Revisiting the correlation between the Valdivia and San Pedro ceramic complexes (based on technological characteristics)

Автор: Popov A.N., Marcos J.G., Zhushchikhovskaya I.S., Lazina A.A., Lazin B.V., Kanomata Y., Fedorets A.N., Emelyanova T.A.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: Paleoenvironment, the stone age

Статья в выпуске: 2 т.52, 2024 года.

Бесплатный доступ

This article presents the results of a study of ceramics associated with the Valdivia and San Pedro complexes at the Real Alto site, southwestern Ecuador. The test sample, studied in 2022, includes fragments of vessels from two morphological and functional groups, relating to the first two phases of the Valdivia culture (bowls and pots) and those representing the San Pedro complex (vessels with necks and a bowl). A comparative analysis was based on identified technological indicators marking various stages of pottery manufacture. Certain differences are seen in the composition of paste and in the hand-shaping of the vessels. Significant differences were revealed in surface treatment and decoration. This is evidenced by the use of colored and plain coating, high-quality solid or matte striped polishing, and complexity of decoration. Distinctive features of firing include the use of different kilns and various atmospheric modes. Parallels include broadly similar firing temperatures. The technological difference between the two morphological and functional groups of the Valdivia complex is that bowls were manufactured with more complex and labor-consuming techniques, whereas pots are technologically somewhat similar to those from San Pedro. Radiocarbon dates (4640–4450 BP) suggest that the two traditions coexisted. Differences may reflect their cultural distinctness.

Samples, fragments of vessels, morphological and functional groups, history, archeology, radiocarbon dates

Короткий адрес: https://sciup.org/145146993

IDR: 145146993 | DOI: 10.17746/1563-0110.2024.52.2.037-046

Текст научной статьи Revisiting the correlation between the Valdivia and San Pedro ceramic complexes (based on technological characteristics)

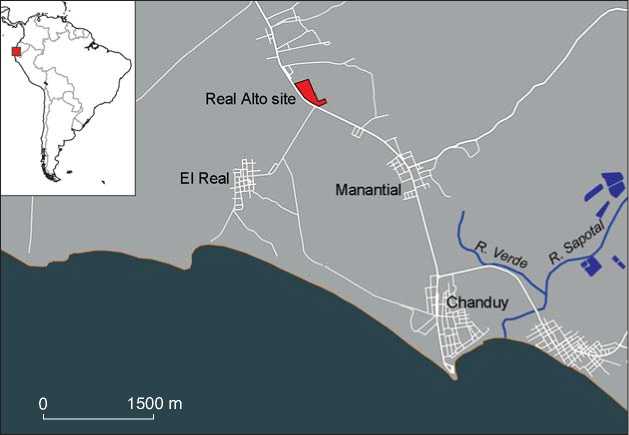

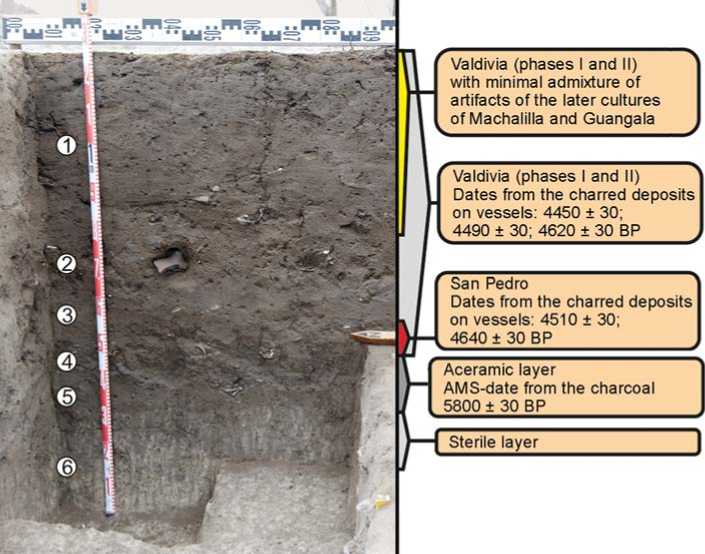

The site of Real Alto was found by J.G. Marcos in 1971. It is located in the southwestern part of Ecuador (Fig. 1), in Santa Elena Province, in the Verde River basin, on a gentle hill (Lathrap, Marcos, Zeidler, 1977). In 2014–2017, the joint Russian-Ecuadorian archaeological expedition worked at the settlement site of Real Alto (heads A.N. Popov and A.V. Tabarev) (Pamyatnik Real-Alto…, 2015; Tabarev, 2016; Tabarev et al., 2018). An excavation trench (104 m2) was established in the northeastern part of the site. Six stratigraphic layers were identified (Fig. 2):

-

1. Dense, cemented, fine-grained sand of gray shades (20–25 cm) with an admixture of grayish-brown sandy loam and alluvial sand of medium and fine

Fig. 1 . Location of the site of Real Alto.

Fig. 2 . Stratigraphic column and the stratigraphic position of artifacts with dates.

-

2. Grayish-brown sandy loam with an admixture of alluvial sand of medium and fine fractions, containing Cerithidea valida shells and solitary Anadara granosa valves (not exceeding 15 % of the layer contents); thickness 12–25 cm.

-

3. Grayish-brown sandy loam with an admixture of alluvial sand of medium and fine fractions (10–15 cm).

-

4. Grayish-brown sandy loam with an admixture of alluvial sand of medium and fine fractions, saturated with Anadara granosa valves (up to 50 % of the layer’s contents); thickness 10–15 cm.

-

5. Grayish-brown sandy loam with an admixture of alluvial sand of medium and fine fractions (5–10 cm).

-

6. A virgin layer composed of grayish-yellow cemented sand (30 cm and below).

fractions, and with a soddy-humus horizon containing modern plants’ roots; the latter horizon was absent in some portions of the trench, and therefore not identified separately from layer 1 (40–50 cm).

In these layers, the following materials were found: in the bottom part of layer 1 and in layers 2 and 3, pottery attributable to phases I and II of the Valdivia culture; in the base of layer 3, in the contact zone with layer 4, pottery designated as “San Pedro” by the researchers who discovered it (Bischof, Viteri, 1972: 548); in layer 4 and in the contact zone with layer 5, artifacts of the “aceramic” pre-Valdivian complex (mainly stone products). For the first time, the San Pedro pottery was recovered from a clear stratigraphic context and contained not only single fragments, but also an archaeologically intact vessel. This discovery provided the opportunity to determine its morphological and ornamental features at Real Alto (Tabarev et al., 2018: 10; Tabarev et al., 2021: 77) and to compare it with the ceramics of the Valdivia culture.

There are several hypotheses concerning the chronology of these pottery traditions: the ceramic tradition designated as San Pedro may be a predecessor of the Valdivia (Bischof, Viteri, 1972) or represent a separate cultural phase between the Archaic (Las Vegas culture) and Early Formative (Valdivia) periods (Bischof, Viteri, 2006). Therefore, the studies in 2022 were focused on the comparative analysis of the technical and technological features of the Valdivia ceramics (phases I and II) and the San Pedro complex, in order to establish their cultural and chronological relationship.

Materials and study methods

The test sample includes 40 specimens from the two early phases (I and II) of the Valdivia culture and

11 fragments of San Pedro pottery from the Real Alto collection. The Valdivia test set comprised samples of vessels from two morphological and functional groups: pots with necks ( n =19) and wide low bowls with rims folded outward or inward ( n =21) (Raymond, 1993; Marcos, 1988: 135–136; 2015: 127–137; Pamyatnik Real-Alto…, 2015: 19–27). Both are characterized by rounded bottoms. The San Pedro test sample includes small vessels with rounded wide bottoms and poorly profiled necks, and one fragment of a bowl.

Visual examination of ceramic samples using a magnifying glass with ×10 magnification and backlight provided certain information about the macro-features: the curvature, texture, and color of external and internal surfaces, outlines and thickness of walls, presence or absence of use-wear traces in the form of charred remains, etc. To get more detailed information on surface texture features, some potsherds from both samples were studied using a light optical microscope with a magnification of up to ×50 at the Engineering and Technology Center of the Institute of Chemistry Far Eastern Branch of the Russian Academy of Sciences (FEB RAS).

Profile polished sections of all ceramic samples were examined using a magnifying glass with ×10 magnification. This method reveals the textural features of ceramic masses, size ranges and patterns of distribution of non-ductile inclusions and holes, and traces of organic impurities (Thuesen, Oldenburg, Iørgensen, 1989).

A petrographic study of transparent thin sections of pottery with a polarizing microscope was carried out on 29 Valdivia specimens and 10 San Pedro fragments. The analysis was carried out in the Laboratory for Micro- and Nanoresearch of the Far Eastern Geological Institute FEB RAS (identification by L.G. Kolesova) and in the Laboratory of Geological Formations of the Ilyichev Pacific Oceanological Institute FEB RAS. Petrographic microscopy reveals the qualitative and quantitative mineralogical composition of the ceramic paste and some optical signs of minerals and rocks associated with the firing temperature (Pentedeka, Dimoula, 2009; Quinn, Burton, 2009).

The SEM-EDS (scanning electron microscopy combined with energy-dispersive spectroscopy) method was used to study four fragments of the Valdivia pottery and six specimens from the San Pedro complex. Scanning electron microscopy determines the features of the ceramic substance’s microstructure, in particular the signs of vitrification of the clay fraction caused by firing conditions. Energy dispersive spectroscopy identifies the chemical elemental composition of a ceramic substance, which depends mainly on the features of the raw materials used (Tite, Maniatis, 1975; Maniatis, 2009; Palanivel, Meyvel, 2010). The microstructure was studied using equipment No. 200556 of the Center for Collective Use of the Far Eastern Federal University and the Electron Microscopy Center of the Zhirmunsky National Scientific Center of Marine Biology FEB RAS.

Selective water absorption testing of the samples, in other words, for the open (relative) porosity, was carried out in order to get additional information about the quality of the pottery under study. It is known that water absorption rate depends directly on the firing temperature and on the density of the ceramic paste (Shepard, 1985: 127–130; Rice, 1987: 230–232).

The study methods used made it possible to obtain a certain amount of information on the technological characteristics of the paste, vessel shaping, surface treatment, and technical and technological features of pottery firing.

Study results

Valdivia ceramics

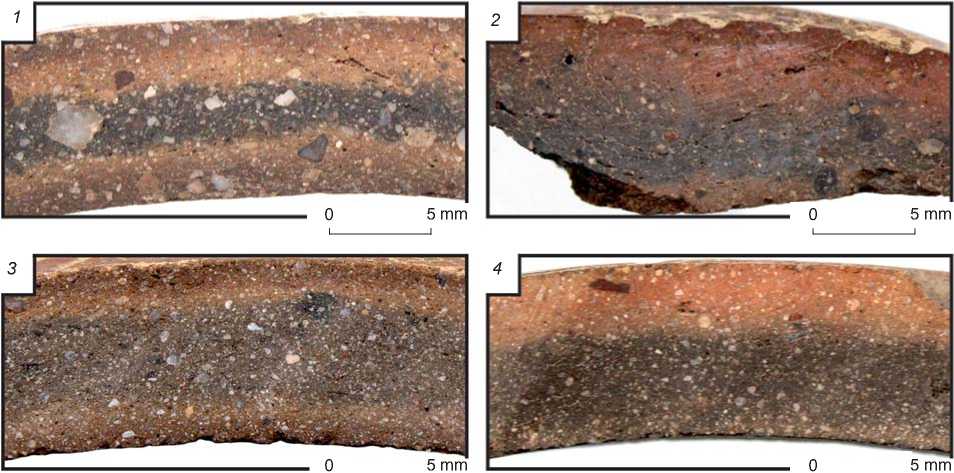

Paste. Analysis of polished sections has shown the relative textural homogeneity of the paste. Fine- and medium-grained mineral inclusions, with a grain size not exceeding 0.5 mm, are evenly distributed within the ductile substance; larger inclusions, up to 1.0– 2.0 mm, are rare (Fig. 3, 1).

The petrographic analysis has revealed that the paste is composed of approximately equal amounts of ductile clay fraction (particle size ≤ 0.05 mm) and clastic material (particle size > 0.05 mm). The mineral of the clay fraction was presumably attributable to illite of the group of hydromicas. This fraction contains a silty admixture of tiny grains of quartz, feldspars, sometimes iron hydroxides, quite few particles of ore mineral, and other admixtures.

The mineralogical composition of the clastic fraction corresponds mainly to rhyolites, i.e. volcanic rock, very similar in composition to granites. Grains of rhyolite and the rock-composing minerals (quartz, feldspars) together account for the share of 45–50 to 70 % of the total amount of clastic material. There are small shares of fragments of andesites, dacites, and sedimentary rocks (cherts, mudstones, shales). Hornblende from green to brown and red-brown color is a constant admixture (from 1–3 to 15–20 %). Some samples contain tuff and hematite grains.

Characteristic features of the clastic material’s texture are the absence of marked differentiation of grain-size ranks and the small number of grains larger than 0.5 mm. Few grains measured 2.0–3.0 mm. From the point of view of the petrography of archaeological ceramics, these features can be interpreted as indicators of the natural origin of non-plastic inclusions in the paste rather than artificial admixtures (Montana, Polito, Iliopoulos, 2009; Martian et al., 2009).

Fig. 3 . Profile polished sections of the Valdivia ceramic samples.

The EDS analytical data revealed the proportions of the main elements of the chemical composition of the paste, which determine its properties. The content of alumina (A1) varies in the range of 4.49–14.23 %, that of silica (Si) from 17.38 to 42.57 %. The Al : Si ratio, calculated from average values, is approximately 1 : 3. Such composition characterizes the clay raw material as fusible (Dana et al., 2014). The iron (Fe) content of 1.10–15.47 % corresponds to moderate and high values and is compatible with petrographic finding on the occurrence of iron hydroxides in the ductile fraction, and of hematite inclusions in the clastic material. The share of calcium (Ca) in most of the studied samples varies from 0.32 to 3.82 %, which corresponds to noncarbonate clays (Tite, Maniatis, 1975).

Both morphological and functional groups of pottery show certain similarity in the composition of paste. This can be explained by the fact that the pottery makers used the clays containing similar admixtures of rhyolite or rhyolite-andesite of the parent rock from a single geological region. Rhyolites and andesites are the products of volcanic activity, widespread in the mountainous regions of Central Ecuador, and can well be considered as clay-forming rocks (Hall, Mothes, 2008; Mothes, Hall, 2008). It is possible that the clay raw material preliminarily underwent dry or water refinement, large inclusions were removed, and the purified clay was used as paste, with its chemical and mineralogical characteristics suitable for the technological tasks of pottery making.

Shaping technique. The heavy fragmentation of the artifacts from the test collection provides only for the most general ideas about the techniques of pottery making. Notably, there are no signs of the use of a potter’s wheel. As for the probable methods of hand-shaping, these can hardly be identified because no traces of vessel construction have been identified on the surfaces of the potsherds. The possibility of using standard constructing elements, such as bands or wide coils, cannot be excluded. In the process of manufacture, the connecting “seams” and joining areas between the sequentially laid coils can be rubbed and utterly leveled.

The thickness of the product walls is an important feature of the pottery-making technique. No single standard was traced for the potsherds in the collection. The thickness varies in the range of 0.5–1.3 cm. Five samples from the collection reveal a wall thickness in the range of 0.5–0.7 cm; that of most fragments exceeds 0.8 cm. This parameter varies in the range of 1.0–2.0 mm throughout one fragment of a vessel, in rare cases 3.0–4.0 mm. These data show a tendency towards fairly uniform wall-thickness in the course of pottery shaping.

Surface treatment. Techniques of coating and mechanical processing have been identified. They show a certain differentiation according to the morphological and functional groups of pottery. Two types of surface coating have been noted: colored and plain. The vessels with colored coating show a bright and even red color of various shades. Such coating was present on the exterior surface of most bowl fragments from the collection, sometimes on both sides. One fragment of a vessel with a neck had a red coating on its interior surface. On most samples, the coating looks dense and uniform, and has strong adhesion to the ceramic core. In some cases, the coating layer is poorly preserved.

Optical microscopic analysis has shown that the red coating layer was less than 0.1 mm thick. The coating layer differs from the ceramic body not only in color, but also in greater textural homogeneity. On the surface of the red coating, there is a network of thin cracks, almost invisible to the naked eye. According to the EDS findings for two samples, the red coating contains a basic share of Si and Al and up to 30.0–34.0 % of Fe. The paint could have been prepared on the basis of a ferrous pigment, such as ocher. Ocher in the form of small pieces has been reported from the sites of the Valdivia culture (Pamyatnik Real-Alto…, 2015: 31). Judging by the signs noted above, the color-coating technology has been sufficiently well developed with respect to the properties of the raw materials used.

Plain coating was recorded mainly on the interior surfaces of bowls and both surfaces of vessels with necks. Such a coating forms a layer of aluminosilicate substance, as thin as that with pigments, but with a significantly lower iron content. Probably, a waterclay suspension with a fine texture was used for this coating type.

Mechanical processing aimed at making the walls smooth and shiny was carried out by polishing. Bowls with the red coating are particularly smooth and show an even shine. Striped polishing with a slight gloss is typical of the interior surfaces of bowls with plain coating. The fragments of vessels with necks show no signs of careful surface treatment. Some fragments show faint traces of striped matte polishing.

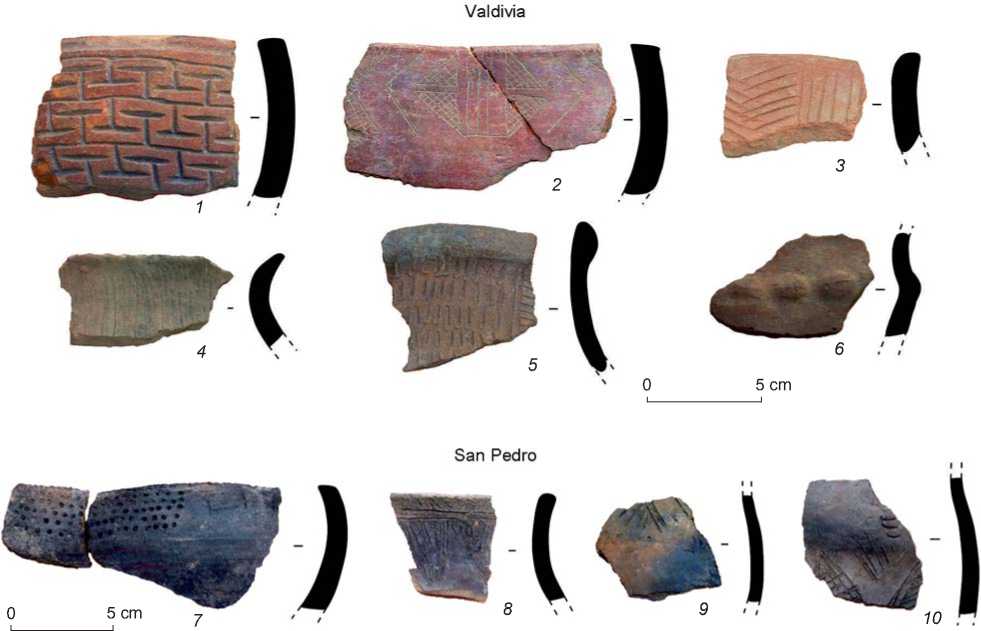

Ornamentation techniques. From the artifacts in the test collection, impressed and raised types of ornamentation can be distinguished (Fig. 4, 1–6 ). Impressed motifs were executed by carving, scratching (sgraffito), combing, and incision. Each technique shows characteristic macrosigns, which are determined through visual examination.

The carving and sgraffito techniques were used in decorating the exterior surfaces of the bowls. Using the technique of cutting on a hard surface, “grooves” were made, with clear and sharp edges without clay overlaps. At the bottoms of the “grooves”, vivid longitudinal grooves made by the edges of the working tools are usually clearly visible. The color of the incisions is similar to the color of the ceramic core. In ornamental compositions, “grooves” were usually made mutually perpendicular, in the form of T-shaped or L-shaped figures (Fig. 4, 1 ). The sgraffito technique produced straight “hard” lines on the surface, forming a simple net or other patterns. The color of the scratched elements contrasts considerably with the color of the core surface (Fig. 4, 2 ).

An important difference between the techniques of carving and sgraffito, popular in ancient and traditional pottery in some parts of the world, is that carving was performed on a hard surface before firing, while sgraffito patterns were performed after firing. That is why the cut ornament does not differ in color from the surface of the fired vessel, and the sgraffito patterns are distinguished by the lighter color (Rice, 1987: 146– 147; Hayes, Blom, 1996: 17).

Examples of combed and incised patterns have been recorded on vessels with necks. For the combing, a tool with a serrated working edge was used, which produced parallel rows of grooves on the surface (Fig. 4, 3). The decoration was carried out over the quite wet walls of the product; there were overlaps of clay on the edges of the grooves. A ceramic fragment with an incised pattern executed by combing with maize grains (Zea mays) over a wet surface is noteworthy (Pamyatnik Real-Alto…, 2015: 25–26); the resulting pattern shows grooves of various width and depth (Fig. 4, 4). A fragment of a vessel with a neck bears a unique incised decoration pattern. Short grooves 0.2 cm wide were made over a wet surface, judging by the typical overlaps of clay on their edges (Fig. 4, 5).

A raised ornament was noted on two fragments of vessels with necks. It shows a horizontal row of rounded convexities formed by squeezing out a ductile paste from the inside by maize grains (Fig. 4, 6 ) (Zevallos et al., 1977).

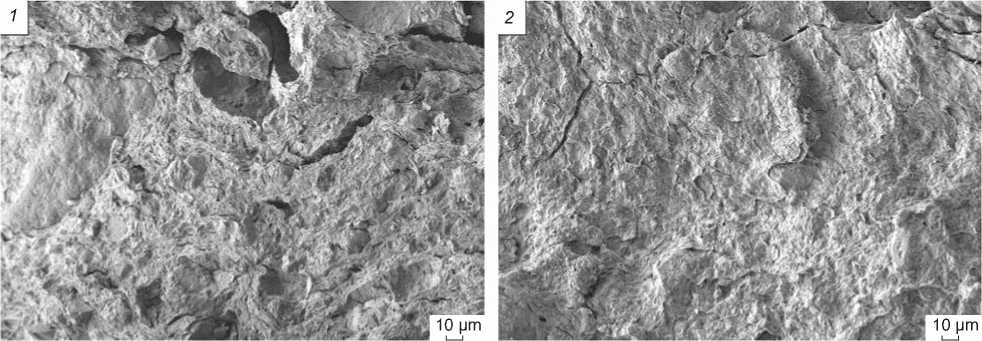

Firing. The SEM analysis has revealed several samples with signs of initial vitrification of clay, namely the areas with the so-called fibrous or fiber-like structures, having small sections with tiny closed pores (Fig. 5, 1 ). Vitrification in non-carbonate clays, i.e. in clays with Ca ≤ 6.0 %, starts under the temperature of 800–850 °C in an oxidizing environment. An

Fig. 4 . Ceramic fragments.

atmosphere saturated with carbon leads to a slight decrease in the temperature at which this process begins (Tite, Maniatis, 1975; Maniatis, 2009).

Comparative analysis of colors of polished sections and surfaces indicates the use of various atmospheric modes of firing. Several samples show an even color of “warm” tones on the fracture and both surfaces— the result of firing in an oxidizing environment. On most fragments, various combinations of light and dark gray or black zones were recorded. Option 1: the fracture is dark gray in color, the exterior surface is light (red), the interior is darker, but less dark than the fracture (see Fig. 3, 2 ). Option 2: in the middle of the fracture, there is a dark stripe, the marginal zones and both surfaces are light-colored (see Fig. 3, 3 ). Option 3: half of the fracture surface and the exterior surface are light-colored, the other half and the interior surface are dark (see Fig. 3, 4 ). These options obviously indicate an alternation, during the firing process, of the phases of oxidative mode with free access of oxygen with the phases of saturation of the air with carbon as a product of fuel combustion. Noteworthy is the fact that the exterior surfaces of the bowls are always light, regardless of the color of the fracture. The light color reflects the targeted effect of the oxidative mode at the latest stage of firing.

Taking into account the more or less prolonged exposure of the ceramic products to an atmosphere saturated with carbon during firing, it can be assumed that the firing temperatures did not exceed 800 °C. Available petrographic data on the color features of hornblende grains in the mineralogical composition of ceramics are of certain interest. The abovementioned color transitions from green to brown or reddish-brown tones may be the result of thermal transformations of this mineral. It is known that at the temperature of 750–850 °C, green hornblende gradually changes its color to various tones of brown (Ignat et al., 2019).

Water absorption tests of the available ceramic fragments showed the results within average values of 5.0–15.0 % (Shepard, 1985: 130). The main value interval is quite narrow—10.5–12.7 %, which suggests a certain “quality standard” of ceramic products. The testing data are consistent with the SEM results showing the signs of initial vitrification. Such features are typical of archaeological ceramics with a water absorption rate of 9.0–11.5 % (Zhushchikhovskaya, 2017).

San Pedro ceramics

Paste. The petrographic analysis has revealed that the paste consists of a clay fraction with particles ≤ 0.05 mm in size and clastic material in approximately equal amounts. The clay fraction is composed of a mineral from the hydromica group, presumably montmorillonite. The clastic material is composed mainly of rhyolite represented by rock fragments, as well as grains of quartz, feldspar, biotite, and hornblende. There is a constant but insignificant admixture of fragments of andesites and sedimentary rocks (cherts, mudstones, opals). Interestingly, some ceramic specimens contain grains of sedimentary rocks with traces of radiolarians—fossilized marine microorganisms.

No clearly defined differentiation between various-size fractions and a small number of grains larger than 0.5 mm has been recorded in the texture of the clastic material. Grains measuring 2.0 mm are rare, and were noted only in some specimens. In general, the textural

Fig. 5 . Microstructure of ceramic paste of vessel fragments of the Valdivia ( 1 ) and San Pedro ( 2 ). ×1000 magnification.

features of non-ductile inclusions most likely indicate their natural origin associated with composition of the original clayey raw material.

According to EDS data, the Al content in the ceramic paste is 5.68–15.08 %, Si – 9.74–39.60, Fe – 0.75–26.14, and Ca – 0.46–4.97 %. In general, the chemical composition of the samples is similar to that of the Valdivia ceramics. However, a trend towards higher iron content can be noted.

Shaping technique . The examined samples of San Pedro ceramics do not allow us to identify the signs of certain shaping techniques. Serial observations can be carried out only on the wall thickness of the products. This indicator varies in the range of 0.3–0.8 cm, with an average of 0.4–0.5 cm for most specimens.

Surface treatment. Techniques of plain surfacecoating and polishing were identified. Visual examination reveals a thin layer formed by a waterclay suspension on the exterior and interior surfaces. The dull horizontal stripes made with a hard tool are interpreted as polishing marks.

Ornamentation techniques. The analyzed ceramic fragments bear a deep-relief ornament made by incision and embossing techniques (see Fig. 4, 7–10 ). The main decorative element is a narrow groove incised on a ductile surface, judging by clay overlaps on its edges. The grooves usually form triangular or rectangular geometric figures (see Fig. 4, 7 , 8 ). The embossing technique was used to create a pattern of horizontal rows of rounded impressions (see Fig. 4, 7 ). The nature of the imprints suggests the use of a tubular plant stem as an ornamenting tool.

Firing. A characteristic feature of the ceramic fragments is the rather intense black coloring of the surfaces and fractures, which may indicate that the products were subjected to a long-term firing in a smoky atmosphere with a high content of solid carbon. According to SEM data, the microstructure of the ceramic substance of some specimens shows signs of initial vitrification, similar to those recorded for the Valdivia ceramics (see Fig. 5, 2 ). The water absorption values are 10.0–10.9 %, which is lower than those of the Valdivian samples. It is known that solid carbon deposited in the pores of ceramics during firing in a smoky atmosphere makes the core more dense and somewhat reduces its water absorption, thereby improving the practical qualities of the product (Avgustinik, 1956). On the basis of the totality of data, it can be assumed that firing temperatures were around 800 °C.

Conclusions

The results of analysis of the pastes of the Valdivia and San Pedro pottery suggest the use of clay raw materials similar in their quality and mined in the same geological area, but probably from different local outcrops. Certain differences in the hand-shaping techniques of the vessels are indicated by such a parameter as wall thickness.

The method of surface treatment of constructed products reveals similarity in terms of techniques for coating the walls with a water-clay compound, and polishing. This is especially noticeable when comparing Valdivia vessels with necks and San Pedro pottery. However, Valdivian bowls demonstrate a more complex set of technological skills, including the use of colored coatings and high-quality solid polishing. Significant differences also concern the ornamentation techniques: the Valdivia pottery, primarily the group of bowls, provides evidence of a much wider range of techniques.

Heat treatment of ceramic products by the bearers of both cultural traditions was presumably executed with the use of firing devices that were similar in technical capabilities and were able to reach a temperature up to 800–850 °C. However, the devices themselves and the principles of their operation could have been different. The alternation of atmospheric modes assumed for Valdivia ceramics corresponds rather to fire baking, while the “smoking” mode for San Pedro ceramics can be correlated with pit firing (Vukovic҅ , 2018).

Valdivia specimens demonstrate a certain distinction between the two morphological and functional groups, but generally reflect a fairly consistent set of potterymaking techniques, which conforms with research data (Meggers, Evans, Estrada, 1965: 86–87; Raymond, 1993). The results of the analysis of San Pedro ceramics also indicate well-developed skills in working with raw materials and making vessels with adequate practical qualities.

This study confirms the previously stated assumption that the ceramics of Valdivia and the San Pedro complex belong to different cultural traditions (Kanomata et al., 2019). The peculiarities of the stratigraphic position of these artifacts at Real Alto and the radiocarbon dates derived from charred deposits on the vessels allow us to conclude that the San Pedro ceramic complex and the pottery from the first two phases of the Valdivia culture existed simultaneously in the period of 4640–4450 BP (Tabarev et al., 2021). Our findings suggest multi-vector Neolithization in Coastal Ecuador. In general, the issue remains quite promising for the continuation of comprehensive archaeological research in this region.

Acknowledgments

This study was supported by the Russian Science Foundation, Project No. 22-28-00059 . The authors express their gratitude to Y.A. Mikishin for providing the data of geomorphological studies carried out at the site of Real Alto.