Structure formation of lime composites with polysaccharide additives

Автор: Loganina V.I., Garkina I.A., Tkach E.V., Stepina I.V.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 3 Vol.16, 2024 года.

Бесплатный доступ

Introduction. The research is aimed at obtaining a lime composition and coating based on it for the restoration of cultural heritage sites. Materials and methods. We used for study slaked lime (fluff) with an activity of 83%. Sunbo PC 1021 (a superplasticizer based on polycarboxylate ether), MasterGlenium 115 and Sika ViscoCrete-226 P were used as plasticizing additives. The cohesive strength of the coatings was determined by the axial tensile strength. Rheological properties were assessed by plastic strength, which was determined using a KP-3 conical plastometer. Results and discussions. It was revealed that the introduction of polysaccharide additives contributes to a sharp increase in plastic strength compared to the control composition. The additive Sika ViscoCrete-226 P has the greatest plasticizing effect. It was revealed that the qualitative mineralogical composition of lime composites is the same. However, analysis of X-ray diffraction patterns indicates an increase in the intensity of CaCO3 reflections, which indicates an increase in the carbonization front. Control samples contain higher amounts of portlandite. A slight increase in the width of the CaCO3 peaks is observed, which indicates the possible introduction of organic molecules into the calcite composition. A change in the parameters of the crystal lattice was established in samples prepared with slaked lime in the presence of polysaccharides. Conclusion. The absence of chemical interaction between lime and polysaccharides has been established. It has been shown that coatings based on lime compositions with the addition of polysaccharides are characterized by higher cohesive strength. A change in the parameters of the crystal lattice was established in samples prepared with slaked lime in the presence of polysaccharides.

Lime binder, polysaccharides, structure formation, plastic strength, cohesive strength

Короткий адрес: https://sciup.org/142240865

IDR: 142240865 | DOI: 10.15828/2075-8545-2024-16-3-211-217

Текст научной статьи Structure formation of lime composites with polysaccharide additives

Review article

L ime compositions are widely used for the restoration of cultural heritage sites [1, 2]. To increase the durability of coatings based on lime finishing compositions, various modifying additives are introduced into their formulation. To increase the durability of lime coatings, works [3] proposed introducing synthesized hydrosilicates (HSS), silicic acid sol [4–7], synthesized hydroaluminosilicates [8], and organomineral additives [9, 10] into the formulation. To restore historical masonry, it is proposed

in [11–14] to use lime compositions, the formulation of which includes metakaolinite. Of interest is the use of polysilicate mortar in lime compositions for restoration and finishing of building walls. Polysilicates are a dispersion of colloidal silica in an aqueous solution of alkali metal silicates. Studies have shown the effectiveness of using polysilicate mortar in lime compositions as a modifying additive [15, 16].

In [17, 18], a proposal was made to use lime compositions in the formulation of which organic components (polysaccharides, proteins and fatty acids) are introduced

CONSTRUCTION MATERIALS SCIENCE as part of the implementation of restoration projects. The authors determined that the introduction of animal glue as an additive increases the mechanical strength of the solution by 2 times, increases the carbonization front by 2 times, and reduces porosity and pore size. In the Old World, plant extracts, glutinous rice, fruit juices, oils, and animal fats were added to slaked lime to improve the properties of lime mortars and plasters [19–20]. For example, in his book De Architectura, Vitruvius indicated that oil (Oleo subacta) should be added to lime to make the mortar waterproof. In the Americas, there is ample ethnohistorical, archaeological and analytical evidence for the use of plant extracts by the ancient Maya stonemasons.

Despite a significant amount of research devoted to methods for increasing the durability of lime composites, many issues of ensuring their durability, especially during the restoration of cultural heritage sites, remain unsolved. It is of interest when developing a formulation for a lime composition to use a biomimetic method, which consists in obtaining a lime composite with meso-nanostructural characteristics corresponding to calcite biominerals. This will significantly increase the operational durability of the restoration material.

MATERIALS AND METHODS

The work used slaked lime (fluff) with a true density of 2230 kg/m3, bulk density of 280 kg/m3, activity of 83%, with a specific surface area Ssp of 559 m2/kg.

Water-soluble modified polysaccharides Atren Cem LV and Atren Cem NV (TU 2458-062-63121839-2014) were used as an organic additive.

The additives used as plasticizing additives were RS 1021 (superplasticizer based on polycarboxylate ether), MasterGlenium 115 and Sika ViscoCrete-226 P. The amount of plasticizer was 1% by weight of lime. The water-lime ratio W/L in all compositions was W/L = 1.0. Additives were introduced along with the mixing water.

The cohesive strength of the coatings was determined by the axial tensile strength on samples measuring 10×10×50 mm and calculated using the formula

% = ! , (1)

where P is taken to be the destructive force, N; F is cross-sectional area of the sample before testing, m2.

Rheological properties were assessed by plastic strength, which was determined using a KP-3 conical plastometer.

Studies of the mineralogical composition were carried out using a D8Advans powder diffractometer (Germany), (CuKα radiation, sample rotation, continuous (1 deg/min), step-by-step (0.02° step, 10 s exposure) modes in the angle range 2Θ = 5°–100°) [17]. When identifying phases, we used the ICDD PDF2 and Crystallography Open Database1

RESULTS

It has been established that the introduction of the addition of Atren Cem LV and Atren Cem HV polysaccharides contributes to a sharp increase in plastic strength compared to the control composition by 1.5 times at the time of mixing. The introduction of Sunbo PC 1021 plasticizer into the lime mixture helps reduce plastic strength. At the time of mixing, the plastic strength of the control composition was 105 kPa, and with the addition of Atren Cem LV and the plasticizer Sunbo PC 1021 – 58 kPa. The plasticizing effect of the Sika ViscoCrete-226 P additive at the initial moment of hardening is the same as the effect of the Sunbo PC 1021 additive, however, after 8 hours of hardening, the plasticizing effect of the Sunbo PC 1021 additive decreases, the plastic strength of the composition becomes equal to the composition with the MasterClenium 115 additive, while compositions with with the addition of Sika ViscoCrete-226 P they retain a low plastic strength of 85 kPa (Table 1).

Table 1

Plastic strength of lime composition with the addition of polysaccharides Atren Cem LV

|

Compound |

Plastic strength value, kPa |

|

Lime+water, W/L = 1.0 |

105 |

|

composition with the addition of Atren Cem LV 1% by weight of lime, W/L = 1.0 |

149 |

|

composition with the addition of Atren Cem LV and plasticizer Sunbo RS 1021, W/L = 1.0 |

58 |

|

composition with the addition of Atren Cem LV and plasticizer MasterClenium 115, W/L = 1.0 |

76 |

|

состав с добавкой Atren Cem LV и пластификатором Sika ViscoCrete-226 P, W/L = 1,0 composition with the addition of Atren Cem LV and plasticizer Sika ViscoCrete-226 P, W/L = 1.0 |

56 |

CONSTRUCTION MATERIALS SCIENCE

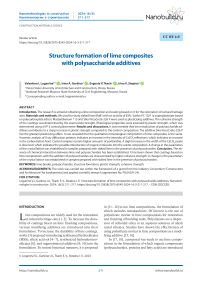

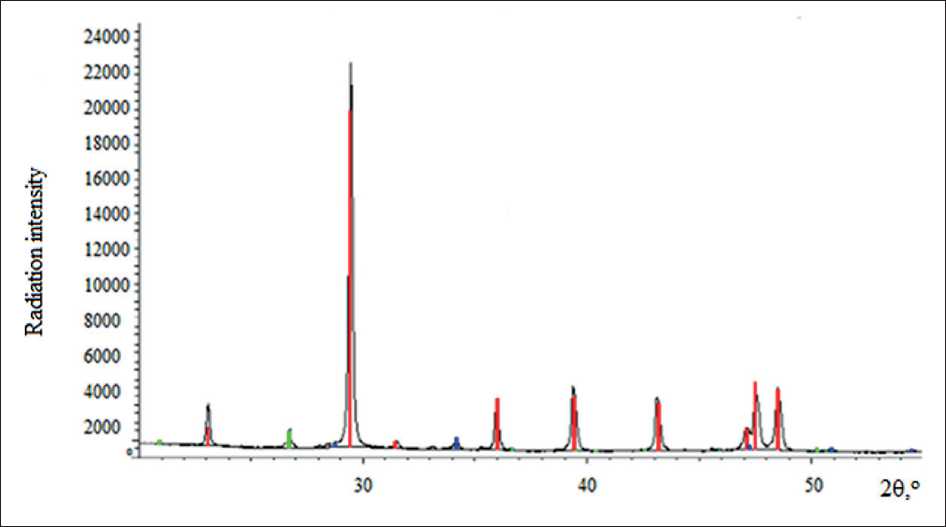

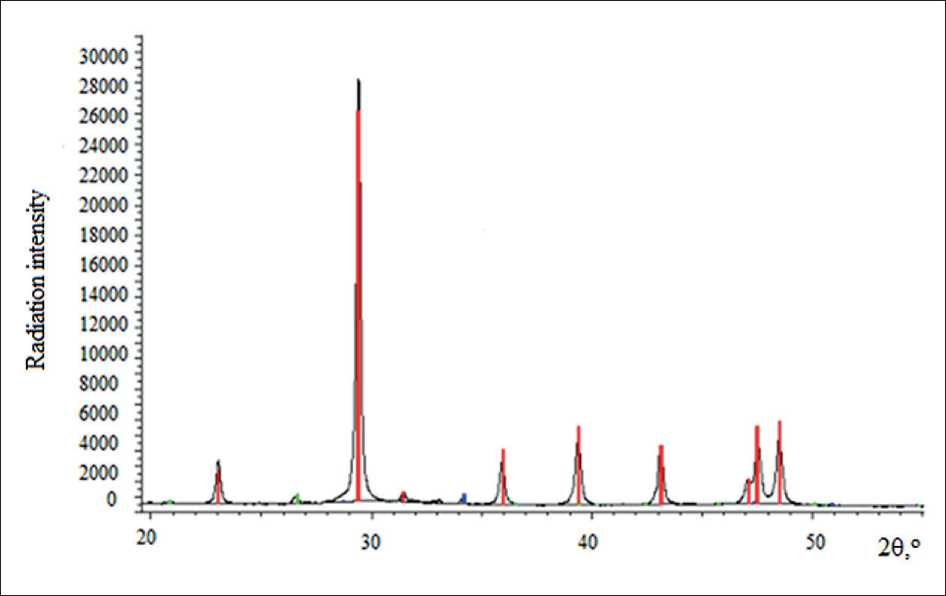

In Fig. 1–3 show diffraction patterns of the samples – control and with the additive. Analysis of the data given in Table 2 indicates that the qualitative mineralogical

composition is the same. However, analysis of diffraction patterns indicates an increase in the intensity of CaCO3 reflections, which indicates an increase in the carboniza-

Fig. 1. X-ray diffraction pattern of lime composite (control composition)

Fig. 2. X-ray diffraction pattern of lime composite (with the addition of Atren Cem HV polysaccharide)

Table 2

Mineral content of lime composites

|

Compound |

Mineral content(peak intensity ratio) |

||

|

СаСО3(I/Ic) |

Са(ОН)2(I/Ic) |

SiO2(I/Ic) |

|

|

control |

87.4064% (3.74) |

3.1247% (3.530) |

4.1834% (4.810) |

|

Slaked in the presence of an additive |

92.2662% (3.490) |

2.1550% (3.840) |

2.1778% (4.520) |

|

With additive |

88.8736% (3.74) |

2.9287% (3.840) |

2.9404%(4.810) |

|

Crystal lattice parameters |

|||

|

СаСО3 |

Са(ОН)2 |

SiO2 |

|

|

control |

|||

|

а |

4.98700 |

3.58440 |

4.90000 |

|

с |

17.05800 |

4.89620 |

5.40000 |

|

Slaked in the presence of an additive |

|||

|

а |

4.99100 |

3.58620 |

4.91580 |

|

с |

17.06200 |

4.88010 |

5.40910 |

|

With additive |

|||

|

а |

4.98700 |

3.58620 |

4.91000 |

|

с |

17.05800 |

4.88010 |

5.40000 |

CONSTRUCTION MATERIALS SCIENCE

Fig. 3. X-ray diffraction pattern of a lime composite (lime slaked in the presence of the addition of Atren Cem HV polysaccharide)

3000(^

28000 :

24000 :

22000-

CONSTRUCTION MATERIALS SCIENCE tion front. The control samples contain a larger amount of portlandite, amounting to 3.1247%. In samples prepared with lime slaked in the presence of an additive, the content of portlandite is only 2.155% and in samples prepared with an additive – 2.9404%. Obviously, due to the waterretaining effect of the additive, more favorable conditions are created for the carbonization of lime. The amount of calcite in control samples is 87.4%, in samples prepared with slaked lime in the presence of an additive – 92.266% and in samples prepared with an additive – 88.87%.

Due to the amorphous structure, organic substances are not identified on the x-ray diffraction pattern.

A slight increase in the width of the CaCO3 peaks is observed, which indicates the possible introduction of organic molecules into the calcite composition. A change in the parameters of the crystal lattice was established in the samples, especially those prepared with lime slaked in the presence of polysaccharides. Samples of limestone based on lime, slaked in the presence of polysaccharides, demonstrate higher crystal lattice parameters c and a compared to calcite of the control composition (Fig. 1–3, and Table 2). This indicates the presence of organics in the form of intracrystalline occlusions in the sample.

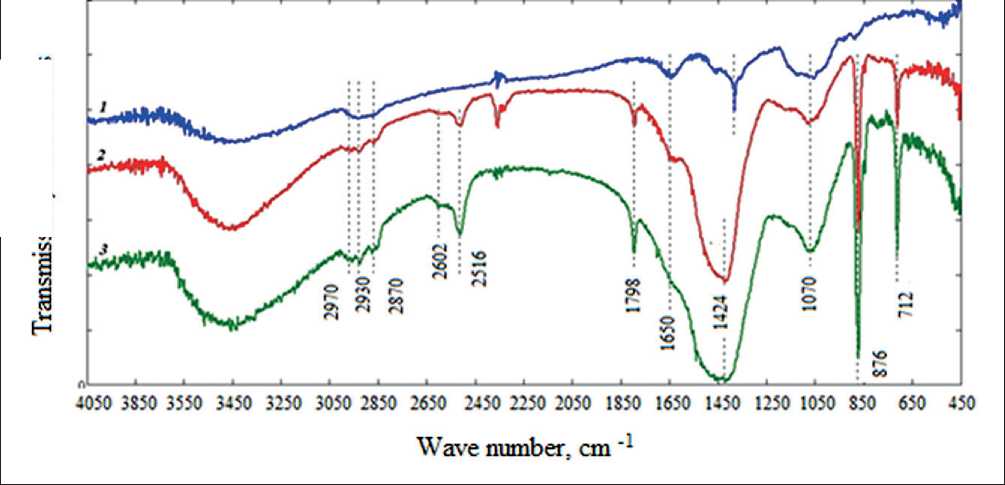

Additionally, IR transmission spectra of the samples under study were obtained (Fig. 4) using an FSM 1201 IR Fourier spectrometer (Infraspek LLC, Russia). The samples were prepared in the form of tablets pressed with potassium bromide at a mass ratio of x:10x, where x is the mass of the initial sample, 10x is the mass of KBr. The samples were not degassed during the pressing process.

Measurements were carried out in the spectral range 450– 4050 cm–1 with a spectral resolution of 4 cm–1. For ease of perception, the IR spectra were normalized and additively shifted relative to the zero point along the ordinate axis.

Analysis of the IR spectra presented in Fig. 4 shows that the studied samples 2 and 3 are characterized by the presence of a significant number of absorption modes corresponding to their expected chemical composition – Ca(OH)2 + CaCO3. The infrared absorption spectra with maxima at 1424 cm–1 are due to the CO3 group in calcite crystals. There is also an intense narrow absorption band in the region of 876 cm–1, characteristic of calcite. The higher intensity of the peak in the region of 876 cm–1 indicates a higher content of calcite in the sample with the addition of Atren Cem HV. Obviously, due to the water-holding capacity of polysaccharides, more favorable conditions are created for the carbonization of lime.

Analysis of the IR spectra shows that sample 3 is characterized by the presence of a number of absorption modes corresponding to organic components, as evidenced by the C─H stretching vibration bands at 2970 and 2870 cm–1.

The pronounced intensity of the absorption band with a maximum of 1650 cm–1, corresponding to the deformation vibrations of H–O–H, indicates the presence of water in an unbound form in the water-soluble modified polysaccharide Atren Cem HV (sample No. 1) and in the control sample (without additive) (sample No. 2). The introduction of the Atren Cem HV additive (sample No. 3) does not lead to the emergence of new vibrational

epn Ә 宅 EFJdos

Fig. 4. IR transmission spectra of the studied samples: 1 – water-soluble modified polysaccharide Atren Cem HV; 2 – control composition; 3 – composition with the addition of polysaccharide Atren Cem HV

CONSTRUCTION MATERIALS SCIENCE modes or a noticeable shift in the absorption maximum of those already present, which suggests the absence of their chemical interaction. An interesting feature of sample No. 3 is the almost complete disappearance of the absorption peak at 1650 cm–1 and a noticeable increase in the intensity of the absorption band 3100–3650 cm–1, corresponding to the symmetrical stretching vibrations of OH groups and Ca–OH. This feature, apparently, may indicate that the introduction of a polysaccharide additive into slaked lime helps to reduce the concentration of free water in the material.

The results of assessing the cohesive strength of coatings are given in Table 3.

The results obtained indicate that lime compositions with the addition of Atren Cem LV polysaccharides are characterized by higher cohesive strength. As the age of hardening increases, the increase in cohesive strength of samples with the addition of synthetic polysaccharide Atren Cem LV is more pronounced. Thus, at the age of 28 days of hardening, the cohesive strength of samples based on the control composition is R 0.22 MPa, and with the addition of a polysaccharide – 0.24 MPa. At the age

of 3 months of hardening, the differences in the values of cohesive strength are more pronounced. The cohesive strength of control samples is 0.264 MPa, and of samples with the addition of Atren Cem LV in an amount of 1% by weight of lime – 0.47 MPa, with the addition of Atren Cem LV in an amount of 0.5% by weight of lime – 0.379 MPa.

CONCLUSION

The results of the studies indicate the absence of chemical interaction between lime and polysaccharides. It has been shown that lime compositions with the addition of polysaccharides are characterized by higher cohesive strength due to the high content of calcite. A change in the parameters of the crystal lattice was established in samples prepared with slaked lime in the presence of polysaccharides. Samples of limestone based on lime slaked in the presence of polysaccharides demonstrate higher crystal lattice parameters compared to calcite of the control composition, which indicates the presence of organics in the form of intracrystalline occlusions in the sample.

Table 3

Tensile Strength of Lime Specimens

|

Compound |

Tensile strength, MPa |

|

Curing age 28 days |

|

|

Control (lime+water) |

0,22 |

|

Composition with the addition of Atren Cem LV in an amount of 1% by weight of lime |

0,24 |

|

Curing age 3 months |

|

|

Control (lime+water) |

0,264 |

|

Composition with the addition of Atren Cem LV in an amount of 1% by weight of lime |

0,47 |

|

Composition with the addition of Atren Cem LV in an amount of 0.5% by weight of lime |

0,379 |

Список литературы Structure formation of lime composites with polysaccharide additives

- Zapevalova M.V. Review of the dry building mixtures market. Construction materials and services: Electronic Scientific journal. 2022; 6. http://www.vashdom.ru/articles/strm5.htm. (access date 2022.06)

- 2.Bokan Bosiljkov, V. The use of industrial and traditional limes for lime mortars. In: Lourenco, P.B., Roca, P. (Eds.), Historical Constructions. University of Minho, Guimaraes: 2001; 343–352.

- Loganina V.I., Frolov M.V. Fine filler based on calcium silicates for lime mixtures. Bulletin of Civil Engineers. 2015; 5(52): 144-147.

- Loganina V., Davydova O., Fediuk R., Amran M., Klyuev S., Klyuev A., Sabitov L., Nabiullina K. Improving the durability of lime finishing mortars by modifying them with silicic acid sol. Materials. 2022; 15: 2360. https://doi.org/10.3390/ma15072360

- Loganina V.I., Davydova O.A., Simonov E.E. Study of the patterns of influence of silicic acid sol on the structure and properties of diatomite. Construction Materials. 2011; 12: 62-65.

- Komokhov P.G. Sol-gel as a concept of cement composite nanotechnology. Construction Materials. 2006; 9: 14-15.

- Komokhov P.G. Nanotechnology of radiation-resistant concrete. Construction materials, equipment, technologies of the 21st century. 2006; 5:22-23.

- Loganina V.I., Kislitsyna S.N., Makarova L.V., Sadovnikova M.A. Rheological properties of composite lime binder using synthetic zeolites. News of higher educational institutions. Construction. 2013; 4 (652): 37-42.

- Loganina V.I., Petukhova N.A., Gorbunov V.N., Dmitrieva T.N. Prospects for the production of organo-mineral additives based on domestic raw materials. News of higher educational institutions. Construction. 2009; 9 (609): 36-39.

- Loganina V.I., Petukhova N.A., Akzhigitova E.R. Development of organomineral additives for dry construction mixtures. Bulletin of Belgorod State Technological University named after. V.G. Shukhova. 2011; 3: 8-12.

- Evaluation of pozzolanic activity and physico-mechanical characteristics in metakaolin–lime pastes / A. Bakolas, E. Aggelakopoulou, S. Anagnostopoulou, A. Moropoulou. J. Therm. Anal. Calorim. 2006; 84 (1): 157–163.

- Bakolas A. Evaluation of pozzolanic activity and physico-mechanical characteristics in ceramic powder-lime pastes / A. Bakolas, E. Aggelakopoulou, A.Moropoulou. J. Therm. Anal. Calorim. 2008; 92 (1): 34–351.

- Cabrera J. Mechanism of hydration of the metakaolin–lime–water system / J.Cabrera, M.Frias. Cement and Concrete Research. 2001; 31 (2): 177–182.

- Cachim P. Effect of Portuguese metakaolin on hydraulic lime concrete using different curing conditions / P.Cachim, A. Velosa, F.Rocha. Construction and Building Materials. 2010; 24: 71–78.

- Krasinikova N.M. The influence of polysilicate on the structure formation of cement stone / N.M. Krasinikova, Z.F. Iksanova. News of KGASU. 2019; 4: 347–352.

- Loganina V.I. Compositions for Limestone Restoration / V.I. Loganina, M.V. Zaytseva. Key Engineering Materials. 2022; 909: 177-183.

- Degryse P. Study of ancient mortars from Sagalassos (Turkey) in view of their conservation / P. Degryse, J. Elsen, M. Waelkens. Cement and Concrete Research. 2002; 32(1457): 63.

- Genestar C. Ancient covering plaster mortars from several convents and Islamic and Gothic palaces in Palma de Mallorca (Spain). Analytical characterization / C. Genestar, C.Pons. Journal of Cultural Heritage. 2002; 4: 291–298.

- Littmann E.R. Ancient Mesoamerican mortars, plasters, and stuccos: The use of bark extracts in lime plasters. Am. Antiquity.1960; 25:593–597.

- Magaloni D., Pancella R., Fruh Y., Cañetas J., Castaño V. Studies on the Mayan mortars technique. MRS Online Proc. Lib. 1995; 352: 483.