Production method of nanostructured wood-polymer composition with microwave application

Автор: Evgeny V. Boev, Liliya Z. Kasyanova, Aigul A. Islamutdinova, Elmira K. Aminova

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 4 Vol.15, 2023 года.

Бесплатный доступ

Introduction. Currently, wood-polymer compositions (WPC) are widely used in the national economy and construction. The composition of WPC varies widely depending on the further purpose. Improving the binding quality in the wood-polymer system is one of the promising areas for enhancing operational characteristics. Organic and inorganic substrates nanostructured with individual substances, including metal particles, are used as binding components. In the petrochemical industry, most high-capacity productions use catalysts based on active carriers like heavy metals when developing targeted products for various purposes. After several stages of regeneration, recovering these heavy metals becomes impossible. Consequently, spent catalysts accumulate in sedimentation tanks and sludge collectors, lacking an efficient method for disposal and secondary use. One of the components included in the composition of spent catalysts is chromium (+6), which belongs to carcinogenic metals. Numerous disposal methods are currently inadequate for neutralizing this metal on an industrial scale, which is of interest for research. Methods and materials. The study is aimed at converting carcinogenic chromium (+6) into non-carcinogenic chromium (+3) by ultrahigh frequency exposure (microwave), which will open up opportunities for its use as a chromium-containing nanocomplex binding a tree-polymer. Results and discussions. The ultrahigh-frequency effect on the mixture of wood-polymer composition and spent chromium (+6) causes an increase in the penetration depth of high–frequency waves, characterized by a uniform distribution of energy over the entire area of the composite, which is explained by the reduction of chromium (VI) oxide into chromium (III) oxide, and there is also a change in the color of the nanostructured wood-polymer composition (WP – compositions) from yellow to malachite. Conclusion. This study, which consists in the application of microwave exposure to the wood-nanoparticle-polymer system, confirms the receipt of a durable construction product and its use in the construction of roofs, facade boards, sidewalks, piers, port facilities, etc.

Wood-polymer materials, spent alumochrome catalyst, chromium cations, nanocomplex, compounding, microwave radiation, polypropylene

Короткий адрес: https://sciup.org/142238308

IDR: 142238308 | DOI: 10.15828/2075-8545-2023-15-4-342-348

Текст научной статьи Production method of nanostructured wood-polymer composition with microwave application

Original article

C urrently, the consumption of wood materials is growing annually with an increase in consumption in various areas of construction. Among the most popular tree species, pine, spruce, cedar and larch should be singled out. Their popularity in the Russian Federation can be attributed to their widespread availability and affordability. Products made from these wood varieties boast exceptional strength, durability, and resistance to decay. Statistics show that the woodworking industry generates a large amount of waste (sawdust) that is not fully used.

The accumulation of large volumes of sawdust, most often stored on the soil surface, has a serious negative impact on it and significantly acidifies the soil cover, as well as impoverishes it in nitrogen. In this regard, part of the research is aimed at studying the possibility of qualified use.

The production of thermally stable plastic wood-polymer materials is currently a priority and constantly developing direction in the construction industry. Waste from the technology of sawmilling and woodworking production is multi-tonnage and harms the soil by oxidizing it. To date, the use of sawdust in the production of wood-polymer materials is generally recognized and environmentally friendly. Various types of polymers are used as a binding component of wood-polymer materials. Part of the polymers are by-products, the second is waste

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION or substandard product. Materials that do not cause negative effects on humans and are resistant to environmental influences (light, air, temperature changes, humidity, etc.) are in great demand. Despite this, most building materials do not satisfy consumers in terms of technological indicators, having low-quality components and fillers [1–4]. The method of introducing nanocomponents into the structure of polymer-plant materials is diverse. The technology of introducing nanocomponents into the composition of building materials allows you to adjust the performance characteristics of the product according to customer requirements [5–9].

One of the most common methods is compounding, since it allows the nanoadditioning to be evenly distributed in the main polymer-wood material with subsequent heat treatment [5–11]. The great demand for this type of nanostructured plant material is associated with an increase in demand due to the increase in construction sites in the newly annexed territories of the Russian Federation. Thus, the growing demand for wood-polymer compositions requires the search for more effective binding materials to meet customer orders.

One of the interesting approaches to obtaining nanostructured wood-polymer materials is to obtain them using spent or secondary materials of petrochemical industries. As practice shows, it has been proved by research that metals forming complexes are capable of forming nanostructures that ensure the strength and durability of the building material.

In this regard, we have studied chromium-containing catalyst waste, which accumulates annually in large volumes and has not yet found proper use.

The main source of chromium-containing waste is large-tonnage production associations and other petrochemical industries. Alumochrome catalysts are mi-crospherical and are used in processes such as dehydrogenation of light hydrocarbons, in particular, isobutane and isopentane. The process is carried out in a fluidized bed. Despite the fact that the technology that uses such catalysts containing hexavalent chromium, which is a carcinogen, is justified from an economic point of view, since the components included in this catalyst are cheap and affordable, the use of these catalysts is economically justified, and the disposal of solid waste from production using alumochrome catalysts is an urgent task.

Petrochemical enterprises spend billions of rubles annually on the disposal of spent catalysts. Despite this, the number of accidents is growing. However, enterprises take into account only the possibility of regeneration of spent catalysts and their reuse in catalytic processes. Although these wastes can be considered from the point of view of valuable recyclables, for many industries, including in construction, about 95% of industrial wastes used alu-mochrome catalysts are not qualified due to their high toxicity. More than 80% of accidents occur due to a high degree of deterioration and long-term use of storage facilities. Many researchers have been developing ways to recycle these wastes. The previously proposed methods of waste disposal of alumochrome catalysts have a number of disadvantages: incomplete extraction of solid waste of valuable metals, separation of components using aggressive media of acids and alkalis, methods involving high costs for processing, significantly exceeding the cost of raw materials, which is not economically justified.

The paper proposes the processing of carcinogenic chromium-containing waste under the influence of a microwave field into non-toxic chromium (+3) and its secondary use as a nanostructured complex in the production of building materials. The proposed method can be implemented in production using the technologies of heterogeneous catalysts widely used in petrochemistry. The use of microwave radiation will lower the calcination temperature. Lowering the temperature will significantly reduce energy consumption by reducing the calcination time and conducting reactions in milder conditions. In production, during the dehydrogenation of isoparaffins, in particular, isopentane, an alumochrome catalyst of the IM-2201 brand is used, the active center of this catalyst is hexavalent chromium. By subjecting the spent alumochrome catalyst of the IM-2201 brand to reduction in the microwave field, it is possible to neutralize highly toxic chromium (VI) oxide into less toxic chromium (III) oxide. This transition will significantly increase the speed of the recovery process of hexavalent chromium oxide.

Ultrahigh-frequency exposure, firstly, ensures uniform distribution of heating and drying of almost any material at a high speed [12]. Secondly, it effectively warms and dries composite materials without radiating harmful effects on the external environment with a wide frequency coverage. Absorption of residual moisture from the studied objects is usually used in the range of more than 300 MHz [13, 14].

In [15, 16], the authors applied microwave exposure during the preparation of heterogeneous catalysts, which allowed increasing the rate of catalyst production, uniform distribution of active centers and uniform heating of the bulk phase of contact. The subject of the study is attractive because these alumochrome catalysts are widely used in the production of popular monomers of the composition C3–C5, intermediates of high-molecular compounds [17].

The use of microwave exposure to various materials was actively studied back in 2000–2010 and still arouses the interest of scientists, in connection with which the possibility of microwave processing of a wood-polymer composition, which includes a spent catalyst containing chromium and aluminum ions, the main component of which is carcinogenic chromium (+6) as a complex, has been investigated nano-binding. Under microwave exposure, chromium is simultaneously restored and a three-

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION component wood-metal nanoparticle-polymer complex is formed.

A modern and effective method of recycling waste from the woodworking industry is the creation of woodmetal compositions. The presence of metal fillers in the composition of the wood-polymer composition makes it possible to obtain materials with high vibration-damping properties, in addition, they provide high thermal conductivity of the composition, such characteristics are important for building structural materials.

The analysis of scientific literature has shown that an increase in the wear resistance of parts and structures made of wood-metal compositions is probably achieved by improving the volumetric characteristics associated with the structure and physico-chemical properties of individual structural components of the wood matrix and metal nanostructure. The presence of metal fillers makes it possible to obtain more durable materials.

The use of metal elements introduced into the volume of wood-polymer compositions leads to a change in the structure of the surface layer, improves the mutual microgeometry of the contacting surfaces. This composition increases the coefficient of friction and effectively removes heat from the metal surface over the entire area of the composition. This thermal effect contributes to the formation of high adhesion in the wood-metal-poly-mer complex. With the further use of such materials in construction, it is possible to obtain products with the geometric shape required by consumers, such as sheets, beams, slabs, floors, etc.

Depending on the fraction and composition of sawdust and polymer materials, when solid waste of an alu-mochrome catalyst is included in their composition, it is also possible to regulate such basic physical properties for the consumer as plasticity, flexibility, heat resistance, moisture capacity and color fastness.

METHODS AND MATERIALS

The paper proposes a study of sawdust obtained by longitudinal and transverse cutting of sawmaterials, which include crushed wood in an amount of 5–10% of the total weight. The fractional composition of sawdust (diameter) ranges from 5.5 to 0.16 mm (the fraction was sorted by a sieve with a diameter of no more than 5.5 mm). Sawdust having a diameter of more than 6 mm, when compounded with polymer and catalyst waste during microwave processing, showed an uneven surface of the material, a decrease in the quality of adhesion, and heterogeneity of the nanocomposition. Thus, it was decided to continue the study using smaller fractions of wood processing industry waste, not exceeding 6 mm.

Polyethylene, polypropylene, and polystyrene films of substandard composition were studied as a polymer material. Thus, the problem of an additional method of recycling polymer industry waste was solved in the work. Of the studied polymer waste, polypropylene proved to be the most preferable for compounding due to its strength and resistance to environmental factors. The disadvantage of polystyrene composite is the presence of an odor that is not acceptable when used in construction, especially in enclosed spaces.

For the processing of waste from the woodworking industry, it is necessary to take into account their physicochemical parameters when exposed to high-frequency radiation. An important indicator determining the depth of penetration is the degree of absorption of electromagnetic radiation by a wood-polymer composition [18, 19]. The calculation of the height of the layer of a wood-polymer composition is determined by the depth of full penetration of microwave radiation [20]. The effect of an electromagnetic field on an alumochrome catalyst contributes to the conversion of a hexavalent chromium (Cr+6) nanoparticle into trivalent chromium (Cr+3). The geometric dimensions of the wood-polymer composition are significantly larger than the penetration depth of the electromagnetic field, which leads to uneven absorption of electromagnetic energy and heterogeneity of heating of the WP-composition.

The impregnation method for the synthesis of catalysts based on aluminum-chromium includes the following sequential operations. The preparatory stage consists of the preparation of an impregnation solution, impregnation of the contact base of the catalyst, its drying with subsequent activation. The process of preparation of the catalyst is associated with its physical and chemical changes, therefore, the effect of microwaves and the depth of their penetration during the compounding of wood-polymer waste with aluminum-chromium catalyst waste is different at each stage.

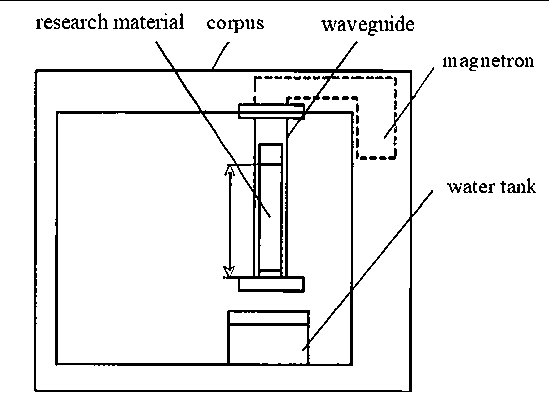

The calculation of the distance of penetration of microwave radiation into the studied nanocomposition is shown in Fig. 1. Research conditions: RF = 2450 MHz, G = 366.24 watts.

Fig. 1. Installation of radiation depth detection

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

Table 1

The penetration depth of microwave radiation

|

Name of samples of wood-polymer composites |

Bulk density, g/cm3 |

Penetration depth, cm |

Specific power, kW/kg |

|

Sample WP-composition 1 (without chromium, wet) |

1.17 |

10 |

3.571 |

|

Sample WP-composition 2 (chromium – 5%) |

1,21 |

17 |

4.123 |

|

Sample WP-composition 3 (chrome – 10%) |

1.25 |

15 |

2.575 |

RESULTS

The results of the study on calculating the penetration depth of electromagnetic exposure to a WP-composition containing chromium nanoparticles are shown in Table 1.

According to the table, the penetration depth of electromagnetic radiation was 10 cm without compounding with waste of alumochrome catalysts, and in the composition with chromium – 5% and 10%, 17 cm and 15 cm, respectively.

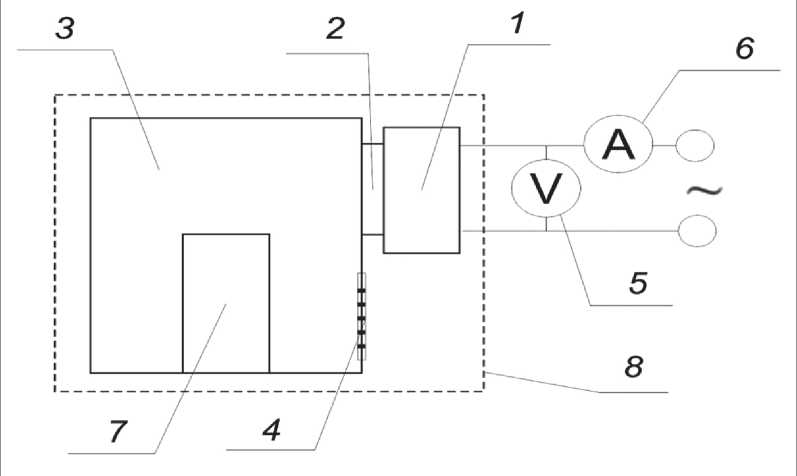

The installation of high-frequency electromagnetic exposure is shown in Fig. 2. Samples of the wood-polymer composition were exposed in the resonator of an electromagnetic radiation generator. Experimental conditions: G = 900 W, CHI = 2450 MHz (wavelength 12.2 cm). The uniformity of the heating distribution of the transverse layer of the test sample was carried out by control points in the experimental unit of the electromagnetic furnace with a mercury thermometer. The rate of temperature change in the studied samples was monitored using a Testo 882 thermal imager every 10 minutes. The duration of the experiment is 30 minutes, at the end of the experiment, the samples were subjected to weight analysis.

At the end of the microwave exposure, the penetration depth of samples 2 and 3 was 17 and 15 cm. The penetration depth increased significantly, which is explained by the significant content of crystallization water in the wood-polymer material without chromium. As moisture is removed during heat treatment from WP-compositions, the depth of penetration of radiation increases to 17 and 15 cm. A WP-composition with a chromium content of 5% has a greater depth of penetration of microwave radiation, an increase in the concentration of waste reduces the depth of penetration of the microwave field.

Fig. 2. Diagram of a laboratory microwave installation: 1 – electromagnetic generator;

2 – waveguide; 3 – experimental unit; 4 – ventilation holes; 5 – voltmeter; 6 – ammeter;

7 – WP-composition samples; 8 – electromagnetic radiator housing

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

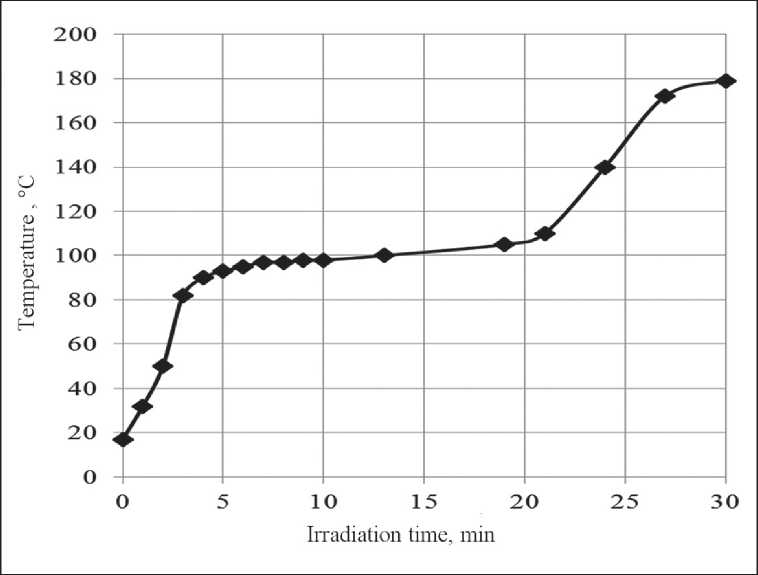

Fig. 3. The curve of the heating rate of the WP composition

This is due to a change in the nanostructure of the WP-composition in terms of such indicators as density and strength. It should also be noted that the microwave exposure caused a change in the chemical composition of the WP-composition: Cr+6 recovered to Cr+3 (CrO3 → Cr2O3).

The heating rate depending on the temperature in the range from 20 to 200оC in time is shown in Fig. 3. The heating rate curve demonstrates in the first five minutes of the experiment a sharp removal of moisture in the upper layers of the WPC sample. Then, over the next 15 minutes, there was a slow evaporation of water associated with the transformation of the nanostructure and the transition of chromium (VI) to chromium (III). Further, a sharp rise in the velocity curve indicates the transition of the WP-composition into a homogeneous structure.

DISCUSSION

The conducted studies using microwave radiation on a compound of WP-composition and spent chromium (+6) allow solving the environmental problem of catalytic processes where carcinogenic chromium compounds are formed to obtain strong and durable nanomaterials in demand in construction. The depth of penetration of high-frequency waves is determined, which contributes to a decrease in the valence of chromium, and a change in the color of the nanostructured wood-polymer composition (WP-compo-sition) from yellow to malachite is also observed.

The resulting nanostructured wood-polymer composite was tested for the technological indicators presented in Table 2.

Table 2

Technological indicators

|

The name of the indicator |

WP-composition (chrome 5%) |

WP-composition (chrome 10%) |

|

Density |

0.911 |

0.978 |

|

Tensile strength |

20.136–30.338 |

30.178–39.15 |

|

Compressive strength |

27 |

35 |

|

Flexural strength |

18–33 |

37.5 |

|

Swelling |

0.01 |

0.01 |

APPLICATION OF NANOTECHNOLOGIES AND NANOMATERIALS IN CONSTRUCTION

The proposed WP-composition is not inferior in its technological characteristics and improves bending strength, surpassing the performance of a pure polymer. In terms of strength, it surpasses the indicators of pure wood.

The second advantage is the low water absorption rate, which contributes to durability and resistance to microbiological decomposition.

Water absorption is noticeable in the outer layers of the WP-composition, it decreases evenly into the depth of the material.

Thus, microwave exposure is an effective way to obtain a WP-composition. It is worth paying attention only to the size of the treated area of the WP-composition when used in industrial conditions or it is necessary to design special microwave exposure devices [22].

CONCLUSION

With microwave exposure to the charge, the composition of softwood sawdust – chromium (III)-polypro-pylene is preferable to use a fraction of sawdust in the range of 2.5–1 mm. The resulting product after microwave treatment is a homogeneous, almost smooth plastic mass. This nanocomposite material was extruded through a die (extrusion method) to obtain a construction profile. The nanostructured compositions obtained by us based on waste from the woodworking industry will allow us to solve two technological problems: firstly, to reuse waste from woodworking, and secondly, to dispose of carcinogenic chromium (+6) to obtain safe, high-performance nanomaterials that can be used in the construction of roofs, facade boards, sidewalks, piers, port facilities, etc.

Список литературы Production method of nanostructured wood-polymer composition with microwave application

- Klesov A.A. Wood-polymer composites. Saint Petersburg: Scientific foundations and Technologies; 2010.

- Tyukina Yu.P., Makarova N.S. Technology of sawmill and woodworking production [Text] / Yu.P. Tyukina, N.S. Makarova. M.: Higher School; 1988.

- Kokta B.V. Composites of Polyvinyl Chloride-Wood Fibers. Vinyl Tech. 1990;12(3):146–53.

- Matuana L.M., Balatinecz J.J., Park C.B. Surface Characteristics of Chemically Modified Fibers Determined by Inverse Gas Chromatography. Wood Fiber Sci. 1999;31:116–27.

- Korshun O.A., Romanov N.M., Nanazashvili I.H. Environmentally friendly wood-filled plastics. Build Mater. 1997;5:8-11.

- Boev E.V., Islamutdinova A.A., Aminova E.K. Development of technology for obtaining anticorrosive nanostructured polyalkenylamide-succinimide coatings in construction. Nanotechnol Constr. 2023;15(1):6–13.

- Ilin V.M., Boev E.V., Islamutdinova A.A., Aminova E.K. Development of heavy metal-based nanostructured complex technology for use in building mortar. Nanotechnol Constr. 2022;14(5):398–404.

- Boev E.V., Islamutdinova A.A., Aminova E.K. Method of obtaining calcium silicate for construction. Nanotechnol Constr. 2021;13(6):350–57.

- Boev E.V., Islamutdinova A.A., Aminova E.K. Obtaining the retainer for waterproofing road bitumens. Nanotechnol Constr. 2021;13(5):319–27.

- Karimov O.H., Daminev R.R., Kasyanova L.Z., Karimov E.H. The use of microwave radiation in the preparation of metal oxide catalysts. Fundam Res. 2013;4-4:801-805.

- Karimov O.H., Daminev R.R., Kasyanova L.Z., Karimov E.H. Modification of an alumina carrier for a catalyst for dehydrogenation of light hydrocarbons under the action of a microwave field. Bashkir Chem J. 2012;19(4):7-9.

- Musin I.N., Fayzullin I.Z., Wolfson S.I. The effect of additives on the properties of wood-polymer composites. Bull Kazan Technol Univ. 2012;15(24):97-99.

- Rogov I. A., Nekrutman S. V. Ultra-high-frequency heating of food products. Moscow: Food Industry; 1986.

- Bikbulatov I.H., Daminev R.R., Shulaev N.S., Shulaeva E.A. The use of electromagnetic radiation of the ultrahigh frequency range for drying mineral salts. Izv Vuz Chem Chem Technol. 1999;42(2):135-138.

- Khaidurova A.A., Fedchishin V.V., Konovalov N.P. Microwave drying of brown coals and improvement of their technological characteristics. Izv High Educ Inst Energy Probl. 2010;1-2:31-35.

- Bykovsky N.A., Puchkova L.N., Fanakova N.N. Study of the toxicity of distiller liquid of ammonia-soda production by various test objects. Ecol Ind Russia. 2015;19(10):48-51.

- Bolshina E.P. Ecology of metallurgical production. Novotroitsk: NF NUST MISIS; 2012.

- RU Patent 2176288, IPC C23F1/46. Method for disposal and neutralization of waste from titanium production etching / A.N. Trubin, G.I. Gril. No. 2000105528/02; filed on 06.03.2000, published on 27.11.2001.

- RU Patent 2546646 C1. Catalyst, method of its preparation and the process of dehydrogenation of paraffin hydrocarbons C4-C5 olefin using a catalyst” / L.Z. Kasyanova, A.N. Ibragimov, I.D. Gumerov, D.A. Zhavoronkov No. 2014110169/04; application 17.03.2014, publ. 10.04.2015.

- Patent 4943419 USA, IPC C01G23/00. Process for recovery in galkali metal titanium fluoride salts from titanium pickleacid baths / JosephA.Megy (USA). No.US07/331.583; application 30.03.1989, publ. 24.07.1990.

- Karimov E.H., Flid V.R., Movsumzade E.M., Teptereva G.A., Chetvertneva I.A. Application of lignosulfonates to reduce waste of spent ion exchange catalysts in petrochemical production. Ecol Ind Russia. 2022;26(1):4-8.

- Azarov V.I., Burov A.V., Obolenskaya A.V. Chemistry of wood and synthetic polymers. Saint Petersburg: SPbLTA; 1999.