Structure formation in the «clay soil – carbide sludge» dispersed system

Автор: Sokolova Yu.V., Frolova M.A., Ayzenshtadt A.M., Korolev E.V.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The results of the specialists’ and scientists’ researches

Статья в выпуске: 4 Vol.16, 2024 года.

Бесплатный доступ

Introduction. Clay soil is a multiphase, multicomponent aluminosilicate dispersed system with specific properties determined not only by its composition but also by the formation of coagulative and transition contacts (binds) between the soil particles. One of the methods of changing soil properties is the introduction of active mineral additives that promote the formation of phase contacts (binds) between soil particles as a result of the pozzolanic reaction. The effectiveness of using carbide sludge, which is a multi-tonnage lime-containing waste (the content of active calcium oxide reaches 56%) as an additive, has been proved. However, to date, the proposed mechanism of interaction in the «clay soil – carbide sludge» system is based only on the literature data and has not been experimentally verified. The purpose of this research is to study the mechanism of structure formation in the «clay soil – carbide sludge» dispersed system. Methods and materials. A soil model has been created by mixing saponite-containing material with sand, which corresponds to the composition and properties of sandy loam. The carbide sludge in the form of a suspension was selected from the sludge collector, dried to a constant mass and sieved. Microstructural analysis, differential thermal analysis (DTA), and X-ray phase analysis were used to study the mechanism of structure formation. Results and discussions. Based the results of the differential thermal analysis, there is a decrease in the intensity of the endothermic effect in the range of 460 to 470°C associated with the decomposition of calcium hydroxide in the treated sample. Additionally, an endothermic effect is observed at 750°C, which indicating the decomposition of calcium silicate hydrate. The results of differential thermal analysis are confirmed by X-ray phase analysis, which shows the presence of tobermorite group hydrosilicates in the reaction medium. The study of the microstructure of the analyzed mixtures revealed a decrease in the specific volume of pores with a diameter of 4–5 nm in the modified clay soil. This is associated with gelling from particles of new hydrate formations. Besides that, the volume of pores with a diameter of more than 6 nm increased, which indicates the process of contraction. Conclusion. The mechanism of structure formation in the «clay soil – carbide sludge» system has been established.

Dispersed system, clay soil, active mineral additive, carbide sludge, structure formation, phase contacts

Короткий адрес: https://sciup.org/142242265

IDR: 142242265 | DOI: 10.15828/2075-8545-2024-16-4-375-382

Текст научной статьи Structure formation in the «clay soil – carbide sludge» dispersed system

Review article

Sokolova Yu.V., Frolova M.A., Ayzenshtadt A.M., Korolev E.V. Structure formation in the «clay soil – carbide sludge» dispersed system. Nanotechnologies in Construction. 2024; 16(4): 375–382. – EDN: HXVOGO.

An analysis of the condition of regional and local roads in the Northern Part of the European Russia, in particular, in the Arkhangelsk region, showed that more than 50% of these roads do not meet regulatory requirements [1]. The lack of well-developed, stable and safe transport system hinders the socio-economic, historical and cultural development of the region in question, which is included in the list of priority geostrategic territories of the Russian Federation. One of the possible causes of road damage is the weak roadbase, which is composed of clay-based soils that are prevalent in the northern and Arctic territories. These soils include sandy loams, clay loams, and clays, with inclusions of gravel, pebbles, and boulders [2].

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Clay soil is a classic subject for colloidal chemistry both theoretically and practically, which is explained by the clarity and convenience of studying the nature of the interaction of nano- and microparticles using clay dispersions as an example, as well as its wide application in various sectors of human economic activities [3–13]. The soil is a multiphase multicomponent aluminosilicate polydisperse system consisting of solid, liquid and gaseous components that can act both as a dispersed phase and a dispersion medium. In addition, the soil is a capillary-porous body in which the solid frame and pore system are continuous, which meets the main characteristic of the dispersion medium. The solid component of clay soil is composed of various minerals, among these, the presence of clay minerals (up to 20%) gives specific physicochemical properties characteristic to the soil as a colloidal system: weak water resistance (soaking, high hydrophilicity, ability to swell and shrink), heaving properties, stickiness, plasticity, cation-exchange capacity, thixotropy and increased adsorption capacity [14–18]. This is due to the particle size distribution and structural characteristics of clay rocks. They have a small particle size, typically ranging from 1 to 100 microns, and a highly developed specific surface area (from 100 m 2 /kg for sandy loams and clay loams to 100,000 m : /kg for clays) [19]. Clay minerals have a layered structure with a rigid or sliding crystal structure in which two two-dimensional tetrahedral silica-oxygen grids surround two-dimensional octahedral alumohy-droxyl grids on both sides [20].

In addition, coagulative and transition contacts have a significant effect on the properties of clay soils. These contacts form between mineral particles due to long-range molecular, magnetic, electrostatic and valence forces and are characterized by low strength and reversible nature of destruction [19]. The mechanism of formation of point (transition) contacts in clay dispersed systems related to the phenomenon of «self-assembly», which occurs due to the redistribution of nanoparticles and crystallization of water-soluble salts within the contact gap, which leads to an increase in the area of interaction between the particles [21]. Less often, high-strength phase contacts form between clay particles due to an increase in the contact area (crystallization) or the development of a new phase at the contact (cementation). This contributes to the improvement of the physico-chemical and physico-mechanical characteristics of clay soils [19].

It is known that one of the most effective and widely used methods for creating phase contacts between mineral particles of clay soils is the introduction of substances called active mineral additives [22–27]. Various industrial waste can be used as additives: pulverized fuel ash, hydraulic removal ash, sewage sludge combustion ash, granulated blast furnace slag, cement and lime dust, dolomite lime, ceramic waste, rice husk ash, waste paper, phosphogypsum and palm oil production ash.

These materials are characterized by a high content of calcium hydroxide, which enters into chemical interaction (pozzolanic reaction) with active siliceous and aluminous components of the soil to form cementing compounds or gels – calcium silicate hydrate (CSH) according to scheme 1. Additionally, calcium aluminate hydrate (CAH) and calcium aluminosilicate (CASH) may also form.

6SiO2+5Ca(OH)2 → 5CaO×6SiO2×5H2O. (1)

In [28–30], the effectiveness of using carbide sludge as an active additive was proved. This is a multi-tonnage lime-containing waste, formed annually in amounts ranging from about 18 to 70 million liters as a result of quenching calcium carbide in the production of acetylene. The introduction of carbide sludge into the clay soil in an amount of up to 9% from the soil mass on dried basis increases the strength, water resistance and frost resistance of the soil. Besides that, the study of the particle size distribution and mineral composition showed that clay soils are characterized by the pozzolanic activity, which is the ability of active clay components in the soil to interact with calcium hydroxide [31]. However, to date, the proposed mechanism of interaction in the «clay soil – carbide sludge» system is based only on the literature data and has not been experimentally verified.

Thus, the purpose of this research is to study the mechanism of structure formation in the «clay soil – carbide sludge» dispersed system.

METHODS AND MATERIALS

Materials

Due to the remoteness and inaccessibility of the northern and Arctic territories, as well as due to the restriction of economic activity in some territories, a model system of clay soil was created based on bibliographic and archival research by mixing the clay component and sand in a ratio of 1:6, respectively. We selected the river polymineral sand from the «Krasnoflotsky-Zapad» deposit with a fineness modulus of Mf = 1.1. Saponite-containing material was used as a clay component, which is a multitonnage waste (up to one million tons per year) of industrial enrichment of kimberlite ores from the diamond deposit named after M.V. Lomonosov. The developed soil model according to the mineral composition, particle size distribution and physical properties presented in [31] corresponded to sandy loams as one of the characteristic types of the soils in the Northern part of the European Russia.

The carbide sludge was collected in the form of a suspension from the sludge collector at the Carbide and Ferroalloy Plant, in Inta town (Komi). It was then dried to

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Table 1

Chemical composition of the carbide sludge

|

Component |

Ca(OH)2 |

Fe2O3 |

CaCO3 |

CaSO 4 |

SiO2 |

Al2O3 |

|

Content, % |

79.6 |

0.2 |

14.9 |

1.0 |

3.0 |

1.3 |

Table 2

Characteristics of the carbide sludge

Methods

Initially, two groups of samples were created:

-

1) The dry initial components: saponite-containing material S1, carbide sludge СS1 and a mixture of saponitecontaining material and carbide sludge (S–CS)1;

-

2) The dry initial components were mixed with water (5% of the dry mixture weight, which corresponds to optimal conditions of structure formation [30]), dry-rodded and hardened under normal conditions (at a temperature of 20±2°C and relative humidity 95±5%) for 28 days: saponite-containing material S2, carbide sludge CS2 and a mixture of saponite-containing material and carbide sludge (S–CS)2.

The rational ratio of components in the S–CS mixture for groups 1 and 2 of the samples was assumed to be the same, and it was 7:1, respectively [31].

To study the mechanism of structure formation in the «clay soil – carbide sludge» dispersed system, a set of scientific research methods were used, including microstructural, differential thermal and X-ray phase analysis.

The microstructural features of the samples were examined using scanning electron microscopy (SEM) with a Carl Zeiss Sigma VP scanning electron microscope (Carl Zeiss, Germany). The morphometric parameters of the microstructure (specific adsorption surface area and porosity) were determined by the sorption method on an

Autosorb-iQ-MP analyzer (Quantachrome instruments, USA) and calculated using the Brunauer–Emmett–Teller (BET) method.

The amount of reduction in the relative pore volume was calculated using the formula:

-

-Д Р =^^100 %, (2)

where Р2 – the pore volume in the sample of the group 2, cm3/g; Р1 – the pore volume in the sample of the group 1, cm3/g.

The “–” sign indicates a decrease in the relative pore volume.

Differential thermal analysis (DTA) was performed on a thermal analyzer Discovery SDT 650 (TA Instruments, USA) in alumina crucibles in a nitrogen atmosphere (consumption 50 ml/min) at a heating rate of 10°C/min.

X-ray phase analysis was performed on a Shimadzu XRD-7000 S X-ray diffractometer (Shimadzu, Japan) on a standard holder, with a rotation of 30 rpm. Operating parameters of the X-ray tube: accelerating voltage 40 kV, current 30 mA, target material – Cu. The scanning range at an angle of 2θ is from 10 to 150°, the scanning speed is 2 deg/min, the measurement pitch is 0.02°. Similarity matching was carried out using the PDF-2 database (Powder Diffraction File™ PDF-2 Release 2010, International Centre for Diffraction Data), taking into account the elemental composition of the sample.

RESULTS AND DISCUSSION

The results of the specific adsorption surface area, presented in Table 3, indicate that the values of this parameter for the samples from the group 2 are lower than those for the samples from the group 1. This difference can be attributed to the different manufacturing processes. However, the additivity law is not followed for either group of samples, confirming the structure formation in the S–CS system.

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Table 3

Specific adsorption surface area of the samples

|

Sample |

S1 |

S2 |

CS1 |

CS2 |

(S–CS)1 |

(S–CS)2 |

|

Specific surface area, m2/kg |

41 255 |

18 530 |

7609 |

1328 |

21 933 |

8870 |

-AE%

-20

-40

■ S ■ CS ■ S-CS

ШИ

Pore diameter; nm

Fig. 1. Dependence of the decrease in the relative volume of pores on their diameter for the samples: S – saponitecontaining material; CS – carbide sludge; S–CS – modified clay soil

An analysis of the morphometric features of the microstructure of the samples (Figure 1) showed that the specific volume of pores with a diameter greater than 9 nm increased in the saponite-containing material (S samples).

This is due to the formation of reversible coagulative and transition contacts (binds) between clay particles facilitated by a thin equilibrium liquid film up to several tens of nanometers in thickness, which is partially removed in a degassing at a temperature of 100°C. In the carbide sludge (CS samples), the specific volume of pores with a diameter greater than 4 nm decreased due to compaction of the mixture during sample forming and the physicochemical processes of structure formation during carbonate hardening. In the modified clay soil (S–CS samples), the specific volume of pores with a diameter of 4–5 nm decreased, which is associated with gelling from particles of new hydrate formations, and the volume of pores with a diameter of more than 6 nm increased, which, in our opinion, indicates the process of contraction.

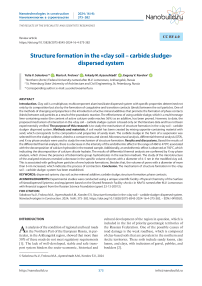

According to the results of the differential thermal analysis (Figure 2), the thermogram 3 ((S–CS)2 sample) shows a decrease in the intensity of the endothermic effect in the range of 460 to 470°C, which is associated with the decomposition of calcium hydroxide. This indicates that the carbide sludge is interacting with the active components of the saponite-containing material. In addition, there is an endothermic effect at 750°C, characteristic of the decomposition of calcium silicate hydrate (CSH).

2 О-2-4-6-8 bo/M .MOD 1EDH

Fig. 2. Differential thermal analysis (DTA) for the group 2 of the samples: 1 – saponite-containing material (S2); 2 – carbide sludge (CS2); 3 – a mixture of the saponite-containing material and the carbide sludge (S–CS)2; CSH – calcium silicate hydrate

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES ooooooooooooo 210987654321 1 1- 1*

slan ЗАПЕ 屮-昼snsUI

■ portlandite

• saponite ▲ tobermorite

40 50 60 70 80 90 100

28, deg.

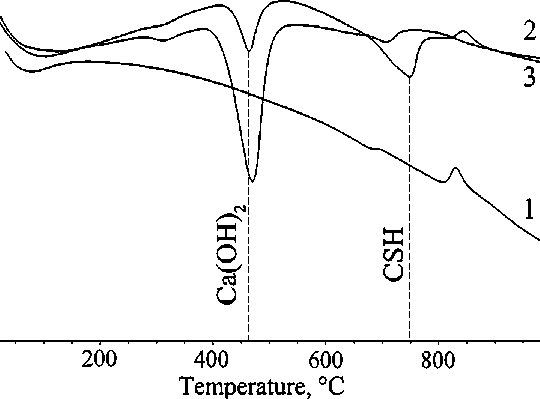

Fig. 3. X-ray photograph of the sample from the group 2 from a mixture of saponite-containing material and carbide sludge (S–CS)2

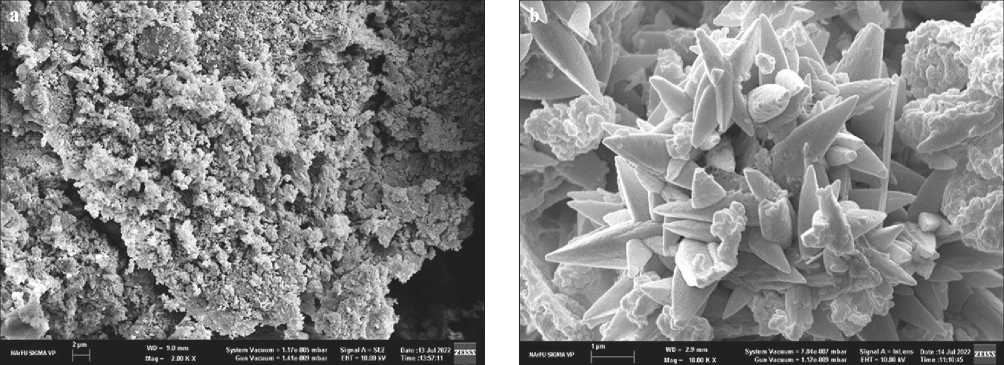

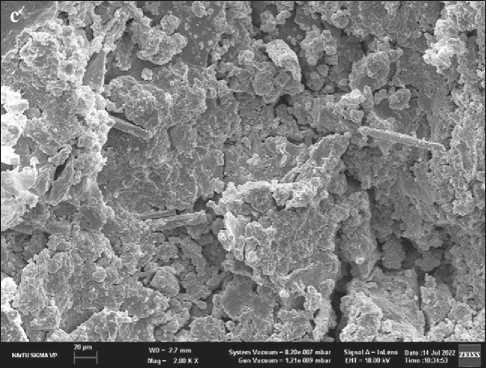

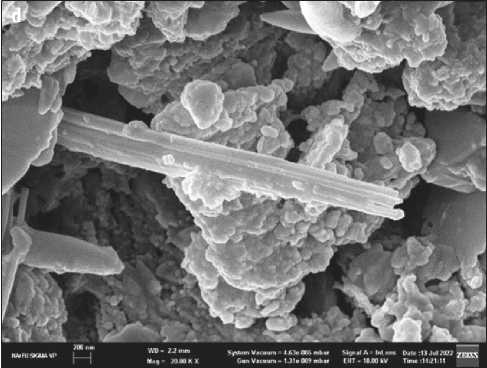

Fig. 4. The microstructure of the sample from the group 2 from a mixture of saponite-containing material and carbide sludge (S–CS)2: the images show the sample at different magnifications: а, c –×2000 magnification; b –×10,000 magnification; d –×20,000 magnification, where a, b, c, d are photographs of different areas on the sample’s surface

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

The DTA results are supported by X-ray phase analysis (Figure 3). X-ray photographs of the (S–CS)2 sample present reflexes, which are characteristic of the tobermorite group hydrosilicates, and they are absent on the X-ray photographs of the saponite-containing material.

Analysis of microstructural features in the (S–CS)2 system (Figure 4) showed the formation of the initial phases of calcium silicate hydrate consisting of white microscopic aggregates in the form of randomly oriented lamellar and needle-like crystals 1–60 microns in length.

CONCLUSION

Thus, using microstructural, differential thermal, and X-ray phase analysis, the mechanism of structure formation in the «clay soil – carbide sludge» dispersed system was established. The mechanism involves the interaction of carbide sludge with active clay components in the soil with the formation of calcium silicate hydrate, contributing to the formation of phase contacts between mineral particles of the soil and, as a result, improving its physico-chemical, and physical and mechanical characteristics.

Список литературы Structure formation in the «clay soil – carbide sludge» dispersed system

- Regions of Russia. Named regions with the best quality of roads. RIA Rating URL: https://riarating.ru/regions/20220704/630225323.html. (accessed 09.01.2023).

- Trofimov V.T., Voznesensky E.A., Korolev V.A. Engineering Geology of Russia. Volume 1. Soils of Russia. Moscow, KDU Publ.; 2011. (In Russian).

- Moshnyakov M.G. Russian Clay Deposits and the Possibility of Their Use for Import Substitution of Raw Material Bases in the Production of Porcelain Granite. Bulletin of the Belgorod State Technological University named after V.G. Shukhov. 2016; 4 (60): 65. (In Russian).

- Barbane I., Vītiņa I., Lindiņa L. Investigation of the chemical and mineralogical composition of romancement synthesized from Latvian clay and dolomite. Building materials. 2013; 1:40–43. (In Russian).

- Yakovleva A.A., Nemchinova N.V. Prospects for the use of clays of local occurrence in metallurgical practice. Bulletin of the Irkutsk State Technical University. 2019; 23(2): 415–425. DOI: 10.21285/1814-3520-2019-2-415-425. (In Russian).

- Korolev V.A. History of the use and study of clays, clayey soils and minerals. Engineering geology. 2021; 16(3): 6–25. DOI: 10.25296/1993-5056-2021-16-3-6-24. (In Russian).

- Guryeva V.A., Doroshin A.V. Low-quality brick clays and ash and slag waste in the production of ceramic bricks. Building materials. 2023; 5: 30–34. DOI: 10.31659/0585-430X-2023-813-5-30-34. (In Russian).

- Suleimenov Zh., Sagyndykov A.A., Moldamuratov Zh.N., Bayalieva G.M., Alimbayeva Zh.B. High-strength wall ceramics based on phosphorus slag and bentonite clay. Nanotechnology in Construction: Scientific Internet Journal. 2022; 14(1): 11–17. DOI: 10.15828/2075-8545-2022-14-1-11-17. (In Russian).

- Lavrov I.Y., Beregovoy V.A. Clay-Based Printing Compounds for Additive Technologies. PSUAC Bulletin: Construction, Science and Education. 2022. 1(14): 19–26. (In Russian).

- Baklay A.A., Makovskaya N.A., Leontyeva T.G., Kuzmuk D.A., and Moskalchuk L.N. Sorption CS(I) on clays of the Markovskoye (Belarus) and 10th Khutor deposits (Khakassia, Russia). Radiochemistry. 2022; 64(2): 193–200. (In Russian).

- Lakhov S.D., Petrova Yu.V., Bachinskaya V.M. Experience in the use of a multicomponent feed additive based on bentonite clay in animal husbandry. Hippology and veterinary medicine. 2022; 1(43): 82–88. (In Russian).

- Balykov A.S., Nizina T.A., Volodin S.V. Optimization of technological parameters for obtaining mineral additives based on calcined clays and carbonate rocks for cement systems. Nanotechnology in Construction: Scientific Internet Journal. 2022; 14(2): 145–155.DOI: 10.15828/2075-8545-2022-14-2-145-155. (In Russian).

- Sinitsin D.A., Shayakhmetov U.Sh., Rakhimova O.N., Khalikov R.M., Nedoseko I.V. Nanostructured foam ceramics for construction purposes: production and application technology. Nanotechnology in Construction: Scientific Internet Journal. 2021; 13(4): 213–221. DOI: 10.15828/2075-8545-2021-13-4-213-221. (In Russian).

- Khankhasaeva S.Ts., Dashinamzhilova E.Ts., Badmaeva S.V., Bardamova A.L. Adsorption of Triarylmethane Dye on Ca-Montmorillonite: Equilibrium, Kinetics and Thermodynamics. Colloid Journal. 2018; 80(4): 472–478. DOI: 10.1134/S0023291218040043. (In Russian).

- Uriev N.B. Rheological and thixotropic properties of an aqueous suspension of bentonite clay preliminarily subjected to electrohydrodynamic action. Colloid Journal. 2011; 73(1): 90–96. (In Russian).

- Osipov V.I., Karpenko F.S., Kalbergenov R.G., Kutergin V.N., and Rumyantseva N.A. Rheological properties of clayey soils. Geoecology. Engineering Geology, Hydrogeology, Geocryology. 2017; 6: 41–51. (In Russian).

- Taubaeva R., Meszarosh R., Musabekov K., Baran Sh. Electrokinetic potential and flocculation of bentonite suspensions in solutions of surfactants, polyelectrolytes and their mixtures. Colloid Journal. 2015; 77(1): 100. DOI: 10.7868/S0023291214060172. (In Russian).

- Apkaryan A.S., Sablina T.Y. Physical and technical properties of clay from the Kornilovskoye deposit in the Tomsk region. News of Higher Educational Institutions. Physics. 2022; 65(7); (776): 35–41. DOI: 10.17223/00213411/65/7/35. (In Russian).

- Osipov V.I., Sokolov V.N. Clays and their properties. Composition, structure and formation of properties. Moscow: GEOS; 2013. (In Russian).

- Sonin A.S., Churochkina N.A., Kaznacheev A.V., and Golovanov A.V. Liquid crystals of clay dispersions. Colloid Journal. 2018; 80(6): 629–651. DOI: 10.1134/S0023291218060174. (In Russian).

- Korolev V.A. On the issue of «ion-electrostatic bonds» in clays and the causes of clay hardening during dehydration. Engineering Geology. 2019; 14(3): 6–19. DOI: 10.25296/1993-5056-2019-14-3-6-18. (In Russian).

- Rahgozar M., Saberian M., Li J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transportation Geotechnics. 2018; 14: 52–60. DOI: 10.1016/j.trgeo.2017.09.004.

- Marto A., Latifi N., Eisazadeh A. Effect of non-traditional additives on engineering and microstructural characteristics of laterite soil. Arabian Journal for Science and Engineering. 2014; 39(10): 6949–6958. DOI: 10.1007/s13369-014-1286-1.

- Latifi N., Marto A., Eisazadeh A. Physicochemical behavior of tropical laterite soil stabilized with non-traditional additive. Acta Geotechnica. 2016; 11(2): 433–443. DOI: 10.1007/s11440-015-0370-3.

- Sol-Sánchez M., Castro J., Ureña C., Azañón J. Stabilisation of clayey and marly soils using industrial wastes: pH and laser granulometry indicators. Engineering Geology. 2016; 200: 10–17. DOI: 10.1016/j.enggeo.2015.11.008.

- Latifi N., Meehan C., Majid M., Horpibulsuk S. Strengthening montmorillonitic and kaolinitic clays using a calcium-based non-traditional additive: A micro-level study. Applied Clay Science. 2016; 132–133: 182–193. DOI: 10.1016/j.clay.2016.06.004.

- al-Swaidani A., Hammoud I., Meziab A. Effect of adding natural pozzolana on geotechnical properties of limestabilized clayey soil. Journal of Rock Mechanics and Geotechnical Engineering. 2016; 8(5): 714–725. DOI: 10.1016/j.jrmge.2016.04.002.

- Grishin A.N., Panchenko A.I., Kharchenko I.Ya., Bazhenov M.I. Finely dispersed composite binder for soil fixation by injection method. Vestnik MGSU. – 2017; 12(11) (110): 1289–1298. DOI: 10.22227/1997-0935.2017.11.1289-1298. (In Russian).

- Rodygin K.S., Gyrdymova Yu.V., Ananikov V.P. Carbide sludge as a key inorganic component of a sustainable carbon cycle. Advances in chemistry. 2022; 91(7): RCR5048. DOI: 10.1070/RCR5048. (In Russian).

- Sokolova Yu.V., Nelyubova V.V., Aizenstadt A.M., Strokova V.V. Rheology of soil concrete mixtures based on polymer-organic binder with mineral modifier. Building materials. 2022; 12: 26–32. DOI: 10.31659/0585-430X-2022-809-12-26-32. (In Russian).

- Sokolova Yu.V., Aizenstadt A.M., Frolova M.A., Shinkaruk A.A., Makhova T.A. Potentiometric method for assessing pozzolanic activity of highly dispersed materials. Nanotechnology in Construction: Scientific Internet Journal. 2023; 15(4): 349–358. DOI: 10.15828/2075-8545-2023-15-4-349-358. (In Russian).