Study of the pectin-based beverage preparation technology from fruits and vegetables grown in Azerbaijan

Автор: Aliyev Shakir, Khalilov Mushfig, Saidov Rasim

Журнал: Бюллетень науки и практики @bulletennauki

Рубрика: Сельскохозяйственные науки

Статья в выпуске: 4 т.8, 2022 года.

Бесплатный доступ

An optimal variant of food used to provide the human organism with biologically active substances that is considered acceptable to every consumer is fruit and vegetable-based juice, which biological value is determined by the maximum retention of nutrients in the product during processing. As the research was related to the preparation of a pectin-rich beverage, the Palavkadu 268 variety of pumpkin, which is a melon fruit, and orange juice were used as the main components of the product. To this end, first of all, the obtained pumpkin puree was treated with enzymes, and then orange juice was added to the mass. Besides, the recipe of the product included sugar, milk powder, sourdough, and 2% liquid pectin. The finished product was made on the basis of this mixture. The effect of the types and concentrations of pectic substances on the probiotic properties of the prepared fruit and vegetable drinks was also studied. The amount of pectin in fruit juice should be taken into account when producing it because a high concentration of pectin increases the viscosity of the juice, and it becomes turbid. By regulating the amount of pectin, it is possible to increase the juice yield. The enzymes of microbial origin are the most widely used substances in the production of juice because they contribute to the expansion of the range of products and the achievement of high juice yield. As a result of our research, it can be concluded that a product with a better bifidogenic effect can be obtained when using 2% liquid pectin in the preparation of beverages.

Pumpkin, orange, probiotics, pectinase, skim milk

Короткий адрес: https://sciup.org/14123647

IDR: 14123647 | УДК: 663.8:664.292

Текст научной статьи Study of the pectin-based beverage preparation technology from fruits and vegetables grown in Azerbaijan

Бюллетень науки и практики / Bulletin of Science and Practice

UDC 663.8:664.292

Natural juices are rich in vitamins and microelements. Being very beneficial to the human organism, they strengthen the immune system, have a positive effect on all organs [1] (On the other hand, the studies have shown that pectic substances are good probiotics. The effectiveness of using natural pectin in vegetables and fruits has been determined [2, 3]. It is also important to note that natural-ecological pectins have high com-plex-forming ability and are more important in terms of replacing chemical methods with ecological methods. Pectic substances bind heavy metals penetrate into the digestive tract, prevent resorption of metals and remove them from the organism.

Currently, to increase the range of juices, juice industry is focused on producing non-alcoholic beverages on the basis of juice-nectar and juice-puree using vegetables and fruits as raw materials.

The mentioned non-alcoholic beverages are optimal foods, enriching the human organism with biologically active ingredients.

When choosing a juice-based non-alcoholic beverage, the consumer basically focuses on its functional properties. Such drinks should have prophylactic and healthy effects on the human organism, and the use of them should create a positive emotion.

Vegetable and fruit juices and purees rich in vitamins and minerals should be chosen purposefully to form high taste characteristics in drinks.

Therefore, additional studies have been conducted to determine the effectivenessof the pectic supplements, the effect of the type and dose of pectic substance on the development of beneficial bacteria (bifidobacteria) and lactic acid microorganisms.

Azerbaijan has very favorable soil and climatic conditions for the cultivation of fruits and vegetables. Pumpkin is widely cultivated in gardens and farms [4, 5]. Pumpkin is rich in fats, macro- and microelements, vitamins, pectin and food fibers [6], which prevent various diseases. Pumpkin is useful in the treatment of the diseases related to cardiovascular system, kidney [7], blood circulation [8], liver, biliary tract, hypertension, obesity, prostate, oncology, etc. Pharmacological properties and the technology of the use of pumpkin are considered also in healthcare. Vitamins B 1 , B 2 , B 5 , B 6 , H in the food ration do not only serve as cofactors in metabolic processes of the organism, they also directly participate in the metabolism of sulfur-containing amino acids and histamine, which leads to the radioprotective effect. Vitamin B 6 is an additional source of sulfur and vitamin B 1 enhances radioprotective ability of other food substances [9].

Pumpkin is rich in β-carotene, cellulose and minerals [10] and it is including in daily food ration is effective in solving problems caused by vitamin A deficiency. Pumpkin is the main source of carotene in the plant world. Beta-carotene has strong antioxidant properties, which allows neutralizing free radicals. Carotene is safer for the human organism than its A provitamin. Consumption of fruits and vegetables rich in carotenoids decreases the risk of hair loss, cardiovascular diseases, yellow spot, cataract and degenerative diseases such as various types of cancer. It suggests that the use of beta-carotene can prevent these diseases. Moreover, beta-carotene ensures the formation of the visual pigment rhodopsin [11]. A lot of orange trees are grown in the southern regions of Azerbaijan and on the Black Sea coast. Orange juice is indispensable for the prevention and treatmentof cold and avitaminosis. It raises the tone, eliminates fatigue, strengthens blood vessels, kills bacteria, improves immunity, helps to remove cholesterol from the organism, normalizes the function of the intestines, reduces the risk of congenital malformations in children and protects against many forms of cancer. Doctors advice to drink orange juice during atherosclerosis and hypertension as well as in liver diseases.

These plants are ecologically clean because no medicinal preparations were used in their cultivation [12, 13]. However, very few food products, including juices are produced from them using industrial methods. The analysis of literature data and our research results revealed that high-quality fruit juices should be rich in simple sugars,organic acids, vitamins and minerals [14, 15]. In this regard, the main purpose of our research was to produce high-quality juice using pumpkin and orange, by adding pectic substances.

Materials and methods

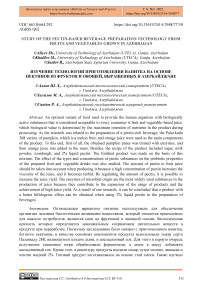

A pectin-rich drink was taken as the object of the research. For this purpose, the Palavkadu 268 variety of pumpkin was chosen. After the preparation of fermented pumpkin puree, orange juice was added to it and enriched with pectic substances. The technological scheme of fruit and vegetable-based drinks containing pectin was given and the stages of juice preparation were shown. The drink was made by mixing fermented pumpkin puree, orange juice, sugar, skim milk, 2% liquid pectin. Lactic acid bacteria and bifidobacteria were quantified in the prepared drinks. In addition, 10 juice samples were prepared in different proportions, then organoleptic evaluation of these samples was carried out, as a result of which the average scores on all indicators were obtained and sensory profiles were determined. Juices were tasted and evaluated on a 10-point scale. The chemical composition of the juice with the highest score was analyzed.

Chemical analysis of the product mixture based on the established recipe, i. e. with the addition of pumpkin puree and orange juice treated with pectolytic enzymes, showed that it had not only bifidogenic properties but also the ability to form complexes.

Results and discussion

Technological processing stages for each raw material and auxiliary materials have been identified for the process of preparing a new, range beverage. These stages are as follows:

-

a) The pumpkin was first subjected to organoleptic control, washed, cut into pieces, cleaned of seeds, and stewed for 10 minutes. In this case, due to the breakdown of protopectin in the raw material, it was softened, and microbiological contamination was also prevented. Then the pumpkin parts passed through a two-stage grater with sieve holes having a diameter of 1.5–1.2 and 0.8–0.4 mm. The crushed mass (pulp)coming out of the grater was treated with 2% Pectinex® Ultra SP-L, a pectolytic liquid enzyme. The fermentation of the pulp was carried out at 45–55 °С for 120 minutes. The resulting mass was mixed with sugar and transferred to a homogenizer, and then after adding other components, it was placed to the pot;

-

b) To obtain the juice, the orange was washed, peeled, chopped, squeezed. The juice was filtered, separated, reaerated, pasteurized, and concentrated under vacuum (up to 60% dry matter). When peeling, the essential oils should not be mixed with the juice;

-

c) Skim milk was poured into another container containing water (up to half the amount specified in the recipe). The mass in this container with a mixer was mixed at 20°C until completely dissolved. When the milk was completely dissolved, it was added to water (the other half of the amount prescribed in the recipe) heated to a temperature of 70–80 °C. The obtained milk mass was heated at 85–90 °C for 5 minutes with stirring;

-

d) In another container, the homogenized pumpkin puree, orange juice, water, and pectin extract (dry or liquid) were mixed and heated to 80–85 °C as described above. The process continued until complete dissolution. Then, dissolved milk was added to this fruit and vegetable mass and mixed, and the resulting product was heated to 90°C for 10 minutes. In order to study the prebiotic properties of the fruit and vegetable components, the mixture was cooled to a temperature of 37±2°C, which made possible lactic acid fermentation, then probiotic Bifilakt-PLUS 1EA concentrate was added up to 5% of the total mass and kept for 9 hours. Active acidity (pH) of 4.3– 4.7 indicated the end of the process. The obtained finished drink was aseptically canned and sent for further operations (Figure 1).

Heating (90°C), Kept for 10 min

Cooling (37±2°C)

Fermentation for 9 hours

Aseptic

Figure 1. Technological scheme of the drink prepared with the addition of a mixture of fruits and vegetables rich in pectin

To study the effects of microorganisms, different ingredients of the product were used. The number of both lactic acid bacteria and bifidobacteria (CFU/g) was determined in the test samples.

MRS, a dense semi-liquid nutrient medium, was used to determine the number of lactic acid bacteria. The sample was planted in a Petri dish using the Surface Technology. The incubation period of microorganisms lasted 72 hours at 37±2°С.

Detection of bifidobacteria is based on the method of deep culture in a test tube, containing their nutrient medium. Blaurok medium, a modified hepatic cysteine mixture, was used as the nutrient medium. The incubation period of bifidobacteria lasted 48–72 hours at a temperature of 37±1°С. To ensure the presence of these bacteria, swabs were prepared from grown colonies and stained according to the Gram’s method.

Table1

THE NUMBER OF LACTIC ACID BACTERIA AND BIFIDOBACTERIA IN THE SAMPLES (CFU/g)

|

Samples |

Indicators |

Acceptable level |

Results of the analysis |

||

|

4 days |

9 days |

Expiration Date 10 days |

|||

|

No. 1 |

Lactic acid bacteria, CFU/g |

1×107 |

1.20×1010 |

1.20×1010 |

1.2×1010 |

|

Bifidobacteria, CFU/g |

1×106 |

5.10×108 |

6.20×1010 |

6.2×1010 |

|

|

No. 2 |

Lactic acid bacteria, CFU/g |

1×107 |

1.15×1010 |

1.15×1010 |

1.15×1010 |

|

Bifidobacteria, CFU/g |

1×106 |

2.10×108 |

3.20×109 |

3.2×109 |

|

|

No. 3 |

Lactic acid bacteria, CFU/g |

1×107 |

1.15×1010 |

1.15×1010 |

1.15×1010 |

|

Bifidobacteria, CFU/g |

1×106 |

2.60×109 |

2.10×1010 |

2.1×1010 |

|

|

No. 4 |

Lactic acid bacteria, CFU/g |

1×107 |

1.20×1010 |

1.20×1010 |

1.2×1010 |

|

Bifidobacteria, CFU/g |

1×106 |

4.20×109 |

3.20×109 |

3.2×109 |

|

|

No. 5 |

Lactic acid bacteria, CFU/g |

1×107 |

1.17×1010 |

1.17×109 |

1.17×109 |

|

Bifidobacteria, CFU/g |

1×106 |

1.90×109 |

3.10×108 |

3.1×108 |

|

Microbiological analyses were performed following the accepted standard and the results obtained are presented in Table 1. As seen in the table, the high content of microorganisms in all samples favorably affects the fermentation process. The presence of pectic compounds also affects their growth rate. When compared, the best result in terms of the number increase was observed in sample number 4 (with the addition of 2% liquid pectin). Therefore, it is recommended to use 2% liquid pectin in the recipe when preparing such drinks, as the guaranteed shelf life of such a product is usually 10 days. Based on the data presented in Table 1, taking into account the great number of lactic acid microorganisms and bifidobacteria in all samples, as well as the effectiveness of the use of liquid pectin, using the mathematical modeling, the recipe of the proposed drink was developed by optimization, and the quality indicators of the samples were determined.

Table 2 PREPARED RECIPE VARIANTS (content, %)

|

No |

Components |

Samples |

|||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

||

|

1 |

Orange juice |

25 |

- |

10 |

30 |

10 |

- |

8 |

20 |

- |

- |

|

2 |

Fermented pump kin puree |

50 |

50 |

58 |

40 |

60 |

70 |

60 |

50 |

75 |

50 |

|

3 |

Sugar |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

15 |

|

4 |

Liquid pectin |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

|

5 |

Dry skim milk |

- |

23 |

5 |

3 |

- |

3 |

5 |

3 |

3 |

18 |

|

6 |

Yeast |

3 |

5 |

5 |

5 |

8 |

5 |

5 |

5 |

- |

5 |

|

7 |

Water |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

Бюллетень науки и практики / Bulletin of Science and Practice Т. 8. №4. 2022

Based on the recipe, 10 samples of drinks were prepared, and their components are given in Table 2. Samples 3 and 7 were distinguished by their organoleptic properties. In color, taste, and aroma, these selected drinks are reminiscent of the fruits and vegetables from which they are made.

The chemical composition was examined, and the quality indicators of beverage sample no. 7 were determined (Table 3). Each indicator was determined by chemical analysis: proteins by the Kjeldahl method, oils by Soxhlet apparatus, total sugars by the Bertrand method, total dietary fiber by the Enzymatic-gravimetric method, pectin by the Calcium Pectate method, total acid by titration, lactose by Polarimetry.

Table 3

ORGANIC COMPOUNDS OF INGREDIENTS

AND THE FRUIT-VEGETABLE BEVERAGE CONTAINING PECTIN g/100 g

|

Indicators |

Pumpkin puree |

Orange juice |

Dry skim milk |

Finished drink |

|

Proteins |

1.68 |

1.0 |

33.2 |

2.960 |

|

Oils |

6.10 |

0.2 |

1.0 |

3.776 |

|

Total sugars |

6.29 |

9.5 |

52.6 |

7.394 |

|

Dietary fiber |

1.21 |

0.3 |

0 |

0.750 |

|

Pectin |

0.30 |

- |

- |

2.180 |

|

Total acids |

0.10 |

1.3 |

1.2 |

0.224 |

|

Lactose |

0 |

0 |

49.3 |

2.465 |

|

Bifidobacteria, CFU/g |

- |

- |

- |

2.5×109 |

The amount of vitamins and minerals in beverage sample no. 7 was found by various chemical methods (Table 4). The amount of β-carotene was determined by spectrophotometer, thiamine and riboflavin — by fluorimetry, nicotinic acid — by the colorimetric method based on the color reaction of nicotinic acid with rhodonite and bromide, ascorbic acid — by iodometry, sodium, potassium, calcium, phosphorus by the potentiometric method and ferrum was determined with phenanthroline.

Table 4

VITAMIN CONTENT AND MINERALS

IN INGREDIENTS AND THE FRUIT-VEGETABLE BEVERAGE CONTAINING PECTIN, g/100 g

|

Indicators |

Pumpkin puree |

Orange juice |

Dry skim milk |

Finished drink |

|

β-carotene |

1.310 |

0.062 |

- |

0.790 |

|

Thiamine, B 1 |

0.042 |

0.043 |

0.32 |

0.045 |

|

Riboflavin, B 2 |

0.060 |

0.024 |

1.84 |

0.130 |

|

Nicotinic acid, PP |

0.400 |

0.340 |

7.60 |

0.650 |

|

Ascorbic acid |

3.900 |

42.400 |

4.70 |

6.000 |

|

Sodium |

190 |

178 |

540 |

155.28 |

|

Potassium |

170 |

12 |

1785 |

192.21 |

|

Calcium |

60 |

19 |

1258 |

127.32 |

|

Magnesium |

13.0 |

12 |

115 |

14.51 |

|

Phosphorus |

54 |

15 |

975 |

82.35 |

|

Ferrum |

2.25 |

0.4 |

0.41 |

1.402 |

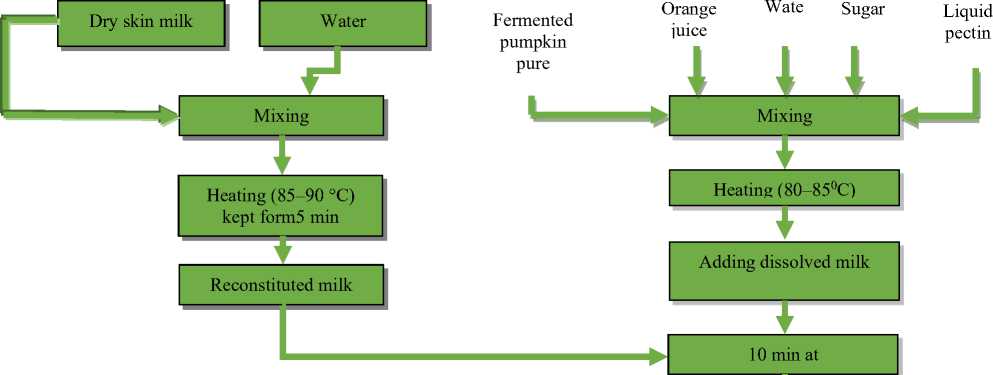

Organoleptic evaluation of the products was based on the following indicators: color, aroma, taste, texture, outward appearance. A 35-point grading system was used for this purpose (Table 5).

As seen in Table 5, the organoleptic characteristics of samples 3 and 7 were better (Figure 2). The products had a soft and harmonious taste, a pleasant aroma of orange juice used, and the golden color of pumpkin puree.

ORGANOLEPTIC EVALUATION OF FINISHED DRINKS

Table 5

|

Organoleptic indicators |

Samples |

|||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

|

Color |

25 |

20 |

30 |

30 |

20 |

20 |

35 |

25 |

25 |

30 |

|

Aroma |

30 |

30 |

35 |

20 |

35 |

35 |

35 |

25 |

35 |

30 |

|

Taste |

20 |

25 |

35 |

25 |

20 |

20 |

35 |

30 |

20 |

25 |

|

Texture |

20 |

20 |

30 |

30 |

25 |

25 |

35 |

25 |

25 |

25 |

|

Outward appearance |

25 |

25 |

30 |

30 |

30 |

30 |

35 |

30 |

30 |

25 |

The product prepared according to the recipe was chemically analyzed to establish whether it was ecologically clean food. Lead was quantified by nephelometry, arsenic-bymercurybromide, cadmium — by polyarography, and mercury by colorimetry. As seen in Table 6, the content of toxic elements in the product was within acceptable limits.

Color

Figure 2. Diagram of organoleptic evaluation of finished beverages

^^^^^м Sample 1

^^^^^^^^ш Sample 2

^^^^^^^^ш Sample 3

^^^^^^^м Sample 4

^^^^^^^^ш Sample 5

^^^^^^^^ш Sample 6

^^^^^^^^м Sample 7 ^^^^^^^^м Sample 8

^^^^^^^* Sample 9

Sample 10

SAFETY INDICATORS OF BEVERAGE SAMPLE NUMBER 7

Table 6

|

Indicators |

Acceptable amount, mg/kg |

Amount of toxic elements in sample no. 7, mg/kg |

|

Lead |

1.0 |

<0.01 |

|

Arsenic |

0.1 |

<0.002 |

|

Cadmium |

0.03 |

<0.001 |

|

Mercury |

0.02 |

<0.002 |

Conclusions

-

1. Chemical and microbiological analysis of the drink prepared based on the developed recipe has shown that this product can be used effectively for children, as well as for therapeutic and prophylactic purposes. Thus, this drink has the properties of a functional food product.

-

2. The study of the mineral content of the finished product once again has confirmed that it meets the standard requirements developed for safe food.

-

3. Organoleptic analysis of finished product samples for different component compositionshas allowed establishing a beverage sample having better quality.

I would like to thank the Department of Food Engineering and Expertise of the Azerbaijan University of Technology and the Gilan Gabala Cannery (Azerbaijan) for their support in conducting the research.

Список литературы Study of the pectin-based beverage preparation technology from fruits and vegetables grown in Azerbaijan

- Fataliyev, H. K. (2015). Ichkilerin müayinesi. Baku. (in Azerbaijani).

- Vavilova, O. I. (2004). Ispol'zovanie promyshlennoi pektinazy v sokovoi industrii. 2. Opredelenie kineticheskikh parametrov promyshlennoi pektinazy, immobilizovannoi na anionoobmennoi makroporistoi smole. (Turtsiya). Pishchevaya i pererabatyvayushchaya promyshlennost'. Referativnyi zhurnal, (3), 999 999. (in Russian).

- Donchenko, L. V., & Firsov, G. G. (2007). Pektin: osnovnye svoistva, proizvodstvo i primenenie. Moscow. (in Russian).

- Abasov, I. (2010). Agriculture in Azerbaijan. Baku.

- Akhmedov, A. I. (2014). Medicinal properties of edible plants. Baku.

- Nawirska, A., Figiel, A., Kucharska, A. Z., Sokół Łętowska, A., & Biesiada, A. (2009). Drying kinetics and quality parameters of pumpkin slices dehydrated using different methods. Journal of Food Engineering, 94(1), 14 20. https://doi.org/10.1016/j.jfoodeng.2009.02.025

- Dobrek, Ł., & Thor, P. (2010). Future potential indications for pharmacotherapy using renin angiotensin aldosterone system inhibitory agents. Advances in Clinical and Experimental Medicine, 19(3). (in Russian).

- Zaman, M. A., Oparil, S., & Calhoun, D. A. (2002). Drugs targeting the renin angiotensin aldosterone system. Nature reviews Drug discovery, 1(8), 621 636. https://doi.org/10.1038/nrd873

- Bourland, C., Kloeris, V., Rice, B. L., & Vodovotz, Y. (2000). Food systems for space and planetary flights. Nutrition in spaceflight and weightlessness models, 19 40.

- Dhiman, A. K., Sharma, K. D., & Attri, S. (2009). Functional constitutents and processing of pumpkin: A review. Journal of Food Science and Technology, 46(5), 411.

- Stutz, H., Bresgen, N., & Eckl, P. M. (2015). Analytical tools for the analysis of β carotene and its degradation products. Free radical research, 49(5), 650 680. https://doi.org/10.3109/10715762.2015.1022539

- Pashaev, F. A. (1997). Catalog of zoned varieties of agricultural plants of the Republic of Azerbaijan for 1998. Baku.

- Akhundzade, I. M. (1990). Citrus plants of Azerbaijan. Baku. 3 75.

- Nabiev, A. A., & Muslemzade, E. A. (2008). Biokhimiya pishchevykh produktov. Baku.

- Tretyakov, N. I. (2002). Fiziologiya i biokhimiya sel'skokhozyaistvennykh rastenii. Moscow. (in Russian).