Study of ignition parameters and the thermooxidative degradation of wood in the presence of flame retardants with a bioprotective effect

Автор: Artem A. Kobelev, Nataliya I. Konstantinova, Olga N. Korolchenko, Sergey G. Tsarichenko, Elena S. Bokova

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Research results of scientists and specialists

Статья в выпуске: 5 Vol.15, 2023 года.

Бесплатный доступ

Introduction. This study aims to carry out comprehensive comparative research of thermal degradation and inflammation parameters of timber covered with fire resistant biological flame retardants of different chemical composition. We also looked at the efficiency and the action mechanism of the latter. Materials and methods. As the objects of research, the means were selected – phosphorase-containing water-soluble compounds of the nanoscale series, complex biocides and special bioplasticizers (Agent 1) and water-soluble nanoscale diammonium hydrophosphate (Agent 2) applied to pine wood by surface treatment and deep impregnation methods. Results and discussion. Thermogravimetric studies of wood treated with flame retardants have shown that its decomposition occurs in the following temperature ranges: 30–150°C – the process of loss of moisture by wood; 150–400°C – the effect of protective mechanisms of the compositions, as well as the process of decomposition of the main components of wood (hemicellulose, cellulose, lignin) and the formation of a coke layer; 400–800°C – the process of gradual burnout of the coke layer taking into account its thermophysical characteristics up to the ash residue. It has been established that both flame retardants act by the mechanism of catalytic dehydration and reduce the rate of decomposition of wood from 29 to 10%/min. Conclusion. The features of the thermal decomposition of wood protected by two different chemical composition and method of its processing means are determined. The parameters of the flammability of pine wood treated with fire-protective compounds by surface and deep impregnation were obtained, which indicate their high efficiency, which is confirmed by the values of the coke residue at 400°C, the nature of DTG peaks and DSC curves. The possibility of using the obtained materials from wood for interior decoration and cladding of facades of buildings that meet regulatory requirements for their safe use is shown.

«Ignition parameters», thermal degradation, flame retardants, bioprotective effect, wood, fire protection, fire safety, construction, nanodisperse composition

Короткий адрес: https://sciup.org/142238327

IDR: 142238327 | DOI: 10.15828/2075-8545-2023-15-5-474-481

Текст научной статьи Study of ignition parameters and the thermooxidative degradation of wood in the presence of flame retardants with a bioprotective effect

Original article

T oday wooden structures are widely used for construction of individual residential buildings, low-rise public buildings, social and cultural facilities, large span structures (arenas, tennis courts), sport and recreation centres, agricultural buildings, warehouses, etc.

Wooden buildings are made of light, cost-efficient, quickly reproducible, earthquake-resistant accessible material. Strengthening the wooden house construction priority requires new scientific developments, new approaches to expanding capabilities of new technologies in this area, etc. Wood has always been one of the most environmentally friendly materials. According to the experts,

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS at present there is a stable demand for construction of houses not only from solid timber but also wooden panels.

It should be noted that timber and timber-based composite materials have been used in Europe and America for construction of high-rise residential buildings, various public facilities (schools, hospitals, stadiums, shopping centres, etc.) for decades. Moreover, the scope of pubic construction from wood is significant since this material is environmentally-friendly and reliable.

The set of regulatory documents stipulating technical safety parameters for buildings, requirements, classification and quality of all wooden elements and structures necessary for wooden construction play an important role in the modern wooden house construction development in Russia. Providing fire, sanitary and environmental safety including using fire protection methods to wooden building structures and cladding materials is still relevant [1–6].

Therefore, the interest in new efficient fire protection methods and ways to apply them is growing. These methods provide:

– strength, size stability, weather and humidity resistance of wood and wooden structures;

– low corrosiveness;

– compliance with sanitary and hygienic safety requirements;

– compatibility with various types of top coats [7–17].

This study aims to carry out comprehensive comparative research of thermal degradation and inflammation parameters of timber covered with fire resistant biological flame retardants of different chemical composition. We also looked at the efficiency and the action mechanism of the latter.

MATERIALS AND METHODS

We have selected agents applied to timber using surface treatment and deep impregnation methods [18–19]. That provide biological flame protection effect in line with existing regulatory fire safety requirements in the form of mandatory certification and state sanitary and epidemiological rules and norms as study subjects.

Agent 1 is a comprehensive fire protection and biocidal product. It is produced from phosphorus and nitrogen containing water soluble compounds of the nanoscale series, complex biocides and special bioplasticizer ensuring I (first) group of fire protection efficiency at additional dry salt weight of 30 kg/m3 for the deep (vacuum – pressure – vacuum) impregnation method and minimum consumption of 380 g/m2 – for the double surface treatment method

Agent 2 is a water solution of non-organic salts and biologically active substances with nanoscale diammonium hydrogen phosphate as the main component. It ensures I (first) group of fire protection efficiency at minimum additional dry salt weight of 40 kg/m3 for the deep (vacuum – atmosphere) impregnation method and minimum consumption of 400 g/m2 – for the triple surface treatment method.

When studying the process of thermal oxidative degradation of fire resistant agents, thermal analysis was carried out using METTLER TOLEDO TGA/DSC 1. The following methods were used: thermogravimetric (TGA), derivative thermogravimetric (DTGA) and differential scanning calorimetry (DSC). TGA and DTGA analyses produced sample mass and mass loss speed vs. heating temperature and DSC analysis – sample heat generation intensity at different temperatures.

For these purposes we prepared 150×60×30 mm timber samples treated with agent 1 and agent 2 using the deep impregnation method.

When preparing timber samples for comparative research of fire protection mechanisms of impregnation solutions, we assumed that the impregnation solution usually penetrates to maximum 2 mm timber depth for the surface treatment method and up to 40 mm for the deep impregnation method depending on the technology and chemical components [20].

One of the main targets of the studies was to identify the degree of fire protection effect produced by impregnation solutions at various depths from the timber surface. Therefore, samples were taken from each sample both from the surface and 10 mm deep layer. Thus, studies were carried out on four samples of fire resistant timber and the initial pine sample for comparison purposes. Properties of samples taken for the thermal analysis are provided in Table 1.

Studies were conducted in the air atmosphere at 2.5; 5; 10 and 20°С/min heating speed in 30–800oС range.

The research looked at sample inflammation time vs. incident heat flow density under GOST 30402–96 Building materials. Ignitability test method . For this purpose, we used samples treated with Agent 1 and 2 using deep impregnation and surface treatment methods.

Experimental studies of critical areal heat flow density (CAHFD) causing inflammation for considered types of fire resistant pine timber were carried out using the testing method and measurement tools. 165×165×15 mm fire resistant timber sample was subject to radiant heat flow of 5-50 kW/m2 surface density. CAHFD was assumed to be the minimum value when flame combustion starts.

RESULTS AND DISCUSSION

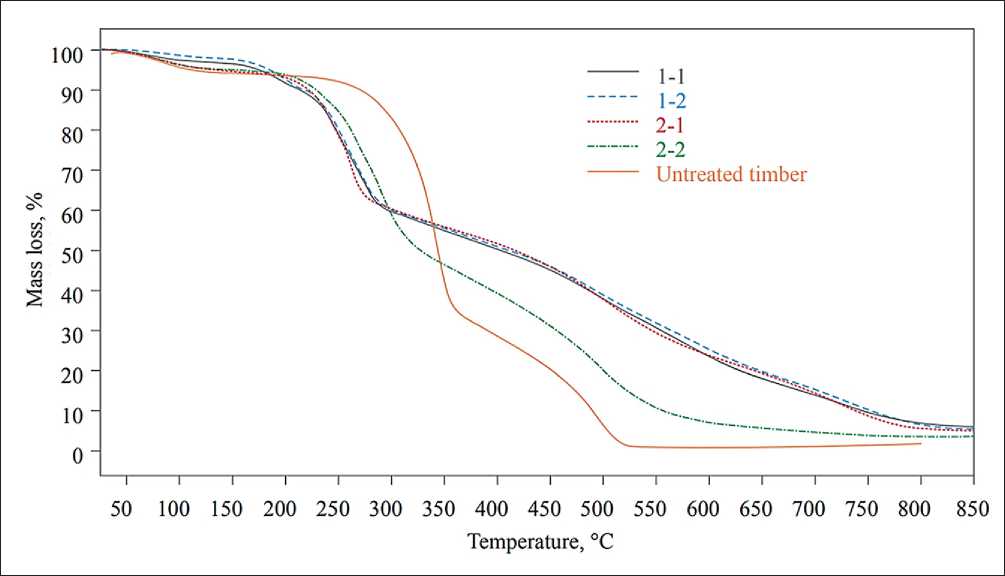

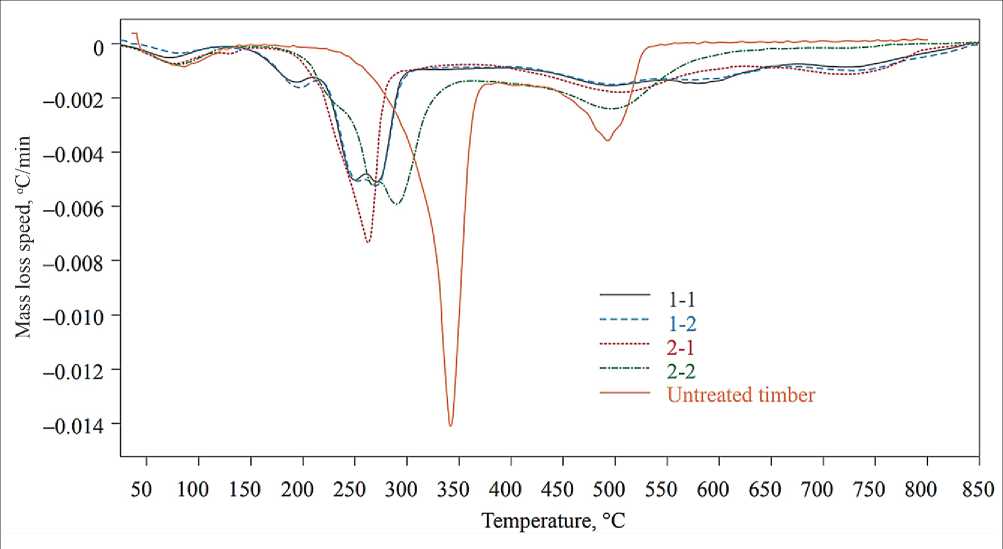

Fig. 1 and 2 show mass loss and mass loss speed vs. temperature of timber samples treated using the deep impregnation method and untreated pine timber samples calculated using TGA and DTGA methods respectively.

Results of TGA and DTGA studies are provided in Table 2. Mass loss in 30–150oС range indicates the dehu-

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS

Table 1

Properties of samples for the thermal analysis

|

No. of sample |

Fire protection method |

Sampling point |

Sample weight, mg |

|

1-1 |

Agent 1 |

Sample surface |

11.16 |

|

1-2 |

10 mm distance from the surface |

11.51 |

|

|

2-1 |

Agent 2 |

Sample surface |

11.87 |

|

2-2 |

10 mm distance from the surface |

11.06 |

Fig. 1. Mass loss of untreated pine timber samples and samples treated using the deep impregnation method vs. heating temperature calculated using TGA method midification process and in 150–400oС range (main peak on the curve) – material degradation and coke generation process. The coke residue fraction was registered at 400oС, ash residue – at 800oС. For the main peak on DTGA curves of all samples maximum mass loss speed Аmax and process temperature Тmax are shown in 250–350oС range.

Thus, the analysis of the thermogravimetric study of timber treated with fire resistant solutions (see Fig. 1) shows that degradation happens within the following temperature ranges:

-

1) 30–150oС – timber dehumidification;

-

2) 150–400oС – active range of protective mechanisms, degradation of main timber components (hemicellulose, cellulose, lignin) and generation of coke layer;

-

3) 400–800oС – gradual burnout of coke layer with account of its thermophysical properties up to ash residue.

It should be noted that the thermophysical study of samples from timber surface layers treated with agents 1 and 2 using deep impregnation (samples 1-1, 2-1) shows that their behaviour differences are insignificant and are determined by the difference in resistance mechanisms within 150–300oС range, which is caused in its turn by chemical components of agents and their synergy. The study of samples taken from the 10 mm deep layer (samples 1-2, 2-2) show a difference in curves. Thus, the coke residue of sample 1-2 impregnated with agent 1 almost does not change its properties, its fraction accounts for 50.84% of the initial sample mass and is little different from the coke residue value of sample 1-1

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS

Fig. 2. Mass loss of untreated pine timber samples and samples treated using the deep impregnation method vs. heating temperature calculated using DTGA method

Table 2

Results of the gravimetric analysis

|

No. of sample |

Mass loss, %, in the temperature range, oС |

Residue fraction, % |

Main peak |

|||

|

30–150 |

150–400 |

Coke at 400oС |

Ash at 800oС |

T max, oС |

A max, %/min |

|

|

1-1 |

3.62 |

49.85 |

50.15 |

6.75 |

249 |

10 |

|

1-2 |

2.49 |

49.16 |

50.84 |

6.58 |

252 |

10 |

|

2-1 |

5.54 |

48.48 |

51.52 |

5.49 |

264 |

15 |

|

2-2 |

5.08 |

60.89 |

39.11 |

3.40 |

267 |

10 |

|

Untreated timber |

5.91 |

71.61 |

28.39 |

1.56 |

345 |

29 |

(50.15%). The coke residue of sample 2-2 (agent 2) amounted to 39.11% which is by 12.5% less compared to sample 2-1. It means that the sample treated with agent 1 using deep impregnation did not lose its fire resistant qualities at the 10 mm depth. On the contrary, the sample treated with agent 2 demonstrated significant efficiency reduction.

Let us look at DTGA analysis results (see Fig. 2) for samples 1-1 and 2-1 showing the protective mechanism properties of agents 1 and 2 respectively and compare them to the untreated timber sample. The general analysis of the curves and data on the main chemical components of agents lead to the conclusion that both fire resistant agents have a catalytic dehydration mechanism. Table 2

shows that the peak of the main stage of thermal degradation is shifted from 345oС for untreated timber, by 249oС for timber impregnated with agent 1 and by 264oС – agent 2. Moreover, the DTGA curve for agent 1- treated timber has another peak with maximum at 190oС, which most likely points to the reaction of a functional additive. There are also two more maximums in 240–280oС range. The 400–800oС coke oxidation temperature range has three small peaks for the timber sample treated with agent 1 – at 498, 579 and 727oС. The timber sample treated with agent 2 has only 2 peaks that almost coincide with those mentioned above – at 503 and 715oС.

Judging by the intensity of peaks observed during the main degradation stage, it can be concluded that un-

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS

Fig. 3. Heat generation intensity vs. heating temperature during untreated pine timber degradation at 20oС/min speed treated timber degrades 3 times faster than fire resistant one (degradation speed is 29 and 10%/min respectively).

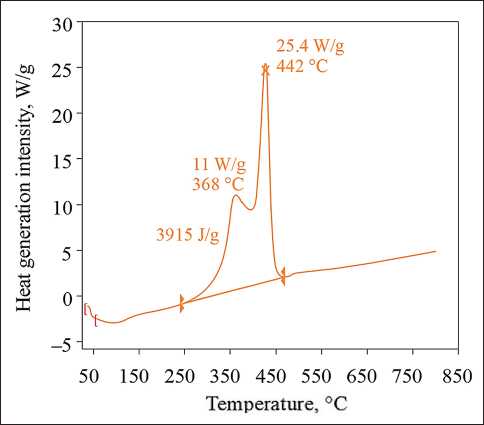

When studying the efficiency of fire protection tools, heat generation parameters are important. DSC analysis produced heat generation vs. temperature for all fire resistant samples and untreated timber and the volume of heat generated during degradation. Fig. 3 shows heat generation intensity vs. temperature during untreated pine timber degradation.

Fig. 3 shows that total heat generation amounted to 3915 J/g and the curve has two typical maximums – at 368°С with 11 W/g heat generation intensity and 442oС with 25.4 W/g heat generation intensity. The main stage of heat generation happens in 250–470oС range.

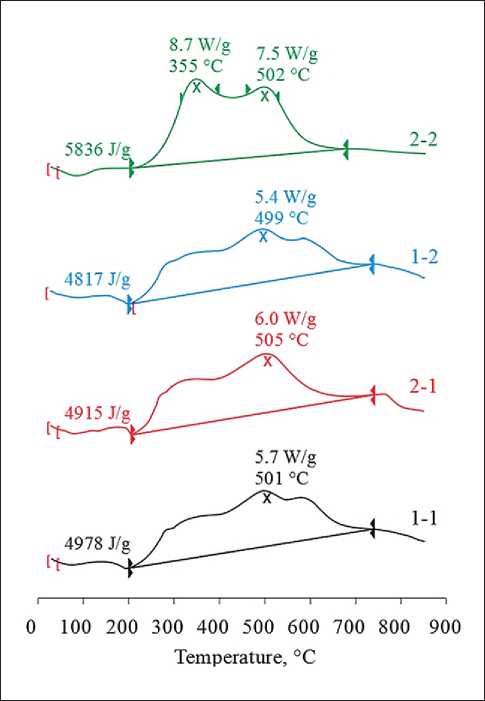

Fig. 4 shows heat generation intensity vs. temperature during degradation of pine timber samples treated using the deep impregnation method.

There is insignificant difference in total heat generation for samples 1-1, 1-2 and 2-1. It falls within 4817– 4978 J/g range. Sample 2-2 has significantly higher heat generation – 5836 J/g which shows the reduction of the protective effect of agent 2 at 10 mm depth from the surface. Heat generation intensities largely coincide in samples 1-1, 1-2 and 2-1: they have one prominent heat generation peak around 500oС, peak intensity amounts to 5.4–6.0 W/g, which is approximately 5 times less than peak heat generation of untreated timber.

The change in the overall shape of DSC peak with smoothed peaks and time stretching of timber thermal oxidative degradation process is an important property to confirm the fire resistant effect of studied agents.

The heat generation temperature range for untreated timber sample is 250–470oС, which corresponds to

Fig. 4. Heat generation intensity vs. heating temperature during degradation of pine timber treated using the deep impregnation method at 20oС/min speed

11 minutes of testing. For samples with a more prominent protective effect (1-1, 1-2, 2-1) the heat generation temperature range amounts to 200–720oС, which corresponds to 25 minutes of testing. Sample 2-2 has the heat generation temperature range of 210–680oС and the time range of 22 minutes. These data correlate with the results of standard laboratory combustibility testing of timber samples treated with studied agents [21].

Thus, we can conclude that both agents are efficient fire protection tools that change timber thermal oxidative degradation process via the catalytic dehydration mechanism [22]. The curves show the distinctive features of this mechanism for every agent. The efficiency of agents is proved by coke residue values at 400oС, DTGA peaks and DSC curves. The results have been analyzed and the most important numerical parameters of the thermal oxidation process have been calculated.

One of the main conclusions of the test is that agent 1 completely preserves its fire resistant properties at 10 mm minimum depth. Thus, we can forecast higher fire resistant properties and lower fire risk for wooden building structures treated with this agent.

RESEARCH RESULTS OF SCIENTISTS AND SPECIALISTS

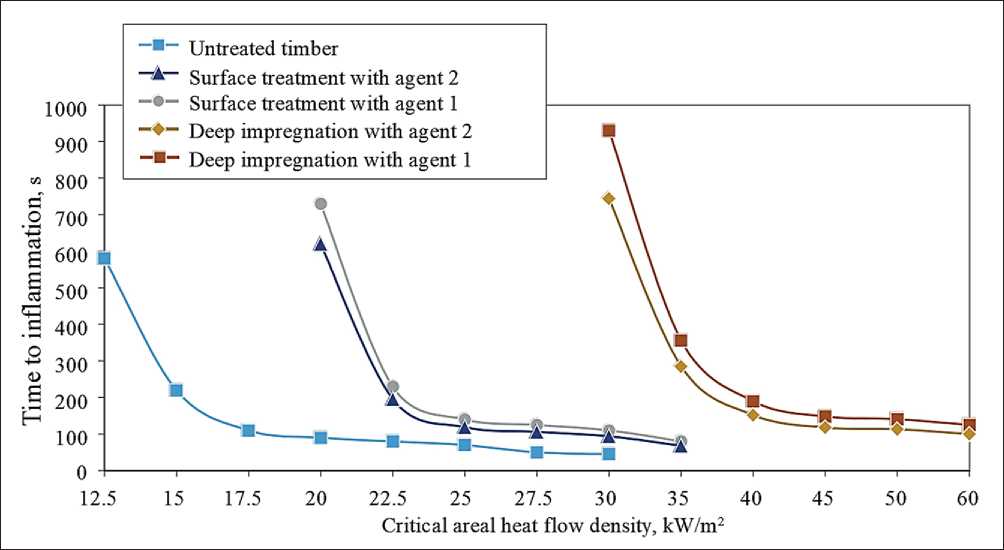

Fig. 5. Timber inflammation time vs. CAHFD

The results of experimental studies of CAHFD are presented in Fig. 5.

The experimental dependance revealed that CAHFD for initial pine timber samples amounts to 12.5 kW/m2. Surface treated timber samples inflamed at 20 kW/m2 heat flow density. It means that they belong to different classification groups based on inflammation properties – В3(highly inflammable) and В2 (moderately inflammable). The study of samples treated using the deep impregnation method showed higher resistance to the heat flow impact. The inflammation time for the timber sample treated with agent 1 at 30 kW/m2 CAHFD amounted to 930 s, which means that it belongs to B1 inflammability group (inflame resistant) under GOST 30402. It is a big advantage for using finishing materials produced from timber treated using the deep impregnation method by a comprehensive fire resistant biocide agent based on phosphorus and nitrogen containing water soluble compounds.

CONCLUSION

The research has produced the following results: the properties of thermal degradation of timber treated with two agents different in terms of chemical composition and treatment method have been determined; the differences in the mechanism and fire resistant effect of agents applied to timber using surface treatment and deep impregnation methods have been identified; the higher efficiency of the modified fire resistant agent 1 compared to agent 2 both for surface treatment and deep impregnation methods has been proved; the combustibility parameters of pine timber treated with biological flame retardants using surface treatment and deep impregnation methods have been identified. They prove high efficiency of these agents and the possibility to produce timber materials for interior finishing works and cladding of building facades that comply with regulatory requirements for safe application.

Список литературы Study of ignition parameters and the thermooxidative degradation of wood in the presence of flame retardants with a bioprotective effect

- Korolchenko D., Pizhurin A. Simulating operational control of production in lumber house building businesses. MATEC Web of Conferences. 2017; 117. Paper Number 00084. https://doi.org/10.1051/matecconf/201711700084

- Bogdanova V.V., Kobets O.I., Kirlitsa V.P. The mechanism of action and the synergistic effect of nitrogenand phosphorus-containing fire retardants in fire protection and wood and peat fire suppression. Russian Journal of Physical Chemistry B. 2016; 10: 306–312. https://doi.org/10.1134/S1990793116020160

- Lowden L.A., Hull T.R. Flammability behaviour of wood and a review of the methods for its reduction. Fire Science Reviews. 2013; 2(1): 4. https://doi.org/10.1186/2193-0414-2-4

- White R.H. Fire resistance of wood members with directly applied protection. Fire and materials, 2009 electronic resource: 11th International Conference and Exhibition, 2009 January 26-28, Fisherman’s Wharf, San Francisco, USA. London: Interscience Communications Ltd.; 2009: 492-503.

- Aseeva R.M., Serkov B.B., Sivenkov A.B. Fire behavior and fire protection in timber buildings. Series: Springer Series in Wood Science. Netherlands: Springer Dordrecht; 2014. https://doi.org/10.1007/978-94-007-7460-5

- Özdemir F., Tutus A. Effects of fire retardants on the combustion behavior of high-density fiberboard. BioResources. 2013; 8(2): 1665–1674. https://doi.org/10.15376/biores.8.2.1665-1674

- Van der Veen I., De Boer J. Phosphorus flame retardants: Properties, production, environmental occurrence, toxicity and analysis. Chemosphere. 2012; 88(10): 1119–1153. https://doi.org/10.1016/j.chemosphere.2012.03.067

- Garashchenko A.N., Antonov S.P., Vinogradov A.V. Studying the thermal characteristics and effectiveness of structural fire proofing made of PROSASK Firepanel cement boards by means of reproducing the high-temperature effect. Pozharovzryvobezopasnost [Fire and Explosion Safety]. 2022; 31 (6): 13-29 (In Russ.). https://doi.org/10.22227/0869-7493.2022.31.06.13-29

- Khelfa A., Bensakhria A., Weber J.V. Investigations into the pyrolytic behaviour of birch wood and its main components: Primary degradation mechanisms, additivity and metallic salt effects. Journal of Analytical and Applied Pyrolysis. 2013; 101: 111–121. DOI: 10.1016/j.jaap.2013.02.004.

- Tychino N.A. Fire- and bioprotection of wood and ecology. Pozharovzryvobe-zopasnost. [Fire and Explosion Safety]. 2012; 21(1): 44–46 (In Russ.)

- Artsybasheva O.V., Vizgalova G.I., Aseeva R.M., Serkov B.B., Sivenkov A.B. Fire protection means and technique analy sis to reduce fire hazards and increase fire resistance of wooden constructions. Fire and Emergencies: Prevention, Elimination. 2014; 3: 13–20 (In Russ.)

- Boruszewski P., Borysiuk P., Jaskółowski W., Fajkowska K., Mamiński M., Jenczyk-Tołłoczko I. Characteristics of selected fireproof properties of parti-cleboard made from particles impregnated with salt agent. Annals of Warsaw university of Life Science — SGGW, Forestry and Wood Technology. 2011; 73: 142–146.

- Sivenkov A.B. Impact of physical and chemical properties of timber on its fire risk and fire protection efficiency. Doctor of technical sciences thesis. Moscow; 2015.

- Borozdin S.A., Gittcovich G.A., Vetrov V.V., Morozov S.S. Efficiency of fire-protective compositions at application of them to various breeds of wood. The Journal Modern Problems of Civil Protection. 2020; 3(36): 70–76 (In Russ.).

- Korolchenko A.Ya., Korolchenko O.N. Fire protection means. Reference book. 2nd ed. Moscow, Pozhnauka Publ.; 2009. (In Russ.)

- Kruglov E.Yu., Aseeva R.M. Flameless burning of wood: parameters of macrokinetics of pyrolysis and thermooxidative decomposition. Pozharovzryvobezopasnost [Fire and Explosion Safety]. 2020; 29(1): 43-54 (In Russ.). https://doi.org/10.18322/PVB.2020.29.01.43-54

- Kobelev A.A. Development of the comprehensive biological moisture and flame retardant based on compounds ensuring timber surface modification. PhD in technical sciences thesis. Moscow; 2012.

- Korolchenko O.N. Dependence of fire-technical characteristics of fire-protected wood on the method of its processing. Materials of the V International Scientific and Practical Conference “Theoretical and applied issues of integrated security”. St. Petersburg; 2022.

- Anokhin E.A., Polishchuk E.Yu., Sivenkov A.B. Use of fire-retardant impregnating compositions for reducing fire hazard of wooden structures of various lifetimes. Pozharovzryvobezopasnost [Fire and Explosion Safety]. 2017; 26: 22-35 (In Russ.). https://doi.org/10.18322/PVB.2017.26.02.22-35

- Nigmatilina D.M. Reducing fire risk of wooden structures using deep impregnation with biological flame retardants. PhD in technical sciences thesis. Moscow; 2017.

- Korolchenko O.N., Tsarichenko S.G., Konstantinova N.I. Flammability properties of fire-retardant timber. Pozharovzryvobezopasnost [Fire and Explosion Safety]. 2021; 30(2): 23-34 (In Russ.). https://doi.org/10.22227/PVB.2021.30.02.23-34

- Pokrovskaya E.N., Portnov F.A., Kobelev A.A., Beltsova T.G. Influence of surface layer structure formed during thermal degradation of wood on smoke generation property. Pozharovzryvobezopasnost [Fire and Explosion Safety]. 2015; 24(6): 16-22 (In Russ.)