Study of the strength regulation factors for the adhesive bonding “cement matrix – reinforcing fiber” in composites for 3D-build printing

Автор: Galina S. Slavcheva, Olga V. Artamonova, Kristina S. Kotova, Maria A. Shvedova, Pavel Y. Yurov

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Development of new polymer materials

Статья в выпуске: 2 Vol.15, 2023 года.

Бесплатный доступ

Introduction. As part of the solution for the problem of creating a new class of materials for building additive technologies, cement composites reinforced with high-strength fiber, this work presents the results of experimental studies of the strength of the adhesive bonding between cement matrices and reinforcing fibers with different chemical compositions, diameters, and tensile strength. Materials and methods. Rheological properties of cement systems were studied using shear and squeeze rheometry, the method of micromechanical testing for determining the strength of the adhesive bonding “cement matrix – reinforcing fiber” based on the pull-out test, which involves pulling out the fiber from the cement matrix layer; after the pull-out test for all the studied systems, the microstructure of the contact surface “cement matrix – reinforcing fiber” was assessed using a Thermo Scientific™ Phenom ™ Desktop SEM scanning electron microscope; the compressive strength of hardened cement paste-samples was determined using an INSTRON Sates 1500HDS testing machine. Results and discussions. It was established that the combination of strength characteristics of matrices, fibers, and adhesive strength at their interface allowed securing the required strength characteristics of reinforced construction composites. In the “cement matrix – carbon fiber” systems, the value of adhesive strength was 9 – 11 MPa; in the “cement matrix – steel wire” systems, the value of adhesive strength was 3 – 4 MPa. Conclusions. Matrices with viscosity modifiers containing nano- and micro-sized particles of SiO2 (complex nano-sized additive and metakaolin) are reasonable options for combinations of the “cement matrix – reinforcing fiber” components. Carbon fiber and steel wire are recommended to be used as reinforcing fibers.

Cement composites, additive technologies, rheology of dispersed systems, structure modification, reinforcement, adhesive strength

Короткий адрес: https://sciup.org/142237968

IDR: 142237968 | DOI: 10.15828/2075-8545-2023-15-2-124-133

Текст научной статьи Study of the strength regulation factors for the adhesive bonding “cement matrix – reinforcing fiber” in composites for 3D-build printing

Original article

C urrent development of additive 3D-printing technologies in construction cannot be ensured without a new class of building composites that are adapted to the technological conditions of 3D-printing and also possess a set of physical and mechanical properties allowing them to be used in thin layers of 3D-printed structures.

Despite a great number of research and development [1 – 9], today 3D-printing is used in construction only for building the shell of vertical structures, primarily walls that are reinforced and finished in the traditional manual way. There are two ways to change this situation. The first one is improving the process of reinforcement of printed constructions with the help of traditional reinforcement elements (mats and bars) along and across the layer [5 – 7]. However, this requires a lot of manual

DEVELOPMENT OF NEW MATERIALS labor, which contradicts the idea of 3D-build printing as a robotic technology. The second one is related to increasing tensile strength and reducing crack resistance of printing composites through the introduction of continuous reinforcing fibers in the course of extrusion and concrete layering [9 – 12] or using fiber [13, 14].

Thus, to implement the potential of 3D-build printing, it is necessary to obtain a new class of reinforced composites, the idea of which involves a rigid matrix based on cement and fillers (with various compositions and size) that will be reinforced with high tensile strength fibers in the course of printing.

Theoretical approaches to the formation of the structure and properties of 3D-built reinforced composites that we previously formulated [15] are based on the regulation of the composition, rheological properties of the mixture, and physical-mechanical properties of the matrix after its hardening, properties of reinforcing fibers, and parameters of “cement matrix – reinforcing fiber” adhesive strength in the composite. Based on this, we justified the geometric, physical-mechanical, and physical-chemical means of the structure formation and properties of reinforced composites. The conditions ensuring physical-chemical and physical-mechanical interaction in the “cement matrix – reinforcing fiber” system based on the implementation of the principles of continuity, compliance, and compatibility of the system components were the determining factor in the formation of the structure of reinforced cement composites as a whole.

Physical-mechanical parameters of the “cement matrix – reinforcing fiber” interface were determined both by the geometric parameter of the contact area and by physical-mechanical parameters that depended on adhesive strength of the “cement matrix – reinforcing fiber” bonding.

Therefore, this issue of the regulation of strength of the adhesive strength has not been studied properly for the investigated systems. Theoretically, it can be assumed that the solution of this issue depends on two factors.

First of all, these are the conditions for the physicalchemical compatibility of the adhesive (matrix) and the substrate (fibers) that will be determined by the energy and number of bonds acting through the boundary surface, depending on the chemical nature of the adhesive and the substrate, the presence of the substrate on the surface and in the adhesive structure of the functional groups capable of chemical interaction, the action of in-termolecular forces or diffusion.

Second, these are the conditions of the matrix wetting the surface of the fibers that depend on rheological properties of the pastes (viscosity and plasticity). As we demonstrated before [3], the rheological properties of the matrix in the viscoplastic state as a heterogeneous system depend on the following: the concentration of particles of the dispersed phase in the dispersed medium; the prop- erties of the dispersed phase, including particle size and their morphology, chemical and mineralogical composition, physical-chemical properties of the particle surface; and the properties of the dispersed medium, including its ionic composition, viscosity, and density.

Therefore, the goal of this work was to establish the influence of the component composition of matrices on the strength of the adhesive bonding in the “cement matrix – reinforcing fiber” systems, which determines their rheological characteristics and mechanical properties, as well as the types of fibers that with different chemical compositions, diameters, and tensile strength.

MATERIALS AND METHODS

To obtain cement systems for 3D printing, we used Portland cement (C) CEM I 42.5 (GOST 31108 – 2016), process water (V) (GOST 23732-2011), and a superplasticizer (SP) based on polycarboxylate ethers ( Sika® ViscoCrete ® T100).

We introduced a superplasticizer and modifier additives affecting the density and viscosity of the dispersed medium in the cement system as variable compositional factors that affect the rheological characteristics and physical-mechanical properties of cement mixtures.

We used the following additives as viscosity modifiers: metakaolin ((MKL), VMK-45, TU 23.99.19-00434556001-2017), xanthan gum ((XG), FUFENG ® 80) and potassium pyrophosphate ((TPPPh), commercial grade, YUCHENG ), as well as a complex nano-sized additive based on SiO2 (CNA), the synthesis of which was described in detail in [16].

As reinforcing fibers, we used (Table 1): steel wire (SW) type 4L22 GOST 14311-85), carbon fiber based on a PAN precursor ((CF), UMT-49-12K-EP), basalt fiber ((BF), Basfiber), and glass fiber ((GF), GOST 171392000). For all types of fibers, we determined the maximum tensile strength according to the results of tensile test on an INSTRON Sates 1500HDS testing machine. Unlike the GOST 34261-2017 methodology, which involves curing fibers with epoxy resin, we tested basalt, carbon, and glass fibers for fiber breaking in the initial state, since the use of cured fibers is technologically impractical when creating composites for 3D-printing and this method is not expected to be applied.

Cement pastes were obtained for the study in a blade mixer through mixing Portland cement with water and corresponding additives for 3 minutes. The factor space of experimental studies with the characteristics of modified cement systems and reinforcing fibers is presented in Table 2.

Rheological properties of cement systems were studied using shear and squeeze rheometry.

Shear rheometry was used for 4 cement systems in order to study their rheological behavior on a Rheotest

DEVELOPMENT OF NEW MATERIALS

Table 1

Reinforcing fiber characteristics

|

Type of the reinforcing fibers |

Single fiber diameter, µm |

Tensile strength, MPa |

|

Steel Wire (SW) |

230 |

2769–2950 |

|

Carbon Fiber (CF) |

5–7 |

841–955 |

|

Basalt fiber (BF) |

10–12 |

567–644 |

|

Glass Fiber (GF) |

18–20 |

230–302 |

Table 2

Matrix of experimental studies

|

№ |

Acronyms of the cement matrixes |

Cement matrix mix design |

Fiber, pcs. in one sample |

|||||

|

Viscosity modifying additive / mass cement (%) |

W/C |

Superplasticizer / mass cement (%) |

GF |

BF |

SW |

CF |

||

|

1 |

C+W+SP |

– |

0.22 |

1.2 |

35 |

30 |

1 |

50 |

|

2 |

C+W+SP+MKL |

2 |

0.22 |

1.2 |

||||

|

3 |

C+W+SP+(XG+TPPPh) |

0.2/0.2 |

0.24 |

1.2 |

||||

|

4 |

C+W+SP+CNA |

0.2 |

0.20 |

0.7 |

||||

RN 4.11 rotational viscometer. The measurements were conducted using a cylindrical measurement system in a wide range of stresses and shear rates. Cement paste was subject to a shear in a gap between the rotating internal spindle and the stationary external cylinder. Each measurement included three experiments. The first experiment was the beginning of the measurement when the state of rest of the investigated system was disturbed and the rotation rate increased to the maximum specified value (120 min –1 ). The measurement time was 120 seconds. The second experiment was the preservation of the rotation rate for 65 seconds. The final third step of measurements was reducing the rotation rate of the nozzle until it stops (measurement time: 120 seconds). Viscosity and flow curves were plotted automatically.

Plastic response of cement systems was assessed using squeeze rheometry. A squeezing test with a constant deformation rate of 5 mm/s was used to evaluate the plasticity. To assess shape retention, the test was conducted with a constant load rate 0.5 N/s, which corresponded to the average rate of load increase in the course of 3D-build printing. The squeezing test is an original method that was described in detail in [17].

Compressive strength of the hardened cement paste samples sized 5 × 5 × 5 cm was determined after 28 days of hardening in the standardized environment ( t = 20 ± 2 o C, RH = 100%) on a INSTRON Sates 1500 HDS testing machine. The series contained

-

12 samples, and the interserial coefficient of result variability did not exceed 7%.

The method of micromechanical testing intended for determining the strength of the adhesive bonding “cement matrix – reinforcing fiber” is based on the pull-out test in which the fiber (substrate) is pulled out from the layer of the cement matrix (adhesive) [18]. This method was adjusted and improved for the studied cement systems. In the course of preliminary experiments, we established that in order to ensure the reliability and adequacy of tests, the number of reinforcing fibers in one sample must depend on the diameter and strength of a single fiber and was 1 pc. for steel wire 35 pcs. for glass fiber, 30 pcs. for basalt fiber, 50 pcs. for carbon fiber; the thickness of the cement matrix layer for all types of fibers was 2 mm, and 5 mm for steel wire (the ratio of the fiber diameter and the length of the matrix layer was 1:20 – 1:30).

To conduct micromechanical tests, we produced cement paste with a specified consistency that was filled into bowls of a specified height, 10 mm in diameter, and the fiber was placed in the center of the bowls. The bowls were primarily placed in a fiber fixing unit to ensure the geometric stability of samples. The samples remained in the forms until the end of the hardening process. 30 samples were made for each series of the experiment.

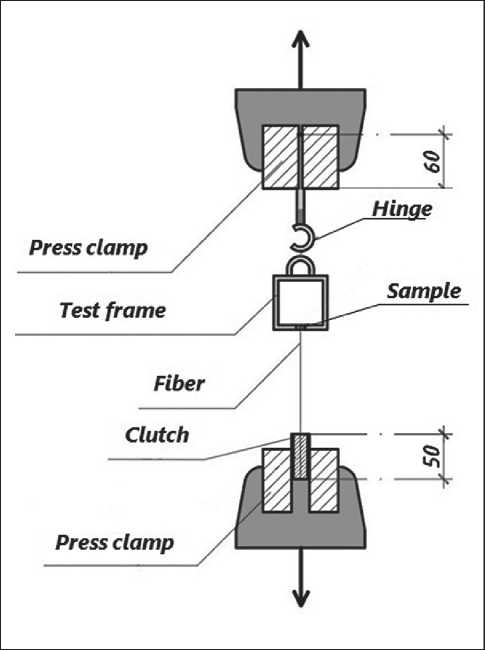

Based on the results of fiber pull-out tests from a sample cylinder, the strength of the adhesive compound was determined on a specially designed unit (Fig. 1), adapted

DEVELOPMENT OF NEW MATERIALS

Fig. 1. Diagram of the installation for testing samples for pulling out to the INSTRON5982 universal floor electromechanical testing system.

The load rate was 40 mm/min. Processing of the test results included measuring the force Fi required to pull out the fiber from the layer of the cement matrix upon the destruction of the sample and the area of the adhesive bonding Si . The Si value was calculated based on the thickness of the adhesive layer in the samples, which was determined using a micrometer after the tests.

Adhesive strength of the i sample was calculated using the formula suggested in [19]:

τi = Fi / Si . (1)

The test results were statistically processed: in each series, the distribution of adhesive strength values in the variability intervals corresponded to the normal distribution, and the coefficient of variation did not exceed 10%.

Once the pull-out tests were performed for all the studied systems, we assessed the microstructure of the contact surface “cement matrix – reinforcing fiber” using a Thermo Scientific™ Phenom™ Desktop SEM Phenom XL scanning electron microscope. We used the Phenom User Interface software package to obtain, process, and analyze the images.

RESULTS AND DISCUSSION

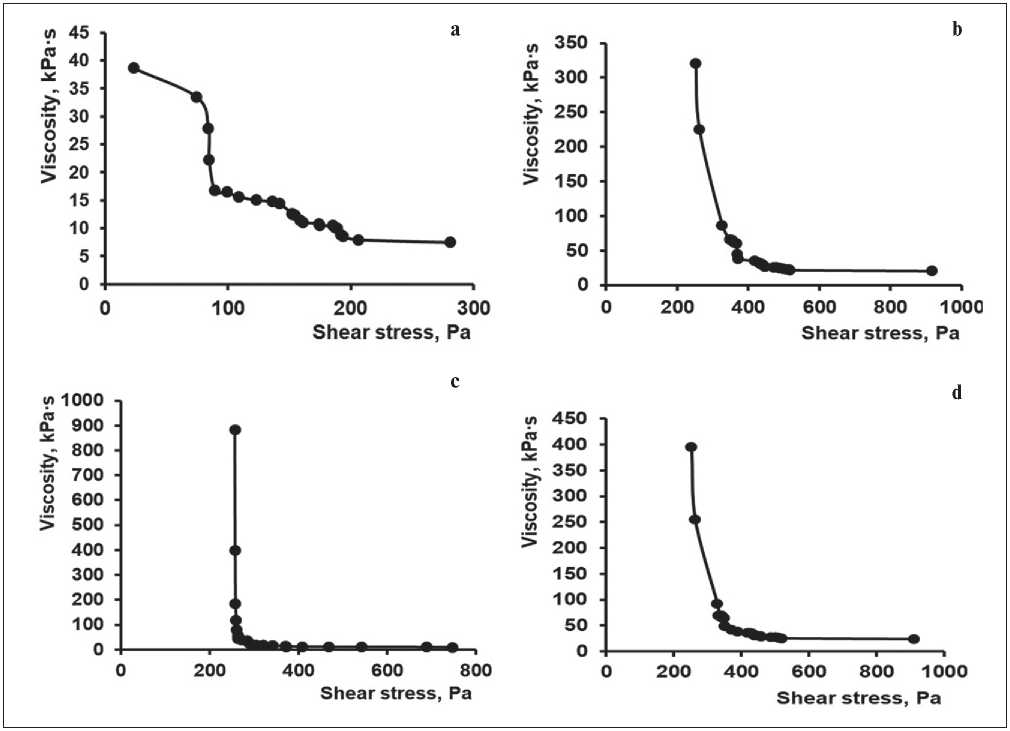

Results of experimental studies of rheological characteristics and physical-mechanical properties of cement matrices. Based on the analysis of the rheological behavior of cement pastes using share and squeeze rheometry (Table 3, Fig. 2), we established the following. The introduction of a superplasticizer reduced the static and dynamic viscosity of the cement mixture by more than 20 and 40 times. On the contrary, yield stress (static and Bingham, respectively) increased by 2 and 3 times. The type of rheological behaviour changed, and a creep area appeared on the rheological curve.

The introduction of viscosity modifying additives into the plasticized system naturally increased static viscosity but did not have a significant effect on dynamic viscosity, which indicated high thixotropy of these systems.

The transition of systems from viscosity modifying additives into the state of flow was achieved with the values of the shear stress which were an order of magnitude higher as compared to the systems without them. It should be noted that the cement system 3 (C+W+SP+(TPPPh + XG)) had the greatest viscosity (η0 = 882,4 kPa•s), which would lead to the lowest wetting of the fiber with the cement mixture.

The results of squeeze rheometry showed that regarding the regulation of plasticity and shape retention pastes, the introduction of modifying additives allowed changing the plastic yield value by 2 – 2.5 times and the shape retention indicators by 2 – 4 times as compared to reference systems without modifiers.

The analysis of the obtained results allowed establishing that the systems with viscosity modifying additives showed higher values of structural σ0 and plastic σpl strength and minimal plastic deformations ∆pl as compared to the reference systems, while all modified systems had shape retention indicators (σ0, σpl, ∆pl) (Table 2) that were close to optimal [17]. The best shape retention values were demonstrated by the 3 (C+W+SP+MKL) system with the highest values σ0 = 3,5 kPa.

The highest values of compressive strength were typical for cement systems modified with CNA and metakaolin additives (93 and 86 MPa, respectively, Table 3), which was logically associated with the close crystalchemical affinity of these additives to the minerals of cement clinker new growths and with their physicalchemical activity.

Experimental results of micromechanical tests determining the strength of the adhesive bonding “cement matrix – reinforcing fiber”. According to the data of micromechanical tests, the patterns of the influence of the component composition of cement matrices, types and characteristics of fibers on the adhesive strength were established for the pull-out of the reinforcing fiber from the cement matrix.

DEVELOPMENT OF NEW MATERIALS

Table 3

Rheological and mechanical properties of cement matrixes

|

№ |

Acronymes of the cement matrices |

о о .о 55 |

Я © О О 8 я Q |

Ри 6 ад хжх 55 |

ад я 2 ад я хжх |

3 |

Р^ 5 я хжх 3 Я 55 |

Р^ хжх Я 3 |

8 8 »-<г 2 |

6 а °® 8 О О |

|

0 |

C+W |

847.3 |

302.7 |

13.14 |

31.92 |

2.38 |

0.87 |

45.2 |

0.07 |

37 |

|

1 |

C+W+SP |

38.6 |

7.46 |

23.34 |

89.08 |

1.06 |

1.10 |

45.1 |

0.02 |

68 |

|

2 |

C+W+SP+MKL |

320.0 |

2.42 |

252.6 |

369.6 |

1.28 |

3.50 |

34.2 |

0.06 |

86 |

|

3 |

C+W+SP+ +(XG+TPPPh) |

882.4 |

10.48 |

256.5 |

271.3 |

0.87 |

2.30 |

36.6 |

0.05 |

75 |

|

4 |

C+W+SP+CNA |

395.1 |

3.62 |

253.1 |

350.8 |

1.42 |

2.64 |

41.2 |

0.13 |

93 |

Fig. 2. Complete rheological curves obtained on the Rheotest RN4.11 rotary viscometer for cement matrices: a) C+W+SP; b) C+W+SP+MKL; c) C+W+SP+(XG+TPPPh); d) C+W+SP+CNA

DEVELOPMENT OF NEW MATERIALS

Table 4

The average adhesive strength in the «cement matrix – reinforcing fiber» systems

|

№ |

Acronymes of the cement matrices |

Adhesive strength, MPa |

|||

|

Steel Wire |

Carbon Fiber |

Basalt Fiber |

Glass Fiber |

||

|

1 |

C+W+SP |

3.95 |

11.6 |

2.16 |

2.31 |

|

2 |

C+W+SP+MKL |

3.54 |

9.18 |

2.78 |

2.65 |

|

3 |

C+W+SP+(XG+TPPPh) |

2.73 |

4.93 |

1.77 |

1.69 |

|

4 |

C+W+SP+CNA |

3.84 |

8.94 |

2.81 |

3.41 |

The determining factor for the regulation of the adhesive strength in the “cement matrix – fiber” system was the type of reinforcing fiber. Among all the studied matrices, the highest values (up to 11.6 MPa) were recorded for the “cement matrix – carbon fiber” systems (Table 4).

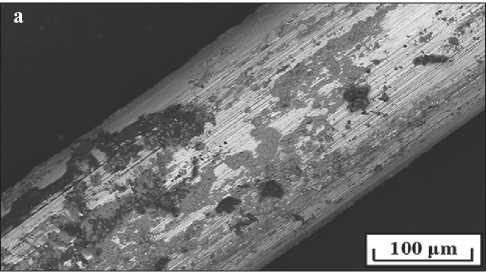

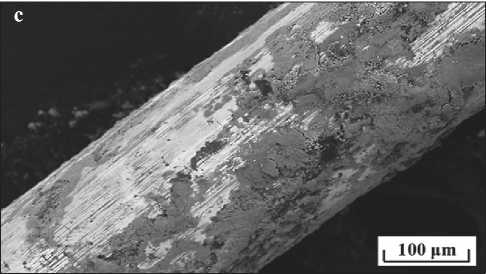

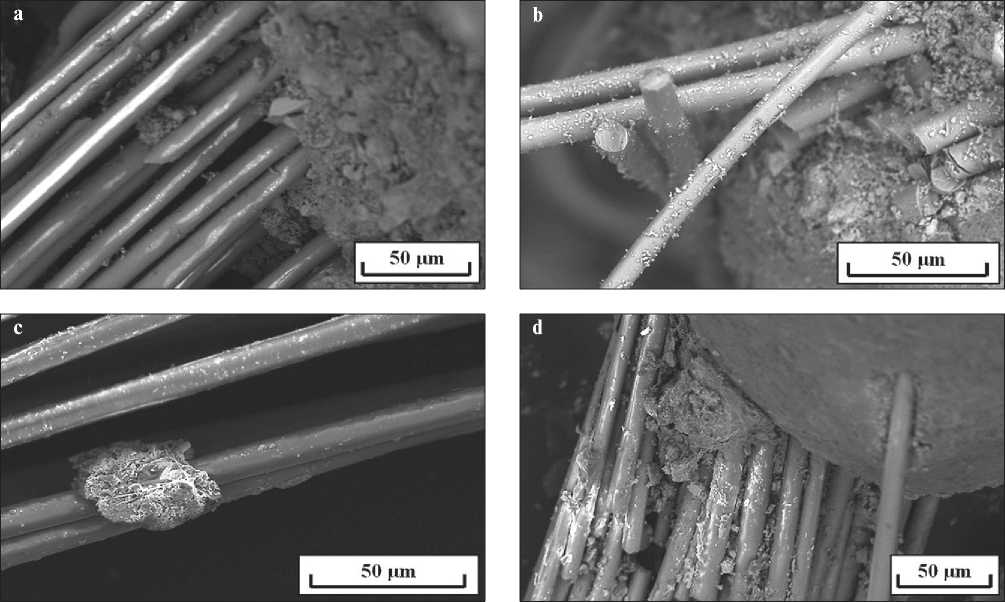

In all systems, there was a tendency towards the reduction of the adhesive strength upon the introduction of all viscosity modifiers, which was naturally associated with the deterioration of the conditions of wetting the fiber with modified cement pastes the viscosity of which was an order of magnitude higher as compared to the reference system. According to the electron microscopic analysis of the steel wire surface after pulling out, the destruction in this system occurred along the interface of the phases, and the largest area of hydration products areas adhesively bonded to the fiber surface was recorded (Fig. 3).

As steel wire has a heterogeneous structure (ferrite and cementite regions can be distinguished as well as multiple defects), the adhesive strength with the cement matrix will be determined by mechanical interlocking, on the one hand, because “rivets” that connect the components of the adhesive bonding by mechanical interlocking are formed between the fiber and the cement matrix.

On the other hand, adhesion can be the result of the interaction between hydration products of the matrix and the fiber through the intermolecular forces of interaction.

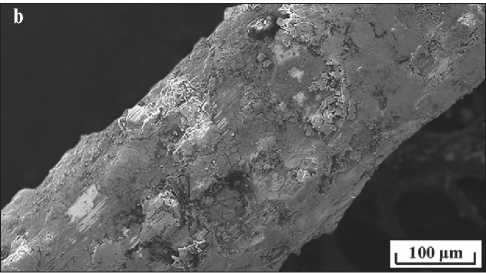

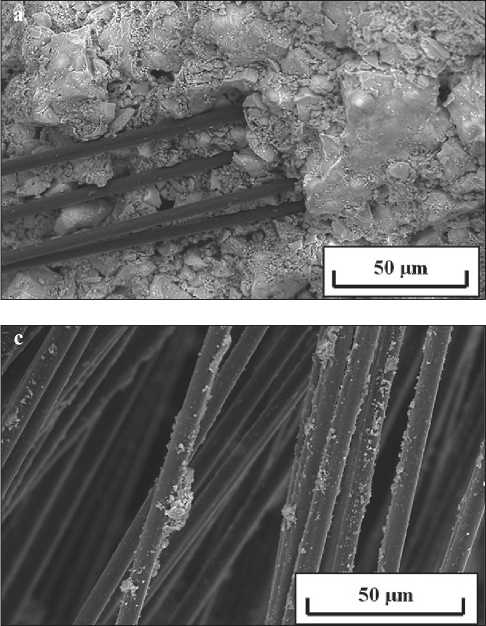

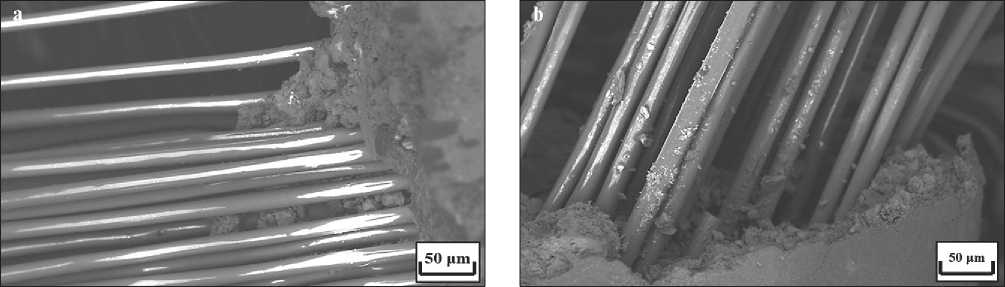

As for the systems with carbon fiber, areas of hydration products adhesively bonded to the fiber surface were practically not observed due to the absence of chemical affinity with the components of the cement matrix (Fig. 4).

Fig. 3. Micrographs of the adhesive compound in the «cement matrix – steel wire» systems, with various viscosity modifiers. It is designated: a) C+W+SP; b) C+W +SP+MKL; c) C+W+SP+(XG+TPPPh); d) C+W+SP+CNA

DEVELOPMENT OF NEW MATERIALS

50 pm

Fig. 4. Micrographs of the adhesive compound in the «cement matrix – carbon fiber» systems, with various viscosity modifiers. It is designated: a) C+W+SP; b) C+W+SP+MKL; c) C+W+SP+(XG+TPPPh); d) C+W+SP+CNA

The obtained carbon fiber based on the polyacrylonitrile precursor (-CH2–CHCN–)n was chemically inert in regard to the cement matrix.

The adhesive bonding of the fiber with the cement matrix will be determined mainly by the forces of mechanical interlocking which are highly significant for fibers of small diameter d = 5 µm. However, the presence of a functional nitrile group in the fiber structure can contribute to the interaction of the fiber with the cement matrix due to non-dispersive intermolecular forces of attraction, which ensures the formation of a strong adhesive bonding (up to 11.6 MPa), if we take into account the small diameter and the largest number of fibers in a unit volume of the cement system (50 pcs).

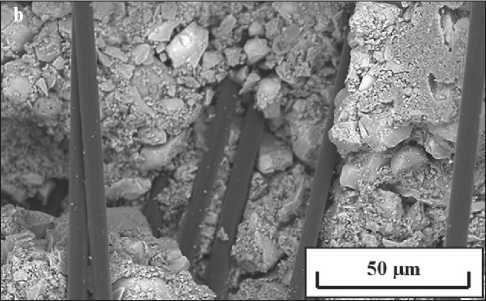

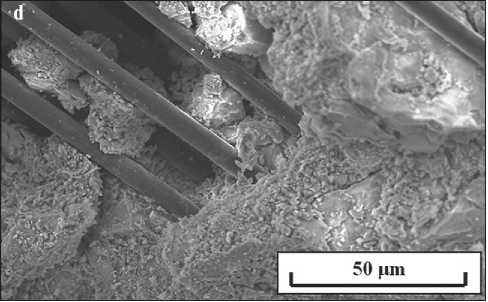

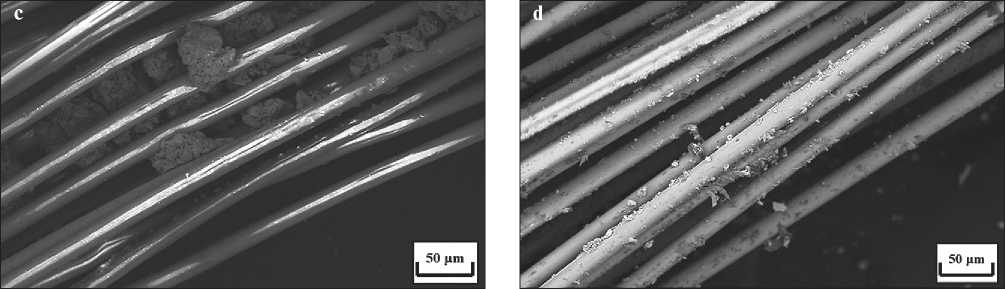

As for systems with fibers of similar silicate compositions and diameters (basalt fiber d = 10 µm and glass fiber d = 20 µm), the adhesive strength had similar values and was in the range of 1.69 – 2.81 MPa for basalt fiber and 1.22 – 3.41 MPa for fiberglass. In these systems, only certain sections of the hydration products were recorded that were adhesively bonded to the surface of the fiber and formed at the points of inhomogeneities and defects on its surface (Fig. 5 – 6).

As basalt and glass fibers consist of a mixture of oxide phases (SiO2, Al2O3, CaO, MgO, etc.), which have chemical and mineralogical composition similar to the cement matrix, in this case the adhesive strength can be determined by the chemical interaction of the components of the adhesive joint.

The composition of the matrices has the greatest impact on the adhesive strength in systems with silicate fibers. The highest adhesive strength was typical for matrices with viscosity modifiers that contained nano-sized and micro-sized SiO2 particles (CNA and metakaolin, respectively), which accelerated the heterogeneous hydration processes. The effect of a significant increase in adhesive strength in the 4 (C+W+SP+CNA) system could be explained by the nanosized SiO2 particles included in CNA, which possess increased values of surface energy and a similar crystal-chemical structure and can accelerate the heterogeneous hydration processes as much as possible, thus leading to acceleration of hydration and structural build-up.

At the same time, the superplasticizer contained in CNA reduced their interphase energy due to mono- and polymolecular adsorption on the surface of hydration products of the cement system, which resulted in particle dispersion. Part of the immobilized water was released, which reduced the viscosity of the system and increased the wetting ability of the fiber. Cement matrices that contained chemically inert gum, which increased viscosity and slowed down the processes of phase formation of

DEVELOPMENT OF NEW MATERIALS

Fig. 5. Micrographs of the adhesive compound in the «cement matrix – basalt fiber» systems, with various viscosity modifiers. It is designated: a) C+W+SP; b) C+W +SP+MKL; c) C+W+SP+(XG+TPPPh); d) C+W+SP+CNA

Fig. 6. Micrographs of the adhesive compound in the «cement matrix – glass fiber» systems, with various viscosity modifiers. It is designated: a) C+W+SP; b) C+W+SP+MKL; c) C+W+SP+(XG+TPPPh); d) C+W+SP+CNA

DEVELOPMENT OF NEW MATERIALS hydration products, demonstrated the lowest adhesion strength with all types of fibers.

Therefore, matrices with viscosity modifiers containing nano- and microsized particles of SiO2 (CNA and metakaolin) should be considered as reasonable options for combinations of the “matrix – reinforcing fiber” components regarding ensuring the adhesive strength, and it can be recommended to use carbon fiber and steel wire as reinforcing fibers.

It should be noted that these types of matrices and fibers had the greatest individual strength as compared to other their types in the studied systems (Tables 1, 3). The combination of high strength characteristics of matrices, fibers and adhesive bonding at the interface of their contact will ensure the strength properties required for 3D-build printing of reinforced composites.

CONCLUSIONS

We obtained experimental data on the rheological characteristics and physical-mechanical properties of cement matrices as well as the results of micromechanical

tests determining the strength of the adhesive strength “cement matrix – reinforcing fiber”.

According to the results of micromechanical tests, it was established that the highest adhesive strength in the “matrix – fiber” system was achieved when using cement matrices modified with nano-sized and micro-sized SiO2 particles (CNA and metakaolin) combined with carbon and metal reinforcing fibers.

The value of adhesive strength was 3 – 4 MPa in the “cement matrix – steel wire” systems, while the formation of adhesive bonding in this system can be determined by mechanical interlocking and interaction between hydration products of cement matrix and the fiber through intermolecular forces of interaction.

The value of adhesive strength was 9 – 11 MPa in the “cement matrix – carbon fiber” systems. The formation of adhesive bonding in this system was also determined by mechanical interlocking, however, the presence of a functional nitrile group in the carbon fiber structure can contribute to the interaction of the fiber with the cement matrix due to non-dispersive intermolecular forces of attraction, thus significantly increasing the adhesive strength.

Список литературы Study of the strength regulation factors for the adhesive bonding “cement matrix – reinforcing fiber” in composites for 3D-build printing

- Lu B., Weng Y., Li M., Qian Y. A systematical review of 3D printable cementitious materials. Construction and Building Materials. 2019; 207: 477 – 490. https://doi.org/10.1016/j.conbuildmat.2019.02.144

- Slavcheva G.S., Artamonova O.V. Rheological behavior of 3D printable cement paste: criterial evaluation. Magazine of Civil Engineering. 2018; 84(8): 97 – 108. https://doi.org/10.18720/MCE.84.10

- Slavcheva G.S., Artamonova O.V. Controlling the Rheological Behavior of Mixtures for Construction 3D Printing: An Experimental Evaluation of the Possibilities of the “Nano” Arsenal. Nanotechnologies in Construction. 2019; 11(3): 325 – 334. https://doi.org/10.15828/2075-8545-2019-11-3-325-334

- Paul S.C., Tay Y.W.D., Panda B., Tan M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Archives of Civil and Mechanical Engineering. 2018; 18(1): 311 – 319. https://doi.org/10.1016/j.acme.2017.02.008

- Ngo T.D., Kashani A., Imbalzano G., et al. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Composites Part B: Engineering. 2018; 143: 103. https://doi.org/10.1016/j.compositesb.2018.02.012

- Malaeb Z., Hachem H., Tourbah A., et al. 3D Concrete Printing: Machine and Mix Design. International Journal of Civil Engineering and Technology. 2015; 6(4): 14 – 22.

- Poluektova V.A., Shapovalov N.A. Concrete chemicalization for digital printing: control of rheology and structure formation. Lecture Notes in Civil Engineering. 2021; 95: 59 – 65. https://doi.org/10.1007/978-3-030-54652-6_9

- Perrot A., Jacquet Y., Rangeard D., et al. Nailing of Layers: A Promising Way to Reinforce Concrete 3D Printing Structures. Materials. 2020; 13. P. 1518. https://doi.org/10.3390/ma13071518

- Marchment T., Sanjayan J. Penetration Reinforcing Method for 3D Concrete Printing. In Proceedings of the Second RILEM International Conference on Concrete and Digital Fabrication, Eindhoven. 2020. P. 680 – 690. https://doi.org/10.1007/978-3-030-49916-7_68

- Hass L., Bos F. Bending and Pull-Out Tests on a Novel Screw Type Reinforcement for Extrusion-Based 3D Printed Concrete. In Proceedings of the Second RILEM International Conference on Concrete and Digital Fabrication, Eindhoven. 2020. P. 632 – 645. https://doi.org/10.1007/978-3-030-49916-7_64

- Mechtcherine V., Grafe J., Nerella V.N., et al. 3D-printed steel reinforcement for digital concrete construction—Manufacture, mechanical properties and bond behaviour. Construction and Building Materials. 2018; 179: 125 – 137. https://doi.org/10.1016/j.conbuildmat.2018.05.202

- Weger D., Baier D., Straßer A., et al. Reinforced Particle-Bed Printing by Combination of the Selective Paste Intrusion Method with Wire and Arc Additive Manufacturing—A First Feasibility Study. In Proceedings of the Second RILEM International Conference on Concrete and Digital Fabrication, Eindhoven. 2020. P. 978 – 987. https://doi.org/10.1007/978-3-030-49916-7_95

- Katzer J., Szatkiewicz T. Properties of concrete elements with 3-D printed formworks which substitute steel reinforcement. Construction and Building Materials. 2019; 210: 157 – 161. https://doi.org/10.1016/j.conbuildmat.2019.03.204

- Bos F.P., Ahmed Z.Y., Jutinov E.R., Salet T.A.J.M. Experimental exploration of metal cable as reinforcement in 3D printed concrete. Materials. 2017; 10: 1314. https://doi.org/10.3390/ma10111314

- Slavcheva G.S., Artamonova O.V. Development of principles for creating reinforced composites for building 3D additive technologies. Construction Materials. 2022; 12: 52 – 58. https://doi.org/10.31659/0585-430X-2022-809-12-52-58

- Artamonova O.V. Synthesis of nano-modifying additives for the technology of building composites. Gorod: Voronezh, 2016. – 100 p.

- Slavcheva G.S., Shvedova M.A., Babenko D.S. Analysis and criterion evaluation of the rheological behavior of mixtures for building 3d printing. Construction Materials. 2018; 12: 34 – 40. https://doi.org/10.31659/0585-430X-2018-766-12-34-40

- Gorbatkina Yu.A., Ivanova-Mumzhieva V.G. Adhesion ability of carbon black-filled epoxides. Adhesives. Sealants. Technologies. 2008; 11: 2 – 5.

- Gorbatkina Yu.A. Adhesion strength in polymer-fiber systems. Gorod: Moscow, 1987. – 190 p.