Properties of Nano Engineered Concrete Subjected to Accelerated Corrosion

Автор: A. Maher El-Tair, M.S. El-Feky, Alaa Mohsen, M. Kohail

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 5 Vol.13, 2021 года.

Бесплатный доступ

Introduction. Many research had worked on improving the performance of concrete subjected to severe environment and improve concrete corrosion resistance. Using nano-materials is one of the methods had been used recently to improve concrete properties. In this research, a comparison between the performance of nano-silica and nano-clay in enhancing the durability properties of concrete was investigated. Methods and Materials. The experimental program was carried out through examining water absorption, water permeability, rapid chloride penetration test, corrosion resistance, bond strength of steel rebar before and after subjected to corrosion, and finally microstructure test. Nano-silica and nano-clay were added at 1%, 3%, and 5% as a partial replacement by weight of cement. Results. Both nano-silica and nano-clay showed significant performance in reducing the permeability and porosity of concrete and improve corrosion resistance of concrete. For comparison, nano-clay had a significant impact than that of nano-silica on concrete properties; in which the water permeability resistance of nano-clay mixes was enhanced by 87% than that of the control mix, while for nano-silica, it was 51% only. The chloride ion penetration was reduced by 72% for nanoclay mixes, while in nano-silica was 28%. Discussion. Nano-clay had a significant effect than that of nano-silica on the concrete durability properties; the flat-shaped of nano-clay particles had improved the microstructure of the cement matrix through the damping effect, besides the filling effect through the microstructure of the matrix which reduces the chloride ion penetration and improves water absorption and permeability of concrete. Conclusion. The optimum percentage of nano-silica is 1% by weight of cement as a partial replacement of cement by weight. However, for nano-clay is 5%, which gives the best performance in improve the durability properties of concrete.

Nano-silica, nano-clay, permeability, chloride penetration, bond strength, corrosion resistance, microstructure analysis

Короткий адрес: https://sciup.org/142228307

IDR: 142228307 | DOI: 10.15828/2075-8545-2021-13-5-293-305

Текст научной статьи Properties of Nano Engineered Concrete Subjected to Accelerated Corrosion

Original article

T he construction revolution occurred in Egypt in the last 6 years, starting with the digging of the new Suez

Canal and the development projects all over Egypt, from the development of the east bank of the Suez Canal and to the construction in new coastal cities as New Allamin City [1, 2]. In addition to, the new extension of Port-Said and Damietta ports requires a new technique and new materials to be added in the construction industry. Also, introducing a new and optimized technique to improve concrete resistance to corrosion of the steel rebars [3–5].

Steel rebar corrosion is one of the major problems that cause deterioration and reduce the service life of concrete structures [6–8]. The presence of chloride ions or sulfates from seawater or air can penetrate and destroy the passive film formed by concrete [9–12]. By improving the cement matrix's microstructure to reduce the porosity and permeability of concrete [13–18].

Using supplementary cementing materials in the micro-scale as silica fume, fly ash, coal ash, and ground blast furnace slag had been studied in the last decades to improve the microstructure and to reduce the porosity of the cement matrix and studied their effect in improving the corrosion resistance of concrete [19–26]. Using

CONSTRUCTION MATERIAL SCIENCE supplementary materials in nano-scale is one of the hot topics these days to enhance the cement matrix's porosity andimprove the strength of the Interfacial Transition Zone (ITZ) [27–34].

Nano-Silica (NS), Carbon nanotubes (CNTs), Nano-Clay (NC), Nano-Cellulose (NCL) are one of the available nano-materials in the construction industry; however, nano-clay is the most available nano-materials in the Egyptian market as it is locally produced. These nano-materials are added as a replacing material to cement by weight to improve the mechanical and durability properties of concrete; through filling, pozzolanic, and nucleation effect of the nano-materials [35–43]. One of the main problems that nano-materials face in the construction industry, besides its high cost, is the consistency of concrete, where adding nano-materials to concrete had a negative effect on its workability [15–17]. Many researchers had worked on improving the workability of the nano-materials, generally, in concrete and enhance their dispersion in the cement matrix [35]. Some researchers had introduced the sonication process, especially the indirect sonication method, which was the optimum method to improve the dispersion of the nanomaterials in the cement matrix [39, 40, 44]. The researchers found that every nano-materials had a specific concentration, with a corresponding indirect sonication time that must be applied before adding to concrete [13, 14, 35, 44, 43]. In this research program, a comparison will be carried out to investigate the individual performance of nano-silica and nano-clay on improving the porosity and corrosion resistance of concrete through absorption test and permeability test, in addition to their impact on the bond strength between the steel rebar and concrete before and after subjected to corrosion through a pull-out test. In addition, a microstructure test will be applied through Scanning Electron Microscopy (SEM) to study the effect of nano-silica and nano-clay in improving the microstructure of the cement matrix.

2. EXPERIMENTAL PROGRAM

2.1. Materials

2.2. Mix design proportions

Ordinary Portland Cement (CEM I) with a grade of 42.5 N, complying with the requirements of ASTM

Table 2

Physical Properties of Sand and Crushed Dolomite

|

Property |

Sand |

Dolomite |

|

Specific Weight (kg/m 3 ) |

2.89 |

2.76 |

|

Bulk Density (kg/m 3 ) |

1.67 |

1.82 |

|

Fineness Modulus |

2.75 |

|

|

Water Absorption % |

– |

1.85 |

|

Crushing Value % |

– |

14.3 |

|

Clay and Fine Dust Content % |

1.95 |

0.55 |

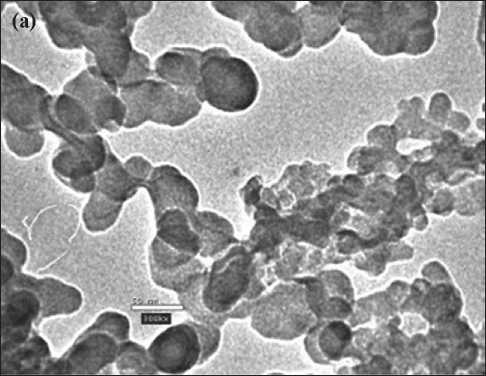

C150 [45] standard, was used. Table 1 shows the chemical composition of used cement. Natural sand was used complying with ASTM C33 [46] with a particle size less than 0.5 mm, and specific gravity of 2.58 g/cm 3 . Table 2 shows the properties of fine aggregate used. Crushed dolomite is used as a coarse aggregate, with an average size of 12 mm and a specific surface area of 2.76 g/cm 3 . The mixes consist of 35% fine sand and 65% crushed dolomite by total aggregate weight. Nano-silica is used with white colorand with particles size ranges between10 nm and 15 nm. The chemical properties of nano-silica are shown in Table 1. Nano-clay used was off-white in colorand with an average particles size of 30 nm. The chemical composition of nano-clay is shown in Table 1. The high value of L.O.I of nano-clay can be due to the evaporation of the physical combined water. Nano-Silica and Nano-clay were produced by the physics department in National Research Center in Egypt. Figure 1 shows the SEM of nano-silica and nano-clay particles, as the shape of nanosilica particles is spherical while nano-clay particles are hexagonal shape (platelet). The superplasticizer used is a polycarboxylate solution of type G.

In this research, seven concrete mixes were used; control mix, three mixes using nano-silica as a partial replacement of cement with different percentages (1, 3, and 5%), three mixes using nano-clay the same as used in nano-silica mixes. Nano-silica and nano-clay were both subjected to indirect sonication (bath sonicator). Nano-

Table 1

Chemical Composition of Cement, Nano-Silica, and Nano-Clay (%)

|

SiO2 |

Fe 2 O 3 |

Al 2 O 3 |

CaO |

MgO |

TiO2 |

Na2O |

K 2 O |

P2O |

L.O.I |

|

|

Cement |

20.13 |

3.61 |

5.32 |

61.63 |

2.39 |

– |

0.37 |

0.13 |

– |

1.96 |

|

NS |

99.1 |

0.06 |

0.13 |

0.14 |

0.11 |

– |

0.4 |

– |

0.01 |

|

|

NC |

61.24 |

1.06 |

20.89 |

0.16 |

0.22 |

1.61 |

0.71 |

– |

– |

14.11 |

Table 3

Concrete Mixes Proportions (kg/m3)

|

Mix |

Cement |

Aggregate |

Water |

SP |

NS |

NC |

|

C |

450 |

1706 |

192 |

2.7 |

– |

– |

|

1% NS |

445.5 |

1706 |

192 |

2.7 |

4.5 |

– |

|

3% NS |

436.5 |

1706 |

192 |

2.7 |

13.5 |

– |

|

5% NS |

427.5 |

1706 |

192 |

2.7 |

22.5 |

– |

|

1% NC |

445.5 |

1706 |

192 |

2.7 |

– |

4.5 |

|

3% NC |

436.5 |

1706 |

192 |

2.7 |

– |

13.5 |

|

5% NC |

427.5 |

1706 |

192 |

2.7 |

– |

22.5 |

CONSTRUCTION MATERIAL SCIENCE

Fig. 1. SEM micrographs of (a) nano-silica (50 µm) and (b) nano-clay (10 µm) particles

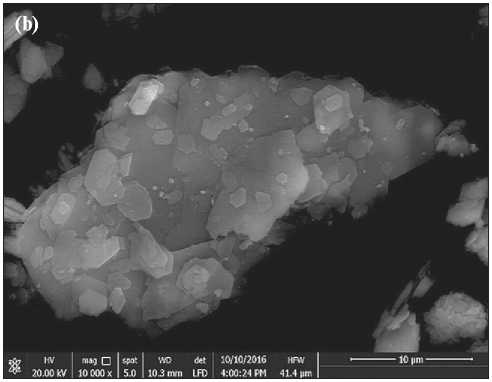

silica were added to the mix in a solution with a concentration of 1:10 and subjected to ultrasonic waves for 5 minutes, as reported by [13,14]. While nano-clay was used in a solution with a concentration of 1:4, with an indirect sonication time of 10 minutes, as reported by [39, 43]. Indirect sonication was performed using a bath sonicator, as shown in Figure 2, with a constant power of 135W and frequency of 40 kHz [44]. The water to binder ratio was a constant value of 0.35 for all mixes. Table 3 shows the mix proportions of the concrete mixes.

2.3. Mixing procedures

Half of the mixing water was added to the cement for the control mix and mixed for 2 minutes in a turn-tilt mixer. Then the second half of mixing water was added to the mix and continue mixing for 3 minutes. Fine aggregate was added and mixed for 2 minutes, and finally, crushed dolomite was added and mixed for 3 minutes. A preparation step for the solution was carried out before the mixing process for nano-silica and nano-clay mixes. Both nano-silica and nano-clay, individually, were sub-

Fig. 2. Bath sonicator jected to ultra-sonic waves through a bath sonicator; each one was subjected to a specific sonication time and concentration ratio. As mentioned before, nano-silica was added to mixing water with a concentration ratio of 1:10 and subjected to ultrasonic waves for 5 minutes.

CONSTRUCTION MATERIAL SCIENCE

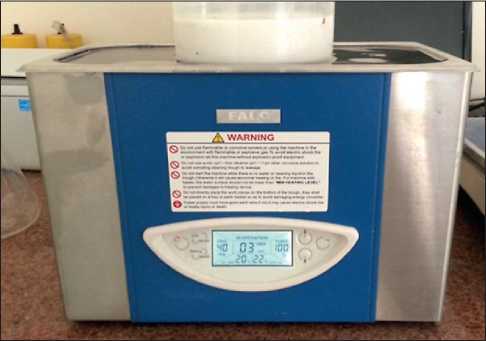

Fig. 3. A schematic drawing for the bond test sample

While the concentration ratio for a nano-clay solution was 1:4 and sonicated for 10 minutes. After that, the mixing process starts through dry mixing of cement, then the nano-solution was added and mixed for 3 minutes. The remaining mixing water was added to the mix with the superplasticizer and continued mixing for another 3 minutes. Then both fine and coarse aggregate was added as done in the control mix.

2.4. Preparation of the specimens, curing, and tests

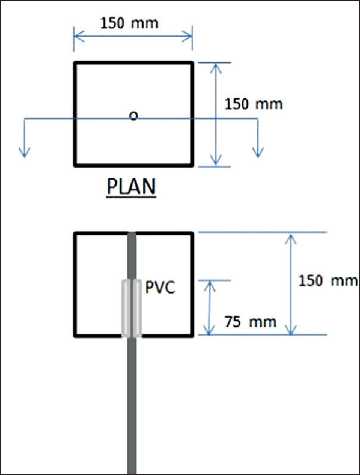

After the mixing process had finished, cubes of (150 x 150 x 150) mm 3 were cast for water permeability test [47], bond strength [48], and corrosion resistance [49] tests after 28 days. For both bond and corrosion tests, steel rebar

Fig. 5. Vacuum chamber

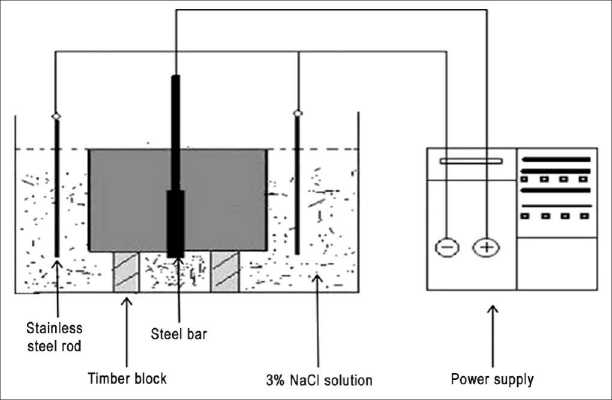

Fig. 4. A schematic drawing for the corrosion test

of diameter 12 mm was embedded in the cube to check the effect of nano-silica and nano-clay in enhancing the bond of the steel rebar in normal conditions and after subjecting to corrosion. Three specimens were prepared for each test, and the final result is the average between them. A 75 mm length of polyvinyl chloride tubing is utilized to de-bond the steel rebar rooted inside the specimen, making the bond sliding failure dominate over other types of failure like splitting and yielding steel rebar, as shown in Figure 3. Figure 4 shows the setup of the corrosion test. While the rapid chloride penetration test was carried according to ASTM C1202 [50]. The specimen used in this test is a cylinder specimen with a diameter of 100 mm and a height of 50 mm. the specimen was coated with epoxy, then placed in a vacuum chamber for 3 hours to remove the humidity from the specimen before testing, as shown in Figure 5. While the chloride penetration test set-up is shown in Figure 6. A microstructure test was carried out to check the effect of nano-silica and nano-clay on the microstructure of the cement matrix through Scanning Electron Microscope (SEM).

Fig. 6. Rapid chloride penetration test setup

CONSTRUCTION MATERIAL SCIENCE

3. RESULTS AND DISCUSSION

3.1. Water absorption test

3.2. Water Permeability Test

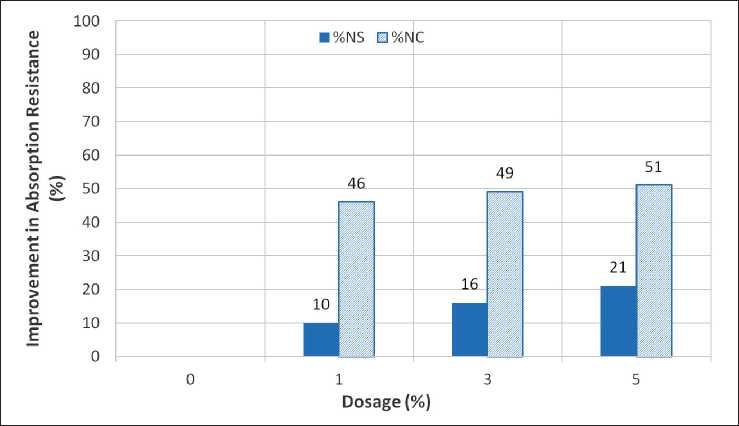

Figure 7 shows a comparison between the effect of adding nano-silica and nano-clay on the absorption of concrete. Where both nano-silica and nano-clay had a positive impact in reducing the absorption of concrete. From Figure 7, it is clear that the impact of nano-clay in reducing the porosity and absorption of concrete is more significant than that with nano-silica. As the absorption of nano-silica, at 5% replacement with nano-silica, was reduced by 21% than that in the control mix, while in the nano-clay mix, the reduction of the absorption was by 51% at 5% nano-clay. These can be attributed to the filling effect, which plays a vital role in this property, where the nano-particles fill the internal pores in the cement matrix and improve its microstructure to become more denser and uniform as will be discussed later in the microstructure analysis. The more significant effect of nano-clay than that of nano-silica can be attributed to the flax shape of clay nano-particle that gives nano-clay an extra advance, which is the damming effect between the micro and nano-particles of the cement matrix.

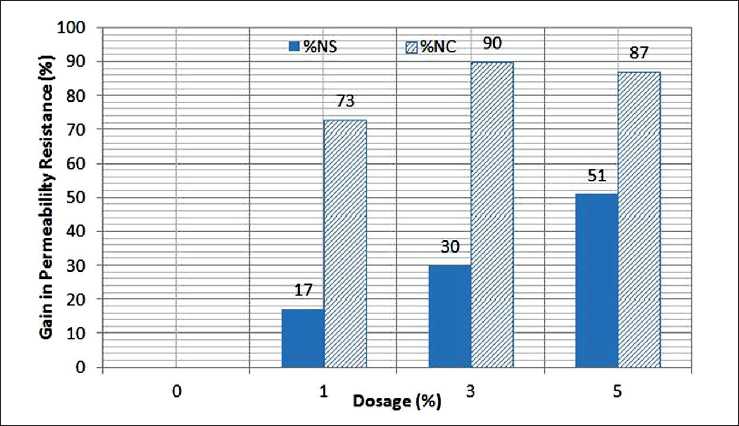

Figure 8 represents a comparison between the impact of nano-silica and nano-clay on the permeability of concrete. The results obtained exhibit the same trend as

Fig. 7. Improvement in the absorption resistance for nano-silica and nano-clay concrete

Fig. 8. Gain in water permeability resistance of nano-silica and nano-clay concrete

CONSTRUCTION MATERIAL SCIENCE in the water absorption test, as the effect of adding both nano-silica and nano-clay had reduced the permeability of concrete. This reduction can be attributed to the filling effect of both nano-silica and nano-clay, the pozzolanic effect in which reacting with the excess Ca(OH)2 forming more C–S–H, which improve the homogeneity of ITZ, and the nucleation effect of nano-silica and nano-clay, resulting in densifying the microstructure of the cement matrix. The damming effect of clay nano-particles had blocked the nano-voids in the cement matrix, resulting in a more homogenous cement matrix and, hence, reduced the permeability of concrete.

3.3. Chloride Penetration Test

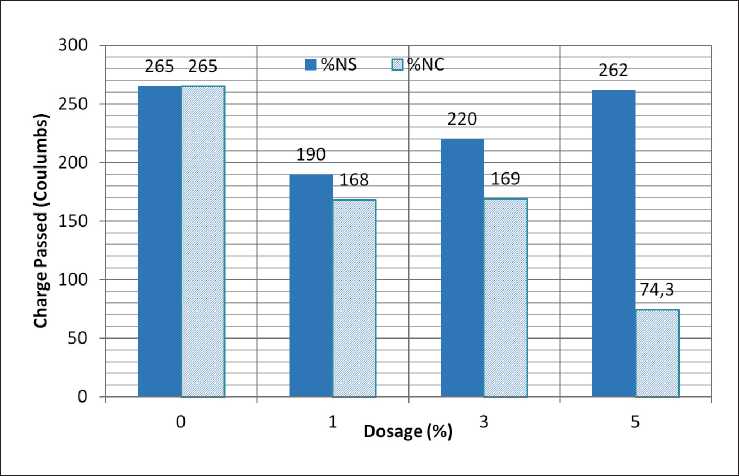

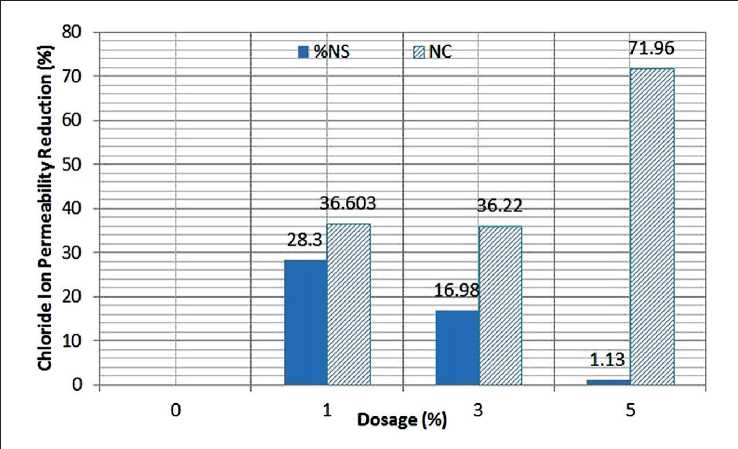

Figures 9 and 10 show the charges passing through the control, nano-silica and nano-clay concrete with different dosages. For nano-silica concrete, at 1% of nano-silica, the charges passed reduced by 28% than the control mix and then the charges increase again until it reached 262 coulombs with an unremarkable reduction of 1%. This can be attributed to the fact that the nanosilica filling effect had a significant impact on absorption and permeability properties. Whereby increasing nanosilica percentage agglomeration occurred to silica nano-

Fig. 9. Coulombs passed vs. nano-silica and nano-clay content

Fig. 10. Reduction of Coulombs passed of concrete with nano-silica and nano-clay content

CONSTRUCTION MATERIAL SCIENCE particles, which negatively impacted the homogeneity of the microstructure of the cement matrix; in other words,a large amount of nano-silica cannot be distributed well even after being subjected to sonication. As mentioned before in section 2.2. the concentration was 1:10, and as reported by Sharobim et al. [13, 14], the optimum percentage was 1:10. In which sonication will be difficult at higher percentages and not effective.

While at nano-clay concrete, as increasing nano-clay percentages the coulombs passed reduced. This can be attributed to the fact that the optimum percentage for nano-clay is 5% by weight of cement. In addition to, the filling, pozzolanic, and nucleation effect of clay nanoparticles improve the microstructure of the ITZ and make it more homogenous, as reported by Nehal et al. [39]. Plus, the damming effect is the result of the clay particle shape, in which the microstructure of the ITZ became more homogenous and denser.

3.4. Corrosion Resistance

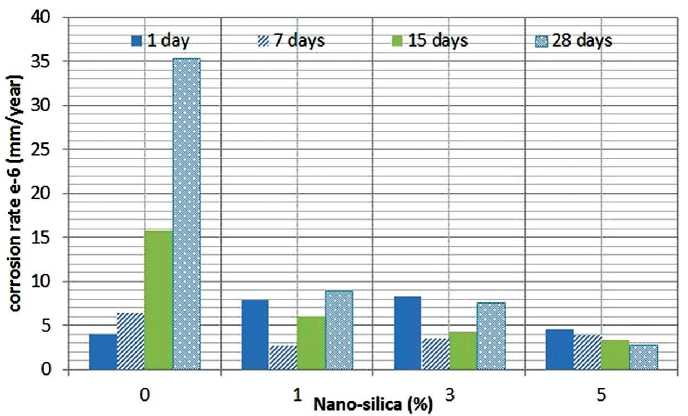

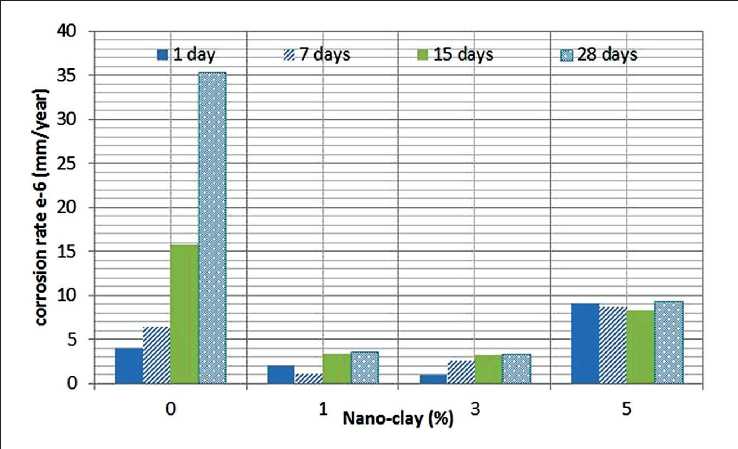

The addition of both nano-silica and nano-clay to concrete had improved the corrosion resistance of concrete than that without any additive. Figures 11 and 12

Fig. 11. Effect of nano-silica content on the corrosion rate of concrete

Fig. 12. Effect of nano-clay content on the corrosion rate of concrete

CONSTRUCTION MATERIAL SCIENCE showed the individual effect of nano-silica and nano-clay in reducing the corrosion rate of the steel rebar. This behavior can be attributed to the positive impact of nanosilica and nano-clay in improving the microstructure of the cement matrix. In addition, the sonication process enhances the dispersion and homogeneity of these nano particles and reduces the porosity of the interfacial transition zone of the cement matrix. The filling effect property of both nano-silica and nano-clay fills the nano-pores and reduces the porosity of the cement matrix, in addition to the pozzolanic effect, which improves the cement matrix's microstructure. However, the damping effect of the flatshape of clay nano-particles reduces the cement matrix's porosity. These results agreed with Kelestemur et al. [51] and Eskandari et al. [52].

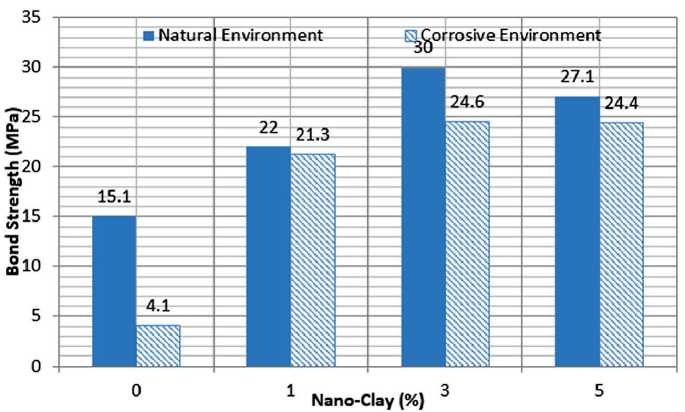

3.5. Bond strength

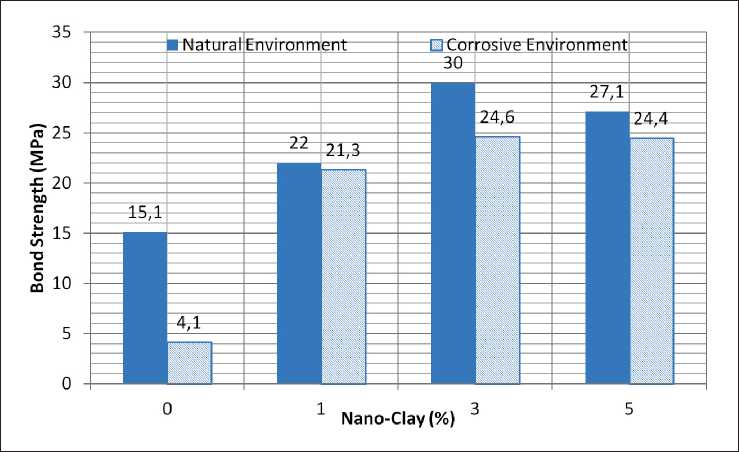

Figures 13 and 14 show the bond strength of a 12 mm steel rebar for nano-silica and nano-clay concrete before and after being subjected to a corrosive environment. The failure for all concrete specimens was a pullout failure. For nano-silica concrete mixes, as shown in Figure 10, the optimum percentages obtained for

Fig. 13. Bond strength of nano-silica concrete at the natural and corrosive environment

Fig. 14. Bond strength of nano-clay concrete at the natural and corrosive environment

CONSTRUCTION MATERIAL SCIENCE nano-silica was 1% as a partial replacement of cement. However, after being subjected to corrosion, the bond strength is enhanced by increasing nano-silica percentages; this can be attributed to the filling effect of silica nano-particles which improve the ITZ to make it more homogeneous and well-compacted and denser than that without nano-silica and reduce the spaces of the voids that aids the chlorides to attack the steel rebar. In addition, the pozzolanic reactivity of nano-silica improves the microstructure of the cement paste. On the other side in Figure 11, the effect of nano-clay is relatively more evident than that of nano-silica. This can be due to the formation of clay nanotubes, which will be illustrated in the microstructure analysis, which enhances the bond of the steel rebar even after being subjected to corrosion. That for sure, besides the filling, nucleation, pozzolanic, and damping effect of clay nano-particles, these findings agreed with those obtained byother researchers [51–54].

-

3.6. Microstructure Analysis

-

3.6.1. Scanning Electron Microscopy

-

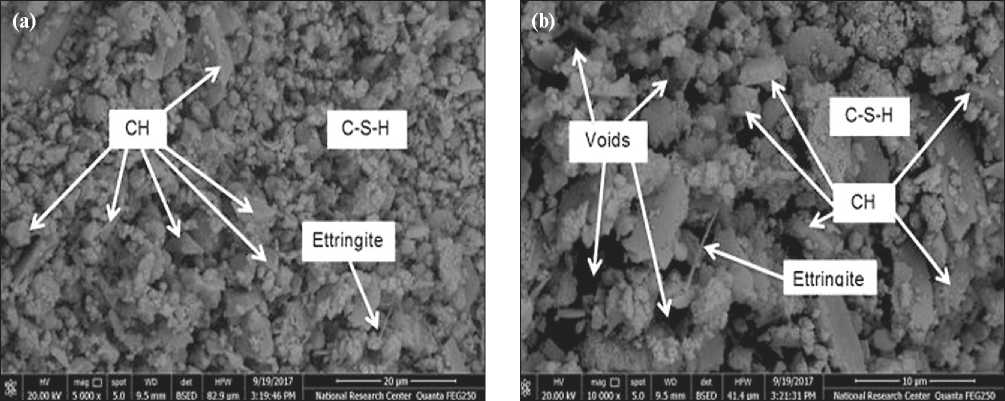

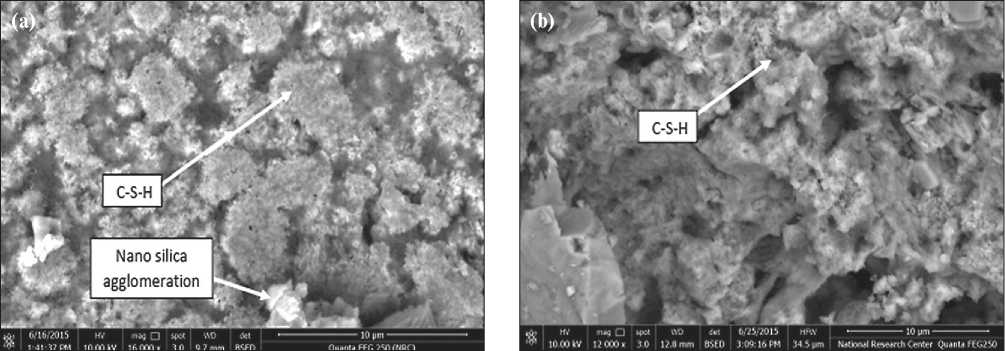

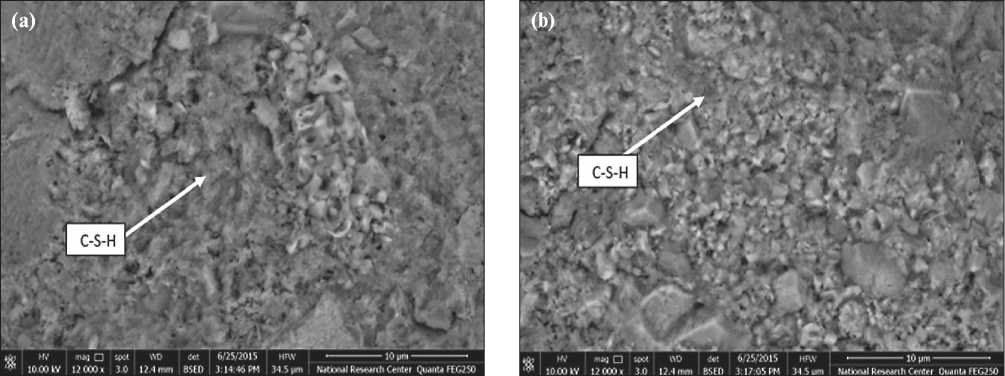

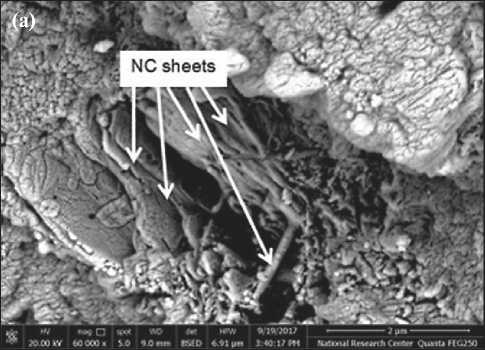

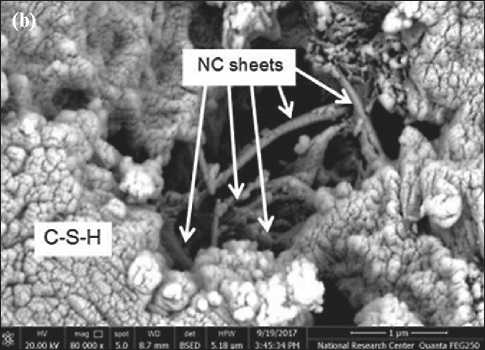

Figures 15, 16, 17, and 18 showed the microstructure analysis of the control, nano-silica and nano-clay mixes; the microstructure analysis had explained the results of the permeability, corrosion, and bond tests shown previously in this paper. Figures 15(a) and 15(b) show the control mix's microstructure; without any nano-materials, the control mix showed a relatively much weaker microstructure compared with the nano-silica nano-clay samples. Ettringite needles, voids, and calci- um hydroxide crystals are obvious in control, indicating a relatively weaker matrix. While in nano-silica mixes, the addition of nano-silica to the cement matrix had improved the homogeneity and the microstructure of the cement matrix, as shown in Figures 16 and 17. Figures 17(a) and 17(b) show the mixes with the optimum replacement percentage of 1% nano-silica by weight; it is clear that the microstructure had improved with the addition of nano-silica. The microstructure became more uniform and denser, attributed to the pozzola-nic and the filling effect of silica nano-particles, which produce more CSH crystals and minimize the void ratio within the cement matrix. These results agreed with [56–59]. However, adding nano-silica more than 1% wt. resulted in a relatively weaker microstructure, as shown in figures 16(a) and 16(b). this can explain the performance of nano-silica with a dosage of 5% in the corrosion, permeability, and bond test. This can be explained by reducing the pH value of concrete due to increasing the pozzolanic reactivity of nano-silica, resulting in reducing the amount of calcium hydroxide. For nano-clay specimens, the microstructure of the cement matrix had become denser and more uniform due to the filling and the pozzolanic effect of nano-clay, in addition to the pozzolanic effect. In figures 18(a) and 18(b) showed the formation of clay nano-tubes produced from the rolling of the plate shape of clay nanoparticles forming fibers needles in the nano-scale, which had a positive effect on the bond strength of steel rebar and explained the relatively high results of bond strength before and after corrosion than that of the nano-silica samples, this results agreed with obtained by other researchers [39, 31–33, 54].

Fig. 15. SEM Micrograph for control mix

CONSTRUCTION MATERIAL SCIENCE

Fig. 16. SEM Micrograph for nano-silica concrete at 5% nano-silica content

Fig. 17. SEM Micrograph for nano-silica concrete at 1% nano-silica content

Fig. 18. SEM Micrograph for nano-clay concrete at 5% nano-clay content

CONSTRUCTION MATERIAL SCIENCE

4. CONCLUSION

From the experimental work done through studying the individual effect of nano-silica and nano-clay, the following conclusions can be taken:

-

• The optimum percentage of nano-silica is 1% by weight of cement as a partial replacement of cement by weight. However, nano-clay can be taken by 5%.

-

• The filling effect of nano-clay and nano-silica improve the water absorption and permeability properties as by increasing their percentages, the porosity and the permeability of concrete are reduced.

-

• Nano-silica and nano-clay had improved the resistance of concrete to chloride pentation and steel rebar corrosion through the filling, pozzolanic, and nucle-

ation effect by enhancing the ITZ's homogeneity and producing more C–S–H gels.

Nano-clay had introduced an advanced performance than nano-silica in the chloride penetration resistance and corrosion resistance and steel rebar de-bonding through the damming effect of the flat-shape of clay nano-particlesin addition to the fiber effect of the produced clay nano-fibers.

Using nano-clay as a partial replacement to portend cement is more optimum than using Nano-silica due to its structural and durability performance and production cost as the production cost of nano-clay is much less than the production of nano-clay nanosilica by 70% due to the availability of nano-clay in the Egyptian market.

Список литературы Properties of Nano Engineered Concrete Subjected to Accelerated Corrosion

- “The Report Egypt 2016”, reported submitted by Oxford Business Group, www.oxfordbusinessgrouo.com.

- “Environmental and social impact assessment (ESIA) for Egyptian EETC 500 kV transmission lines project”, reported by EcoConServ, Sept. 2015.

- Angst U. M. Challenges and opportunities in corrosion of steel in concrete. Materials and Structures. 2018; 51(1): 1–20.

- QuraishiM. A., Nayak D. K., Kumar R., Kumar V. Corrosion of reinforced steel in concrete and its control: An overview. Journal of Steel Structures and Construction. 2017; 3(1): 1–6.

- Guevara B., Juárez C., Fajardo G., Castro-Borges P. Shear strength behaviour on corrosion damaged stirrups of reinforced concrete beams. RevistaIngeniería de Construcción. 2011; 24(3): 259–270.

- Angst U., Elsener B., Larsen C. K., Vennesland Ø. Critical chloride content in reinforced concrete – a review. Cement and concrete research. 2009; 39(12): 1122–1138.

- Moser R. D., Singh P. M., Kahn L. F., Kurtis K. E. Chloride-induced corrosion resistance of high-strength stainless steels in simulated alkaline and carbonated concrete pore solutions. Corrosion Science. 2012; 57: 241–253.

- Ahmad S. Reinforcement corrosion in concrete structures, its monitoring and service life prediction – a review. Cement and concrete composites. 2003; 25(4-5): 459-471.

- Gerengi H., Kocak Y., Jazdzewska A., Kurtay M., Durgun H. Electrochemical investigations on the corrosion behavior of reinforcing steel in diatomite-and zeolite-containing concrete exposed to sulphuric acid. Construction and Building Materials. 2013; 49: 471-477.

- Pradhan B., Bhattacharjee B. Rebar corrosion in chloride environment. Construction and Building Materials. 2011; 25(5): 2565–2575.

- Pradhan B., Bhattacharjee B. Performance evaluation of rebar in chloride contaminated concrete by corrosion rate. Construction and building materials. 2009; 23(6): 2346–2356.

- EGüneyisi E., Gesoğlu M., Karaboğa F., Mermerdaş K. Corrosion behavior of reinforcing steel embedded in chloride contaminated concretes with and without metakaolin. Composites Part B: Engineering. 2013; 45(1): 1288–1295.

- Sharobim K. G., Mohammedin H., Hanna N. F., El-Feky M. S., Khattab E., El-Tair A. M. Optimizing sonication time and solid to liquid ratio of nano-silica in high strength mortars. Int J Curr Trends Eng Res. 2017; 3: 6–16.

- Sharobim K. G., Mohamadien H. A., Hanna N. F., El-Feky M. S., Khattab E., El-TairA. M. Optimizing sonication time and solid to liquid ratio of nano-silica in high strength concrete. Int J SciEng Res. 2017; 8: 687–693.

- El-Feky M. S., El-Rayes M. The Effect of Nano Cellulose Synthesized from Rice Straw on the Performance of Cement Composite Reinforced with Carbon Nano Tubes. International Journal of Scientific & Technology Research. 2019; 8(10): 2401–2410.

- El-Feky M. S., El-Tair A. M., Kohail M., Serag M. I. Nano-fibrillated cellulose as a green alternative to carbon nanotubes in nano reinforced cement composites. Int J InnovTechnolExplor Eng. 2019; 8: 484–491.

- El-Feky M. S., Youssef P., El-Tair A. M., Ibrahim S., Serag M. Effect of nano silica addition on enhancing the performance of cement composites reinforced with nano cellulose fibers. AIMS Materials Science. 2019; 6(6): 864–883.

- El-Feky M. S., El-Khodary S. A., Morsy M. Optimization of hybrid cement composite with carbon nanotubes and nano silica using response surface design. Egyptian Journal of Chemistry, 62(The First International Conference on Molecular Modeling and Spectroscopy 19-22 February, 2019), 2019; 57–67.

- Hashem M. M., Serag M.I., Elkady H., El-Feky M. Increasing the reactivity of silica fume particles using indirect sonication: effect of process parameters. Civ Environ Res. 2015; 2: 537–557.

- Mohamadien, H. A. The Effect of marble powder and silica fume as partial replacement for cement on mortar. International journal of civil and structural engineering. 2012; 3(2): 418.

- Karaşin A., Doğruyol M. An experimental study on strength and durability for utilization of fly ash in concrete mix. Advances in Materials Science and Engineering, 2014.

- Zhou Q., Lu C., Wang W., Wei S., Lu C., Hao M. Effect of fly ash and sustained uniaxial compressive loading on chloride diffusion in concrete. Journal of Building Engineering. 2020; 31: 101394.

- Wang W., Lu C. Time-varying law of rebar corrosion rate in fly ash concrete. Journal of hazardous materials. 2018; 360: 520-528.

- Wang X. Y., Lee H. S. Effect of global warming on the proportional design of low CO2 slag-blended concrete. Construction and Building Materials. 2019; 225: 1140–1151.

- Yan X., Jiang L., Guo M., Chen Y., Song Z.,Bian R. Evaluation of sulfate resistance of slag contained concrete under steam curing. Construction and Building Materials. 2019; 195: 231–237.

- Teixeira E. R., Camões A., Branco F. G., Aguiar J. B., Fangueiro R. Recycling of biomass and coal fly ash as cement replacement material and its effect on hydration and carbonation of concrete. Waste Management. 2019; 94: 39–48.

- Duffó G. S., Reinoso M., Ramos C. P., Farina S. B. Characterization of steel rebars embedded in a 70-year old concrete structure. Cement and concrete research. 2012; 42(1): 111–117.

- Khan I., François R., Castel A. Prediction of reinforcement corrosion using corrosion induced cracks width in corroded reinforced concrete beams. Cement and concrete research. 2014; 56: 84–96.

- Elkady H.M., Yasien A.M., Elfeky M. S.,Serag M.E. Assessment of mechanical strength of nano silica concrete (NSC) subjected to elevated temperatures. Journal of Structural Fire Engineering. 2019.

- Batis G., Pantazopoulou P., Tsivilis S., Badogiannis E. The effect of metakaolin on the corrosion behavior of cement mortars. Cement and Concrete Composites. 2005; 27(1): 125–130.

- BoradeA. N., KondraivendhanB. Effect of metakaolin and slag blended cement on corrosion behaviour of concrete. In: Proceedings of the 2nd international conference on civil engineering and materials science. 2017; 216.

- Siddique R., Klaus J. Influence of metakaolin on the properties of mortar and concrete: A review. Applied Clay Science. 2009; 43(3-4): 392–400.

- Ramezanianpour A.A., Jovein H.B. Influence of metakaolin as supplementary cementing material on strength and durability of concretes. Construction and Building materials. 2012; 30: 470–479.

- Gameiro A.L., Santos Silva A., Veiga M.D.R., Velosa A.L. Lime-metakaolin hydration products: a microscopy analysis. Materiali in tehnologije, 2012; 46(2): 145–148.

- Youssef P., El-Feky M.S., Serag M.I. The Influence of Nano silica surface area on its reactivity in cement composites. Int J SciEng Res. 2017; 8: 2016–2024.

- El-Feky M.S., El-Khodary S.A., Morsy M. Optimization of hybrid cement composite with carbon nanotubes and nano silica using response surface design. Egyptian Journal of Chemistry, 62(The First International Conference on Molecular Modeling and Spectroscopy 19-22 February, 2019). 2019; 57–67.

- Serag M.I., Yasien A.M., El-Feky M. S., Elkady H. Effect of nano silica on concrete bond strength modes of failure. Int J GEOMATE. 2017; 12: 2892–2899.

- El-Feky M. S., Serag M. I., Yasien A. M., Elkady H. Bond strength of nano silica concrete subjected to corrosive environments. ARPN Journal of Engineering and Applied Sciences. 2016; 11(23): 13909–13924.

- Hamed N., El-Feky M.S., Kohail M., Nasr E.S. A. Effect of nano-clay de-agglomeration on mechanical properties of concrete. Construction and Building Materials. 2019; 205: 245–256.

- El-Feky M.S., Youssef P., El-Tair A., Serag M. Indirect sonication effect on the dispersion, reactivity, and microstructure of ordinary portland cement matrix. AIMS Materials Science. 2019; 6(5): 781–797.

- Sikora P., Lootens D., Liard M., Stephan D. The effects of seawater and nanosilica on the performance of blended cements and composites. Applied Nanoscience. 2020; 1–18.

- AbdElrahman M., Chung S. Y., Sikora P., Rucinska T., Stephan D. Influence of nanosilica on mechanical properties, sorptivity, and microstructure of lightweight concrete. Materials.2019; 12(19): 3078.

- El-Tair A. M., El-Feky M. S., Sharobim K. G., Mohammedin H., Kohail M. Improving the reactivity of clay nano-partciles in high strength mortars through indirect sonication method. Int J SciTechnol Res. 2020; 9: 1045–1054.

- Elkady H., Serag M. I., Elfeky M. S. Effect of nano silica de-agglomeration, and methods of adding super-plasticizer on the compressive strength, and workability of nano silica concrete. Civil and environmental research. 2013; 3(2): 21–34.

- ASTM C150-02 Standard Specification for Portland cement, Annual book of ASTM standards, 2002.

- ASTM C33, Standard Specification for concrete aggregate.

- CRD-C48-92, Standard test method for water permeability of concrete.

- ASTM A944-10, Standard test method for comparing bond strength of steel reinforcing bars to concrete using beam-end specimens.

- ASTM C876-15, Standard test method for corrosion potentials of uncoated reinforcing steel in concrete.

- ASTM C1202, Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration.

- Keleştemur O., Demirel B. Effect of metakaolin on the corrosion resistance of structural lightweight concrete. Construction and Building Materials. 2015; 81: 172–178.

- Eskandari-Naddaf H., Ziaei-Nia A. Simultaneous effect of nano and micro silica on corrosion behaviour of reinforcement in concrete containing cement strength grade of C-525. Procedia Manufacturing. 2018; 22: 399–405.

- Serag M., Elkady H., Elfeky M. The effect of indirect sonication on the reactivity of nano silica concrete. International Jr. of scientific and engineering research, IJSER. 2014; 12: 334–345.

- Gamal H. A., El-Feky M. S., Alharbi Y. R., Abadel A. A., Kohail M. Enhancement of the concrete durability with hybrid nano materials. Sustainability. 2021; 13(3): 1373.

- Arandigoyen M., Alvarez J. I. Blended pastes of cement and lime: Pore structure and capillary porosity. Applied surface science. 2006; 252(23): 8077–8085.

- Shi J. J., Sun W. Effects of phosphate on the chloride-induced corrosion behavior of reinforcing steel in mortars. Cement and Concrete Composites. 2014; 45: 166–175.

- Civjan S. A., LaFave J. M., Trybulski J., Lovett D., Lima J., Pfeifer D. W. Effectiveness of corrosion inhibiting admixture combinations in structural concrete. Cement and Concrete composites. 2005: 27(6); 688–703.

- Ghasemi A.R., Parhizkar T., Ramezanianpour A.A. Influence of colloidal nano-SiO2 addition as silica fume replacement material in properties of concrete. In: Proceeding, Second international conference on sustainable construction materials and technologies. 2010, p. 28–30.

- Du H., Du S., Liu X. Effect of nano-silica on the mechanical and transport properties of lightweight concrete. Construction and Building Materials. 2015; 82, 114–122.