Self-healing concrete using fly ash, macro synthetic fibres and recycled aggregates

Автор: Sabri Mohanad Muayad Sabri, Javed Muhammad Faisal, Muhammad Arslan

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 6 (104), 2022 года.

Бесплатный доступ

The development of cracks in concrete can reduce its durability and service life, causing its steel rebar to be exposed to harmful substances from the external environment, eventually leading to strength loss of concrete and high repair costs. Self-healing technique can eradicate the crack spontaneously, likely replacing or decreasing maintenance and repair costs. Self-healing concrete using low calcium Fly Ash with recycled Aggregate (RCA) and macro synthetic fibers is a novel approach to increase durability and serviceability, decreasing repair and maintenance costs. This research intends to create self-healing concrete using different volumes of Fly Ash with partially replaced RCA and macro synthetic fibers and to study the autogenous behavior of Fly Ash. Various volumes of Fly Ash 35%,45%, and 60%, respectively, were used. In addition, the coarse Aggregate was partially replaced with RCA. The results show that replacing RCA with natural Aggregate and using Fly Ash significantly decreased the strength of concrete. Thus, to increase the mechanical properties of concrete macro synthetic fibers were used at two percentages 5% and 1%, respectively. After that, concrete samples were cracked after 28 days of curing, and after 5 weeks, they were cured for autogenous self-healing. The results showed that using Fly Ash from 45-50% gave the optimum healing to cracks in 5 weeks and the use of macro synthetic fibers at 0.5% caused the best improvement in mechanical properties of concrete with good workability.

Self-healing, fly ash, macro synthetic fibres, concrete, healing properties, mechanical properties

Короткий адрес: https://sciup.org/143179861

IDR: 143179861 | УДК: 69 | DOI: 10.4123/CUBS.104.5

Текст научной статьи Self-healing concrete using fly ash, macro synthetic fibres and recycled aggregates

-

1 Introduction

Concrete is extensively consumed in construction projects. It can be designed to have several decades of serviceability [1] . It is an essential component that has been extensively utilized in the building of many infrastructures to fulfill the large demand for concrete; cement is manufactured on a global scale, with an annual production estimate of 3.5 billion tons in 2011 [2,3] . Concrete is likewise a flexible structure material since it is moldable and can be cast into any shape in proper framework and its physical qualities can be employed in multiple structural applications. Concrete characteristics and efficiency significantly influence the overall quality of infrastructures globally due to its extensively utilized in construction.

Concrete is one of the only materials with excellent compressive strength, high fire and heat resistance, and more durability with outstanding service life. However, the concrete shows highly brittle behavior, leading to cracking during construction. Concrete's fragile nature makes it vulnerable to cracking, reducing the lifespan and sustainability of concrete structures. One of the main causes which Sabri M.M.; Javed M.F., Arslan M.

Self-Healing Concrete Using Fly Ash, Macro Synthetic Fibres and Recycled Aggregates;

induce cracks in concrete is extreme loading, earthquakes, and adverse environmental factors. These cracks weaken the concrete, causing its strength loss due to more exposure to harsh environments. Consequently, more maintenance and repair costs are required, and a decrease in concrete strength and service life is observed [4-10] .

Thus, research development started taking another direction towards developing new materials and technologies to enhance the concrete material properties and restoration of current infrastructure, as well as new infrastructure building against many multi-hazards. According to practical experience, the hydration of concrete may repair its structural cracks. As a result, the concept of "self-healing" is motivated, which has usually originated from biomimicry, like the natural occurrence of blood coagulation or the mending of cracked or broken bones.

Abrams identified concrete's self-healing capability in 1925 [11] . Concrete samples had several cracks after the compression test was repaired after putting them outdoors for eight days, and their compressive strength was twice as high as that in 28 days. It was observed that freeze-thaw damage to the concrete sample might self-heal after curing. Parts of the resonant frequencies were restarted, and ettringite crystals and calcium hydroxide crystals were found in cracks [4,5,12-14] . Following crackhealing research may be classified into two self-healing techniques: the first is "intrinsic healing," which has suggested the crack-healing phenomena in concrete is produced by a chemical hydration process as follows (a) Ca(OH)2 can be carbonated to generate CaCO3 precipitation; (b) Further hydration of un-hydrated cementitious particles (c) Closing cracks caused by water impurities or loosened concrete particles may also result in self-healing, and last (d) Matrix swelling (Calcium Silicate Hydration) products (C-S-H). It has been determined that the formation of precipitates of calcium carbonate CaCO3 is the leading cause of autogenous self-healing. The second self-healing approach is subdivided into two parts: vascular and capsule-based healing methods may detect deterioration with or without human involvement. For self-repair, both methods rely on incorporating adhesive reserves inside the matrix. However, certain technical flaws emerged when the chemical substances were not simultaneously present at the affected locations. Furthermore, long-lasting voids were formed inside the concrete after absorbing the whole reservoir, leading to a decline in durability. The intrinsic healing investigations resulted in a considerable reduction in fracture width, less water permeability, and improved/recovered mechanical characteristics [4-6,9,15-22] .

This intrinsic or autogenous self-healing is the ability of concrete to self-heal cracks that appears during the lifespan. This is a frequent healing process in concrete water-retaining structures, culverts, and pipelines. It was identified by the French Academy of Science in 1836 and has since become extensively investigated, particularly concerning pipes and other water-retaining structures [23-25] . Autogenous self-healing in concrete is incorporated using mineral admixtures like SCM's Fly Ash and Blast Furnace Slag, expansive minerals, and crystalline admixtures etc.

Mineral admixtures, in particular, have high activity. Mineral admixtures in concrete might conserve cement, minimize hydration temperature rise, and improve mechanical qualities [26,27] . Due to its secondary hydration mechanism, Fly Ash and slag will improve pore construction, compactness, and durability when mixed with concrete [26,27] . Along with that, using Fly Ash will decrease the use of cement and will positively impact the conservation of cement production, which is one of the main causes of Carbon dioxide production in the environment.

Fly Ash has been used in different volumes to investigate autogenous self-healing. The main purpose of this research was to examine the behavior of Fly Ash at various volumes and different crack widths. Results showed that the use of Fly Ash in higher volumes until 50-60 percent were meant to be more prone towards calcium carbonate precipitation.

Macro-synthetic fibers have progressed considerably in the previous decade and can now impart significant durability to concrete and increase its mechanical properties [9]. In terms of the role of cement-based materials in sustainability, fibers are usually used in connection with clinker substitutes such as Fly Ash and silica fume, as well as in collaboration with crystalline admixtures to enhance selfhealing capability [26,27] .

This research investigates the effect of Fly Ash as a mineral admixture incorporated at different volumes on autogenous self-healing properties in concrete. Natural Aggregate was partially replaced with RCA for making environment-friendly concrete, and for increasing the mechanical properties of concrete macro synthetic fibers were used at 0.5%. New techniques were developed to induce selfhealing capabilities using Fly Ash as a cement autogenous self-healing addition. This method can modernize the concrete industry and has excellent capability to decrease repair and maintenance costs and make the structure more durable and sustainable, increasing its serviceability. In addition, using Sabri M.M.; Javed M.F., Arslan M.

Self-Healing Concrete Using Fly Ash, Macro Synthetic Fibres and Recycled Aggregates;

recycled Aggregate to replace natural Aggregate by 50% is considerably beneficial for the environment as it makes our natural resources more reserved and makes concrete economic and positive use of construction waste.

-

2 Methods

This research revolves around the significance of using supplementary cementing material Class F Fly Ash in concrete to investigate the self-healing phenomenon while using recycled Aggregate and macro fibers to increase its strength. The materials used in this study are shown in Table 1.

Table 1. Materials used

MATERIALS

Coarse Aggregate

Macro synthetic Fibres

Fly Ash

Ordinary Portland cement

Ordinary Portland cement used in this research fineness is approximately 301 m2/kg, and its specific gravity was 3.15 g/cm3. The chemical composition of the cement is presented in table 2.

Table 2. Chemical Composition of Cement

|

Chemical composition (% by weight) |

|

|

SiO 2 |

21.24 |

|

Al 2 O 3 |

5.56 |

|

Fe 2 O 3 |

3.24 |

|

CaO |

63.53 |

|

MgO |

0.93 |

|

Na 2 O |

0.13 |

|

K 2 O |

0.62 |

|

SO 3 |

2.55 |

|

Free lime |

0.55 |

|

Insoluble residue |

0.64 |

|

Loss on ignition |

1.24 |

2.1 Concrete mix

Various quantities of cement aggregates and water content were evaluated to prepare of M30 concrete. A cubic (6in*6in) concrete of 30 Mpa strength was designed as the control group (reference), as shown in Table 3.

Table 3. Mix Design of Control Group

|

Concrete Mix Design For Control Group (ЗОМРа) |

||||

|

Description |

Cement (kg) |

Fine Aggregate (kg) |

Coarse Aggregate (kg) |

Water Content (kg) |

|

Ratio |

1 |

1.725 |

2.416 |

0.46 |

|

Per Cube (6in x 6in) |

1.60 |

3.17 |

3.7 |

0.784 |

|

Perm3 |

420.23 |

724.92 |

1015.11 |

193.3 |

2.2 Fly Ash

Fly Ash is a term used to describe the ash produced when coal is burned in an industrial setting. This substance Fly Ash is heterogeneous in nature. Fly Ash is generally composed of the following materials:

-

• Silicon dioxide (SIO2)

-

• Aluminum oxide (Al2O3)

-

• Ferric oxide (Fe2O3)

-

• Calcium oxide (CaO)

-

• Magnesium oxide (MgO)

-

2.3 Macro Synthetic Fibres

Fig. 1 - Fly Ash

The chemical compositions of Class F Fly Ash used in this research are given in Table 4.

Table 4: Chemical Composition of Class F Fly Ash

|

Analysis |

Result |

|

II |

|

|

Loss on ignition (LOI) (%) |

1.53 |

|

Chloride (as Cl) (%) |

0.011 |

|

Sulphate (as SO3) (%) |

0.51 |

|

Free CaO (%) |

Nil |

|

Reactive CaO (%) |

4.06 |

|

Total CaO (%) |

4.42 |

|

SiO2 (%) |

51.55 |

|

А1гОз(%) |

33.32 |

|

Fe2O3 (%) |

3.34 |

|

51О2+А12Оз+Ре2Оз (%) |

88.21 |

|

Na2O (%) |

0.51 |

|

MgO (%) |

0.75 |

|

Phosphate (as P2O5) mg/kg |

6.22 |

Macro synthetic fibers, also known as 'structural' synthetic fibers, are made from a polymer blend, and were initially created to replace steel fibers in specific applications. Due to their lightweight, they are used instead of steel fibers as they produce less dense concrete than steel fiber reinforced concrete Initially discovered as a potential substitute for steel fibers in splashing concrete, growing research and development demonstrated that they played a role in the design and development of ground-supported slabs and a wide variety of other applications. It has been discovered that macro synthetic fibers may be used for various significant purposes. Visually they are embossed in structure and like 3 inches in length. The physical properties of embossed macro synthetic fibers used in this research are explained in Table 5.

Fig. 2 - Macro Synthetic Fibres

Table 5: Physical Properties of MSF

|

Characteristic |

Property |

|

Material |

100% virgin polypropylene |

|

Surface Texture |

Continuously Embossed |

|

Appearance |

White |

|

Water Absorbency |

Nil |

|

Tensile Strength |

500-700Mpa |

|

Elastic Modulus |

>9000Mpa |

|

Length |

55mm |

|

Density |

0.91g/cm3 |

|

Melting Point |

160-170°C |

|

Resistance to Acid & Alkali |

Excellent |

2.4 Recycled Aggregate

Big lumps of RCA were collected from a demolished site. The Aggregate was crushed into a smaller size of 4.75mm-19mm by an aggregate crusher machine.

2.5 Experimental Program

The displacements and additional fibers were executed according to the plan shown in Table 6.

Table 6: Experimental Program

|

Designation specimen |

Fly Ash (% weight Kg) |

Cement (% weight kg) |

Macro Synthetic Fibres (% by volume) |

Recycled Aggregate (% weight kg) |

|

A |

0 |

100 |

0 |

0 |

|

A1 |

0 |

100 |

0 |

50 |

|

A1A |

35 |

65 |

0 |

50 |

|

A1B |

45 |

55 |

0 |

50 |

|

A1C |

60 |

40 |

0 |

50 |

|

A2 |

0 |

100 |

0.5 |

0 |

|

A2A |

35 |

65 |

0.5 |

50 |

|

A2B |

45 |

55 |

0.5 |

50 |

|

A2C |

60 |

40 |

0.5 |

50 |

|

A3 |

0 |

100 |

1 |

0 |

|

A3A |

35 |

65 |

1 |

50 |

|

A3B |

45 |

55 |

1 |

50 |

|

A3C |

60 |

40 |

1 |

50 |

3 Results and Discussion

3.1 Slump Value Test

Numerous laboratory tests were performed, including water absorption and specific gravity tests of fine and coarse Aggregate slump tests. Laboratory work results are presented in four stages. First, handle the results of control samples of mixed design to obtain strength. The second stage, 50% recycled aggregate replacement with coarse Aggregate, the replacement of Fly Ash with cement at different percentages (35%, 45%, and 60%), and the addition of macro synthetic fibers by volume at 0.5% and 1% is carried out, respectively.

The third stage handles the results of concrete samples in which replacement of Fly Ash with cement at different percentages (35%, 45%, and 60%) and 50% recycled aggregate replacement with coarse Aggregate, also with the addition of macro synthetic fibers by volume at 0.5%. The final stage handles the results of the last concrete samples in which the replacement of Fly Ash with cement at different percentages (35%, 45%, and 60%), 50% recycled aggregate replacement with coarse Aggregate, and the addition of macro synthetic fibers by volume at 1%.

Slump tests were performed in the laboratory environment, and values of 3.5 and 3 inches were obtained

3 inches

Fig. 3 - Slump test values of the natural concrete

3.5 inches

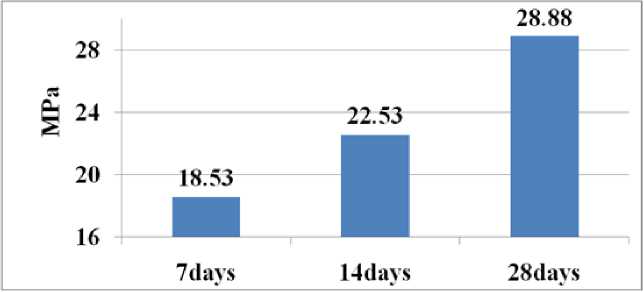

3.2 Compressive Strength of Natural Concrete

The samples before and after the modification were tested under compression after 7,14, and 28 days, respectively. The results are shown in Table 7.

Fig. 4 - Average Values of 7-, 14- and 28-days’ Compressive Strength Natural Concrete

Table 7: Compressive Strength of Natural Concrete

|

COMPRESSIVE STRENGHT OF NATURAL CONCRETE |

|||

|

SAMPLE |

7 DAYS (N/mm2) |

14 DAYS (N/mm2) |

28 DAYS (N/mm2) |

|

NC 1 |

19.01 |

23.13 |

29.17 |

|

NC2 |

18.65 |

22.56 |

28.84 |

|

NC3 |

17.94 |

21.92 |

28.65 |

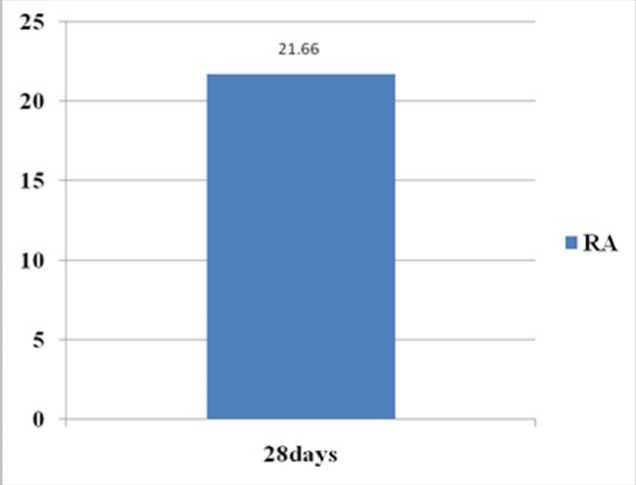

3.3 Replacement of Coarse Aggregate with 50% RCA.

Recycled Aggregate was used as a partial replacement for natural Aggregate. The compressive strength of 28 days was obtained. The results are shown in Table 8 and Figure 4.

Table 8: Compressive strength of 50%RCA Replaced concrete after 28 days

|

SAMPLES |

28 DAYS |

|

RA1 |

20.83 |

|

RA2 |

20.68 |

|

RA3 |

23.49 |

Fig. 5 - Average Compressive Strength of 50% RCA Samples

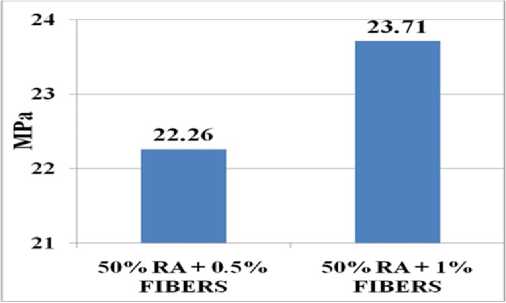

The volume used Macro synthetic fibers on two percentages, 1%, and 0.5%. The macro synthetic fibers were used to increase the mechanical properties of concrete, thereby compensating for the loss of potential strength during the healing process.

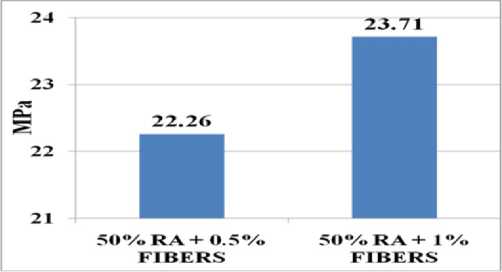

The compressive strength values after 28 days are obtained and given in Table 9 and Figure 5.

Table 9: Compressive Strength of Concrete with Fibres at 1% and .5%

|

COMPRESSIVE STRENGHT OF CONCRETE WITH 50°/o RA <& FIBERS AT 0.5%, 1% |

||

|

SAMPLE |

50°/o RA+ 0.5% FIBERS (N/mm2) |

50% RA + 1 % FIBERS (N/mm2) |

|

1 |

21.41 |

23.13 |

|

2 |

23.5 |

23.92 |

|

3 |

21.87 |

24.09 |

Fig. 6 - Compressive Strength concrete with fibers After 28 days

3.5 Replacement of RCA with the addition of Macro Synthetic Fibres in Concrete

After the addition of macro synthetic fibers in natural concrete, the following mix was to prepare concrete with the addition of 50% RCA with the addition of embossed macro synthetic fibers at percentages of 1% and 0.5%, so the made samples and their compressive strength after 28 days are explained in Table 10 and Figure 6.

Table 10. Compressive Strength of Fibres with the Addition of RCA

|

COMPRESSIVE STRENGHT OF CONCRETE WITH 50% RA & FIBERS AT 0.5%, 1 % |

||

|

SAMPLE |

50% RA + 0.5% FIBERS (N/mm2) |

50% RA + 1% FIBERS (N/mm2) |

|

1 |

21.41 |

23.13 |

|

2 |

23.5 |

23.92 |

|

3 |

21.87 |

24.09 |

Fig. 7 - Average Compressive strength of concrete with fibers and RCA

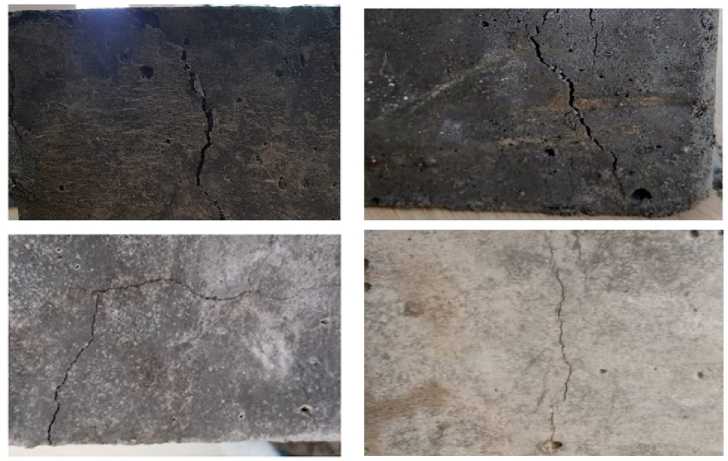

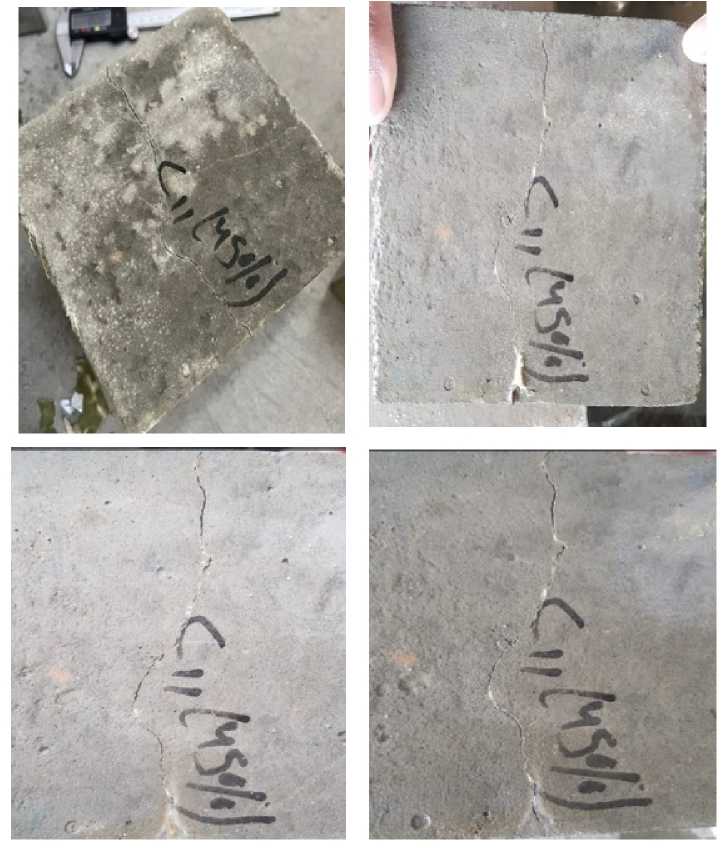

After the compressive strength improvement, cement was replaced with a mineral admixture Fly Ash at different proportions of 35, 45, and 60%, respectively. After 28 days of curing, samples were cracked using a compression machine at various loadings. Cracking loads are shown in Table 11. Cracking Visuals of Fly Ash Concrete are shown in Figure 7.

Table 11. Cracking Loads Applied for Inducing Cracks in Fly Ash Concrete

|

SAMPLE |

FA %age |

PEAK (KN) |

|

1 |

35% |

285.6 |

|

2 |

35% |

229.2 |

|

3 |

35% |

343 |

|

1 |

45% |

318.2 |

|

2 |

45% |

159 |

|

3 |

45% |

118.2 |

|

1 |

60% |

235.2 |

|

2 |

60% |

266.4 |

|

3 |

60% |

258.8 |

Fig. 8 - Cracking Visuals of Fly Ash Concrete After Different Loadings Were Applied and Cracks Were Induced

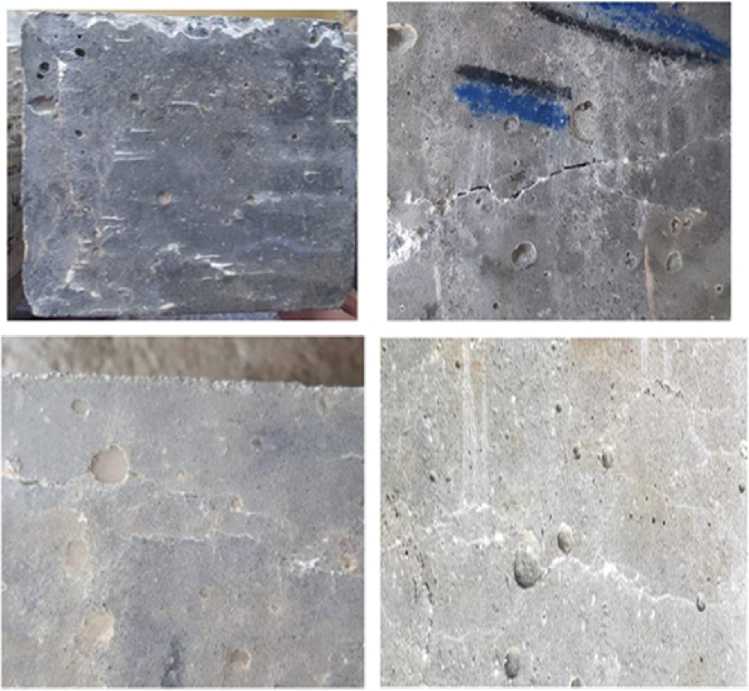

After the cracking process, the samples were submerged in water for autogenous self-healing. The samples before and after the self-healing process are shown in Table 12 and Figure 8, with crack width and healing status. The total healing observation time was 5 weeks.

Fig. 9 - Observing Precipitation in the First Week of Autogenous Self-healing of Fly Ash Concrete

Table 12. Cracking Details and their Healing Status of Fly Ash Concrete

|

Concrete Samples |

Crack width (mm) |

Healing status (crack filled) (after 3 weeks) |

Healing status (crack filled) (after 5 weeks) |

|

Sample (35% Fly Ash) |

|||

|

CC1 |

0.03 |

completely healed |

|

|

CC2 |

0.04 |

completely healed |

|

|

CC3 |

0.06 |

completely healed |

|

|

CC4 |

0.05 |

completely healed |

|

|

Sample (45% Fly Ash) |

|||

|

CC1 |

0.67 |

completely healed |

|

|

CC2 |

0.47 |

completely healed |

|

|

CC3 |

1.22 |

0.67mm healed |

completely healed |

|

CC4 |

0.6 |

completely healed |

|

|

CCS |

0.4 |

completely healed |

|

|

Sample (60%Fh Ash) |

|||

|

CC1 |

0.95 |

0.62mm healed |

completely healed |

|

CC2 |

0.7 |

completely healed |

|

|

CC3 |

0.89 |

0.69mm healed |

completely healed |

|

CC4 |

1.68 |

0.7mm healed |

completely healed |

|

CCS |

0.8 |

0.68mm healed |

completely healed |

After observing all the healing processing in 5 weeks, these samples' compressive strength was tested under compression. The compressive strength values after the healing process are given in Table 13.

Table 13. Compressive Strength of Fly Ash Concrete After Healing

|

Sample |

FA %age |

Strength (N/mm2) |

|

1 |

35% |

19,74 |

|

2 |

35% |

26,25 |

|

3 |

35% |

24,22 |

|

1 |

45% |

12,13 |

|

2 |

45% |

13,38 |

|

3 |

45% |

15,07 |

|

1 |

60% |

10,4 |

|

2 |

60% |

10,52 |

|

3 |

60% |

10,62 |

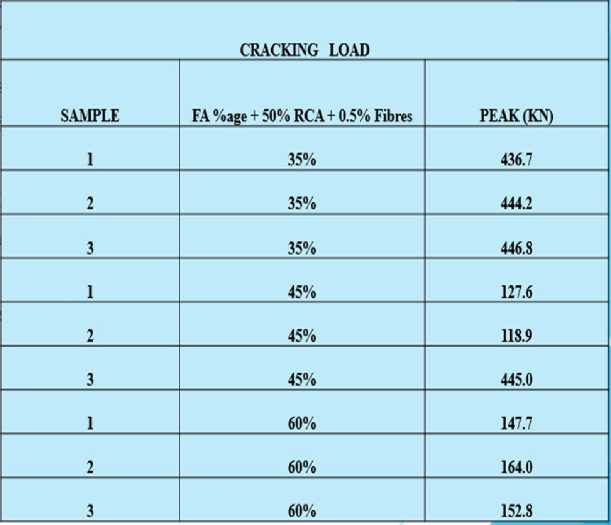

Concrete samples of 35%,45%, and 60% Fly Ash with 50% RCA replacement were prepared. Then, samples were cured for 28 days; then, they were cracked at different loadings, which values are given below in Table 14.

Table 14. Cracking Load Values on 28 Days Strength of Fly Ash, RCA Concrete

|

CRACKING LOAD |

||

|

SAMPLE |

FA %age + 50% RCA |

PEAK (KN) |

|

1 |

35% |

232.2 |

|

2 |

35% |

258 |

|

3 |

35% |

307.3 |

|

1 |

45% |

269.8 |

|

2 |

45% |

318.7 |

|

3 |

45% |

289.4 |

|

1 |

60% |

262.8 |

|

2 |

60% |

226.3 |

|

3 |

60% |

253.5 |

Afterward, the samples were submerged for autogenous self-healing. The crack widths and the healing status are given below in Table 15.

Table 15. Crack Widths and their Healing Status of Fly Ash, R.C.A. Concrete after 3 and 5 Weeks

|

Concrete Samples |

Crack width (mm) |

Healing status (crack tilled) (after 3 aeeks) |

Healing status (crack filled) (alter 5 weeks) |

|

Sample (35%fly ash + 50% recycled aggregate) |

|||

|

('ll |

0.44 |

completely healed |

|

|

(12 |

0.9 |

0.68mm healed |

completely healed |

|

C13 |

0.87 |

0.62mm healed |

completely healed |

|

('ll |

0.68 |

0.60mm healed |

completely healed |

|

('22 |

0.41 |

completely healed |

|

|

1'31 |

1.61 |

0.70mm healed |

compleleh healed |

|

('32 |

1.31 |

0,67mm healed |

complctelv healed |

|

Sample (45%fh ash + 50% receded aggregate) |

|||

|

('ll |

0.69 |

completely healed |

|

|

(12 |

0.38 |

completely healed |

|

|

('ll |

0.89 |

0.71mm healed |

complctelv healed |

|

('22 |

0.84 |

0.69mm healed |

complctelv healed |

|

C31 |

0.6 |

completely healed |

|

|

Sample (60%fh ash + 50% receded aggregate) |

|||

|

('ll |

0.43 |

compleleh healed |

|

|

(12 |

0.38 |

compleleh healed |

|

|

('ll |

0.67 |

0.62mm healed |

completely healed |

|

('22 |

1.06 |

0.64mm healed |

completely heakd |

|

('31 |

0.79 |

0.59mm healed |

completely healed |

u

The compressive strength values after the healing process are obtained and given in Table 16.

Table 16: Compressive Strength of Healed Samples of Fly Ash, R.C.A. Concrete After 5 Weeks of Observation.

|

STRENGTH AFTER HEALING |

||

|

SAMPLE |

FA%age+50%RA |

STRENGTH(N/mm2) |

|

1 |

35% |

22.15 |

|

2 |

35% |

22.43 |

|

3 |

35% |

21.95 |

|

1 |

45% |

14.32 |

|

2 |

45% |

22.68 |

|

3 |

45% |

16.83 |

|

1 |

60% |

10.91 |

|

2 |

60% |

13.45 |

|

3 |

60% |

15.01 |

The macro synthetic fibers were added to increase the mechanical properties of concrete as a loss of significant strength was observed due to the use of Class F Fly Ash and 50% replaced recycled Aggregate. So the samples were prepared using Fly Ash at three volumes of 35%,45%, and 60%, respectively, adding 50% RCA and macro synthetic fibers at the percentage of 0.5% by volume. Then these samples were cured for 28 days and then cracked at different loadings, whose values are described in Table 17.

Table 17. Different Cracking Loads for Fly Ash, R.C.A., and MSF Concrete

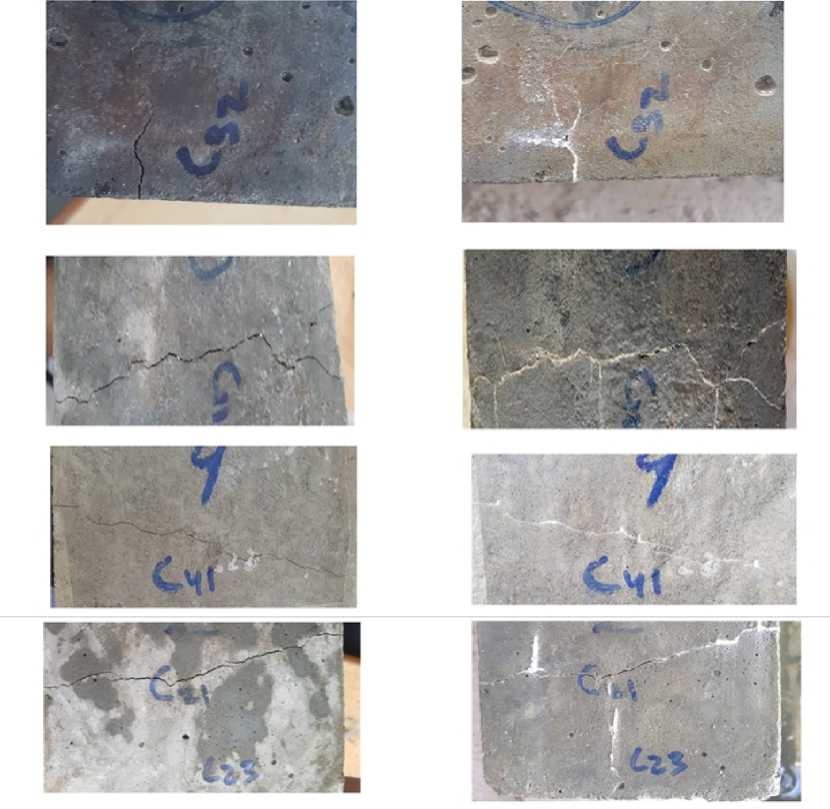

After inducing the cracks, samples were submerged in water for autogenous self-healing, and two observations were made after three weeks and five weeks, so cracking widths and details are given in Table 18 and Figures (10- 12).

Table 18. Cracking Details with Healing Behavior of Fly Ash, R.C.A. and MSF Concrete After 3 and 5

Weeks, respectively

|

CONCRETE SAMPLES |

CRACK WIDTH (mm) |

HEALING STATUS (AFTER 3 WEEK) |

HEALING STATUS (AFTER 5 WEEK) |

|

SAMPLE (35% FLY ASH + 50% RX + 0.5% FIBERS) |

|||

|

Cll |

1.26 |

0.62mm healed |

Completely healed |

|

C12 |

0.7 |

0.68mm healed |

Completely healed |

|

C13 |

0.52 |

Completely healed |

|

|

C14 |

0.91 |

0.65mm healed |

Completely healed |

|

C21 |

0.63 |

Completely healed |

|

|

C22 |

0.55 |

Completely healed |

|

|

C23 |

0.88 |

0.58mm healed |

Completely healed |

|

C24 |

1.07 |

0.68mm healed |

Completely healed |

|

C31 |

0.75 |

0.61mm healed |

Completely healed |

|

C32 |

0.8 |

0.63mm healed |

Completely healed |

|

SAMPLE (45% FLY ASH + 50% RA + 0.5% FIBERS) |

|||

|

Cll |

0.81 |

0.7mm healed |

Completely healed |

|

C21 |

0.35 |

Completely healed |

|

|

C22 |

0.45 |

Completely healed |

|

|

023 |

0.76 |

0.67mm healed |

Completely healed |

|

C31 |

0.58 |

Completely healed |

|

|

SAMPLE (60% FLY ASH + 50% RY + 0.5% FIBERS) |

|||

|

Cll |

0.6 |

Completely healed |

|

|

C12 |

0.63 |

Completely healed |

|

|

C21 |

0.57 |

Completely healed |

|

|

C31 |

0.48 |

Completely healed |

|

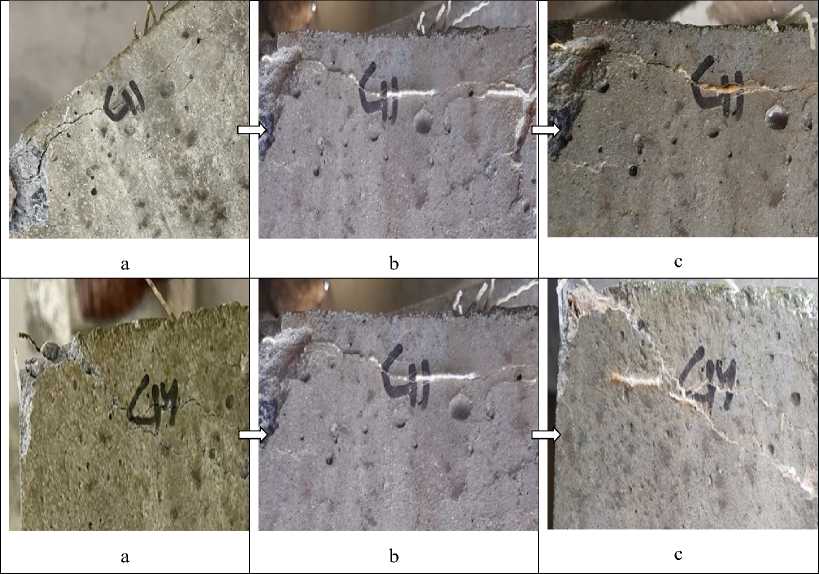

Fig. 11 - Healing in concrete having 35% Fly Ash + 50% RA + 0.5% Fibres. (a) reference (b) after three weeks of healing (c) after five weeks of healing

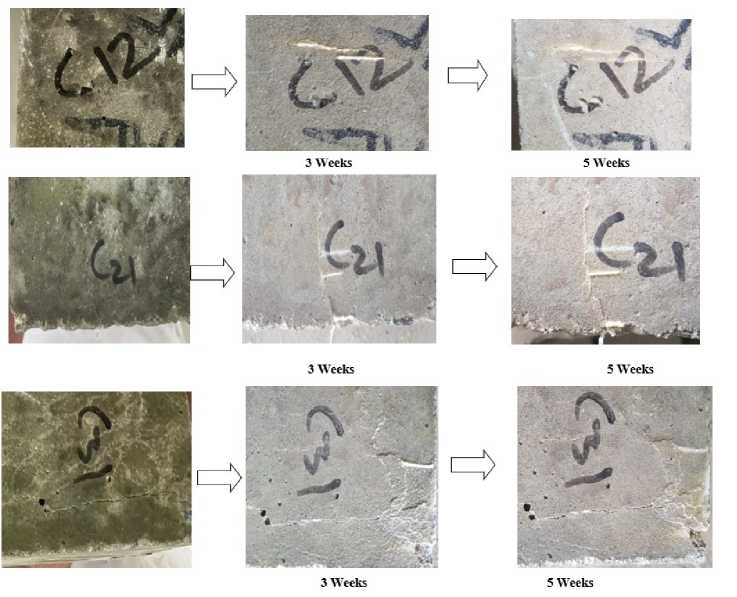

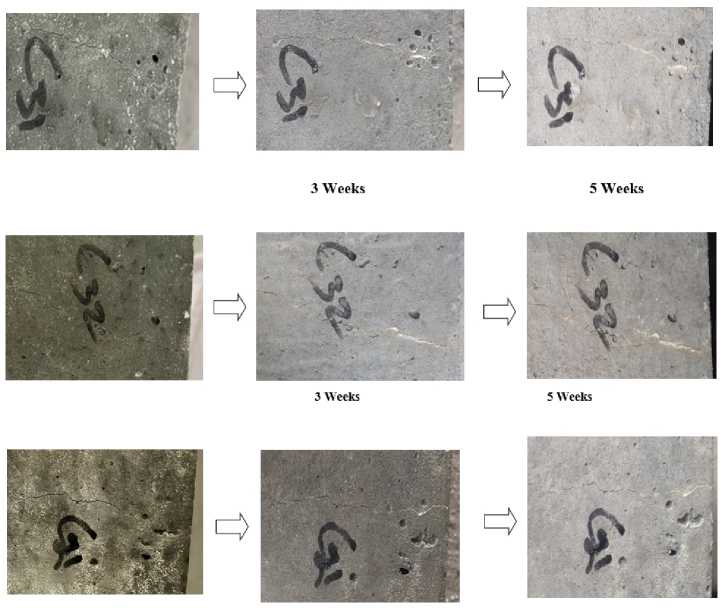

3 Weeks

5 Weeks

5 Weeks

3 Weeks

3 Weeks

5 Weeks

Fig. 12 - Healing in concrete having 45% Fly Ash + 50% RA + 0.5% Fibres

Fig. 13 - Healing in concrete having 60% Fly Ash + 50% RA + 0.5% Fibres

The Compressive Strength of Samples of FA+50%RCA+Fibres After Healing is given in Table 19.

|

STRENGTH AFTER HEALING |

||

|

SAMPLE |

FA %age+50% RA+ 0.5% Fibers |

STRENGTH(N/mm2) |

|

1 |

35% |

21.05 |

|

2 |

35% |

21.3 |

|

3 |

35% |

22.08 |

|

1 |

45% |

21.94 |

|

2 |

45% |

20.29 |

|

3 |

45% |

22.68 |

|

1 |

60% |

14.8 |

|

2 |

60% |

15.91 |

|

3 |

60% |

14.36 |

-

3.6.4 Healing in Major cracks:

Significant cracks were induced, and the healing process was also observed. The healing process of the large cracks is shown in Figures (13- 15).

Fig. 14 - Healing of large crack widths in 35% Volume of Fly Ash

Fig. 15 - Healing of major crack in 45% volume of Fly Ash

Fig. 16 - Healing of Larger Crack in 60% Volume of Fly Ash

-

4 Conclusions

This research aims to investigate the autogenous self-healing behavior and the strength of the concrete modified by various volumes of partially replaced RCA, Fly Ash, and using macro synthetic fibers to increase the mechanical properties of self-healing concrete. Based on the results obtained, the following outcome is drawn:

-

1. When recycled Aggregate and fibers were used in the concrete, a decrease in the workability of concrete was observed, which was stabled with using a higher water-cement ratio.

-

2. The strength of concrete was decreased by using partially replaced recycled Aggregate so an increase in mechanical properties of concrete was observed by using macro synthetic fibers.

-

3. After cracking 28 days of concrete-cured samples, the self-healing behavior of Fly Ash was observed significantly within the first two weeks.

-

4. The self-healing behavior increased with the Fly Ash amount till 45-50% replacement; afterward, a decrease in self-healing ability was observed.

5 Fundings

This research was supported by a grant from the Russian Science Foundation No. 22-79-10021,

Список литературы Self-healing concrete using fly ash, macro synthetic fibres and recycled aggregates

- Zhang, Z.; Gao, Y.; Gao, Y.; Jia, F.; Gao, G. A self-adhesive, self-healing zwitterionic hydrogel electrolyte for high-voltage zinc-ion hybrid supercapacitors. Chemical Engineering Journal 2022, 139014-139014, doi:10.1016/j.cej.2022.139014.

- Luhar, S.; Luhar, I.; Shaikh, F.U.A. A Review on the Performance Evaluation of Autonomous Self-Healing Bacterial Concrete: Mechanisms, Strength, Durability, and Microstructural Properties. Journal of Composites Science 2022, 6, 1-35, doi:10.3390/jcs6010023.

- Islam, M.M.; Hoque, N.; Islam, M.; Ibney Gias, I. An Experimental Study on the Strength and Crack Healing Performance of E. coli Bacteria-Induced Microbial Concrete. Advances in Civil Engineering 2022, 2022, doi:10.1155/2022/3060230.

- Huang, X.; Kaewunruen, S. Self-healing concrete; INC: 2020; pp. 825-856.

- Farhadi, S.; Ziadloo, S. Self-healing microbial concrete-a review. Materials Science Forum 2020, 990 MSF, 8-12, doi:10.4028.

- Sigh, S. Self Healing Concrete ( Bio-Concrete). 2019.

- Morsali, S.; Yucel Isildar, G.; Hamed Zar gari, Z.; Tahni, A. The application of bacteria as a main factor in self-healing concrete technology. Journal of Building Pathology and Rehabilitation 2019, 4, 1-6, doi:10.1007/s41024-019-0045-9.

- Karthik, C.; P, R.M.R. Properties of Bacterial-based Self-healing Concrete- A review. 2019.

- Van Tittelboom, K.; Van den Heede, P.; De Belie, N.D. Self-healing concrete with encapsulated polyurethane; Elsevier Ltd: 2018; pp. 429-466.

- Ubertini, F.; D'Alessandro, A. Concrete with self-sensing properties; Elsevier Ltd: 2018; pp. 501-530.

- Vijay, K.; Murmu, M.; Deo, S.V. Bacteria based self healing concrete – A review. Construction and Building Materials 2017, 152, 1008-1014, doi:10.1016/j.conbuildmat.2017.07.040.

- Amran, M.; Onaizi, A.M.; Fediuk, R.; Vatin, N.I.; Rashid, R.S.M.; Abdelgader, H.; Ozbakkaloglu, T. Self-Healing Concrete as a Prospective Construction Material: A Review. Materials 2022, 15, 1-46, doi:10.3390/ma15093214.

- Research, G.V. Self-healing Concrete Market Size, Share & Trends Analysis Report By Form (Intrinsic, Capsule Based, Vascular), By Application (Residential, Industrial, Commercial, Infrastructure), By Region, And Segment Forecasts, 2020 - 2027. 2020, 1-7.

- De Belie, N.; Wang, J.; Bundur, Z.B.; Paine, K. Bacteria-based concrete; Elsevier Ltd: 2018; pp. 531-567.

- Kanellopoulou, I.A.; Kartsonakis, I.A.; Charitidis, C.A. The Effect of Superabsorbent Polymers on the Microstructure and Self-Healing Properties of Cementitious-Based Composite Materials. Applied Sciences 2021, 11, doi:10.3390/app11020700.

- Karatzas, A.; Bilalis, P.; Kartsonakis, I.A.; Kordas, G.C. Reversible spherical organic water microtraps. Journal of Non-Crystalline Solids 2012, 358, 443-445, doi:10.1016/j.jnoncrysol.2011.10.010.

- Pappas, G.S.; Liatsi, P.; Kartsonakis, I.A.; Danilidis, I.; Kordas, G. Synthesis and characterization of new SiO2–CaO hollow nanospheres by sol–gel method: Bioactivity of the new system. Journal of Non-Crystalline Solids 2008, 354, 755-760, doi:10.1016/j.jnoncrysol.2007.09.007.

- Qureshi, T.; Al-Tabbaa, A. Self-Healing Concrete and Cementitious Materials. Advanced Functional Materials 2020, doi:10.5772/intechopen.92349.

- Kulkarni, P.B.; Nemade, P.D.; Wagh, M.P. Healing of generated cracks in cement mortar using MICP. Civil Engineering Journal (Iran) 2020, 6, 679-692, doi:10.28991/cej-2020-03091500.

- Sudha, N.; Gowsalaya, T.; Hemavarshini, A.; Lakshmi, S.G. Experimental Investigations on Strength Properties of Self-healing Bacterial Concrete Using M-Sand. International Journal of Advance Research and Innovation 2019, 6, 1-4.

- Zhang, M.; Xing, F.; Cui, H.; Lu, H.; Andalib, R.; Abd Majid, M.Z.; Hussin, M.W.; Ponraj, M.; Keyvanfar, A.; Mirza, J.; et al. A Review on Bacteria - Based Self-Healing Concrete. Eco-efficient Repair and Rehabilitation of Concrete Infrastructures 2018, 5, 1-7, doi:10.1016/B978-0-12-818961-0.00003-X.

- Van Tittelboom, K.; Van den Heede, P.; De Belie, N.D.; Andalib, R.; Abd Majid, M.Z.; Hussin, M.W.; Ponraj, M.; Keyvanfar, A.; Mirza, J.; Lee, H.S.; et al. Bacterial Self Healing Concrete-an Innovative Repair Technique. Eco-efficient Repair and Rehabilitation of Concrete Infrastructures 2018, 5, 1-7, doi:10.13140/RG.2.1.3267.5680.

- Gandhimathi, A.; Vigneswari, N.; Janani, S.M.; Ramya, D.; Suji, D.; Meenambal, T. Experimental Study on Self – Healing Concrete. 2012, 5, 17-28.

- Zhang, M.; Xing, F.; Cui, H.; Lu, H. Study on self-healing concrete with pre-embedded healing agent. Advanced Materials Research 2011, 250-253, 405-408, doi:10.4028.

- Varma, P.C.R.; Colreavy, J.; Cassidy, J.; Oubaha, M.; Duffy, B.; McDonagh, C. Effect of organic chelates on the performance of hybrid sol-gel coated AA 2024-T3 aluminium alloys. Progress in Organic Coatings 2009, 66, 406-411, doi:10.1016/j.porgcoat.2009.09.004.

- Feugeas, F.; Tran, M.; Chakri, S. Bio-based admixture with substances derived from bacteria for the durability of concrete. Eco-efficient Repair and Rehabilitation of Concrete Infrastructures 2018, 569-587, doi:10.1016/B978-0-08-102181-1.00020-4.

- Estokova, A.; Smolakova, M.; Luptakova, A.; Strigac, J. Changes in water absorptivity of slag based cement mortars exposed to sulphur-oxidising A.Thiooxidans bacteria. IOP Conference Series: Materials Science and Engineering 2017, 251, doi:10.1088/1757-899X/251/1/012034.