Single-stage water ring vacuum pump with an adjustable degree of internal compression for efficient degassing and deodorization of vegetable oils

Автор: Mohammed Ali S.M., Rodionov Y.V., Nikitin D.V, Sukhova A.O.

Журнал: Вестник Воронежского государственного университета инженерных технологий @vestnik-vsuet

Рубрика: Пищевые системы

Статья в выпуске: 4 (106) т.87, 2025 года.

Бесплатный доступ

The use of a vacuum is essential for processes like degassing and deodorization in the processing of vegetable oils. Water ring vacuum pumps (WRVP) are used for these purposes due to their ability to handle wet gases. The efficiency of the degassing and deodorization process for various liquids and vegetable oils is influenced by the modes of heat and mass transfer within the working volume of the vacuum pump, the uniformity of evacuation pressure, and the degree of internal compressing of the gas-water mixture. These demerits in design and regime of operation result in reduced speed of action of the WRVP and increased energy consumption during the moisture and dissolved gaseous removal process from oils. Detailed analysis of these issues is limited, which restricts the development of these machines, particularly under varying operating conditions. This research aims to present a new design of a WRVP with regulation of the discharge port to improve the overall performance of the vacuum technology for processing oils. The study was based on key principles of thermodynamics, fluid mechanics, WRVP design characteristics, and evacuation process conditions. Mathematical models were created to illustrate the interaction among the thermophysical properties of working fluid and suction gas, such as pressure, temperature, flow rate, speed of action, and power of compression. The investigation's results showed that the new operation regime reduces compression power consumption by 10-15% and shaft power by 25%, while increasing the speed of action by 10% compared to the pump's conventional design under optimal conditions. A technological scheme of a water ring vacuum pump plant with the necessary equipment was developed for the efficient processing of vegetable oils. The use of a vacuum pump with controlled vacuum is an effective method in the technological processes of refining and deodorizing vegetable oils, leading to reduced energy costs, preserving biologically active substances, and providing an environmentally friendly option. The vacuum level, working fluid, and suction gas temperatures entering the pump, along with constructive parameters, are essential in the processes of removing dissolved gases, volatile compounds, free fatty acids, and odor-causing substances during the production of vegetable oils. Experimental validation of the proposed pump design is recommended as a future study, with potential applications to various industrial products.

Single-stage, water ring vacuum pump, adjustable internal compression, degassing, deodorization, vegetable oils

Короткий адрес: https://sciup.org/140313594

IDR: 140313594 | УДК: 621.521 | DOI: 10.20914/2310-1202-2025-4-13-19

Текст научной статьи Single-stage water ring vacuum pump with an adjustable degree of internal compression for efficient degassing and deodorization of vegetable oils

Degassing and deodorizing are important steps in processing vegetable oils. These processes help to ensure the oils stay stable, have a long shelf life, and keep their flavor and aroma. Water ring vacuum pumps (WRVP) are commonly used in installations that require a specific vacuum level. These types of vacuum pumps are widely used in various industries to create vacuum conditions for multiple purposes. WRVP provides several functions, such as compression, creating a vacuum, and pumping working fluids. These pumps are used for several processes such as drying, evaporation, and extraction in chemical and agricultural industrial complexes [1]. The key advantages of these machines are high reliability, durability, environmental friendliness, low cost, and compliance with environmental standards [2]. These machines are available in two categories: single-stage and two-stage. Single-stage is widely used for most technological processes [3].

Application of a WRVP for agrotechnological processes, such as drying of raw materials, evaporation of liquids, degassing and processing of various food products, plays a vital role in developing the quality of products [4–7].

When using water ring vacuum pumps in the degassing and deodorize processes of vegetable oils, several problems arise. The classical WRVP is characterized by a constant degree of compression of the gas-liquid mixture. Unregulated compression leads to inefficiencies, increased energy consumption, and increased heat generation. The excessive heat and pressure reduce the WRVP life cycle and suboptimal oil quality.

Hence, the primary challenges include maintaining precise control over vacuum pressure, temperatures, and the level of compression within the pump to ensure effective operation and the production of high-quality processing oils.

Justify the application of a water ring vacuum pump with an adjustable degree of internal compression of the gas-vapor mixture for improving the energy efficiency and quality of vegetable oils.

Methods and materials

The well-known scientists are engaged in the technological processes and the associated equipment of producing vegetable oils: Ostrikov A.N., Kopylov M.V., Korea E.P., and Vasilenko V.N. [8]. To investigate the mechanism of gas and liquid phase compression in the working chamber of the WRVP, the foundational works of Rodionov Yu.V. and Nikitin D.V. were used [9, 10]. The work was achieved at the FSBEI HE “Tambov State Technical University” department of “Mechanics and Engineering Graphics” in the laboratory of the research and education center of TSTU-МiсhGАU “Ecotechnologies”. The quality analysis of vegetable oils was carried out using the equipment of the Collective Use Center “Breeding of agricultural crops and technologies of production, storage and processing of products for functional and therapeutic purposes”.

Results and discussion

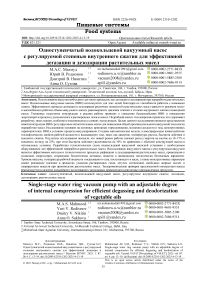

Regulation of the evacuation process, the power of compression, and reduction of action speed losses, and energy costs a key challenges in utilizing the WRVP for refining and deodorizing vegetable oils. A prototype of a new vacuum pump with a regulation of the discharge port (WRVP RDP), (Figure 1) was designed and fabricated, and tested to address the mentioned problems. The key design features include: regulation of the degree of internal compression; elimination of the “harmful space” in the dead zone of the working chamber; reducing the influence of heat generation due to compression; and stable operation under conditions of vegetable oil degassing and deodorization.

Figure 1. Design characteristics of the working cavity of a WRVP: а) traditional design; б) with automatic adjustable of the discharge port: 1 – suction port; 2 – fixed housing; 3 – discharge port; 4 – impeller; 5 – blades; 6 – working fluid

Power consumed during compression [4, 9]:

N comp

N comp

= P s • 5 • —-- ( t )

—

n ave

n ave

n ave

—

1 -a* P , < P comp

n

= P s • S ■ —-- ( t' )

—

n ave

n ср

. —1

—

1 . a' , at p d > J Comp

where, S is the speed of action of WRVP, m3/s; a' is the coefficient that takes into account the reverse flow of the gas phase during compression in the working cell; t is the degree of compression in the working volume of the WRVP [4]:

The proposed design features a vacuum pump equipped with a controlled discharge window (Figure 1b), which facilitates precise regulation of the evacuation processes and degree of compression necessary for the vegetable oil processing [11]. In this design, dynamic regulation of the discharge port size is implemented using an automatically adjustable damper. The position of the discharge port, labeled as 1, 2, and 3, varies depending on the required operational regime of the degassing and deodorization processes. The new design eliminates the loss of action speed caused by the transfer of gas phase from the discharge side to the suction side through the “dead zone”. Control devices and sensors were applied to adjust the regime of operation of WRVP in the processing of vegetable oils. The new vacuum pump maintains the vacuum pressure so that the liquid boils at a temperature below the critical value of the biologically active substances (BAS) of the vegetable oils.

The power (work) supplied to the pump to move the vapor-gas phase (mixture) and remove it from the vacuum pump during the thermodynamic process of polytropic compression is expressed as follows [9, 10]:

V compmax

~ P~ V.

smin

Pa V

^' _ d _ max

PV smin

>

The dimensions of the discharge port and the minimum cell are constant for a conventional design of the WRVP. Therefore, the value τ = V max / V min = F max / F min = const, and regardless of the operating regime of degassing and deodorization processes of vegetable oils, which leads to increased energy consumption and lower product quality. In the new design of the WRVP RDP, the size of the discharge port can be adjusted for a stable compression process in the working cell of the pump [11]. In this case:

p d 'г (рУ . n „

A = N = V dp = s . V„dp = —ave- PV comp s p .d p s s pp P I Pd J nave -1

- 1

where, P is the suction pressure, kРа; is the discharge pressure, kРа.; n is the polytropy index; V is the volume of the suction cavity, m3; V is the volume of the discharge cavity, m3.

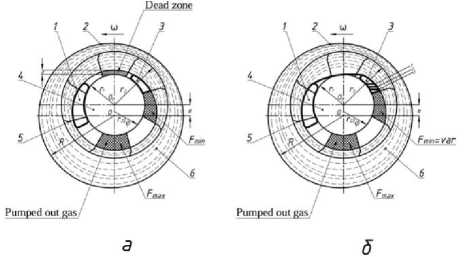

The polytrope index n is taken within the limits, nave = 1.02 ^1.05 , and calculated using the formula [9]:

n ave

where, Т is the temperature of the liquid-gas mixture at the outlet, K.

V . = var, F . = var, and т = V / V . = F IF . = var min min max min max min assuming that:

, ( - ave — 1)/ - ave .. ,

P s ( T — 1) ^ P d = COnst

The effective action speed (volume flow rate of the suction side, productive, capacity) of WRVP is one of the key indicators during the degassing and deodorization of vegetable oils, and is calculated as follows:

S act = S th . X f (5)

where, S is the actual speed of action, m3/s; Sth is the theoretical speed of action, m3/s; A f is the coefficient that refers to productivity losses that occur during the operation of the vacuum pump.

The coefficient ( 2 f ) depends on several factors, such as the properties of the working fluid, the design of the pump, the operating conditions of the agrotechnological processes, the composition of the gas, the temperature, the stability of the liquid ring and cavitation. The following dependence determines this coefficient:

X f = 1 - X 1 - X 2 - X 3 (6)

The coefficients X , X2, X3 characterize the losses of vacuum pump productivity due to gas flows through the dead zone (harmful space), gas flows in gaps and evaporation, respectively, and are calculated by methods presented in the works [9, 10].

In the traditional design of the WRVP, at the initial moment of the pumping, the process of gas over compression occurs, due to which the effect of “harmful volume” arises, reducing the value of the speed of action. The new design regulates the flow space ( τ = var ) of the compression cell and the discharge port, thereby eliminating these losses λ=0 .

Consequently, the coefficient for new WRVP RDP is calculated as:

λ f =1-λ 2 -λ 3 (7)

During the operation of the WRVP in the vegetable oil production line, heat and mass transfer processes occur between the liquid and gas phases. Consequently, liquid droplets undergo evaporation into the functional volume of the working cells, thereby diminishing the operational efficiency. The following coefficient characterizes these losses in action speed:

λ 3

V evap . z π.( r 2 2 2 ϕ - r 1 2 ). b .ψ

Where is the volume of evaporated liquid in- evap side the working cell, m3.

Reduction of the speed of action (capacity of vacuum pump) caused by losses in gaps and heat and mass transfer can be eliminated by application the modification presented in patents [12, 13].

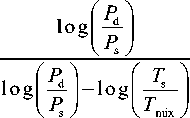

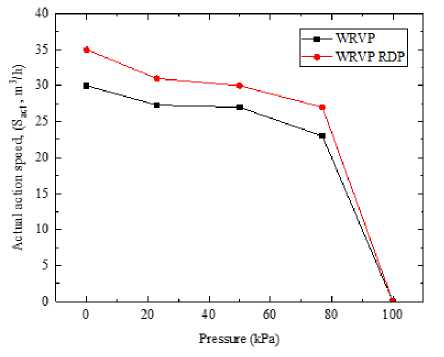

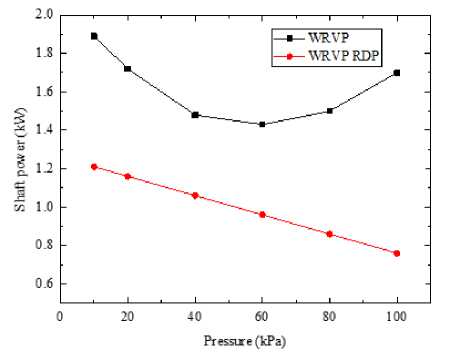

The results of the theoretical calculations (Figure 2) confirm that a WRVP RDP with an adjustable discharge window enables the optimization of internal compression for the process. This adjustment reduces the consumed compression work by 10–15% at the optimal operating regime.

The experimental results (Figure 3а, b) demonstrate that WRVP RDP reduces the power consumption on the shaft by 25% and increases the speed of action by 10% compared with the basic design. The modified configuration of the proposed vacuum pump offers an economical choice in vegetable oil deodorization and degassing.

Figure 2. Theoretical dependence of the compression power vs the created vacuum

(a)

(b)

Figure 3. Experimental dependence: a) actual speed of action vs vacuum pressure; b) shaft power vs vacuum pressure

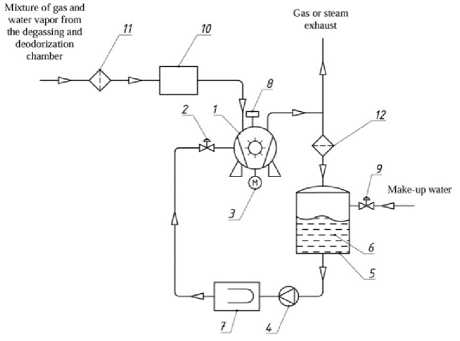

The vacuum technology is the main part of the production plant of vegetable oils. The process of removing dissolved gases, free fatty acids, odor-causing substances, decolourization, and deodorization from oils by the WRVP plant involves a series of mechanisms.

The oil is provided to the degassing/deodor-ization chamber, which has a special design. WRVP (1) with automatic regulation of the discharge port (8) creates of vacuum and generates an environment of low pressure within the chamber for oil thermal vacuum processing. The liquid ring inside the pump's working cavity compresses the sucked gas while rotating in the compression zone. The boiling point of dissolved gases is lowered by the vacuum pump, which leads to evaporation at a lower temperature, and it is pulled out of the degassing chamber. Heating the oil to a given moderate temperature leads to a further reduction in viscosity and enhances the gas release process. The gaseous and liquid phases are separated as they exit the pump in the separator (5). Water as a working fluid is circulated, cooled (7), and supplied to the pump. The control valve (2) is used to adjust the appropriate amount of water needed to prevent the overload heating and normal operation of the vacuum pump. Heat exchanger apparatus (10) serves as a pre-condensation and cooler of the suction gas vapor mixture to eliminate the overload and cavitation inside the pump. Filters (11), (12) are used to protect the pump and auxiliary equipment, ensuring efficient removal of contaminants and maintaining optimal pump operation.

Conclusions

The research findings indicated that the suggested design of a WRVP featuring an adjustable discharge port enhances the effectiveness of degassing and deodorizing vegetable oils. Changing the operating regime leads to a decrease in the power consumption on the compression and the shaft

Figure 4. Technological scheme for an efficient WRVP plant for vegetable oil degassing and deodorization: 1 – WRVP; 2 – hydrodynamic control valve; 3 – electric motor; 4 – circulation pump for additional water fluid; 5 – separator of the gas-liquid phase; 6 – water; 7 – water cooler; 8 – device for automatic regulation of the discharge port; 9 – a hydrodynamic control valve for ensuring a constant level of water in the separator; 10 – pre-condenser/cooler; 11 – vacuum filter; 12 – exhaust filter of vacuum pump of the vacuum pump, and increases the action speed by 15; 25 and 10% respectively, during the evacuation process. This technology preserves biologically active substances in oils, enhances environmental friendliness in production, and opens up new opportunities for various sectors within the food industry.