Research on Adaptive Fuzzy PID Synchronous Control Strategy of Double-Motor

Автор: Biao YU, Hui ZHU, Chi XUE

Журнал: International Journal of Intelligent Systems and Applications(IJISA) @ijisa

Статья в выпуске: 5 vol.3, 2011 года.

Бесплатный доступ

The double-motor synchronous control system is widely used in industrial field. Its performance plays an important role in production. Traditional PID controller parameters are difficult to tune when used in control system, as well as the control effect can not satisfy the requirement of producing process when the controller plant is complex non-linear system. In this paper, adaptive fuzzy PID which can tune the parameters on-line is introduced to apply in the double-motor synchronous control system. In MATLAB / SMULINK simulation environment, the speed of master motor is perfectly followed by slave motor, and high robustness and precision are obtained. The simulation results show that fuzzy logic PID control strategy has better performances than traditional controller.

Adaptive fuzzy PID, synchronous control, simulation, double-motor

Короткий адрес: https://sciup.org/15010221

IDR: 15010221

Текст научной статьи Research on Adaptive Fuzzy PID Synchronous Control Strategy of Double-Motor

Published Online August 2011 in MECS

The large output power is required for the long production line, conveyor line or assembly line in the industrial producing process, but single motor output torque is difficult to achieve. So in certain situations, such as steel continuous casting machine, cold rolling mill (heat), textiles, dyeing machine, paper machine, two or even more motors are necessarily applied to complete the control tasks synchronously and coordinately[1]. High-performance synchronous control can improve the production’s quality of many industries such as textile, metallurgy, machinery, papermaking, printing, packaging, bottle manufacturing and so on. The synchronous performance double-motor or even multi-motor impact on production efficiency and product quality directly. Therefore, the research on the synchronous control has a very important practical significance.

There are several synchronous control strategies in recent years, including parallel control, master slave control, cross coupling control, relative coupling control. These synchronous control strategies can be applied in different occasions flexibly for they have their own advantages [2].

The core of synchronous control strategies is the synchronous control algorithm. The traditional PID controller with simple structure and stable performance is widely used. But it is difficult to meet the high precision and fast response, moreover the parameters tuning of traditional PID controller is so complex and inconvenient. Therefore fuzzy adaptive algorithm is introduced. Fuzzy control is a reflection of the intelligent control strategy of human wisdom. The best feature of this strategy is it expresses the experience and knowledge of the experts as linguistic control rules and use these control rules to control the system, so that the plant can be controlled independent of the exact mathematical model, and the parameters are tuned on-line automatically. The control strategy is introduced in this paper combines fuzzy control toolbox in MATLAB /SIMULINK organically, achieving the modeling and simulation of parameter selftuning fuzzy PID controller for double-motor speed synchronous control system. The simulation results show that the fuzzy self-tuning controller have a better synchronous control performance than the traditional PID controller.

-

II. Master-Slave Control Method

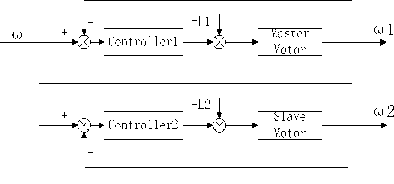

The control method called Master-Slave control is applied in the synchronous controller of double-motor. Its main characteristic is that the revolving speed output of the master motor will be the reference value of the slave motor. Any input signal or disturbance on the master motor can be reflected and followed by the slave motor. On the contrary, the disturbance from the slave motor will never affect the master motor. This control method has great superiority when the dynamic performance of the two motors is much different, and good control effect can be obtained. The simple structure of this control method is shown in the Fig.1

Figure 1. The simple structure of Master-Slave control method

-

III. Adaptive Fuzzy PID Control System

-

A. The Structure of Control System

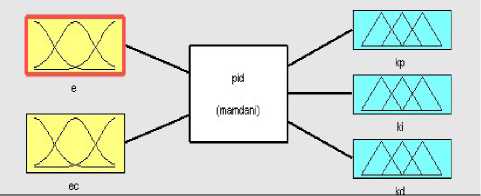

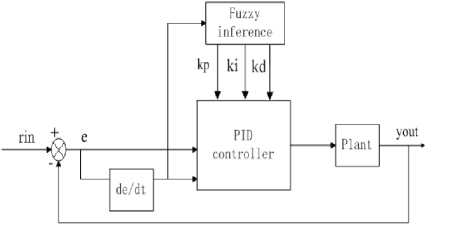

Fuzzy adaptive PID controller applies fuzzy control rules to modify PID parameters on-line using error e and change-in-error ec as inputs, which can meet the request of e and ec in different time for self-tuning PID parameters. The cores of fuzzy PID control system are fuzzy inference system and traditional PID controller.

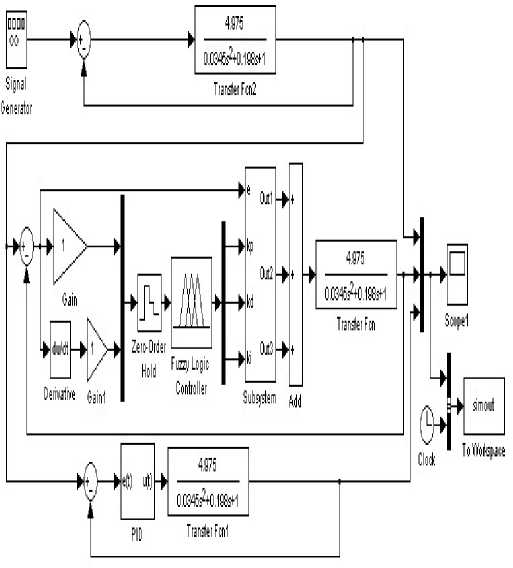

big (PB).The structure of fuzzy-PID control system in MATLAB is shown in Fig. 4.

Figure 4. Structure of fuzzy PID control system

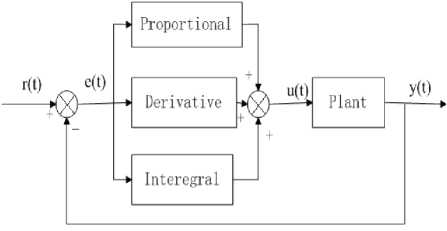

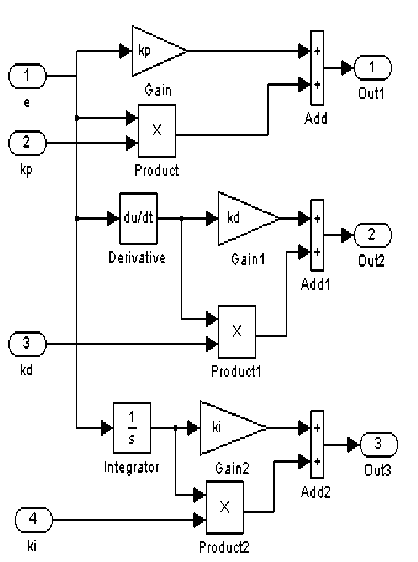

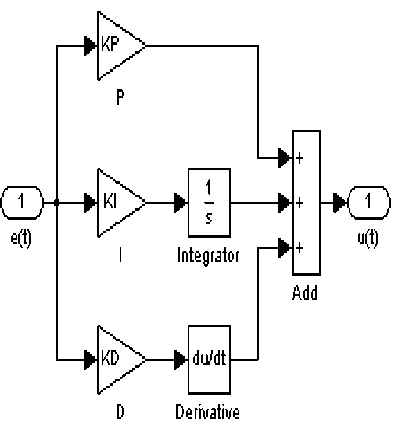

The diagram of PID controller and the diagram of a fuzzy control system are shown in Fig. 2. and Fig. 3[3-4].

Figure 2. Diagram of PID control system

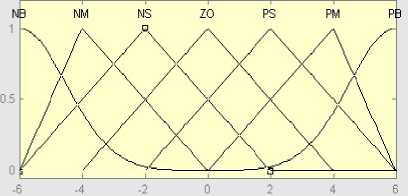

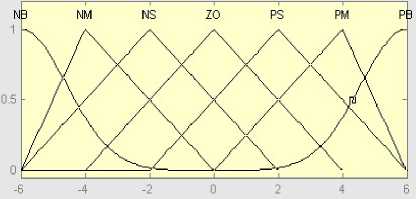

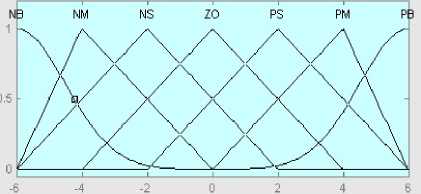

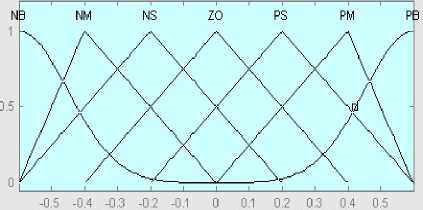

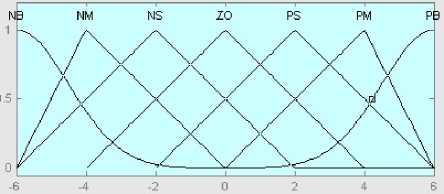

The membership functions for inputs and outputs are shown from Fig. 5 to Fig. 9.

Figure 5. The membership function for e

Figure 3. Diagram of fuzzy adaptive PID controller

Figure 6. The membership function for ec

Traditional PID controller is a kind of linear controller which constitutes the control error e ( t ) according to the given value r ( t ) and the actual output value y ( t ) , and it controls the plant by the control value u ( t ) which is the linear combination of e ( t ) ’s proportion , integral and derivative. The controller’s relationship of input and output can be described as (1):

u ( t ) = Ke ( t ) + K, Г e ( t ) d, + К4^ (1)

0 dt

Where K is the proportional gain, T is the integral pi gain, Td is the derivative gain.

-

B. Choosing Fuzzy Controller Inputs and Outputs

The fuzzy PID controller adopts two inputs and three outputs. Input variables are e and ec ; output variables are the proportional gain kp , the integral gain ki , the derivative gain kd .The domain of e , ec , kp , kd is {-6, -4,-2, 0, 2,4,6}, and ki is{-0.5,-0.4,-0.3,-0.2,-0.1,0,0.1,0.2,0.3,0.4,0.5}. The fuzzy subset of inputs and outputs linguistic variables are expressed as negative big (NB), negative middle (NM), negative small (NS), zero (ZO), positive small (PS), positive middle (PM), positive

Figure 7. The membership function for д kp

Figure 8. The membership function for д k^

Figure 9. The membership function for д kd

-

C. Design of Fuzzy Control Rules

The fuzzy control rule is the summary of the system control experience that captures the expert’s knowledge about how to control the plant, which directly affects the quality of control system [5-8]. In this paper, fuzzy control rules are designed with these tune principles as follows:

-

(1) When e > 0 , ec < 0 and e is large, in order to maintain a rapid response and make the absolute of error reduce in the maximum speed, kp should be bigger and ki , kd should be smaller; with the decrease of e , to prevent the overshoot be too big, kd should be added and kp , ki should be diminished, evenly, ki should be cancelled.

-

(2) When e < 0 , ec > 0 , the system is over steadystate and the error is increasing, in order to decrease the overshoot, kd should be bigger and ki , kp should be smaller.

-

(3) When e < 0 , ec > 0 , the system is tending steady-state, kp should be taken a bigger value in order to promote the response speed and then access to steadystate quickly; kd should be added to decrease the overshoot; ki should be diminished to avoid oscillation caused by integral overshoot.

-

(4) When e > 0 , ec > 0 , the overshoot of the system is negative. When the error is increasing, kd should be taken a bigger value, once the error reach the maximum and the system is tending steady-state, kd should be decreased and kp , ki should be increased.

The fuzzy rule-base is shown from Table 1 to Table 3.

TABLE 1

THE FUZZY RULE-BASE FOR Д kp

|

ec |

|||||||

|

NB |

NM |

NS |

ZO |

PS |

PM |

PB |

|

|

NB |

PB |

PB |

PM |

PM |

PS |

ZO |

ZO |

|

NM |

PB |

PB |

PM |

PS |

PS |

ZO |

ZO |

|

NS |

PM |

PM |

PM |

PM |

ZO |

ZO |

NS |

|

e ZE |

PM |

PM |

PS |

ZO |

NS |

NS |

NM |

|

PS |

PS |

PS |

ZO |

NS |

NS |

NM |

NM |

|

PM |

PS |

ZO |

NS |

NM |

NM |

NM |

NB |

|

PB |

ZO |

ZO |

NM |

NM |

NM |

NB |

NB |

TABLE 2

THE FUZZY RULE-BASE FOR Д ki

|

ec |

|||||||

|

NB |

NM |

NS |

ZO |

PS |

PM |

PB |

|

|

NB |

NB |

NB |

NM |

NM |

NS |

ZO |

ZO |

|

NM |

NB |

NB |

NM |

NS |

NS |

ZO |

ZO |

|

NS |

NB |

NM |

NS |

NS |

ZO |

PS |

PS |

|

e ZE |

NM |

NM |

NS |

ZO |

PS |

PM |

PM |

|

PS |

NM |

NS |

ZO |

PS |

PS |

PM |

PB |

|

PM |

ZO |

ZO |

PS |

PS |

PM |

PB |

PB |

|

PB |

ZO |

ZO |

PS |

PM |

PM |

PB |

PB |

TABLE 3

THE FUZZY RULE-BASE FOR Д kd

|

ec |

||||||||

|

NB |

NM |

NS |

ZO |

PS |

PM |

PB |

||

|

e |

NB |

PS |

NS |

NB |

NB |

NB |

NM |

PS |

|

NM |

PS |

NS |

NB |

NB |

NB |

NM |

PS |

|

|

NS |

ZO |

NS |

NM |

NM |

NS |

NS |

ZO |

|

|

ZE |

ZO |

NS |

NS |

NS |

NS |

NS |

ZO |

|

|

PS |

ZO |

ZO |

ZO |

ZO |

ZO |

ZO |

ZO |

|

|

PM |

PB |

NS |

PS |

PS |

PS |

PS |

PB |

|

|

PB |

PB |

PM |

PM |

PM |

PS |

PS |

PB |

|

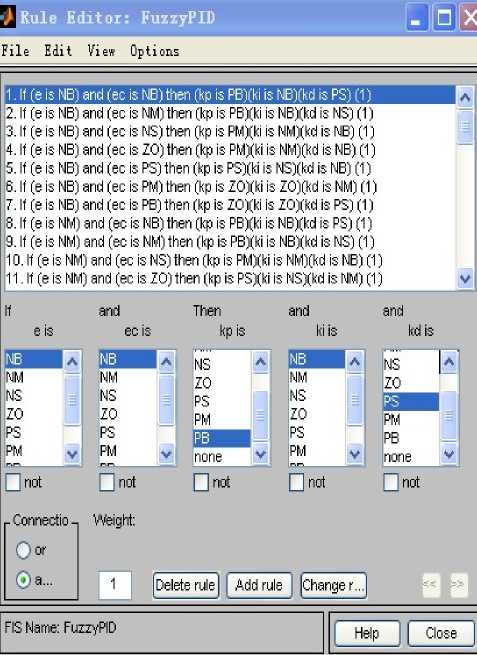

In this paper, fuzzy control rules are designed with the four tune principles shown above. And these rules in the three tables can be written in the format of IF-THEN as follows:

-

1 .If (e is NB) and (ec is NB), then ( Д kp is PB) ( Д ki is NB) ( Д kd is PS) ;

-

2 .If (e is NB) and (ec is NM), then ( Д kp is PB) ( Д ki is NB) ( Д kd is NS) ;

-

3 . If (e is NB) and (ec is NS), then ( Д kp is PM) ( Д ki is NM) ( Д kd is NB)

-

49 . .If (e is PB) and (ec is PB), then ( Д kp is NB) ( Д ki is PB) ( Д kd is PB)

There are total 49 rules can be viewed in the rule editor. And rule editor of fuzzy control in MATLAB is shown in Fig.10.

Figure 10. Rule editor

-

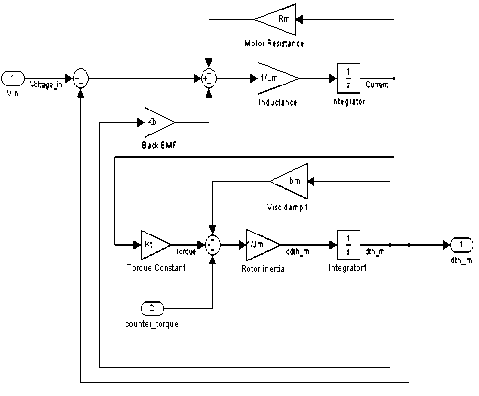

IV. System Simulation Model

The double-motor synchronous control system is based on two excited DC motors; and for simplicity, the two motors are supposed with the same parameters as follow:

Rated output power: Pe =10KW , Rated voltage: U = 220V L = 55 A e ,Rated current : e ,Rated speed: ne = 1000rad / 5 , Moment of inertia: j = 0.02J ■ s2 .a simple two-order model of the DC motor is shown as Fig.11 as below:

Figure 11. Two-order Structure of the DC motor

According to the electrical equation and mechanical characteristic equation of DC motor, the mathematical model of DC motor can be described as (2) and (3)[9]:

LA = u a r a - Ce fi ( t )

dt(2)

-

d Q ( t)

-

J ------= T — T L

dt(3)

DC motor model parameters are shown as follow:

R « U e I e — P e = 0.347 Q C = U /R = 0.201 V ■ s / rad

-

a 2 I 2

U9.55V

L ~ 3.82 — e— = 0.0153 H M = ----e- = 9.55 N ■ m pneIe ne

-

C, = M e = 0.174 N ■ m / A T = L a- = 0.044 5

T I e a R a

T m = JR^ = 0.198 5

C e C T

Transfer function model is described as (4):

G ( s ) = Q ( s ) = 1 C e = 4.975

-

' Ua ( s ) TmTas 2 + T m s + 1 0.0345 s 2 + 0.198 s + 1 (4)

A system model is established to be simulated. The closed-loop transfer function of one of the two motors in the control system is shown as (4). Build the adaptive fuzzy PID synchronous control system shown as Fig. 12 in MATLAB/SIMULINK simulation environment [1016].

Figure 12. System’s SIMULINK simulation model

In this control system model, the specific structure of Subsystem and PID are respectively shown in Fig. 13, Fig. 14. It is supposed that the master motor and the slave motor have the same structure and transfer function.

Figure 13.

Subsystem

Figure 14. PID

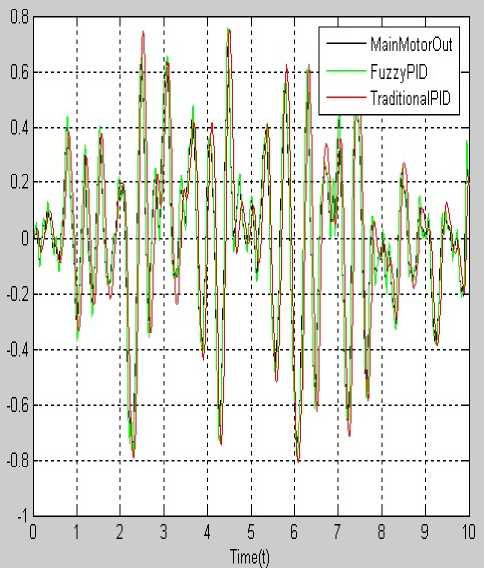

According to the given random input signal, the result of the simulation of the double-motor synchronous system controlled relatively by adaptive fuzzy PID and traditional PID control strategy is shown as Fig.11, the program about how to view the figure in MATLAB command window is appended in Appendix A The M-file of view plot in command window. And in order to compare the effects of both of the strategies, same parameters are tuned to control as follow: Kp=2, Ki=0.5, Kd=0.1.

Figure 15. Simulation result

From the result diagrams, several conclusions can be obtained. The revolving speed of the master motor is better flowed when the controller is adaptive fuzzy PID than the controller is traditional PID, it proves the adaptive fuzzy PID synchronous control strategy is successful and effective. In the detail of the result figure, superiorities of the adaptive fuzzy PID control strategy can be obviously observed, including faster response speed, less overshoot, shorter setting time stronger robustness and better tracking effect.

-

V. Conclusions

A control strategy combining PID with fuzzy theory is introduced in this paper. It can tune the parameters online by itself to adapt the dynamic change of the controlled system. It is applied in the double-motor synchronous working system, which is so widely used in the industry producing. In the MATLAB / SIMULINK simulation environment, two-order DC motor model is established, and two of them compose the double-motor synchronous system[17]. With the result demonstrates that this adaptive fuzzy PID strategy can control the double-motor system more effectively with faster response speed, shorter setting time, stronger robustness and less overshoot, as well as better synchrony. These performances can hardly be achieved by traditional PID controller. And the Adaptive Fuzzy PID controller will have major significance in practical industrial processes as well as theory development.

Appendix A The M-file of view plot in command

WINDOW

MainMotorOut=simout(:,1);

FuzzyPID=simout(:,2);

TraditionalPID=simout(:,3);

t=simout(:,4);

plot(t,MainMotorOut,'k',t,FuzzyPID,'g',t,TraditionalPI D,'r')

grid xlabel('Time(t)')

legend('MainMotorOut','FuzzyPID','TraditionalPID')

Список литературы Research on Adaptive Fuzzy PID Synchronous Control Strategy of Double-Motor

- YANG Chen-na, ZHANG Yi “Design and Simulation for Double-Motor Synchronous Control System” in Industrial Control Computer: vol.22(1), pp. 36-37(in Chinese)

- Servet Soyguder, Mehmet Karakose, Hasan Alli, “Adaptive fuzzy APSO based inverse tracking –controller with an application to DC motors” in Expert System with Application vol.36,pp.3454-3458,2009.

- Karim H. Youssef, Hasan A. Yousef, “Design and simulation of self-tuning PID-type adaptive control for an expert HVAC system,” in Expert System with Application, vol.36 pp. 3454-3458, 2009

- HU Shou-song, Automatic Control Theory,5thEd., Beijing :Science Publisher, 2001, pp.23-65(in Chinese)

- WANG Zhuo, Application of Fuzzy Control in Boiler Water Level System University of Science and Technology Beijing, (2005)(in Chinese)

- YU Biao and ZHU Hui, “Water Level Control Embedded Fuzzy-PID and Pole-Placement Strategy” Key Engineering Materials Vol.464, pp. 43-47, 2011 [4th International Conference on Engineering Technology and Ceeusro 2011, Zhenjiang, Jiangsu, China]

- KATSUHIKO OGATA, Modern Control Engineering, 4th ed., Beijing: Tsinghua University Press, 2005, pp.59-67 (in Chinese).

- LIU Jin-kun, MATLAB Simulation of Advanced PID Control, Beijing: Electronic Industry Press, 2003, pp.63-80 (in Chinese).

- GU Sheng-gu, The basic theory of motor and dragging, 3rd ed., Beijing: Mechanical Industry Press, 2003, pp. 19-55(in Chinese ).

- Francisco. J. Perez Pinal. “Comparison of Multi motor Synchronization Techniques.” Vol.10, pp 2-6,2004 [The 30th Annual Conference of the IEEE Industrial Electronics Society, Busan, Korea, 2004 ]

- Corley. M. J. Lorenz. R. D. “Rotor position and velocity estimation for a salient-pole permanent magnet Jones. L. A, Lang. J.H. “A State Observer for Permanent Magnet Synchronous Motors.” IEEE Trans Ind. Electron, 1998, vol.36, pp: 374-382

- H.R.Berenji, Fuzzy logic controllers, in: R.R. Yager, L.A.Zadeh(Eds.), An Introduction to Fuzzy Logic Application in Intelligent System, Kluwer Academic Publisher, Boston, MA, 1992.

- XUE Ding-yu Computer Aided Control System Design Using MATLAB Language(2nd Eds.) Beijing: Tsinghua University Press, 2006, pp.261-283 (in Chinese).

- Ping-Ho Chen, Jiun-Hong Lai, and Chin-Teng “Application of fuzzy control to a road tunnel ventilation system” in Fuzzy Sets and System, vol: 100, pp: 9-28, 1998.

- HUANG You-rui, and QU Li-guo The Tuning and Realization of PID Controller Beijing: Science Press January, 2010

- W. R. Hwang and S. Zein-Sabatto. “Fuzzy Controller Design Using Genetic Algorithm ” in Engineering new century, Proceeding, IEEE, April 1997

- SUN Feng-lei, SUI Jiang-hua and ZHANG Wen-xiao,“The Simulation of Boiler Water Level Control” in China Water Transport: vol. 9, no. 11, pp. 100-106, November 2009 (in Chinese).