). In the latter series, weight loss was significant during both dehydration and dehydroxylation. The difference in the amount of hydroxyls in ceramics, all other things being equal, results from different quality of firing. Hence, samples from series 1 were subjected to more intense thermal impact than samples from series 2, which may indirectly indicate differences in the firing skills of potters at this settlement.

The minimal weight loss of sample OR7 was most likely caused by a longer time of its firing as compared to other samples, or firing at a higher temperature. Noteworthy is also the presence of grog in the paste in a proportion of 1:3 as opposed to the rest of the vessels, which show a lower concentration of 1:4–5 (according to technical/technological analysis).

Table 1 . Correlation of mineral composition of IPRM in pottery from Kamenny Mys and Dubrovinsky Borok-3

|

IPRM components |

Dubrovinsky Borok-3 |

Kamenny Mys |

|

Clastic material |

KFSp, Pl, Ms, Bt |

KFSp, Pl, Bt and Amp; some Px and fragments of supposedly granite |

|

Cement |

Micaceous; fragments: Pl, KFSp, Ms, Bt |

Micaceous; fragments: Pl, KFSp, grains of Ms, Bt and Px |

|

Accessories |

Apatite |

Apatite, monazite |

Notes : KFSp – potassium feldspar, Pl – plagioclase, Ms – muscovite, Bt – biotite, Amp – amphibole, Px – pyroxenes.

Table 2 . Weight loss in pottery samples from Dubrovinsky Borok-4 in different temperature ranges, %

|

Sample code |

30–350 °С |

350–600 °С |

600–850 °С |

30–850 °С |

|

DBR1 |

2.40 |

1.98 |

1.02 |

5.39 |

|

DBR2 |

6.70 |

1.85 |

0.74 |

9.29 |

|

DBR6 |

7.38 |

1.50 |

0.21 |

9.09 |

|

DBR11 |

3.04 |

1.28 |

0.99 |

5.31 |

Table 3 . Weight loss in pottery samples from Ordynskoye-9 in different temperature ranges, %

|

Sample code |

30–350 °С |

350–600 °С |

600–850 °С |

30–850 °С |

|

OR2 |

4.20 |

2.76 |

1.65 |

8.61 |

|

OR4 |

6.31 |

1.76 |

0.50 |

8.58 |

|

OR5 |

6.39 |

2.47 |

1.05 |

9.9 |

|

OR6 |

3.67 |

1.34 |

0.38 |

5.35 |

|

OR7 |

2.39 |

1.16 |

0.32 |

3.87 |

|

OR9 |

3.26 |

1.32 |

0.18 |

4.76 |

Table 4 . Weight loss in pottery samples from Dubrovinsky Borok-3 in different temperature ranges, %

|

Sample code |

30–350 °С |

350–600 °С |

600–850 °С |

30–850 °С |

|

DB2 |

2.85 |

1.82 |

0.91 |

5.59 |

|

DB3 |

5.82 |

1.95 |

0.74 |

8.52 |

|

DB4 |

5.63 |

2.21 |

1.44 |

9.27 |

|

DB5 |

3.25 |

1.03 |

0.66 |

4.94 |

|

DB6 |

4.34 |

1.70 |

0.88 |

6.92 |

|

DB8 |

1.34 |

2.48 |

1.70 |

5.52 |

|

DB10 |

5.36 |

1.56 |

0.81 |

7.73 |

|

DB11 |

2.4 |

0.70 |

0.43 |

3.53 |

|

DB13 |

5.39 |

1.58 |

0.66 |

7.64 |

|

DB19 |

4.70 |

2.18 |

1.02 |

7.90 |

Table 5 . Weight loss in pottery samples from Kamenny Mys in different temperature ranges, %

|

Sample code |

30–350 °С |

350–600 °С |

600–850 °С |

30–850 °С |

|

1 |

2 |

3 |

4 |

5 |

|

IPRM 1 |

||||

|

KM6 |

4.95 |

1.70 |

0.54 |

7.18 |

|

KM7 |

4.5 |

3.41 |

0.96 |

8.86 |

|

KM8 |

3.28 |

1.56 |

0.68 |

5.52 |

|

KM10 |

2.89 |

1.56 |

0.69 |

5.15 |

|

KM12 |

6.33 |

2.47 |

0.78 |

9.58 |

|

KM4 |

3.35 |

2.06 |

0.98 |

6.39 |

|

KM29 |

5.23 |

3.19 |

1.01 |

9.44 |

|

KM33 |

4.12 |

1.73 |

0.73 |

6.58 |

|

KM34 |

5.1 |

3.06 |

1.51 |

9.67 |

|

KM35 |

3.83 |

1.41 |

0.67 |

5.91 |

|

KM38 |

6.07 |

2.30 |

0.85 |

9.22 |

|

IPRM 2 |

||||

|

KM1 |

1.69 |

1.01 |

0.76 |

3.46 |

|

KM2 |

3.57 |

2.08 |

0.69 |

6.34 |

|

KM4 |

4.81 |

2.26 |

0.87 |

7.94 |

|

KM9 |

4.10 |

1.42 |

0.48 |

6.10 |

|

KM18 |

5.35 |

1.57 |

0.82 |

7.74 |

|

KM19 |

4.87 |

1.71 |

0.89 |

7.47 |

|

KM23 |

5.47 |

2.00 |

0.72 |

8.19 |

Table 5 (end)

|

1 |

2 |

3 |

4 |

5 |

|

KM29 |

5.23 |

3.19 |

1.01 |

9.44 |

|

KM36 |

2.42 |

1.11 |

0.22 |

3.75 |

|

KM37 |

5.23 |

4.28 |

0.85 |

10.35 |

|

IPRM 3 |

||||

|

KM13 |

2.44 |

1.33 |

0.64 |

4.41 |

|

KM17 |

4.71 |

1.47 |

0.32 |

6.50 |

|

KM20 |

4.32 |

2.84 |

1.63 |

8.79 |

|

KM25 |

5.03 |

1.95 |

1.00 |

7.98 |

|

KM26 |

1.15 |

0.59 |

0.31 |

2.05 |

|

KM27 |

3.78 |

1.22 |

0.93 |

5.94 |

|

KM28 |

3.45 |

1.78 |

1.09 |

6.33 |

|

KM30 |

3.87 |

1.72 |

1.02 |

6.61 |

|

KM47 |

3.96 |

2.22 |

1.06 |

7.24 |

Sample OR2 differs from all the other samples in its relatively large loss of mass in the high-temperature range (600–850 °C). This could have resulted from release of carbon-containing compounds, which could have formed during firing of a product made of a paste with organic additives. Technical/technological analysis has shown that out of the entire collection from the settlement only that vessel was made with the addition of an organic solution.

Samples of pottery from Dubrovinsky Borok-3 (DB) were also conventionally divided into two series: 1) DB3, DB4, DB6, DB10, DB13, and DB19; 2) DB2, DB5, DB8, and DB11. They have revealed significant differences in weight loss upon heating up to 900 °C both at the dehydration and dehydroxylation stages (Table 4). In series 2, this indicator is lower, which suggests that these samples were subjected to a more intense thermal impact than those from series 1. This circumstance may indirectly point to the differences in potters’ firing skills.

Significant weight loss in samples DB8, DB4, and DB19 at the high-temperature stage (600–850 °C) can be explained by the release of carbon-containing compounds: according to technical/technological analysis, these three vessels differ from the rest of the pottery in that they have paste with organic additives.

Samples of pottery from Kamenny Mys (KM) were divided into three series depending on the type of IPRM. Most samples are distinguished by significant weight loss, especially at the dehydration stage, and some at the dehydroxylation stage (Table 5). Release of a large amount of water indicates a fairly high porosity of pottery and weak thermal impact. The exceptions are samples KM1, KM26, and KM36 with relatively small total weight

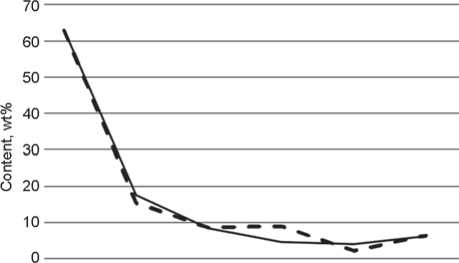

Fig. 5 . Diagram of weight loss by pottery samples in the temperature ranges of 20–350 °C (m 1 ) and 350–600 °C (m 2 ).

a – Dubrovinsky Borok-4; b – Ordynskoye-9; c – Dubrovinsky Borok-3; d – Kamenny Mys.

loss (2.05–3.75 %). It can be assumed that they were subjected to more intense firing.

Four samples (KM20, KM34, KM30, KM47) demonstrate a fairly large mass loss (1.02–1.63 %) in the high temperature range (600–860 °C), associated with release of carbon-containing compounds, since these items were made of pastes containing organic additives.

Differences between pottery samples from all the sites can be more clearly observed in the diagram showing the preservation of the clay component (Fig. 5). The ratio of mass loss during dehydration and decomposition of hydroxyls (m1/m2) for clay of a specific composition is known to be constant. If temper (sand, grus, or grog) is added to the paste, both m1 and m2 decrease, but the ratio remains the same. Since, with rare exceptions, the pottery under study was made of pastes with approximately the same concentration of artificially added tempers, we can compare specific features of thermal transformations of pottery from different sites. The points characterizing the samples from Kamenny Mys are distributed relatively evenly on the diagram and are located far from the sintering line, which indicates a relatively weak thermal impact. Vessels from Dubrovinsky Borok-3 were apparently fired at a lower temperature or for a shorter period of time as compared to those from Kamenny Mys. As far as the samples from Ordynskoye-9 are concerned, the figure clearly shows the existence of two series differing in intensity of firing.

Conclusions

A comprehensive multidisciplinary analysis of the pottery has revealed that the vessels from Kamenny Mys and Dubrovinsky Borok-3 were made of clays procured from the same granitoid massif. Different types of initial plastic raw materials (IPRM), including three for the pottery from Kamenny Mys and two from Dubrovinsky Borok-3, have been distinguished according to their mineral composition, which implies several groups of potters who used different clay pits. The difference was also evident in the skills of paste making. Comparison of IPRM in the pottery from Kamenny Mys and Dubrovinsky Borok-3 has revealed significant differences in the mineral composition. This may indicate that the population of Dubrovinsky Borok-3 did not leave the Kamenny Mys burial ground (it belonged to another population group), or that these sites were populated in different periods. The latter assumption is consistent with the hypothesis of Troitskaya that the sites belonged to different chronological periods of the Novosibirsk variant of the Kulaika culture (1979: 48–50). Thermal analysis of pottery samples from all the sites has shown that some of the vessels had a more intense firing than others, which may indirectly manifest the differences in the skills of potters at different settlements.

Continuing integrated multidisciplinary studies of the Kulaika pottery will expand our knowledge of the Early Iron Age in Western Siberia and will make it possible to reconstruct intercultural contacts, as well as historical and cultural processes in ancient times.

Acknowledgments

This study was supported by the Russian Science Foundation, Project No. 21-78-00039.