Predication and Optimization of Maintenance Resources for Weapon System

Автор: Yabin Wang

Журнал: International Journal of Intelligent Systems and Applications(IJISA) @ijisa

Статья в выпуске: 5 vol.3, 2011 года.

Бесплатный доступ

Maintenance resources are important part of the maintenance support system. The whole efficiency of weapon system is directly affected by the allocation of maintenance resources. Joint support for weapon system of multi-kinds of equipments is the main fashion of maintenance support in the future. However, there is a lack of the efficiency tools and methods for predication and optimization of weapon system maintenance resources presently. For the prediction requirement of maintenance resources of weapon system, the primary infection factors for the requirement of maintenance resources were analyzed. According to the different characteristics of maintenance resources and the analysis for the traditional classification methods, a kind of classification for weapon system’s maintenance resources was given. A prediction flow for the maintenance resources requirement was designed. Four kinds of models for predicting the maintenance resources requirement in a weapon system were designed and described in detail. In this paper, approaches of the optimal selection from the simulation schemes and reverse simulation for the resources allocation optimization were analyzed; some optimization models for maintenance resources such as spare parts and personnel were constructed. Further more, an optimization and decision-making system was not only designed but also developed. At last, an example was presented, which proved the prediction and optimization methods were applicability and feasibility, the decision-making system for the optimization of maintenance resources was a supportable and efficient tool.

Prediction, maintenance resources, modeling, optimization, decision-Making, simulation, weapon system

Короткий адрес: https://sciup.org/15010218

IDR: 15010218

Текст научной статьи Predication and Optimization of Maintenance Resources for Weapon System

Maintenance resources are main assurance of equipment readiness and continuous battle effectiveness. United campaign is the main model under high technology conditions in the future. With the prominent characteristic, such as high technology, high speed and high consumption [1], the traditional support model is not adapted to the battle requirement in the future. Hence, Joint support for weapon system of multi-kinds of equipments is the main fashion of maintenance support in times to come. However, the forecasting and optimization of maintenance resources demands for weapon system has becoming more and more difficult, along with the improvement of technology and complexity of new type equipment, and with the augmentation of training time and intensity. Therefore, it has realistic significance to achieve the accurate forecasting and the optimum allocation of maintenance resources through introducing science technology, in order to improve the battle effectiveness and decrease the maintenance support cost.

Some researchers have worked in the field of predicting and optimizing maintenance resources. Reference [2] has studied the optimization models for spare parts and a math model for maintenance and a service model was presented after analyzing the impact factors for spare parts allocation. Reference [3] has studied the optimization for two level spare parts, and given some models for inventory decision. Reference [4] has studied personnel need for equipment maintenance based on queue theory. Reference [5] has studied the allocation models for Manpower on wartime. Although there are many articles written about the prediction of maintenance resources requirements, most of them took a single kind of equipment as the object or aimed at a group of equipment of the same kind [6, 7, 8, and 9] . In other words, few people took weapon system as an object to study the requirement of maintenance resource for weapon system is made up of many types of equipments which have different configurations, with different tasks and different maintenance resources consumption. The prediction for its resource requirements is quite complicated.

How to synthetically predict all the main resources and build an optimization and decision-making system has seldom mentioned or studied. Hence, it is necessary to design and realize a universal optimization and decision-making system of maintenance resources for weapon system.

-

II. Requirement analysis

-

A. Main influence factors for resources requirement

Equipment maintenance resources is a general designation of manpower, material, outlay, information and time, which are indispensable to equipment maintenance and will be consumed or employed in the maintenance support process [10] . The main influence factors include the implement time for mission, the replaceable unit’s fault rate, the preventive maintenance interval period, the circumstance infection factors, the personnel diathesis of equipment operation and maintenance.

1)The implement time for mission. This factor means the practice runtime for the weapon system under a certain task, which could be the calendar time, shooting numbers and so on. Generally, the implement time is presented by the commander from the campaign presupposition or training task. In order to calculate conveniently, its needs to converse the different unit time to the same unit time before modeling.

-

2 ) The fault rate of replaceable unit. The fault rate of replaceable unit is the design characteristic of equipment itself. This characteristic has a direct influence to the maintenance resources consuming [11] . Currently, the life-span of electron products obeys exponent distribution, while enginery or machine electricity products obey weibull distribution. Hence, the fault rate of each replaceable unit can be calculated by the fault distribution.

-

3 ) The preventive maintenance interval period. This factor directly determine the maintenance cycle of equipment preventive maintenance, which could be gained from the RCM general outline or the distribution table of maintenance task.

-

4 ) The circumstance infection factors. The consuming of maintenance resources will be different for the different circumstance. Temperature, humidity, sand blown by wind, and libration have a biggish infection to electron product, next is the non-electron product, while the circumstance have a least impact to metal product [12] .

-

5 ) Repair influence factors. After repair, the fault unit can be the maintenance spares to be used. This factor is mainly considering the influence of maintenance resources consuming by the repairable ratio after the unit fault.

-

6 ) The diathesis of equipment operation and maintenance personnel. The personnel diathesis has a great influence to the resources consuming. If the equipment operation and maintenance personnel have a high diathesis, the equipment would be having a good care and the accident probability will be small. Otherwise, if the equipment operation or maintenance personnel have a low diathesis, the equipment would be having a worse care and the accident probability will be big.

-

B. Maintenance resources classification

According to the characteristic of unit support, maintenance resources can be classed as currency resources and special resources. Currency resources are those resources which can support many kinds of equipment, such as tyre, oil plants, and standard parts of an apparatus. Special resources are those resources which can only used to a certain kind of equipment, such as xx kind of special charger. Otherwise, according to the resources being consumed or being engaged, the resources can be classified as consumed resources and engaged resources. Engaged resources means maintenance resources are engaged in the maintenance support process all along. When the corresponding activity closed, the support resources will in idle state, such as support facility, tools, establishment, manpower, and technology datum. Consumed resources means the maintenance resources are dissipative gradually along with the time in maintenance support process. Commonly, the resources such as oil, clean material belong to consumed material. For the repairable parts, although they are rehabilitated to be use time after time, the repair number is restricted. Hence, we can regard them as consumed resources.

Synthesized the two kinds of classification methods above, and combined with the support requirement of weapon system, we plot maintenance resources as the follow four parts. They are consumed special resources, consumed current resources, engaged special resources, and engaged current resources, which can be shown as Fig. 1.

Consumed resources

Special resources

I

Such as special charger, special controller

П

Such as engine, pedrail, tyre

HI

Such as technology datum, special wrench

IV

Such as current maintenance equipment, batholith repairman

Current

resources

Engaged resources

-

Figure 1. Maintenance resources classification of weapon system

Thereinto, the I and II resources are all consumed maintenance resources, which need deployed periodically. These resources are difficult to predict for its strong random city. The Ш and W resources are all engaged maintenance resources, which are commonly equipped while the support system being built. These resources needed not to be deployed periodical for the requirement of them are relatively fixed up.

-

C. The prediction process for resources requirement

| Training task

Prediction models

Confirm the type and quantity of weapon system equipment n

Make the main replaceable unit sure

Л

Predication for the unit fault or maintenance requirement n

Prediction mode of resources requirement

Mai ntenance

Equipment

organizing

Equipment

Equipment fault conliguralion

Equipment reliability pa rameters

Maintenance

process info.

The number of maintenance resources requirement

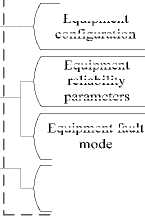

Figure 2. Prediction process for maintenance resources requirement

The scientific predication of maintenance resources requirement is the precondition of maintenance resources deployment. According to the training tasks in peacetime, we can confirm the type and number of the training weapon system. Moreover, basis on the configuration information of each equipment, we could make the main replaceable units certain, which are concerned with the training task. The following step is to predict the fault and maintenance requirements for the key parts. This prediction is very difficult and important and we should use the reliability parameters and equipment fault mode. At last, according to the maintenance process information and the prediction models, the requirement number of each resource could be predicted. The concrete process is shown as Fig. 2.

-

III. Prediction models

-

A. Hypothesis and symbol explain

In this study, we hypothesis that all kinds of equipments have the same equipping time, and the repair style are all replace unit repair. What’s more, we suppose that all kinds of resources are abundance, and there is no conflict problem about resources.

In this paper, the symbols signification can be explained as follows :

L i means the quantity of equipment i .

f Cij means the reparability maintenance frequency of replaceable unit j in equipment i .

f pij means the prevent maintenance frequency of replaceable unit j in equipment i .

f ij (t) means fault density function of replaceable unit j in equipment i .

T means the task time of the weapon system.

m represents the item number of the training task.

αi is the proportion between the training times of task k for equipment i and the total training time.

X kij represents the consumed quantity of spare parts, while equipment i unit j being repaired under the training task k.

P kij is the probability of spare parts being consumed when equipment i unit j being repaired under the training task . If this probability is 1, that means this repair must be replaceable repair. If this probability is less than 1, that means it must be original unit repair.

Hi j is the circumstance influence genes. In generally, the equipment operation circumstance can be classified as good, middle and bad three kinds. The circumstance influence genes are 1, 1.05, and 1.15 correspondingly.

W ij is the diathesis of equipment operation and maintenance personnel. According to the personnel status in our army, the diathesis can be divided into excellence, all right, pass and fail, which with the influence genes are 1, 1.05, 1.15, 1.25 correspondingly.

-

B. Prediction for the I resource

In a period of time, the average requirement S ij for the equipment i unit j can be denoted as follows :

[ 1, 0 < N ;; < 1

ij

1 j | N ij + 1, N ij > 1 (1)

m f (t)

N j = int[ L i X a ik T ( /i ’ + f pi j ) X k ij P kij H k ij W kij ] (2) k = 1 J t f j j (t)d t

-

1 ) if the life-span of replaceable unit obey exponent f ,(t )

distribution, then —^ i H---- = и t ) = a ,

Ю

J t fi j(t ) d t

Therefore, N ij can be denoted as follows: m

N у = int[ L i X a ik T ( A j + f pj j- ) X k ij P kij H k W ] (3)

k = 1

2 ) if the life-span of replaceable unit obey weibull distribution, then

x m( t ) m -1 exp[ - ( t ) m ]

f i j(t ) = n n n = m (£) m -1 ,

J T £(С d t exp[ - J t m ( u ) m -1 du ] n n

0 n n

( t > 0, n ^ 0, m > 0 )

Therefore, N ij can be denoted as follows:

m m

I N ij = int[ L i X « ik T (- j (— ) m j 1 + f p j ) X kj P kij H kj W ky ] k = 1 n ij n ij

(t > 0, n ij > 0, m j > 0)

Commonly, the frequency of preventive maintenance support active is directly confirmed by the preventive maintenance general outline or maintenance task distribution table.

We should pay attention to the frequency unit in the calculate process. That is the frequency of preventive maintenance support active and the fault ratio of the replaceable unit must be unified with the task time T .

C. Prediction for the II resource

The II resource means consumed and current maintenance resources, we assume that there are n kinds of equipments need consume resources j , then the total requirement quantity of this resource can be denoted as S j .

5 -j =1

n

1, 0 < X N ij < 1

i = 1

nn

X N ij + 1, X N ij > 1

. i = 1 i = 1

Engaged maintenances means there are engaged by fault equipment and not consumed in the support maintenance process, such as maintenance establishment, facility, and personnel. The requirement quantity is related to the frequency of maintenance task, maintenance type, maintenance process information, and its working time in a unit time. Take maintenance personnel as an example, each person can work 8 hours in one day. If we have calculated that the total workload for one kind of

maintenance personnel is 20 hours, this personnel requirement number is 2.5.

In the requirement prediction for this type resource, we suppose the equipment i participate in training task k, and unit j was supported. Therefore, maintenance resource q was engaged. The engaged time is T ikjq , while the engaged quantity is Rik j q . The working time for this resource is in one day. Then in this maintenance support process, the average requirement quantity for this resource is Siq

S

i q

1,

.N iq + 1 ,

0 < N iq < 1

N iq > 1

N iq = mt

R s m f ( t )

J = 1k = 1 J t f i j ( t ) dt

T

q

-

D. Prediction for the W resource

These resources was engaged many times in the maintenance support process, such as underpan repairman can repair not only armored equipment, but also ordnance equipment. We suppose that the equipment quantity is n and the unit j was supported. Then, the average requirement quantity for resource q can be expressed as S q .

f 1, 0 < N < 1

q q "tNq +1, Nq > 1 (8)

N q = int

n R i m f ( t )

ZZZ Li«ik T(---+ fpj) J-PHikjWkj yNH J'fij(t)dt

T q

-

IV. methods for Decision-making of Maintenance Resources

-

A. Contents of maintenance resources optimization

Personnel are the main body of using and servicing equipment [13] . The number and the technology level of maintenance personnel is directly affect the maintenance efficiency and availability of the equipments. It is vital to make the best use of all kinds of manpower and enhance the optimization for personnel outfit.

-

2) Optimization for spare parts

Spare parts management is an important part of maintenance activity. Only have we deposit and provide spare parts scientifically, the maintenance task can be economical and efficient. As many people know, Operation research has made a sufficient effect in the optimization of spare parts [14] . However, dynamic programming and Lagrange methods are difficult to solve great models and complex problems, for the many leash conditions and random factors. At the same time, the optimization for spare parts should consider the limitation of funds, The number and the technology level of maintenance personnel is directly affect the maintenance efficiency and availability of the equipments. It is vital to make the best use of all kinds of manpower and enhance the optimization for personnel outfit.

-

B. Principles for decision-making

-

1) Least cost principle

On condition of achieving certain availability, we should choose a maintenance allocation concept which cost is the least.

minC S t s.t.

n

= Z i=1

C„ a, + C„----------- pi ' “' Su - SL + aTLi

+ C bi- ( S U

+ S L - « i T LV C di T L

m

+ Z CjTj j "1

As = =--- bm —= > A„

S T bm + M + D °

C S —Total maintenance cost for the equipment

C P —Price of spare parts

Ca —Cost for once order

Cb —Cost for spares stock in every hour

C j —Maintenance personnel cost for every man-hour

S U —The upper limit for spares stock

S L —The lower limit for spares stock T L —Delay time for ordering

A S — The system’s availability

T bm —Mean time between maintenances

M —Mean time for maintenances

D —Mean delay time

-

2) Biggest availability principle

On condition of certain maintenance cost, we should make the availability biggest.

Tj—Man-hour for personnel j max

s.t.

A = --- bm _

S T bm + M + D

n

Cs "Z Cd a + Cm s pi i ai i=1

a

S U i - S Li + “ i T Li

+ 2 b ( SUi + SLi -

m

« J l? ) + C di Tu + Z C j T j < C о

j = i

-

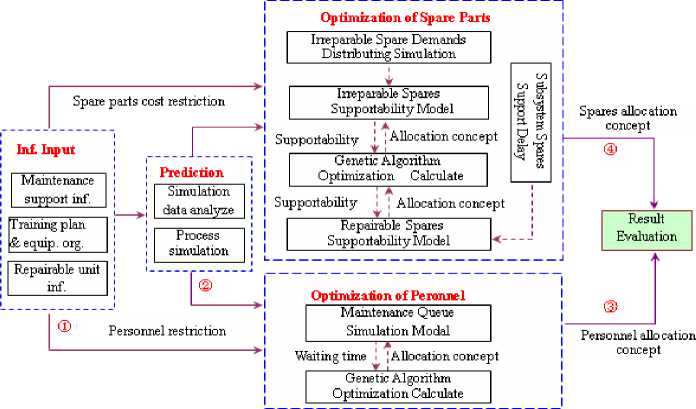

C. Process of decision-making

According to maintenance methods for the failure parts, we disport them into three kinds (irreparable parts, repairable parts and need changing subsystem parts). For each kind, we have built the optimization models for personnel and spare parts. Then we can make an optimization decision process as follows.

Firstly, we must input maintenance support information, training plan, equipment organization and all units’ information

Secondly, we must make a cost restriction for spare parts or personnel clearly, and then run the simulation system, which can give us a lots of useful information about the resource requirement.

Thirdly, according to the restriction conditions, we can use Genetic Algorithm optimization methods to bring out an optimum concept about spares and personnel.

Lastly, we can escalate the result and choose a proper maintenance allocation concept. We can see the whole process as Fig. 3.

Figure 3. Process of decision-making

-

V. designs and realization of the software system

-

A. The Main Frame of the System

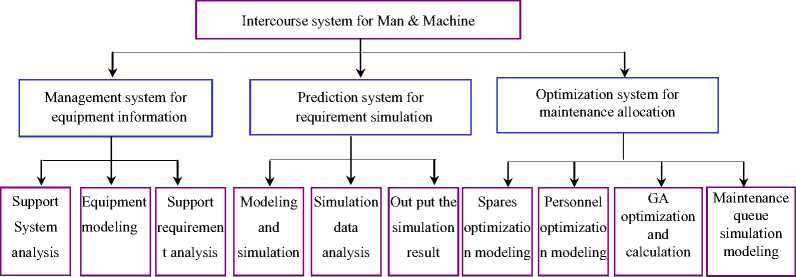

The Optimization and Decision-making system of Maintenance Resources is composed of equipment information management system, prediction of maintenance resources requirement by simulation system and optimization allocation for resources system. The main frame of the system is shown as Fig. 4.

User

Figure 4. Main frame of the optimization and decision-making system

-

B. Functional Design of Modules

-

1) Management system for equipment information. This system mainly complete support system analysis, equipment system modeling and requirement analysis for equipment support. What is more, all the relation information and models will be saved into database and model bases, which can provide useful information for the prediction and optimization of resources.

-

2) Prediction system for requirement simulation. In this system, one function is modeling for the process of maintenance support, and records all kinds of useful data; an other function is to provide restriction information for spares and personnel optimization by the analysis of simulation data. The last function is that the system can

output the requirement information through graphs and tables and bring out availability information which are very useful for the decision-maker to make a correctly and efficiency allocation.

-

3) Optimization system for resources allocation. The main function in this system is to optimization spares and personnel according to spare optimization modeling and personnel optimization modeling. The optimization integrates with Genetic Algorithm and maintenance queue simulation models.

-

C. Database Design

According to the system’s requirement analysis and the main Frame above, this paper have established the system’s database framework, analyzed the relationship by using the latest database, designed the data table and defined the data types in each table, the material databases and data table are narrated as follows.

-

1) Item Manage Database

-

○ 1 Item Integer Information Table. This table is mainly manage integer information of the simulation system, which includes establish units, establish date, establish person, name of the simulated units, equipment’s type and name.

-

○2 Item Manage Information Table. This table includes the maintenance levels, the numbers of units which subordinate to the simulated unit, the subordinate equipment’s outfit numbers and training proportion of the equipment.

-

○3 User Information Table. This table includes user’s name, password and type.

2)Equipment information database

-

○1 Equipment Structure Tree Information Table. This table mainly records the structure relationship between each subsystem and each repairable unit.

-

○2 Repairable Unit’s Information Table. This table mainly records all mutuality information of repairable units, which involve unit name, failure distribute type, maintenance level, maintenance strategy, maintenance interval time, maintenance time, maintenance personnel type and quantity.

-

○3 Distribute Parameter Table. This table records the distribute type and parameters of all unit’s life time and maintenance time.

-

○4 Maintenance Personnel Information Table. The ID mark and number of the demanded maintenance personnel are recorded in this table.

-

○5 Spare Parts and Cost Information Table. This table records spare parts’ name and price which are needed in maintenance.

-

○6 Preventive Maintenance Information Table. This table records all the information related to preventive maintenance.

-

○7 Training Plan Information Table. This table records the information related to the training, such as training time and training topic etc.

3)Simulate and Optimization Operation Dynamic Database

-

○1 Time Information Record Table. This table records all repairable units’ random fault time, random maintenance time and random delay time. What’s more, it records the accumulated maintenance time for different type maintenance personnel in each maintenance level.

-

○2 Quantity Information Table. This table records each unit’s accumulated fault times, all spare part’s type and remaining number in real time for every depot.

-

○3 Optimizations Restriction Information Table. This table records the restriction conditions for different users.

4)Simulate Results Database

-

○1 OR Information Table. This table mainly records the equipment’s OR information and system’s availability information.

-

○2 Spare Parts Consume Information Table. This table mainly records all’s consuming and stocking state in each stock level.

-

○3 Maintenance Personnel Demand Information Table. This table records the maintenance man-hour of all personnel type in each maintenance level.

-

○4 Maintenance Cost Information Table. The maintenance costs demanded in each maintenance level are recorded in this table.

-

○5 Maintenance Time and Delay Time Information Table. This table records the maintenance and delay time in each maintenance level.

-

○6 Fault Times Information Table. This table records the fault times for each unit in every year.

5)Optimization Results Database

-

○1 spare parts Information Table. This table mainly records the number of every kind of spares in each maintenance level.

-

○2 Maintenance Personnel allocation Information Table. This table records the number of every personnel type in each maintenance level.

-

○3 Maintenance Cost Information Table. According to each optimization concept, the maintenance costs demanded in each maintenance level are recorded in this table.

-

○4 System availability Information Table. According to each optimization concept, the system availability will be recorded in this table.

-

VI. CASE study

For one weapon system has been joined in a training task, while two type equipments took a join operation. The equipment name are called A and B respectively. The equipment quantities are 18 and 24 for A and B. The training task was divided into two topics, which are underpan training and jacket training. In underpan training, the training time for equipment A is 50h while for equipment B is 60h. In jacket training, the training time for equipment A is 15h while for equipment B is 20h. The main replaceable unit is a, b of jacket part in equipment A, while c, d, and e in underpan part. While the main replaceable unit is a, f and g in jacket part, d, e, h in underpan part of equipment B. The work time for maintenance personnel is 8 h every day. The circumstance influence genes are 1. The diathesis of equipment operation and maintenance personnel are 1 too. The replaceable units of the two kinds of equipment are all obey exponent distribution. The other parameters are shown as table 1 in detail.

We take spare parts optimization as example, supposing there are 8 kinds of key repairable units selectively and assume the maintenance cost is 280000 Yuan each year, unit’s information are shown as table 2.

T able 1.

T he main parameters of each replaceable unit

|

Serial number |

Unit name |

^ i (1/h) |

f pm (1/h) |

Repair time(h) |

X kij |

Pl kij |

Person A |

Person B |

Person C |

Facility 1 (h) |

Facility2 (h) |

|

1 |

A |

0.003 |

0.2 |

1 |

0.60 |

2 |

0.05 |

0.1 |

|||

|

2 |

B |

0.002 |

0.004 |

0.5 |

1 |

0.85 |

3 |

0.2 |

0.1 |

||

|

3 |

C |

0.004 |

0.006 |

0.5 |

1 |

0.92 |

1 |

3 |

0.3 |

0.1 |

|

|

4 |

D |

0.001 |

0.003 |

0.6 |

1 |

0.65 |

2 |

3 |

0.2 |

0.3 |

|

|

5 |

E |

0.005 |

0.002 |

0.4 |

1 |

0.60 |

1 |

2 |

0.1 |

0.2 |

|

|

6 |

F |

0.002 |

0.005 |

0.5 |

1 |

0.75 |

2 |

0.3 |

0.1 |

||

|

7 |

G |

0.003 |

0.002 |

0.3 |

1 |

0.95 |

3 |

0.1 |

0.1 |

||

|

8 |

H |

0.005 |

0.001 |

0.5 |

1 |

0.85 |

3 |

1 |

0.2 |

0.2 |

T able 2

P arts of I nformation of equipment training and unit

|

Serial number |

Unit Name |

Failure Distributing Kinds |

Distributing Parameter 1 |

Distributing Parameter 2 |

Number In Each Equipment |

Training Plan |

Unit’s Price (Yuan) |

|

|

Aiming (300h) |

driving (300h) |

|||||||

|

1 |

A |

weibull |

η=600 |

β=1.1 |

1 |

√ |

√ |

300 |

|

2 |

B |

weibull |

η=1000 |

β=1.2 |

1 |

√ |

√ |

500 |

|

3 |

C |

weibull |

η=1500 |

β=1.08 |

1 |

√ |

√ |

600 |

|

4 |

D |

weibull |

η=800 |

β=1.1 |

1 |

√ |

√ |

400 |

|

5 |

E |

weibull |

η=1400 |

β=2.3 |

1 |

√ |

√ |

1000 |

|

6 |

F |

weibull |

η=1200 |

β=2 |

1 |

√ |

- |

800 |

|

7 |

G |

weibull |

η=1800 |

β=2.5 |

1 |

- |

√ |

1550 |

|

8 |

H |

weibull |

η=1000 |

β=2 |

1 |

√ |

√ |

850 |

-

A. Analysis

According to the maintenance resources classification mentioned above, spare parts a, d, e and maintenance personnel A, B and facility 1 are all current resources. Spare parts b, c, f, g, h, maintenance personnel C and facility 2 are all special resources. Therefore, spare parts b, c, f, and g, h belong to the I kind maintenance resources. Spare parts a, d, e belong to the II kind maintenance resources. A maintenance personnel C belongs to the Ш kind maintenance resources. Maintenance personnel A, B, facility 1 and facility 2 belong to the W kind maintenance resources.

-

B. Calculation

-

1 ) The requirement prediction for the I kind maintenance resources

Followed by (1), (2) and (3), the requirement quantity of spare part b is: 18 X 15 X ( 0.04+0.02 ) X 1 X 0.85=1.377

The result is 2 after integer calculation. In the same method, we can calculate that the quantity of spare c, f, g and h are 2, 3, 6, and 31.

-

2 ) The requirement prediction for the II kind maintenance resources

Followed by (5), the requirement quantity of spare part a is : [18 X 15 X 0.003 X 1 X 0.60+24 X 20 X 0.003 X 1 X 0.60]=14.

In the same method, we can calculate that the quantity of spare d, e and h are7 and 10.

-

3 ) The requirement prediction for the Ш kind maintenance resources

Followed by (6) and (7), the requirement quantity of Personnel C is: [{18 X 50 X( 0.004+0.006 )X 3 X 0.5 X 0.92+18 X 50 X (0.001+0.003) X 3 X 0.6 X 0.65+18 X 50 X (0.005+0.002) X 2 X 0.4 X 0.6}/8]=2

-

4 ) The requirement prediction for the W kind maintenance resources

Followed by (8) and (9), the requirement quantity of Personnel A is: [{18×50×(0.004+0.006) ×1× 0.5× 0.92+ 18×50×(0.001+0.003) ×2×0.6×0.65+18×50×1×0.4×0.6× (0.005+0.002)×1+24×60×(0.005+0.001) ×3×0.5×0.95}/8] =2

In the same method, the requirement quantity of Personnel B is 3; the requirement quantity of facility 1 and 2 are both 1.

-

C. Optimization

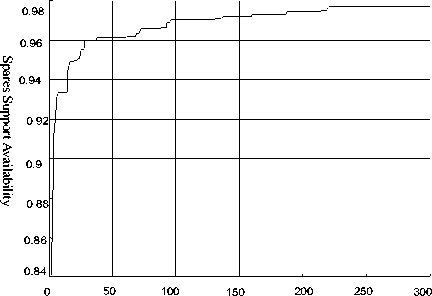

We simulate all the equipments for 10 year’s using. The simulation last 688 seconds for 10 times, and we can get the relationship between Spares support availability and the most optimal individual for each group. The supportability curve in spares optimization is magnified as Fig. 5.

Number of Heredity Era

Figure5. Supportability curve in spares optimization

Fig.5 indicates that when the inherit era reach above 220, the Spares support availability will reach to a

stabilization level. Hence, we can sure that we have fond an optimum allocation concept, and parts of the optimum result are displayed as table 3. The maintenance cost in this concept is 279810 Yuan and the total Spares support availability is 0.9976, which are satisfied with the beginning restriction condition.

From the result, we can see clearly that some valuable and less needed spare parts should to be increase the deposit number in intermediate repertory, and reduce it in basic repertory. On the contrary, for those less cost and more needed spare parts, we should increase the deposit number in the basic repertory, and reduce the deposit number in intermediate repertory.

More importantly, the optimization result is accord with the fact, which is an embodiment of the availability of the models and optimization methods in this paper.

T able 3

P arts of optimum R esult

|

Serial number |

Unit Name |

Require Number in Basic Repertory |

Optimum Result in Basic Repertory |

Optimum Result in Intermediate Repertory |

Apply Number from Repertory |

Support Availability for Single Parts |

|

1 |

a |

19.1 |

24 |

4 |

0.1109 |

0.9993 |

|

2 |

b |

11.8 |

15 |

8 |

0.0107 |

0.9995 |

|

3 |

c |

8.2 |

9 |

8 |

0.0146 |

0.9989 |

|

4 |

d |

14.5 |

17 |

14 |

0.0022 |

0.9985 |

|

5 |

e |

1.2 |

1 |

2 |

0 |

0.9997 |

|

6 |

f |

1.02 |

1 |

0 |

0 |

0.9999 |

|

7 |

g |

1.02 |

0 |

2 |

0.0035 |

0.9996 |

|

8 |

h |

6.8 |

8 |

4 |

0.0654 |

0.9991 |

-

VII. Conclusions

According to the requirement analysis of weapon system maintenance resources, a detailed classification method was presented from resources being consumed/engaged and current/special angle. A prediction flow of maintenance resources requirement was abstracted by the practice support process. The prediction models for four kinds of maintenance resource requirement were designed and presented. It is an emphasis of our study and the models calculation are all numerical value calculation. Lastly, a case study was given, which have proved the practicability of the predication method. Our study can provide an effective theoretic sustentation for maintenance support decision-maker. In the aftertime study, we should lucubrate on different equipping time and resources confliction issues.

Scientifically predict the maintenance resources and optimize the allocation in each level is the precondition to bring the “precision support” into effect. After researched on the methods for decision-making of maintenance resources, this study established the process of decision-making, designed and developed a corresponding simulation software system, and applied a case to the software at last, which validate that the simulation system can relative exactly simulate the maintenance resources’ demand and can provide a optimum result for resources. It is a crucial and realistic significance not only for making a scientific maintenance support decision, but also for optimizing the deployment of maintenance resources.

ACKNOWLEDGEMENT

This paper was sponsored by Mechanical Engineering College funds item (YJJXM09037) 。

Список литературы Predication and Optimization of Maintenance Resources for Weapon System

- AI Baoli, WU Chang, “Modeling and Simulation of Communication Equipments Spare Parts Support System Based on Arena”[J].Journal of Air Force Engineering University, 2010, 11(5):81-85.

- ZHAO Gang, “Research on optimization allocation model for spare parts”, Telecommunications Technology. 2005, 6(10), 31-34.

- YI Fa, “Research on the optimization of two level spare parts”, Military Operations Research and Systems Engineering. 2002,16(4), 2-7.

- YANG Guanghui, “A model of personnel need for equipment maintenance based on queue theory”, Command control and simulation. 2007,12(2).

- ZHANG Fangyu, “Research on allocation models for manpower on wartime”, Military Operations Research and Systems Engineering. 2005,19(2), 23-26.

- WANG Ya-bin, “Research on Simulation of Maintenance Resource Requirements of Typical General Purpose Equipment”, Shijiazhuang: Ordnance Engineering College, 2005.

- FAN Hao, “Study of Requirement Simulation and Allocation Optimization of Maintenance Resources for Representative Currency Weapons”, Shijiazhuang: Ordnance Engineering College, 2007.

- ZHAN Tao, GUO Bo, TAN Yuejin, “Research on a Mission Oriented Maintenance Resources Deployment Decision Support System” , ACTA ARMAMENTAR, 2005, (5):716-720

- ZHOU Xuelin, “Optimization Configuration of Maintenance resources Distribution for Maintenance Management” , National university of defense technology, 2005

- GUO Ji-zhou, ZHAO Chao-xian1, GUO Bo, “Spare Optimization Modeling of Phased-Mission System for Air-Defense Combat Unit”, Mathematics in Practice and Theory, 2009,(12):64-69

- Derek T. Dwyer, “Heuristic Algorithm for U.S. Naval Mission Resource Allocation”, ADA488672, 2008.09

- Scott Wells, “Coordinated Resource Allocation among Multiple Agents with Application to Autonomous Refueling and Servicing of Satellite Constellations”. ADA479643, March 2008

- GAN Maozhi, KANG Jianshe, GAO Qi, “Maintenance Engineering Science for Military Equipment Use”, Beijing: national defense industry publishing company. 2005

- Ruhul Sarker, Amanul Haque, “Optimization of Maintenance and Spare Provisioning Policy Using Simulation”, Applied Mathematical Modeling, 2000, (24),751-760.