Properties of road bitumen after adding tecnical oil acid with ami doamine and imidazoline synthesed

Автор: Abbasov V.

Журнал: Science, Education and Innovations in the Context of Modern Problems @imcra

Статья в выпуске: 6 vol.8, 2025 года.

Бесплатный доступ

Amidoamines were synthesized using technical petroleum acid (TPA) and dieth ylenetriamines (DETA). These amidoamines were added in the amount of 0.5% and 1% to road bitumen. The quality indicators of the obtained bitumens were studied. It was found that the brittleness temperature of road bitumen is minus 180C, and after adding ad ditives this indicator becomes 280C and 300C.

Technical petroleum acids, d iethylenetriamines, amidoamines

Короткий адрес: https://sciup.org/16010816

IDR: 16010816 | DOI: 10.56334/sei/8.6.79

Текст научной статьи Properties of road bitumen after adding tecnical oil acid with ami doamine and imidazoline synthesed

© 2025 The Author(s). Published by Science, Education and Innovations in the context of modern problems (SEI) by IMCRA - International Meetings and Journals Research Association (Azerbaijan). This is an open access article under the CC BY license .

Bitumen is a mixture of organic liquids that are highly viscous, black, sticky, entirely soluble in carbon disulfide, and composed primarily of highly condensed polycyclic aromatic hydrocarbons.

Naturally occurring or crude bitumen is a sticky, tar-like form of petroleum which is so thick and heavy that it must be heated or diluted before it will flow. At room temperature, it has a consistencymuch like cold molasses [1]. Refined bitumen is the residual (bottom) fraction obtained by fractional dis- tillation of crude oil. It is the heaviest fraction and the one with the highest boiling point, boiling at525 °C (977 °F).

In British English, the word 'asphalt' refers to a mixture of mineral aggregate and bitumen (or tarmac in common parlance). The word 'tar' refers to the black viscous material obtained from the destructive distillation of coal and is chemically distinct from bitumen. In American English, bitumen is referred to as 'asphalt' or 'asphalt cement' in engineering jargon. In Australian English, bitumen is some- times used as the generic term for road surfaces. In Canadian English, the word bitumen is used to referto the vast Canadian deposits of extremely heavy crude oil [2]. , while asphalt is used for the oil refin-ery product used to pave roads and manufacture roof shingles.

Due to the 95% of roads covered in asphalt, it is the most widely recycled material in the U.S. by percentage and second only to concrete by tonnage (67.8 million tons of asphalt [3] to 140 million tons ofconcrete [4]).

According to an industry survey conducted by the Federal Highway Administration and the Na- tional Asphalt Pavement Association and released in 2011, more than 99% of the asphalt removed each year from road surfaces during widening and resurfacing projects is reused as part of new pavements, roadbeds, shoulders and embankments. When reclaimed asphalt pavement and shingles are reprocessed into new pavement mixtures, the liquid asphalt binder 716 – , | Issue 6, Vol. 8, 2025

Properties of road bitumen after adding tecnical oil acid with ami- doamine and imidazoline synthesed

Vaqif Abbasov

in the recycled material is reactivated, reducing the need for virgin asphalt binder. Using reclaimed materials also reduces demands on aggregate resources. Warm-mix asphalt technologies allow asphalt pavements to be produced at lower temperatures,which means reduced energy demands, as well as lower emissions during production and paving [5]. The largest use of asphalt/bitumen is for making asphalt concrete for road surfaces and accountsfor approximately 85% of the asphalt consumed in the United States. Asphalt concrete pavement materialis commonly composed of 5% bitumen cement and 95% aggregates (stone, sand, and gravel). Due to its highly viscous nature, bitumen cement must be heated so it can be mixed with the aggregates at the as- phalt mixing plant [6].

Most bitumens contain sulfur and several heavy metals such as nickel, vanadium, lead, chromium, mercury and also arsenic, selenium, and other toxic elements. Bitumens can provide good preservation of plants and animal fossils. The primary use (70%) of asphalt/bitumen is in road construction, where itis used as the glue or binder mixedwith aggregate particles to create asphalt concrete. Its other main uses are for bituminous waterproof- ing products, including production of roofing felt and for sealing flat roofs [7]. Bitumen can now be made from non-petroleum based renewable re- sources such as sugar, molasses and rice, corn and potato starches. Bitumen can also be made from waste material by fractional distillation of used mo- tor oils, which is sometimes disposed by burning or dumping into land fills.

Non-petroleum based bitu- men binders can be made lightcolored. Roads made with lighter-colored pitch absorb less heat from solar radiation, and become less hot than darker surfaces,reducing their contribution to the urban heat island effect [8].

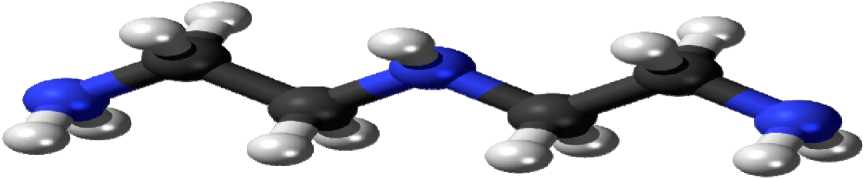

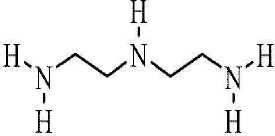

At the present our research work deal with to improve bitumen properties. We took tehnical oil acid and dyethyelenetriamine as raw,because they are very cheap and have very good results.At the result of process of dyethylenetriamine with acidic oil at 140°C temperature obtained amidoamines are sepa- rated two parts. Amidoamines which first part additives to bitumens, second part are being continued at 220 °C for 3-4 hours and become imidazoline. Diethylenetriamine ChemSpider ID: 13835401 Molecular Formula: C 4 H 13 N 3

Average mass: 103.166 Da

Monoisotopic mass: 103.110947 DaSystematic name

N-(2-Aminoethyl)-1,2-ethanediamine

Carbon, C: black Hydrogen, H: white Nitrogen, N: blue

Naphthenic acid second raw material for the amidoamine and imidazoline is very cheap. Naphthenic acids (NAs) are water soluble weak acids, with the general chemical formula CnH2n+zO2, where n is the carbon number, z is referred to as hydrogen deficiency, is a negative even integer and is the number of hydrogen atoms that are lost as the number of rings in naphthenic acid increases. More than one isomer will exist for a given z homolog and the molecular weights differ by 2 mass units (H2) be- tween z-series and by 14 mass units (CH2) between n-series. The number of possible naphthenic acids, with the same molecular com- position, are 134 with n ranging from 6 to 30 and the number of satu- rated rings ranging from 0 to 6. Fig.1 shows examples of the general

The quality properties of amidoamine and imidazoline synthesed additives have been learned and showed table 1.

Table 1. Physical and chemical properties ofadditives

|

Synthesized additives |

Kinematic viscosity mm2/s,100C |

Mass of ash,% |

Density 20°C-d ə kg/m3 |

Freezing point, °C |

|

Amidoamine TNT(280-340): DETA 1:1 molar ratio |

36,13 |

0,02 |

1,001 |

+4 |

|

Amidoamine TNT(280-340): DETA 2:1 molar ratio |

50,72 |

<0,002 |

0,9950 |

+5 |

|

Amidoamine TNT(280-340): DETA 3:1 molar ratio |

27,84 |

<0,002 |

0,9731 |

+10 |

|

Imidazolin TNT(280-340):DETA 1:1 molar ratio |

20,15 |

<0,002 |

0,986 |

+5 |

|

ImidazolinTNT(280-340): DETA 2:1 molar ratio |

104,8 |

0,003 |

0,992 |

+7 |

The primary method for bitumen classification in the European standardisation framework is the penetration test at 25°C.The test involves the determination of bitumen consistency expressed as the dis- tance that a standardised steel needle penetrates vertically into a bitumen sample at a specific tempera- ture. The needle load is 100 g, and the loading time equals 5 seconds.

Table 2. The quality properties ofroadbitumen after adding additives

|

Synthesized additives |

Softening point,ºC |

Penetration P 25 ,0,1mm |

Tension 13°C,sm |

Brittleness,ºC |

||||

|

Road bitumen BND 60/70 |

48,5 |

58 |

10 |

-18 |

||||

|

Additives, % |

0,5 |

1 |

0,5 |

1 |

0,5 |

1 |

0,5 |

1 |

|

Amidoamine TNT(280-340):DETA 1:1 molar ratio |

50,5 |

51 |

58 |

52 |

12 |

8,8 |

-28 |

-20 |

|

Amidoamine TNT(280-340): DETA 2:1 molar ratio |

48,5 |

49,5 |

60 |

61 |

12 |

15 |

-25 |

-27 |

|

Amidoamine TNT(280-340): DETA 3:1 molar ratio |

49,5 |

49 |

51 |

53 |

13 |

12 |

-30 |

-28 |

|

Imidazolin TNT(280-340): DETA 1:1 molar ratio |

49,5 |

50 |

55 |

56 |

10 |

12 |

-20 |

-23 |

|

Imidazolin TNT(280-340): DETA 2:1 molar ratio |

48,5 |

49 |

59 |

60 |

11 |

10 |

-24 |

-25 |

The softening point is adopted as the average temperature at which both bitumen rings soften to thepoint that each ball, covered in bitumen and overcoming its resistance, travels a distance of 25.0 mm ± 0.4 mm.

The breaking point determines low-temperature bitumen properties and represents an approximate (conventional) lower limit of viscoelastic consistency.This has given rise to the partially adapted ductilitytest. It is called the elastic recovery test. The test involves the determination of a conventional expressionof bitumen elasticity being the distance between ends of a stretched and cut sample under pre-set condi- tions. A bitumen sample is stretched at a specified temperature (typically at 25°C or 10°C) at a constant speed of 50 mm/min., until its elongation reaches 200 mm.