Synergetic improvement of technological characteristics of highway road surfaces by bitumen microdispersed emulsions

Автор: Glazachev A.O., Ivanova O.V., Pavlov S.Yu., Salov A.S., Akhmetshin R.M.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 5 Vol.16, 2024 года.

Бесплатный доступ

Introduction. The use of bitumen microdispersed emulsion as a resource-saving method for road surface construction is a popular trend in the development of innovative nanostructures. The technological use of petroleum bitumen as a binder for road materials requires a reduction in rheological viscosity. This can be achieved through synergistic developments that involve the use of various additives and modifiers. Methods and materials. The composition of bitumen microheterogeneous emulsions includes: bitumen-containing raw materials (up to 70–80% of mass); water with hardness up to 6 mg-eq/l (from 20 to 30%); emulsifiers (up to 3%) and other components. For large-tonnage production of water- bitumen emulsions, a colloid mill is the most technologically advanced equipment. Results. Water-bitumen emulsions are formed as a result of two competing processes: crushing (dispersion) and coalescence (merging) of microdroplets of the bitumen dispersed phase. The microheterogeneous bitumen phase is distributed in the aqueous dispersion medium in the form of microdroplets ranging in size from 1 to 10 μm (the main share is made up of bitumen microdroplets with a diameter of 2–4.5 μm). The synergetic durable microstructure of asphalt concrete road surfaces, which is formed by supplementing interaction in the boundary layers of the bitumen binder with the surface of the mineral component, is determined by the dominant interaction of complementary factors. Discussion. The synergetic approach to extending the service life of asphalt concrete road surfaces by using bitumen microdispersed emulsions holds promise for interpreting their evolution. The road construction industry of the Russian Federation at the beginning of the 21st century is characterized by a large-scale revision of regulatory documents, regulating the requirements for the construction and operation of highways. Conclusion. The optimal solution to the current problems of intensive construction and reconstruction of Russian highways is the improvement of technological characteristics of road surfaces by adding bitumen microdispersed emulsions to the composition. In complementary strengthening of weak soils of the road surface of high-speed highways, the use of water-bitumen microdispersed emulsions is also recommended.

Bitumen emulsion, asphalt concrete pavement, synergistic reinforcement, cationic emulsifier, road construction

Короткий адрес: https://sciup.org/142242279

IDR: 142242279 | DOI: 10.15828/2075-8545-2024-16-5-463-472

Текст научной статьи Synergetic improvement of technological characteristics of highway road surfaces by bitumen microdispersed emulsions

Original article

Innovative developments in emulsion nanotechnologies, which allow achieving resource-saving, technological and environmentally friendly construction of high-quality road surfaces, are among the most effective areas in the construction of transport facilities. Microdispersed bitumen road emulsions are used in the technology of building Russian highways: they are effective for creating protective layers with a rough surface; preventive repair of deep potholes at low temperatures; environmentally friendly stabilization of slopes of the roadbed and shifting sands;

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION as a nanoadditive in the complex strengthening of weak soils of the roadbed (with lime, etc.); production of black crushed stone, and other porous, dense crushed stone and gravel-sand materials used in creating the structural layers of high-speed transport highways [1–4].

Resource-saving technological use of petroleum bitumen as road binders requires a reduction in rheological viscosity, which can be achieved by heating to 170°C, dissolving in hydrocarbon diluents and emulsifying in water [5–7]. Water-bitumen emulsions have been used for over a hundred years in road construction: pothole repair, laying of protective thin layers of road surfaces. The preparation of stable water-bitumen emulsions requires the use of effective surfactants - emulsifiers that stabilize the dispersion of bitumen microdroplets and provide stability during long-term storage such as cyclic amine with a stabilizer (block copolymer of ethylene oxide and propylene oxide) wich can last up to 90 days [8]. Synergistic developments in improving the technological characteristics of highway road surfaces using bitumen microdispersed emulsions remain relevant.

The purpose of this article is to study effective methods of preparation and use of water-bitumen petroleum microdispersed emulsions in intensive construction and reconstruction of highways and transport infrastructure.

METHODS AND MATERIALS

In road construction, the most technologically advanced method is the use of direct water-bitumen emulsions (the bitumen dispersed phase is distributed in the form of microdroplets measuring 1–20 µm in an aqueous dispersion medium). The amount of road petro- leum bitumen (from CB (construction bitumen) 40/60 to CB 200/300) varies in microheterogeneous emulsion 30–80 mass %; soft water (hardness up to 6 mg-eq/l) 15–70 mass % (pH ≈ 7, neutral medium); emulsifier up to 3% mass %.

Small amounts of emulsifiers reduce the interfacial tension between water and immiscible bitumen, which promotes stable distribution of bitumen microdroplets in the aqueous phase. The efficiency of emulsification depends on the composite microstructure of road petroleum bitumen, macromolecular nanoadditives, physicochemical characteristics of the emulsifier, and the emulsification mode [9–11]. It has been established that in the case where the ratio of resins and oils in the bitumen petroleum binder exceeds 0.6, and the ratio of resins and asphaltenes is in the range from 0.5 to 2.0, then the bitumen will be effectively emulsified.

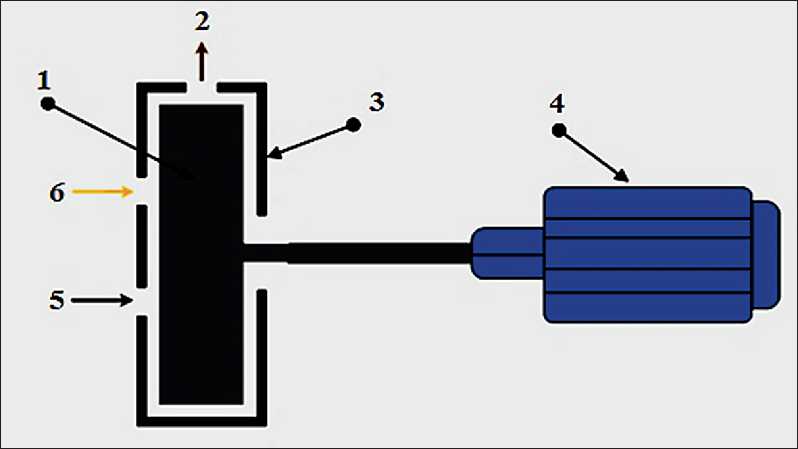

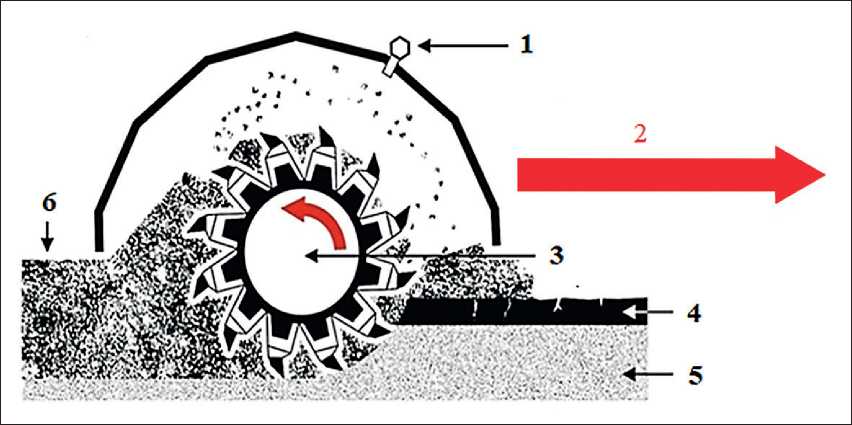

Emulsification (dispersion of bitumen components) is a process of physical crushing (grinding into microdroplets) carried out by various installations: colloid mills, ultrasonic dispersers, etc. For large-tonnage production of water-bitumen emulsions, a colloid mill is the most frequently used technological equipment. A colloid mill consists of a rapidly rotating rotor (angular velocity 2500– 7000 rpm) and a stator; due to centrifugal forces, the bitumen component is split into microdroplets, which are coated with an electrically charged surface-active emulsifier. In the distribution of microdroplets by size (diameter of bitumen microdroplets), the following geometric characteristics of the production [12–14] colloid mill play an important role: the adjustable gap between the rotor and stator, which can vary from 0.25 to 0.5 mm, as well as the angular speed of rotation of the rotor (Fig. 1).

Fig. 1. Operation of a colloid mill in the process of producing water-bitumen emulsion: 1 – rotor, 2 – emulsion, 3 – stator, 4 – electric motor, 5 – bitumen, 6 – aqueous solution of emulsifier

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

First, a surface-active emulsifier in the form of an aqueous solution at a temperature of 50–70°C is fed into the colloid mill; then, molten bitumen at a temperature of 140–170°C, suitable for emulsification with a viscosity of about 0.2 Pa·s, is dosed into the colloid mill. Optimum emulsification (diameter of bitumen microdroplets 5–10 µm) in the colloid mill is achieved with a bitumen component content of no more than 70% and a temperature of no more than 90°C for 25–30 minutes. When this range is exceeded, the production of water-bitumen emulsion becomes ineffective due to the formation of larger bitumen microdroplets, and the prepared road emulsions lose stability when stored in a tank. Conditional viscosity level, adhesive properties, disintegration index, and stability are the main characteristics of bitumen emulsions within the framework of tightening requirements for digital control of the production of asphalt concrete road construction materials [15].

The main function of surface-active emulsifiers is to reduce the surface tension of water-bitumen emulsion and prevent the reverse adhesion of microdroplets. It should be noted that the physicochemical characteristics of emulsifiers have a significant effect on the properties of bitumen emulsion such as viscosity, aggregate stability, ability to break down and adhesion. Bitumen emulsifiers are divided into anionic, cationic, nonionic depending on the composition of the functional group [16].

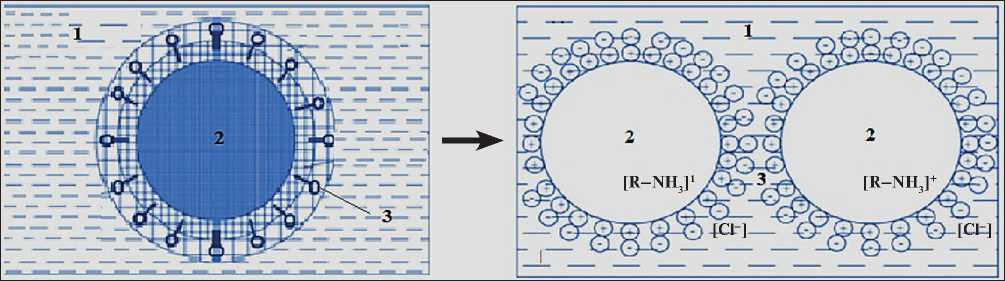

At first, anionic emulsifiers were the most common in the preparation of water-bitumen road emulsions, but since the mid-20th century, cationic emulsifiers have been used more widely in large-scale production (3/4 of the volume of bitumen emulsions is cationic) [17]. The diphilic molecules of emulsifiers consist of polar (hydrophilic “head”) and hydrophobic (non-polar “tail”) parts; the non-polar part is oriented toward the bitumen component, and the hydrophilic part is oriented toward the aqueous phase (Fig. 2).

This synergetic behavior of emulsifier molecules can be explained by the fact that when the molecules concentrate on the interface of two liquid phases that form a mi- croheterogeneous water-bitumen emulsion, they prevent the reverse fusion (coalescence) of bitumen microdroplets due to the double electric layer. Electrostatic repulsion and nanostructured characteristics of the double layer have a strong effect on the stability and viscosity of the bitumen emulsion. In road construction and reconstruction of highways, universal cationic emulsions are more often used in synergistic reinforcement. Cationic emulsifiers are alkylamines with a hydrocarbon chain of 8–22 atoms (the optimal number is 12–14) of carbon and primary amines (R-NH2), which provide a sufficiently high adhesion of the bitumen binder to the surface of mineral powders and crushed stone of acidic and basic nature.

The stability of the technical and economically effective water-bitumen emulsion is determined by the change in its homogeneity during storage, where emulsion samples can be held for a week or a month. The stability during transportation is determined after 2 hours of shaking the sample of water-bitumen emulsion, in this case, irreversible separation into bitumen and water should not occur. The normative technological determination of the properties of the bitumen component isolated from the emulsion is carried out after evaporation of water; the depth of penetration and extensibility should not decrease by more than 15% of the original bitumen.

A rather conventional classification of bitumen microdispersed emulsions is carried out by the type of emulsifiers: anionic, cationic, etc.; depending on the kinetic rate of disintegration when mixed with mineral powder and crushed stone: fast-, medium-, slow-disintegrating; modified (addition of complementary polymers), unmodified, etc. For example, the EBPRC F grade means emulsion bitumen-polymer for roads, cationic, fast-disintegrating.

For the technological preparation of emulsions, CBs (construction bitumen) of the following grades are used: CB 200/300, CB 90/130, CB 60/90, CB 40/60; the corresponding grade of bitumen is selected taking into account the climatic conditions of the construction area and the technological design of the synergetic reinforcement of the road surface. For example, for the construction of

Fig. 2. Formation of bitumen emulsion: 1 – layers of aqueous phase adjacent to the hydrophilic part of the emulsifier; 2 – bitumen microdrop adsorbing the hydrophobic part of the emulsifier; 3 – emulsifier molecules

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION highways in the Republic of Bashkortostan, where winter temperatures usually drop below –20°C, construction bitumens CB 90/130, CB 130/200, CB 200/300 are used.

For synergistic improvement of technological characteristics, water-bitumen emulsion is modified with polymer nanoadditives (latex, polyethylene, epoxy resin, synthetic rubber, synthetic resin, etc.). Aggregate modification of water-bitumen emulsion with macromolecular nanocomponents is carried out in two ways: by introducing a modifying additive into the aqueous phase of the emulsion or directly into the emulsion during its preparation using emulsification of modified bitumen in polymineral dispersions [18].

RESULTS

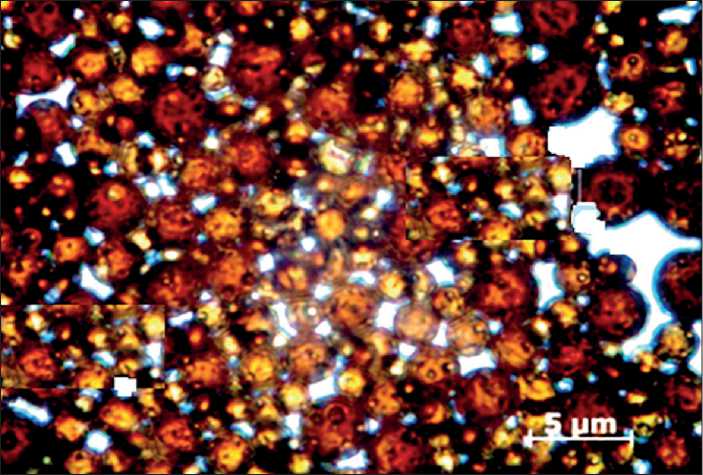

Bitumen road emulsions are colloidal emulsions, where the microheterogeneous bitumen phase is distributed in an aqueous dispersion medium in the form of microdroplets with a size of 1 to 10 µm (the main share is made up of bitumen microdroplets with a diameter of 2–4.5 µm). Figure 3 shows an optical micrograph (Axio Scope.A1 microscope) of the microstructure of bitumen emulsions (the amount of CB 70/100 road bitumen is 61%, the emulsifier Sinterol is 1.8%).

Water-bitumen emulsions are formed as a result of two competing processes: crushing (fine dispersion) and coalescence (merging) of microdroplets of the bitumen dispersed phase. Adsorption of amphiphilic molecules of emulsifiers on the interface of water-bitumen phases and formation of a double electric layer always occurs over a certain period of time. It should be noted that in addition to the presence of emulsifiers, the stability of bitumen emulsions is affected by: temperature, mineralization and acidity of the aqueous phase, concentration of microdroplets of the dispersed phase and their sizes, Brownian chaotic motion, density, viscosity, etc.

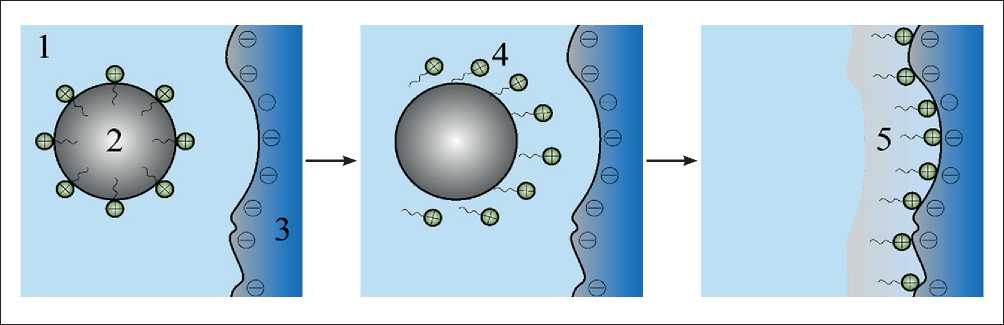

Controlled disintegration of water-bitumen emulsion is a kinetic process of bitumen component release from emulsion after application to highway road surface or combination of bitumen emulsion and mineral material which is also correctly interpreted within the framework of fractal analysis. Synergistic microstructure of asphalt concrete pavements, which is formed by complementary interaction in the boundary layers of bitumen binder with the surface of the mineral component, is determined by the dominant interaction of complementary factors. In most cases, stone materials, such as mineral powders and crushed stones, have negative surface charges, and positively charged emulsifier is attracted electrostatically to synergistic filler, causing controlled disintegration of water-bitumen emulsion (Fig. 4). Synergistic improvement of technological characteristics of road asphalt concrete occurs as a result of formation of continuous films of adsorbed bitumen.

A special feature of the technology of surface treatment of highways using emulsion-mineral mixtures is the need to find the optimal range of time for controlled disintegration of the water-bitumen emulsion in the composition used, i.e. the time from the moment the mixture is prepared until a solid-phase state is achieved. Controlled degradation of the emulsion should occur after the distribution of the synergistic emulsion-mineral mixture over the surface of the asphalt concrete pavement: with a faster disintegration, the mixture will prematurely thicken in the asphalt paver and will become unable to be paved,

Fig. 3. Micrograph of water-bitumen emulsion (magnification in an optical microscope ×1000)

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 4. Disintegration of bitumen microdispersed emulsion: 1 – aqueous phase; 2 – bitumen microdroplet; 3 – mineral powder; 4 – emulsifier molecules, 5 – adsorbed bitumen film

and with a slower one, the liquid composition will flow off the surface of the road pavement.

Cationic bitumen emulsions are divided by the rate of disintegration during processing of mineral complementary materials into: fast-disintegrating – 5–15 minutes, medium-disintegrating – several hours and slow-disintegrating – 1–2 days [19]. To determine the kinetic rate of disintegration of fast-disintegrating water-bitumen microdispersed emulsions, it is recommended to use quartz powder, the mass fraction of which is less than 50%. According to technological characteristics, the expected stability of bitumen road emulsion during transportation should be at least 2 hours. When optimally formulating asphalt concrete emulsions, it is necessary to take into account the stability during storage; bimodal emulsions may have a lower viscosity than monomodal analogues, but have higher stability during storage and transportation [20].

DISCUSSION

The road surface of transport highways directly perceives the impact of physical and mechanical loads, atmospheric factors and determines the most important operational qualities of the road, in the construction of which synergetic bitumen microdispersed emulsions were used. Forecasting the durability of asphalt concrete road surfaces is a fairly significant problem, since it is associated with: the diversity of various external factors (ground transport, weather conditions, etc.) that are difficult to analytically describe mathematically; insufficiently studied internal physical and chemical structuring processes in composite asphalt concrete. The synergetic concept [21] is promising for interpreting the evolution of asphalt concrete road surfaces of highways constructed using water-bitumen emulsions.

Synergetic enhancement of technological characteristics of asphalt concrete pavements, which is formed by in- teraction in boundary layers of bitumen structured binder with the surface of the mineral component, is determined by dominant interaction of complementary factors. Fractal concepts of long-term strength of asphalt concrete road pavement of highways are reflected in the levels of power dependence of nonlinear deformation under load, characterizing entropic nature of elasticity and kinetics of damage or hidden destruction of microstructure from load. Long-term strength of asphalt concrete pavement is characterized by activation energy, determining thermal fluctuation rupture of bitumen bonds at the nanolevel, as well as fractal dimension of asphalt concrete microstructure, determining usage patterns during deformation under load [22]. The main reason for the optimal choice of synergetic technology for the installation of protective wear-resistant layers of asphalt concrete road surfaces using water-bitumen emulsions is to ensure the safe movement of ground transport during the standard service life [23, 24].

In 2020, the annual global production and use of bitumen emulsions in road construction amounted to more than 7 million tons, amounting to 33% in the USA and 16% in France. In the Russian Federation about 250 thousand tons were produced. When choosing the type and brand of water-bitumen emulsion in the process of synergistic improvement of the technological characteristics of road surfaces, the purpose of microdispersed emulsions should be taken into account.

The main advantage of using water-bitumen microdispersed emulsions compared to traditional (hot, liquefied) road bitumens is the convenience in handling of the material [25]: only a sufficiently complete adhesion of the negatively charged surface of the road base with a positively charged cationic emulsion is needed for operation; technological production of bitumen emulsions allows varying the qualitative composition and required characteristics; the use of bitumen emulsions at temperatures from 30°C to 70°C is safe for use and reduces energy consumption

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION by 40–50%; it is permissible to pour bitumen emulsions onto moistened surfaces with the formation of a strong and water-resistant bitumen film on the complementary surface of mineral fillers. In addition, it is worth noting the technological environmental friendliness of the multitonnage preparation and use of water-bitumen emulsion: a minimal volume of harmful substances such as hot and liquefied bitumen is released into the atmosphere, and in addition, production becomes fire- and explosion-proof.

For the road construction industry of the Russian Federation, the beginning of the 21st century is characterized by a large-scale transformation of regulatory documents (GOST 18689-81, 52128-2003, 58952.12020) regulating the requirements for the construction and operation of high-speed highways, which are mainly represented by individual sections of federal highways. Conversion to a fluid state, i.e emulsification of waterbitumen binders at ambient temperature, requires stability during storage and transportation, with simultaneous destruction at a controlled speed during synergistic application to the surface of mineral fillers or road asphalt concrete pavement. One of the constraints for the use of resource-saving nanotechnologies in Russia is the lack of production of effective domestic cation-active emulsifiers and the high cost of imported analogues. However, fairly inexpensive and affordable raw materials have been proposed for the production of the emulsifier: polyamides and products containing fatty acids.

For the synergistic preparation of cast emulsionmineral mixtures for road purposes, slowly disintegrating cationic bitumen or bitumen-polymer emulsions should be used [26]. Complementary introduction of styrene- butadiene latexes up to 5% does not have a significant effect on the homogeneity and stability of water-bitumen emulsions: the most effective is the SKS-65GP latex, since more than 90% of the ultradisperse particles are less than 100 nm in size [27]. The addition of styrenebutadiene latexes has a positive synergistic effect on the main technological characteristics of water-bitumen bitumen compositions, which is manifested in a significant increase in heat resistance up to 100°C, frost resistance up to –15°C, elasticity up to 44%, softening temperature and hardness.

Water-bitumen emulsions are thermodynamically unstable – they are characterized by fractal aggregation of microdroplets of the dispersed phase and the processes of reverse sedimentation, i.e. coalescence. It should be noted that, in turn, bitumen binders are petroleum nanodispersions, the properties of which are determined by nanoparticles of the dispersed phase and the hydrocarbon dispersion medium [28]. Multi-tonnage bitumen road microdispersed emulsions according to GOST R 58952.12020 are divided into: emulsions bitumen anionic (EBA) and emulsions bitumen cationic (EBC).

To date, various methods have been proposed for using water-bitumen emulsions for road construction as a structured complementary binder; recommended areas of use of grades of bitumen road emulsions are given in Table 1.

The data in the table shows that water-bitumen road emulsions are most often used for synergetic priming before applying the upper layer of asphalt concrete, pothole repair and liquid phase surface treatment of road surfaces. For complementary strengthening of slopes of soil

Table 1

Recommended application areas for various grades of road bitumen emulsions

|

Emulsion grades |

Application area of water-bitumen emulsions |

|

EBC-1 EBPC-1 |

Sub-priming (pouring of liquid-phase bitumen emulsion) of road surfaces of transport highways, installation of protective surface treatment. |

|

EBC-2 EBPC-2 |

Technological installation of upper layers of road surfaces by the impregnation method; optimized technology for the preparation of black crushed stone and porous crushed stone mixtures; patching of potholes in highways. |

|

EBC-3 EBPC-3 |

Installation of thin-layer rough wear layers of road surfaces; technological production of dense water-bitumen emulsion- mineral mixtures, including soil mixtures; reinforcement of slopes. |

|

EBPA-1 |

Liquid-phase sub-priming; reinforcement of the surface of slopes of the roadbed; installation of wear-resistant surface treatment. |

|

EBA-2 EBPA-2 |

Technological care of freshly laid cement concrete road surface; preparation of black crushed stone and porous crushed stone mixtures from carbonate rocks; construction of road surfaces by impregnation method. |

|

EBA-3 EBPA-3 |

Optimized production of emulsion-mineral mixtures of dense composition with mandatory introduction of 1-2% lime or 2-3% cement; fixation of shifting sands and weak soils of the upper layers of the roadbed. |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION embankments of steep highways and from clayey weak soils, it is recommended to use water-bitumen emulsions EBA-3 with a bitumen concentration of 50–55%; for gentle and sandy slopes – a microdispersed emulsion with a bitumen phase concentration of 40–50%.

It should be noted that according to the synergistic efficiency of mixing with various mineral fillers, the following classes of water-bitumen emulsions are distinguished: cationic – (EBC-1, EBC-2 and EBC-3) and polymer-modified emulsions (EBPC-1, EBPC-2, EBPC-3); anionic (EBA-1, EBA-2 and EBA-3). The grades of classes EBC-1 (EBPC-1), EBC-2 (EBPC-2), EBC-3 (EBPC-3) correspond to fast, medium and slow rates of disintegration when mixing road bitumen microdispersed emulsions with mineral complementary materials of different granulometric composition.

The complementary components in the composition of water-bitumen emulsion of EBC grades perform synergistic functions: improving complementary adhesion; achieving the required consistency; improving the technological characteristics of wear resistance, plasticity, frost resistance through supramolecular improvement of the road surface of the transport infrastructure with polymer nanocomposites [29]. Regardless of the rate of disintegration, the grades of water-bitumen emulsions have approximately the same concentration of bitumen, viscosity, extensibility, and softening temperature. Technological differences are manifested in the ability to complemen-tarily mix with particles of dense (gravel, crushed stone) and porous (expanded clay gravel) minerals: the EBC-3 water-bitumen emulsion grade is universal for mixing, the EBC-1 grade is not very suitable for this, and EBC-2 interacts well with a porous filler.

A complementary feature of using water-bitumen emulsion of EBC grades is that after application the constituent components are separated into two layers: water evaporates, and the bitumen binder hardens, forming a strong bitumen film on the synergistic surface of the mineral filler with the required performance characteristics [30]. The electrokinetic rate of controlled disintegration determines the optimal scope of use of the waterbitumen emulsion grade: EBC-1 is used for liquid-phase treatment of the surface layer of road protective coatings to improve adhesion; priming of asphalt concrete layers to improve adhesion between them; impregnation of crushed stone layers when laying road surfaces, as well as road potholes during repairs. The EBK-3 brand is used to create a protective layer of road surfaces; a complementary mixture with any mineral filler, and EBC-2 is used for the technological design of an optimal mixture with a porous mineral filler.

The mineral part of emulsion-mineral mixtures used for surface treatments is synergistically selected according to the technological principle and consists of crushed stone mixtures (with of 5–10 mm or 5–15 mm fraction), crushed (or a mixture of both natural 2–5 mm fraction and crushed) sand and mineral powder. The optimal amount of crushed stone and the technological ratio of natural and crushed sand in optimized emulsion-mineral mixtures is selected depending on the granulometric composition and the required coefficient of adhesion of the highway road surface. Complementary mineral powder is added to the emulsion-mineral mixture in an amount such that the content of particles smaller than 0.071 mm is within 5–15% range.

In addition to the above-mentioned mineral materials, man-made wastes can be synergistically used in cast emulsion-mineral mixtures: ash-slag, lime-containing materials, etc. [31–33]. Rational replacement of high-strength expensive stone materials with autochthonous soils reinforced with strengthening binders based on production waste in structural layers of pavements for category IV and V highways allows to reduce not only the cost of road construction by 30–50%, but also the manmade load on the surrounding ecological environment of the regions of the Russian Federation.

In Bashkortostan, the Remstroydormash plant (Ufa) produces water-bitumen emulsions EBRC-F (EBC-1), EBRC-Semulsiya (EBC-2), EBRC-S (EBC-3) for pothole repair, priming and recycling. Modern equipment allows using high-quality synergistic ingredients to produce up to 10 tons of bitumen microdispersed emulsions per hour. The Remstroydormash plant pours water-bitumen emulsion into 200-liter barrels to meet the needs of small businesses that repair roads, parking lots, and local areas in small areas where the use of a tar sprayer is economically impractical. It should be noted that small contractors, in order to reduce the cost of road construction, produce emulsions on their own sites, purchasing road bitumen at nearby oil refineries (in Ufa, in Salavat). In this case, of course, it is difficult to comply with the regulatory technological requirements for high-quality synergetic preparation of water-bitumen emulsions.

In the context of achieving technological sovereignty of the Russian Federation, it is recommended to use quaternary ammonium salts (for example, alkyltrimethylammonium chloride) in the amount of 0.2–0.5% of the water mass as import-substituting cationic emulsifiers. There are encouraging results of using bitumen microdispersed emulsions in the technology of strengthening weak soils of the roadway.

The most productive technology for synergetic strengthening of soil embankments and reconstruction of transport highways with bitumen microdispersed emulsions is the use of specialized machines – recyclers. More universal and technically and economically advantageous recyclers are road machines with one working element of the milling-rotor type, which are equipped with speed sensors and a metered system for feeding water-bitumen microdispersed emulsion (Fig. 5).

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 5. Operation of a road recycler: 1 – injection of bitumen emulsion; 2 – direction of movement; 3 – milling and mixing drum; 4 – destroyed asphalt concrete layer; 5 – road surface; 6 – recycled highway layer

Optimal surface treatment from crushed stone emulsion-mineral mixtures is recommended for usage to ensure the required coefficient of adhesion on emergency sections of highways, and for sand emulsion-mineral mixtures to be used on sections of transport highways with difficult traffic conditions and as a protective wearresistant layer. For synergetic usage of surface treatment of road surfaces of transport infrastructure, it is necessary to use emulsion-mineral mixtures of cast consistency, consisting of mineral materials (crushed stone, sand, mineral powder) and cationic water-bitumen microdispersed emulsion.

It should also be noted that road surfaces in the process of technological operation are under the influence of many multidirectional factors: soil-geological and hydrological conditions, terrain, weather-climatic and physical-mechanical, caused by excessive loads from heavy vehicles. Critical changes in the water-thermal regime of the road surface significantly affect the strength, synergistic durability of the road and lead to a decrease in the transport and operational characteristics of high-speed highways. At the nanolevel of asphalt concrete pavement of the order of 10–7–10–9 m, an accelerated process of rupture of chemical bonds between atoms of the bitumen binder occurs, which leads to a sharp deterioration in adhesive and cohesive characteristics [34, 35]. The currently known methods of technological monitoring of road surfaces have certain limits of applicability, therefore the synergistic approach complements and combines complementary factors.

CONCLUSION

Asphalt concrete road surface is a nonlinear system, and changes in its operational technological characteristics are accompanied by non-additive synergistic effects. Synergistic enhancement of the technological characteristics of road surfaces by adding bitumen microdispersed emulsions to the composition provides an alternative approach, in which bitumen is liquefied by dispersion in water; an optimal solution to the problems of intensive construction and reconstruction of Russian highways. Water-bitumen microdispersed emulsions with microdroplets of 2–4.5 µm in diameter are recommended for the popular technology of complementary strengthening of weak soils of the road surface of high-speed highways.

Список литературы Synergetic improvement of technological characteristics of highway road surfaces by bitumen microdispersed emulsions

- Karpenko F. V., Gureev A. A. Bitumen emulsions. Fundamentals of physical and chemical technology of production and application. Moscow: 1998.

- Abdullin A.I., Idrisov M.R. Bitumen emulsions in road construction. Bulletin of Kazan Technological University. 2011; 23: 124-128.

- Evdokimova N.G., Luneva N.N., Egorova N.A., Makhmutova A.R., Bayguzina Yu.A., Imangulova E.A. On the choice of technology for the production of polymer-bitumen binders as innovative nanobinders for the construction of asphalt concrete pavements // Nanotechnology in Construction. 2018: 10(5): 20-37. https://doi.org/10.15828/2075-8545-2018-10-5-20-37

- Zemlyakov A.Yu., Lobankov E.V., Romadenkina S.B. Development of bitumen emulsion compositions for road construction. Bashkir Chemical Journal. 2019:26.3:52-57. https://doi.org/10.17122/bcj-2019-3-52-57

- Budnik V.A., Evdokimova N.G., Pushkareva T.V. Processes of bitumen emulsification in water and methods of their improvement. Electronic scientific journal Oil and Gas Business. 2008; 1: 32.

- Opasenko O.N., Krutko N.P. Properties and application of bitumen dispersions and bitumen-emulsion materials. – Minsk: Belaruskaya Navuka, 2014. – 270 p.

- Tyukilina P.M., Gureev A.A., Tyshchenko V.A. Production of oil road binders. Moscow: Nedra, 2021. 303 p.

- Abdullin A.I., Dyakonov G.S., Idrisov M.R., Abdullin I.A., Gatiyatullin M.Kh. Bitumen emulsion for road surfaces. RF Patent 2505570. Publ. 01/27/2014.

- Polezhaeva N.I. Physicochemistry of oil dispersed systems. Oil dispersed structures. Krasnoyarsk: Siberian State University named after M.F. Reshetnev; 2022.

- Glazachev A.O., Ivanova O.V., Sinitsyn D.A., Akhmetshin R.M. Complementary improvement of technological characteristics of asphalt concrete road pavements by macromolecular nanocomposites. Nanotechnology in Construction. 2023; 15(5): 453–464. https://doi.org/10.15828/2075-8545-2023-15-5-453-464

- Khalikov R.M., Ivanova O.V., Pavlov S.Yu., Glazachev A.O. Innovative trends in the efficient preparation of bitumen emulsions in road construction. Trends in the development of science and education. 2024; 112-6: 139-142.

- Gingras J.-P., Tanguy P.A., Mariotti S., Chaverot, P. Effect of process parameters on bitumen emulsions. Chemical Engineering and Processing: Process Intensification. 2005; 44(9): 979-986. https://doi.org/10.1016/j.cep.2005.01.003

- Evdokimova N.G., Egorova N.A., Sultanova D.P., Kunakkulova E.M., Serezhkina N.G. Formation of sol-gel nanostructure of road bitumen by the method of selection of group chemical composition. Nanotechnology in Construction. 2019: 11(5): 512-525. https://doi.org/10.15828/2075-8545-2019-11-5-512-525

- Xu L., Hou X., Li X., Xiao F. Impact of constituent migration on colloid structure and rheological characteristics of emulsified asphalt with self-crosslinking modifiers. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2021; 619: 126530. https://doi.org/10.1016/j.colsurfa.2021.126530

- Pudovkin A.N., Khalikov R.M., Bulatov B.G., Sokolova V.V., Nedoseko I.V. Digital control of parameters in the automated control system for the production of asphalt concrete mixture. Electrical and information complexes and systems. 2021: 17; 3-4: 103-113. https://doi.org/10.17122/1999-5458-2021-17-3-4-103-113

- Ayar P. Effects of additives on the mechanical performance in recycled mixtures with bitumen emulsion: An overview. Construction and Building Materials. 2018; 178:551-561. https://doi.org/10.1016/j.conbuildmat.2018.05.174

- Ignatiev A.A. Asphalt concrete additives. Literature review. Izvestiya KGASU. 2023; 1 (63): 14-30. https://doi.org/ 10.52409/20731523_2023_1_14

- Poluektova V.A., Shapovalov N.A., Cherkashina N.I., Kozhanova E.P., Starchenko S.A. Regulation of the aggregate stability of binary polymer-mineral dispersions. Nanotechnology in Construction. 2023; 15(3): 258-266. https://doi.org/10.15828/2075-8545-2023-15-3-258-266. – EDN: EHKULB.

- Usov B.A., Gorbunova T.N. Properties and modification of bitumen binders. System technologies. 2017; 1 (22): 72-88.

- Querol N., Barreneche C., Cabeza LF Storage stability of bimodal emulsions vs. monomodal emulsions. Applied Sciences. 2017; 7(12): 1267. https://doi.org/10.3390/app7121267

- Kirillov A.M., Zavyalov M.A. Synergetic approach to modeling physical wear of engineering systems. Bulletin of MGSU. 2015; 5: 93-102.

- Kiryukhin G.N. Thermal fluctuation and fractal model of durability of asphalt concrete. Roads and bridges. 2014; 1 (31): 247-268.

- Khalikov R.M., Pavlov S.Yu., Glazachev A.O. Qualitative improvement of technological characteristics of asphalt concrete road pavements with complementary innovative additives. Trends in the Development of Science and Education. 2023; 103-7: 119-122. https://doi.org/10.18411/trnio-11-2023-425.

- Glazachev A.O., Pavlov S.Yu., Ivanova O.V., Khalikov R.M. Synergetic technologies for designing wear-resistant layers of asphalt concrete pavements of highways. Trends in the Development of Science and Education. 2024; 106-9: 22-25. https://doi.org/10.18411/trnio-02-2024-481.

- Bikmukhametova G.K., Emelyanycheva E.A., Abdullin A.I., Sibgatullina R.I. Bituminous materials in road construction. Application of water-bitumen emulsions. Bulletin of the Technological University. 2015;18(20): 128-131.

- Korotkov A.V., Kotlyarsky E.V., Gridchin A.M. Requirements for bitumen emulsions for the preparation of cast emulsion-mineral mixtures. Bulletin of BSTU named after V.G. Shukhov. 2010; 1: 10-12.

- Murafa A.V., Makarov D.B., Nuriev M.A., Khozin V.G. Nanomodified bitumen emulsions for construction purposes. Izvestiya KSUACE. 2010; 2(14):245-249.

- Evdokimova N.G., Luneva N.N., Egorova N.A., Makhmutova A.R., Bayguzina Yu.A., Imangulova E.A. On the choice of technology for the production of polymer-bitumen binders as innovative nanobinders for the construction of asphalt concrete pavements. Nanotechnology in Construction. 2018; 10(5): 20–37. https://doi.org/10.15828/2075-8545-2018-10-5-20-37

- Khalikov R.M., Ivanova O.V., Glazachev A.O. Supramolecular improvement of technological parameters of asphalt concrete road surfaces by polymer nanocomposites. Actual problems of technical, natural and humanitarian sciences: Proc. of the International. Conf. Ufa: USPTU; 2022:432-436.

- Lyshchik P.A., Bavbel E.I., Naumenko A.I., Tsvirko M.V. Strengthening of road soils with bitumen emulsion. Proceedings of BSTU. Series 1: Forestry, nature management and processing of renewable resources. 2018; 2 (210): 168-173.

- Gritsuk A.I., Tumanova S.A., Chargazia T.Z., Borodai D.I., Stukalov A.A. Efficiency of using ash and slag in road construction. Economics of construction and urban management. 2017; 13(1): 81-91.

- Khalikov RM, Pavlov SY, Glazachev A. O., Akhmetshin RM Supramolecular mechanism for strengthening clay foundations of highways with complementary nanoadditives. Trends development sciences and education. 2024; 107-9: 83-85.

- Stepanov S.V., Petrovpavlovskikh O.K., Kopylov M.A. Use of metallurgical industry waste in transport construction. Highways and transport infrastructure. 2024; 2 (6): 29-36.

- Kirillov A.M., Zavyalov M.A. Interpretation of the properties of asphalt concrete in road surfaces. Construction materials. 2015; 4: 87-92.

- Smirnov V.A., Korolev E.V., Danilov A.M., Kruglova A.N. Fractal analysis of the microstructure of nanomodified composite. Nanotechnology in construction. 2011; 3(5):78-86.