Production of a nanostructured bitumen modifier in the reprocessing of automobile tires

Автор: Marina P. Krasnovskikh, Sergei Yu. Chudinov, Natalia N. Sliusar, Konstantin G. Pugin, Yakov I. Vaisman

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 6 Vol.14, 2022 года.

Бесплатный доступ

Introduction. Polymer-bitumen binders are innovative nano-binders for asphalt concrete pavement. Introduction of a polymer modifier improves the characteristics of bitumen and asphalt concrete. The use of waste tires rubber for bitumen modification is considered to be an environmentally friendly solution, but it is limited due to the poor cosite of rubber with bitumen. Various methods based on activation of the rubber surface, dispersion of rubber to nanosized particles, and thermochemical transformations of rubber into individual organic compounds are known to overcome this limitation. Methods and materials. The method of joint pyrolysis of rubber with oxygen-containing oil under pressure is proposed to be used for converting it into a nanostructural bitumen modifier. The resulting product is studied by the methods of thermogravimetry, NMR-spectroscopy, chromatomasspectrometry, scanning electron microscopy and solubility in toluene. Results and discussion. It has been established that during joint pyrolysis rubber undergoes devulcanization, cracking and dispersion to nanosized particles, and as a result the product becomes compatible with bitumen. Thermochemical reprocessing of waste automobile tires can be considered to be a promising method for the production of a nanostructured bitumen modifier. Conclusion. The use of thermochemical pressure treatment of waste tire rubber in the presence of oxygen-containing oil makes it possible to obtain a nanostructured product compatible with bitumen for further use of the resulting modifier in the production of asphalt concrete.

Nanostructural modifier, bitumen, car tires

Короткий адрес: https://sciup.org/142235790

IDR: 142235790 | DOI: 10.15828/2075-8545-2022-14-6-501-509

Текст научной статьи Production of a nanostructured bitumen modifier in the reprocessing of automobile tires

Original article

Polymer-bitumen binders are innovative nano-binders for asphalt concrete pavements. Introduction of a polymer modifier improves the characteristics of bitumen and asphalt concrete. The necessary condition for obtaining a bitumen modifier is its ability to dissolve or swell in a bitumen dispersion medium [1]. The quality of bitumens as oil dispersed systems is directly related to their structure and properties, which are determined by the quantitative ratio of oils, resins, and asphaltenes that form a microheterogeneous nanodispersed structure [2].

Waste tires are a common large-scale waste, and their primary production by the petrochemical industry implies the compatibility of used tires with other petrochemical products. Almost 1.5 billion tires are produced every year [3], which is more than 17 million tons. Rubber, being the basis of tires, is highly resistant to degradation in the natural environment. The progress made in recent years in the field of waste management has resulted in the fact that tires are beginning to be perceived as a potential source

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION of valuable raw material [4]. The research works aimed at developing cost-effective and environmentally friendly tire recycling methods are fully justified, since such approach allows the sustainable development of industrially applicable recycling technologies [5].

Rubber crumb obtained from the used tires is a rather chemically inert material due to the presence of a threedimensional structure created at the stage of product formation and additional cross-linking of the polymer by intermolecular bonds of sulfur atoms and filler particles in the form of highly dispersed carbon. Therefore, the seemingly obvious solution for the disposal of crumb rubber by creating a composite with road bitumen for the possibility of forming asphalt concrete turns out to be impracticable in reality due to low or no adhesion of the surface of the used rubber with bitumen.

The crumb rubber resulting from the grinding of recycled tires has been successfully used as a modifier for the asphalt-concrete pavement to provide environmental friendliness, and the end product has been widely known as rubberized asphalt [6]. Although rubberized asphalt has been considered an environmentally friendly paving material with favorable engineering advantages, it suffers from poor compatibility with other asphalt concrete components, in particular bitumen, which has essentially limited its usage. This incompatibility problem is caused by great differences between crumb rubber and asphalt matrix in their chemical nature (molecular size and polarity) and physical characteristics (density and solubility). In this case, the rubber crumb obtained from tires with expired service life becomes a resource needed in another production process to create paving layers [7].

Crumb rubber grinding can be considered to be the simplest technical solution to achieve the compatibility of bitumen and crumb rubber. The authors of [8] showed that the addition of crumb rubber to bitumen in the process of creating asphalt concrete compositions improves the properties of the finished material only with the size of a rubber crumb less than 100 µm and, in some cases, with the particle sizes of 100–200 µm. The use of a larger rubber crumb results in a loss of the improvements achieved through the interaction of bitumen and rubber.

A more technically difficult solution for the compatibility of rubber and bitumen is activation of the crumb surface. Activation of crumb rubber is possible by high-temperature shear co-grinding into a binary mixed powder based on crumb rubber and styrene-butadiene thermoplastic elastomer [9]. The authors propose [10] obtaining a devulcanized product in the process of ultrasonic reprocessing of rubber in an extruder, and this product can be used as filler in an asphalt concrete mixture.

In practice, crumb rubber is subjected to thermochemical treatment and grinding in a colloid mill to obtain a modifier compatible with bitumen. Thus, Tatneft and the Hungarian MOL Group started implementing a project for the construction of a plant for producing rubber-modified bitumen at the TANECO complex. The technology was patented by the MOL Group and a group of scientists from the Pannonian University (patent HU226481) [11]. However, mechanical reprocessing of crumb rubber in a ball mill requires significant time and energy costs, so chemical methods for dispersing rubber to the nanostructure particle size and corresponding compatibility with the colloidal bitumen system seem to be more promising.

Modifying the ground tire rubber to make it compatible with the matrix is a more versatile method. The most well-known technical solutions for its implementation are chemical modification and reactive extrusion [12]. Chemical modification of the rubber crumb surface can be carried out by bitumen itself, if an efficient heat supply is ensured by the microwave treatment [13]. In this case, the devulcanized rubber on the surface of the grains effectively interacts with bitumen, further providing high adhesive properties of the surface.

To overcome the adhesion problem, surface coatings, compatibilizers, additives and energy treatments are used. It is proposed [14] that nanoparticles should be included in the composition with a combination of other methods, which facilitates the production of high-quality composites and creation of competitive materials. Another solution for creating a composite of rubber crumb and high-density polyethylene is activation of the surface of materials using an olefin-maleic anhydride copolymer [15].

Heat treatment of rubber leads to devulcanization and activation of the surface of the material and enables it to interact with the additives that improve adhesion. Thus, the use of microwave electromagnetic energy for the devulcanization of rubber powder results in the production of a new composite with improved properties from the treated material [16]. During the microwave energy treatment, sulfur-sulfur and carbon-sulfur bonds are broken.

During devulcanization, the chemical bonds of sulfur-sulfur (S–S) and carbon-sulfur (C–S) are destroyed without destroying the main network and the material. Devulcanized rubber can be mixed with virgin rubber or with other types of matrices to obtain new compounds without significant reduction in mechanical and physical properties. Many types of devulcanization processes are presented in the literature: chemical, ultrasonic, microwave, thermomechanical, etc. Thermomechanical devulcanization based on extrusion appears to be more suitable for industrial scale applications. Supercritical CO2 has been proposed as an environmentally friendly atmosphere that can be used to improve this type of devulcanization [17]. Under supercritical conditions, CO2 is supposed to swell in the rubber and stretch the sulfide bonds, making them easier to break.

Analysis of literary sources suggests that the presence of any oxygen-containing compounds, and not only car-

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION bon dioxide, accelerates the process of devulcanization and cracking of polymer molecules. This effect is probably associated with a radical mechanism of the pyrolysis process at temperatures above 500оC, when oxygen heteroatoms form radicals, which contribute to the termination of polymer molecules, easier than other atoms [18]. Indeed, many research works confirm the positive effect of oxygen heteroatoms on the degradation of polymer molecules, including the devulcanization process.

Therefore, crumb rubber was proposed to be activated and dispersed by the thermochemical method in the presence of oxygen-containing compounds until it is compatible with the colloidal bitumen matrix. Based on this, the purpose of this research was to determine the possibility of thermochemical devulcanization of rubber to obtain a nanostructural bitumen modifier for its further utilization in asphalt concrete. For the practical implementation of this goal, the products of rubber crumb pyrolysis together with oxygen-containing vegetable oil were studied for the subject of formation of oligomers and compatibility with bitumen.

METHODS AND MATERIALS

Rubber crumb fraction of 1–3 mm produced by Bu-matika LLC was used as waste tire rubber. Sunflower unrefined oil of the “Blago” brand was chosen as the oxygen-containing component.

Pyrolysis of the examined samples took place in a steel retort. It was carried out for 90 minutes at 530оC. The sample mass was 20.0 g. At the end of the process, the pressure in the reactor reached 23–25 atm.

The structure and particle size of the pyrolysis products were analyzed using the Hitachi S-3400N scanning electron microscope with various magnifications.

Thermoanalytical studies were held in an argon atmosphere using the STA 449 F1 synchronous thermal analysis instrument manufactured by NETZSCH (Germany), which allows analysis with the simultaneous recording of thermogravimetric and calorimetric characteristics.

The compatibility of the obtained products with bitumen was determined by the solubility in toluene, according to GOST 20739-75. “Petroleum bitumen. Method for determining solubility”.

After dissolution in bitumen, the toluene extracts were analyzed on the nuclear magnetic resonance (NMR) spectrometer: BrukerAvance III HD (400 MHz 1H, 101 MHz 13C), the solvent – deuterochloroform CDCl3. Chemical shifts are indicated relative to TMS by a residual solvent signal; shooting temperature – 40оC.

The qualitative composition of the pyrolysis products soluble in toluene was determined by the chromatography-mass spectrometry with the Agilent Technologies instrument, 7890B GS System chromatograph, 5977A MSD mass spectrometer, HP-1MS capillary column

(length 30 m, column inner diameter 0.25 mm, deposited layer thickness – 0.25 µm), carrier gas – helium, 1 ml/min. Temperature programming was carried out in the following mode: holding at 50оC for 1 minute, then heating at a rate of 5 degrees per minute to 300оC, 300оC isotherm for 9 minutes, then heating with 5 degrees a minute to 325оC and 325оC isotherm for 1 minute. The injector temperature – 270оС, the exit temperature to the mass spectrometer – 350оС, the mass spectrometer operation mode: the ionization energy – 70 eV, the source temperature – 230оС, the mass range 16–500. The results were processed using the software package supplied with the instrument. The products were identified by comparing their mass spectra with the spectra of the compounds available in the NIST 2017 library supplied with the program.

RESULTS

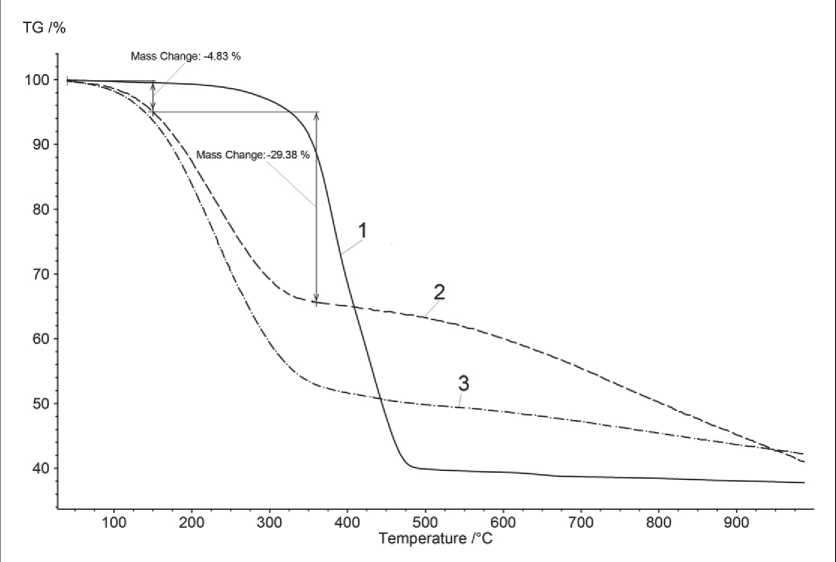

Proceeding from the above assumptions about the mechanism of rubber pyrolysis in the presence of oxygencontaining compounds, the products of joint pyrolysis of rubber and vegetable oil were obtained. Fig. 1 shows the results of the thermogravimetric analysis of the original rubber in the argon atmosphere (1), the sample of rubber subjected to pyrolysis under the above conditions and the sample obtained by pyrolysis of 76 wt.% rubber and 24 wt.% vegetable oil. It is obvious that under thermal exposure part of the rubber undergoes pyrolysis and destruction to form lower molecular weight products even without additional chemical exposure to oxygen-containing oil. In the presence of oil, the process of polymer destruction is even more intense and the amount of low-boiling fractions increases.

Quantitative assessment of the rubber destruction and the formation of low molecular weight light fractions can be carried out by finding the proportion of the hydrocarbons evaporating in a certain temperature range. This method is shown with the example of curve 2. The fraction boiling up to 150C approximately corresponds to the gasoline fraction in the case of direct distillation of oil, and for sample 2 it is 4.83 wt.%. The medium fraction, including kerosene and diesel fuel, is distilled at temperatures of 150–360оC, and for the selected sample it is 29.38 wt.%

The proportions of light and medium fractions for the three described samples are shown in Table 1.

All samples are characterized by the presence of a thermally stable residue of 38–42 wt.%, which probably includes inorganic rubber components and carbon introduced into the original material. It is obvious that as a result of heat treatment the polymer molecules of rubber depolymerize to form light hydrocarbons, the presence of oxygen-containing oil contributing to this process.

Chemical compatibility of rubber reprocessing products with bitumen and the particle size of rubber pyrolysis

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 1. Results of the thermogravimetric analysis of the original rubber (1), the product of rubber pyrolysis (2), and the product of joint pyrolysis of rubber and vegetable oil (3) in argon products insoluble in bitumen are evidently the key tasks of rubber crumb utilization in asphalt concrete. In the first case, the chemical compatibility of rubber depolymerization products with bitumen is defined as the solubility of modifying additives in organic solvents, mainly in toluene [19]. Proceeding from this, the solubility of the rubber crumb and the products of its joint pyrolysis with vegetable oil in toluene was determined. The research results are presented in Table 2.

The proportion of the condensed phase in the individual pyrolysis of rubber crumb and in the joint pyrolysis with oil turns out to be almost the same, but the propor-

Table 1

Proportions of light (up to 150оC) and medium (150–360оC) fractions in the composition of the samples according to thermogravimetry data

|

Sample |

Proportion of light fraction (up to 150оC), wt.% |

Proportion of medium fraction (150–360оС), wt.% |

|

Original rubber |

0.47 |

10.89 |

|

Rubber pyrolisis product |

4.83 |

29.38 |

|

Joint rubber and vegetable oil pyrolisis product |

6.10 |

40.79 |

Table 2

Solubility of samples in toluene

|

Sample |

Proportion of the condensed phase from the initial mass, wt. % |

Proportion of the condensed phase from the initial mass, wt. % |

|

Original rubber |

100 |

100 |

|

Rubber pyrolisis product |

74,2 |

58,6 |

|

Joint rubber and vegetable oil pyrolisis product |

72,1 |

40,6 |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION tion of the fraction soluble in toluene increases significantly in the second case. In the case of joint pyrolysis, the process of rubber devulcanization and polymer degradation obviously proceeds much deeper.

This assumption is confirmed by the NMR analysis data presented in Table 3.

Indeed, in the case of joint pyrolysis, the proportion of aliphatic carbon in the product increases by 1.3 times, and the proportion of aromatic carbon decreases by 1.5 times. At the same time, the mass of vegetable oil in the mixture was 3.2 times less than that of crumb rubber. Therefore, it can be argued that the increase in the proportion of aliphatic carbon in the case of joint pyrolysis cannot be achieved due to the decomposition of oil triglycerides, but is associated with the cracking of the rubber polymers, the formation of oligomers, and their partial dearomatization. As a result, the obtaiined product loses its three- dimensional structure and acquires solubility in toluene and, accordingly, is compatible with bitumen.

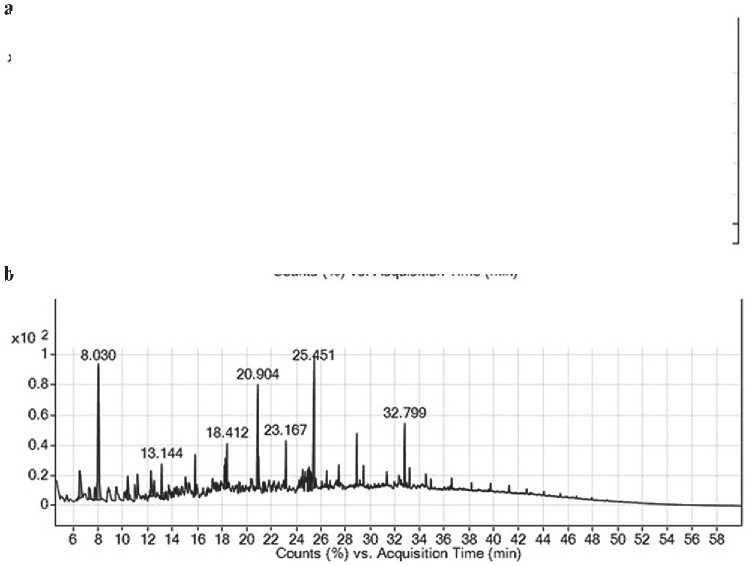

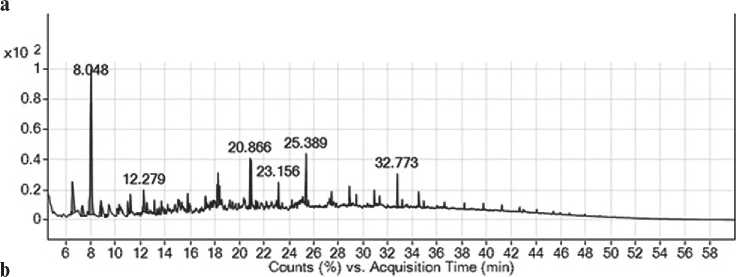

This conclusion is also confirmed by the results of the chromatomass-spectrometric examination of toluene extracts of the product of rubber pyrolysis and the product of joint pyrolysis of rubber and vegetable oil. The resulting chromatograms are shown in Fig. 2

According to the chromatographic analysis, more than 100 individual substances are recorded in both samples. Table 4 shows the relative content of major compounds that are part of the pyrolysis products, identified according to the mass spectrometry data

There is a decrease noticed in the proportion of aromatic compounds and an increase in both the proportion and diversity of aliphatic hydrocarbons in the product of joint pyrolysis of rubber with vegetable oil in comparison with the rubber pyrolysis product. Thus,

Table 3

NMR spectroscopy data

|

Sample |

С13, integration |

|

|

Aromatic carbon, mol. % |

Aliphatic carbon, mol. % |

|

|

Original rubber |

43.78 |

56.22 |

|

Joint rubber and vegetable oil pyrolisis product |

28.76 |

71.24 |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Table 4

Mass spectrometry data

|

Rubber pyrolisis product |

Joint rubber and vegetable oil pyrolysis product |

||

|

Compound |

mol. % |

Compound |

mol. % |

|

1-methyl-4-prop-2-ylbenzene |

23.3 |

1-methyl-4-prop-2-ylbenzene |

14.4 |

|

3-methyl-1-ethylbenzene |

6.5 |

Heptadecane |

8.9 |

|

Heptadecane |

3.4 |

Pentadecane |

5.9 |

|

2,6,10-trimethyltetradecane |

3.1 |

1-methyl-3-ethylbenzene |

3.9 |

|

2,3,6-trimethylnaphthalene |

2.6 |

Oxadecannitrile |

2.9 |

|

Oxadecannitrile |

2.2 |

1-but-3-en-2-yl-3-methylbenzene |

2.1 |

|

Undecane |

1.9 |

||

|

Tridecane |

1.9 |

||

|

2,6,10-trimethyltetradecane |

1.8 |

||

|

2,6-dimethylnaphthalene |

1.5 |

||

Fig. 2. The results of chromatographic analysis of the rubber pyrolysis product (a) and the product of joint pyrolysis of rubber and vegetable oil (b)

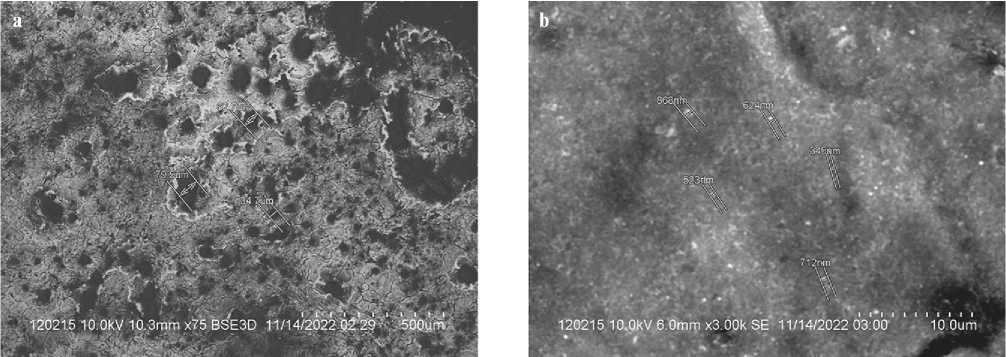

Fig. 3. Micrograph (a) of the organic product film with particles of undissolved polymeric material and micrograph (b) of the organic product film with particles of inorganic impurities

the resulting product is compatible with bitumen in its chemical nature.

In addition to the above mentioned chemical compatibility of the joint rubber vegetable oil pyrolysis product with bitumen, high dispersion of the product to nanosized particles characteristic of bitumen has been revealed. Figure 3 shows the results of electron microscopic studies of a film of the joint rubber vegetable oil pyrolysis product deposited from the toluene solution on a ceramic surface with further removal of the solvent.

It is obvious that thermochemical treatment results, besides the devulcanization and formation of a complex of individual chemical compounds, in the dispersion of the polymeric part of the product insoluble in toluene to a particle size not exceeding 70–80 µm (Fig. 3a). At the same time, inorganic rubber components, such as silicon and magnesium oxides, form nanosized particles smaller than 900 nm. Such nanosized inorganic oxide particles are known to improve the stability of asphalt mixtures [20].

DISCUSSION

During the experiments, it was found that the joint used tires rubber crumb and vegetable oil pyrolysis under pressure leads to the production of a nanostructured product compatible with bitumen. In the course of the thermochemical process, devulcanization and cracking of polymeric rubber molecules occur to form individual organic oligomers and highly dispersed particles of organic and inorganic nature. These results are consistent with the studies by other authors. Thus, it was proved in [21] that at 550оC the joint pyrolysis of rubber from the used tires and polyolefins from the used packaging is

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION significantly accelerated and increases the yield of a liquid product in the presence of corn stalks.The calorific value of the oil obtained is 39.93 MJ/kg. The addition of corn stalks increased the H/C ratio of the pyrolysis oil from 1.43 to 1.50, which meant more saturated hydrocarbons and better oil stability. In that case, the oxygen content in the pyrolysis oil increased and the content of nitrogen and sulfur decreased. The authors explain the latter fact as the binding of sulfur and nitrogen by the oxygen of cellulose or lignin into gaseous products.

In the research work [22], willow leaves and waste tires were subjected to joint pyrolysis at 300–500оC. The resulting liquid product contained 1.79% oxygen and consisted mainly of alkanes and aromatics, which gave it properties similar to diesel fuel at the high calorific value. During the pyrolysis process, sulfur was effectively removed in the form of SO2. It was shown [23] that in the joint pyrolysis of used tires and bamboo sawdust at 550оC, the maximum yield of aromatic hydrocarbons was obtained with a component ratio of 1:1. During rubber pyrolysis, any oxygen-containing compounds can obviously act as a donor of oxygen-containing radicals. In this sense, the described process of obtaining bitumen-like materials is approached by autoclave methods for processing plant biomass with a high content of oxygen atoms. Thus, the hydrothermal conversion of industrial remains of the algae Spirulina sp. at 260оC under autogenous pressure forms a hydrophobic phase with rheological properties similar to those of an elastomeric biobinder [24]. Removal of solid residues from the hydrophobic fraction by filtration results in pure conventional bitumen-like material.

Even a decrease in temperature to certain limits can be compensated by an increase in pressure. Thus, natural rubber, which is similar in structure to the rubber of used tires, can successfully undergo the process of liquefaction in an autoclave at 250–375оC and a reaction time of

15–75 minutes [25]. The liquid product contained various hydrocarbons, predominantly D-limonene and isoprene, as well as aromatics and alkenes with a gross calorific value of up to 46 MJ/kg due to the low oxygen content of 1.02%. Attention is drawn to the fact that the low oxygen content in the product occurs against the background of using alcohols as the main reagent. The high calorific value makes the resulting fluid suitable for its use as a replacement for traditional fossil fuels. Therefore, the pyrolysis of rubber in the presence of oxygen-containing compounds leads to the devulcanization of rubber and the cracking of polymers to compounds that, from a practical point of view, are liquid hydrocarbons under normal conditions. As a result, oxygen is removed from the system in the form of low molecular weight oxides.

The proposed technical solution has an advantage over the pyrolysis of rubber to liquid fuel. It consists in the fact that such natural impurities of rubber as a composite material, in the form of silicon and zinc oxides, as well as carbon black, are a natural part of the asphalt-concrete mixture composition and do not further represent environmental hazards.

Thus, thermochemical reprocessing of automobile tires can be considered as a promising method for the production of a nanostructured bitumen modifier.

CONCLUSION

The use of thermochemical pressure treatment of waste tire rubber in the presence of oxygen-containing oil makes it possible to obtain a nanostructured product compatible with bitumen for the further use of the resulting modifier in the production of asphalt- concrete. The proposed method of recycling waste tires reduces the environmental burden on the environment thanks to the safe disposal of tires and the absence of hazardous emissions.

Список литературы Production of a nanostructured bitumen modifier in the reprocessing of automobile tires

- Evdokimova N.G., Luneva N.N., Egorova N.A., Makhmutova A.R., Bayguzina Yu.A., Imangulova E.A. The selection of production technology of polymer-bitumen binders as an innovative nanobinders used in asphaltic concrete pavement. Nanotehnologii v stroitel’stve = Nanotechnologies in Construction. 2018; 10(5):20–37. https://doi.org/10.15828/2075-8545-2018-10-5-20-37 (In Russian)

- Boev E.V., Islamutdinova A.A., Aminova E.K. Obtaining a fixer for waterproofing road bitumen. Nanotehnologii v stroitel’stve = Nanotechnologies in Construction. 2021; 13 (5):319–327. https://doi.org/10.15828/2075-8545-2021-13-5-319-327 (In Russian)

- Czajczyńska D., Krzyżyńska R., Jouhara H., Spencer N. Use of pyrolytic gas from waste tire as a fuel: A review. Energy. 2017; 134: 1121–1131. https://doi.org/10.1016/j.energy.2017.05.042

- Sienkiewicz M., Kucinska-Lipka J., Janik H., Balas A. Progress in used tyres management in the European Union: A review. Waste Management. 2012; 32(10): 1742–1751. https://doi.org/10.1016/j.wasman.2012.05.010

- Hejna A., Korol J., Przybysz-Romatowska M., Zedler Ł., Chmielnicki B., Formela K. Waste tire rubber as low-cost and environmentally-friendly modifier in thermoset polymers – A review. Waste Management. 2020; 108: 106–118. https://doi.org/10.1016/j.wasman.2020.04.032

- Li J., Chen Z., Xiao F., Amirkhanian S. N. Surface activation of scrap tire crumb rubber to improve compatibility of rubberized asphalt. Resources, Conservation and Recycling. 2021; 169: 105518. https://doi.org/10.1016/j.resconrec.2021.105518

- Bressi S., Fiorentini N., Huang J., Losa M. Crumb Rubber Modifier in Road Asphalt Pavements: State of the Art and Statistics. Coatings. 2019; 9(6): 384. https://doi.org/10.3390/coatings9060384

- López-Moro F. J., Moro M. C., Hernández-Olivares F., Witoszek-Schultz B., Alonso-Fernández M. Microscopic analysis of the interaction between crumb rubber and bitumen in asphalt mixtures using the dry process. Construction and Building Materials. 2013; 48: 691–699. https://doi.org/10.1016/j.conbuildmat.2013.07.041

- Gordeeva I.V., Naumova Yu.A., Dudareva T.V., Krasotkina I.A., Nikol’skiy V.G. Composite modificator of asphalt-concrete obtained by the method of high-temperature shear-induced grinding of crumb rubber and SBS thermoelastoplast. Tonkie khimicheskie tekhnologii / Fine Chemical Technologies. 2018; 13(5): 38-48. https://doi.org/10.32362/2410-6593-2018-13-5-38-48 (In Russian)

- Sokolov M.V., Nikolyukin M.M., Polyansky S.N. Increasing the degree of environmental safety of rubber industry enterprises. Journal of Mining Institute. 2022; 203: 233-236.

- Tatneft and MOL start construction of a modified bitumen rubber plant at TANECO. Available from: https://neftegaz.ru/news/neftechim/687779-tatneft-i-mol-nachali-stroitelstvo-ustanovki-po-proizvodstvu-rezinomodifitsirovannogo-bituma-na-tane/

- Phiri M.M., Phiri M.J., Formela K., Wang S., Hlangothi S.P. Grafting and reactive extrusion technologies for compatibilization of ground tire rubber composites: Compounding, properties, and applications. Journal of Cleaner Production. 2022; 369: 133084. https://doi.org/10.1016/j.jclepro.2022.133084

- Zedler Ł., Klein M., Saeb M. R., Colom X., Cañavate J., Formela K. Synergistic Effects of Bitumen Plasticization and Microwave Treatment on Short-Term Devulcanization of Ground Tire Rubber. Polymers. 2018; 10(11): 1265. https://doi.org/10.3390/polym10111265

- Archibong F. N., Sanusi O. M., Médéric P., Aït Hocine N. An overview on the recycling of waste ground tyre rubbers in thermoplastic matrices: Effect of added fillers. Resources, Conservation and Recycling. 2021; 175: 105894. https://doi.org/10.1016/j.resconrec.2021.105894

- Simon-Stőger L., Varga C. PE-contaminated industrial waste ground tire rubber: How to transform a handicapped resource to a valuable one. Waste Management. 2021; 119: 111–121. https://doi.org/10.1016/j.wasman.2020.09.037

- Aoudia K., Azem S., Aït Hocine N., Gratton M., Pettarin V., Seghar S. Recycling of waste tire rubber: Microwave devulcanization and incorporation in a thermoset resin. Waste Management. 2017; 60: 471–481. https://doi.org/10.1016/j.wasman.2016.10.051

- Asaro L., Gratton M., Seghar S., Aït Hocine N. Recycling of rubber wastes by devulcanization. Resources, Conservation and Recycling. 2018; 133: 250–262. https://doi.org/10.1016/j.resconrec.2018.02.016

- Ketov A., Korotaev V., Sliusar N., Bosnic V., Krasnovskikh M., Gorbunov A. Baseline Data of Low-Density Polyethylene Continuous Pyrolysis for Liquid Fuel Manufacture. Recycling. 2022; 7: 2. https://doi.org/10.3390/recycling7010002

- Muruzina E.V. Evaluation of the compatibility of petroleum bitumen with thermoelastomers. Vestnik MGSU. 2010; 3: 63-68. (In Russian)

- Helal E., Sherif El-Badawy, Alaa G., Zaki S.I. Evaluation of asphalt enhanced with locally made nanomaterials. Nanotehnologii v stroitel’stve = Nanotechnologies in Construction. 2016; 8(4): 42–67. https://doi.org/10.15828/2075-8545-2016-8-4-42-67

- Li H., Jiang X., Cui H., Wang F., Zhang X., Yang L., Wang C. Investigation on the co-pyrolysis of waste rubber/plastics blended with a stalk additive. Journal of Analytical and Applied Pyrolysis. 2015; 115: 37–42. https://doi.org/10.1016/j.jaap.2015.07.004

- Lu W., Guo Y., Zhang B. Co-deoxy-liquefaction of willow leaves and waste tires for high-caloric fuel production. Journal of Analytical and Applied Pyrolysis. 2018; 35: 327-339. https://doi.org/10.1016/j.jaap.2018.08.020

- Wang Y., Dai L., Fan L., Duan D., Liu Y., Ruan R., Yu Z., Liu Y., Jiang, L. Microwave-assisted catalytic fast co-pyrolysis of bamboo sawdust and waste tire for bio-oil production. Journal of Analytical and Applied Pyrolysis. 2017; 123: 224–228. https://doi.org/10.1016/j.jaap.2016.11.025

- Rolland A., Sarda A., Colomines G., Madec Y., Queffelec C., Farcas F., Chailleux E., Leroy E. Biobased bitumen analogue formation during hydrothermal treatment of microalgae residues, part 2: Influence of residence time on reaction products. Journal of Analytical and Applied Pyrolysis. 2020; 152: 104940. https://doi.org/10.1016/j.jaap.2020.104940

- Ahmad N., Abnisa F., Wan Daud W. M. A. Synthesis of valuable intermediate products from natural rubber under supercritical alcohol conditions. Journal of Analytical and Applied Pyrolysis. 2019; 139: 196-204. https://doi.org/10.1016/j.jaap.2019.02.004