Technological development of the Neolithic pottery at Goytepe (West Azerbaijan)

Автор: Alakbarov V.A.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: Paleoenvironment, the stone age

Статья в выпуске: 3 т.46, 2018 года.

Бесплатный доступ

Короткий адрес: https://sciup.org/145145378

IDR: 145145378 | DOI: 10.17746/1563-0110.2018.46.3.022-031

Текст обзорной статьи Technological development of the Neolithic pottery at Goytepe (West Azerbaijan)

In the Southern Caucasus, extensive research has already been carried out (in the mid-1960s to mid-1980s during the Soviet Period, and after the 2000s with new methods and approaches) at settlement mounds in both Azerbaijan and Georgia. Research into the Neolithic of the Caucasus began with the excavations of Kültepe I in 1951, near the city of Nakhchivan (Abibullaev, 1963). In Azerbaijan and Georgia, a group of settlement mounds along the Kura River is representative of an agricultural economy and way of life during the 6th millennium BC. When we take a look at the archaeological context of the region, early Neolithic sites include Shomutepe, Toyrepete, Jinnitepe, Huseyngulutepe (Narimanov, 1987), Garagalartepesi (Narimanov, Mahmudov, 1971), Göytepe (Guliyev, Huseynov, Almammadov et al., 2008; Guliyev, Nishiyaki, Huseinov et al., 2011; Guliyev, Nishiaki, 2014; Guliyev et al., 2015), Haci Elamxanlitepe (Nishiaki et al., 2015b), Menteshtepe (Lyonnet, 2017), and Hasanlu I (Museibli, Agalarzadeh, Akhundova, 2012) in Azerbaijan; and Shulaveris-Gora (Kiguradze, 1986), Imiris-Gora (Kavtaradze, 1981), Chramis Didi-Gora (Dzhavakhishvili, Dzhaparidze, 1975), and Aruchlo (Hansen, Mirtskhulava, 2012) in Georgia. Also, Kamiltepe (Helwing, Aliyev, 2012), in Mil Plain; Ilanlitepe (Narimanov, 1969, 1987), Chalagantepe (Narimanov, 1987) in Karabakh steppe; and Aknashen (Badalyan et al., 2007) in the Ararat valley can be added to this list.

Each of these sites has valuable information about the beginning of agricultural ways of life in the Southern Caucasus. In this respect, Göytepe (40°58′ 11.84′′ N, 45°42′17.81′′ E, ca 430 m a.s.l.) (Kadowaki et al., 2015: 410) also has a very important position in Neolithic cultures. The settlement is situated in the middle stream of the Kura River (western Azerbaijan) and is one of the most important representatives of the ancient agricultural culture, having all the attributes of the Neolithic period.

The site represents one of the largest mounds known in the region, measuring approximately 145 m in diameter (Guliyev et al., 2008: 17; 2010: 45; Guliyev, Nishiaki, 2014: 4; Nishiaki, Guliyev, Kadowaki, 2015a: 283). The excavations, over an area of 1000 m2, revealed 11 m of stratified deposits corresponding to 14 archaeological levels, all of which are assignable to the Shulaveri-Shomu culture, without any breaks in occupation. The results of radiocarbon dating at the main trench of the site (Tokyo University) suggest that Göytepe was occupied during a period from the early to middle 6th millennium BC: more specifically ca 5650 to 5460 BC (Guliyev, 2010; Nishiyaki et al., 2015a: 289; in press; Kadowaki et al., 2017).

This study examines pottery assemblages from the 4th building level of square 2A (2A1-2A2), which is dated to ca 5505 to 5500 BC (Nishiaki et al., in press). First, the paper presents the general characteristics of the pottery over all the 14 building levels at Göytepe. Then, the pottery assemblages of the 4th building level are described according to the several groups defined by their decorative and technological attributes.

General characteristics of the pottery from 14 building levels at Göytepe

All of the Neolithic levels at Göytepe yielded ceramics (Guliyev, Nishiaki, 2012, 2014), but very few sherds were recovered in the earliest levels. All the ceramics are handmade (Guliyev, Gusejnov,Almamedov, 2009; Guliyev et al., 2010), apparently from locally available materials. The petrographic analysis in the future will test this idea. The Göytepe pottery assemblage can be classified according to tempering materials.

Technical features

The earliest pottery assemblages are characterized by mineral-tempered pottery, which slightly diminished in the upper levels. Plant-tempered assemblages are systematically characterized by mixed fine and coarse straw. The most common mineral tempering consists of sand and basalt, while mica, calcite, and quartz are added more rarely. As to the plant-tempered fabrics, they often included minerals such as sand, sometimes basalt, and even obsidian. “Chamotte”, or grog, has also been observed. Only seven fragments are painted with monochrome bitumen around the necks of the vessels. As to applied or relief decorations, these mostly consist of single horizontal round, oval or oblong knobs, or circular or semi-circular patterns. In addition, U- or V-shaped reliefs, zigzag or wavy lines, and anthropomorphic relief depictions are also present (Alakbarov, 2015a: 167; 2015b: 215).

Six groups have been identified in previous studies on the basis of temper, surface treatments, and the presence or absence of decorations (Alakbarov, 2016a: 1695; Guliyev, Alakbarov, 2017: 11): group 1 – slipped, polished, and painted ware; group 2 – plain ware; group 3 – wet-wiped ware; group 4 – applied decoration ware; group 5 – bitumen-painted and bitumen-covered ware; and group 6 – impressed ware. These groups share all the characteristic features of the Neolithic pottery in the region.

Morphology

The most common shape attested at Göytepe is that of hole-mouthed jars; while deep and shallow bowls, basins, and trays occur in smaller numbers. Rim sherds have four basic profiles, such as thinned, rounded, flattened, and tapered. Almost half of the rim sherds were thinned. Tapered rims belonging to the 4th ware group are rare. All the bases are usually flattened, occasionally displaying traces of woven or mat impressions (about 150 of 12,000 sherds), especially in hole-mouthed jars. Generally, the bases are circular in shape, but some are oval. In holemouthed jars, the lower bodies were often curved inward near the bases, thus forming heel-like projections, called “elevated”, for thickening.

As regards prehension, two types of “devices” have been identified on top of hole-mouthed jars. First, the vast majority of these handles are made starting at the rim, which curves inwards with an attached band 3 or 5 cm wide. These seems to have been designed expressly for grasping and carrying the vessels. The other type of prehension is represented by horizontal lugs, oval in shape, that are applied on the exterior surfaces of the jars. As only sherds of this type of vessel have been found, we assume that two opposite lugs were placed on the lower part of the vessels (Alakbarov, 2016b: 60).

Characteristics of the pottery groups in the 4th building level

Earlier, the pottery assemblages of Göytepe were studied according to the 14 building levels. Some of the results have been published (Nishiaki et al., 2015b), while the others are in press. The reason for choosing the limited pottery assemblages from the 4th level is that these are different in terms of many features from the pottery of the same level in a different square, which was previously obtained. Thus, the decorations of several fragments in the 4th level are completely different from those previously discovered at the same level. Also, bituminous ceramics associated with the 5th level have not been found at this level of other squares. The corpus of the pottery fragments that are here analyzed (443 spec.) is composed of one complete profile, rim sherds (70 spec.), body sherds (302 spec.), and fragments of bases (70 spec.). 74 % of the total fragments are mineral-tempered; 21.5 % are vegetable-tempered, and 4.5 % show organic and mineral temper.

Group 1: slipped, polished, and painted ware. The samples comprise 20.5 % of the assemblage. The paste is both mineral- and chaff-tempered. However, the most of the pottery by far features a straw- or vegetable-tempered paste, which is especially common for open shaped vessels. The frequency of small to medium vegetable temper in horizons 1–14 varies from low to heavy, and it is rarely mixed with mineral inclusions.

Minerals include quartz, sand, and basalt. Though sand is densely distributed, quartz and basalt inclusions are seldom present, and occur presumably naturally mixed to the clay. One hole-mouthed rim shows a distinctive type of paste. Occasionally, obsidian temper is found in group 1, together with small-sized, medium-distributed sand inclusions. This group is generally of better quality than other groups. Its appearance is of medium to fine quality.

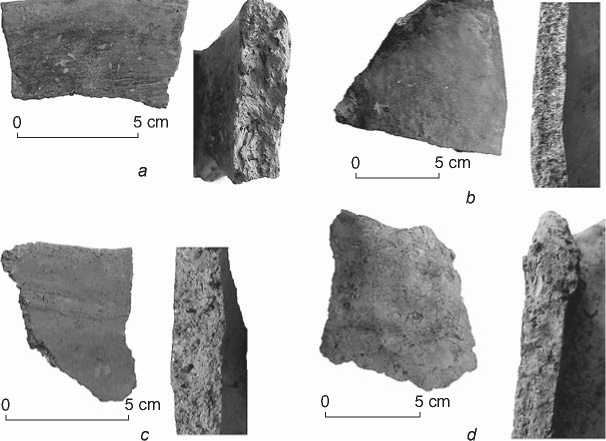

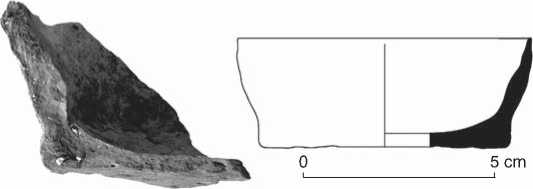

Rims are always simple, sometimes made by a small coil added to the last band. Almost all of the pottery was made using band techniques, with bands 2.0–2.5 cm high, which are clearly visible by observing the junctions (Fig. 1, c )

All the samples show smoothed or burnished surfaces. In some sherds, both the internal and external surfaces were slipped in a red color and then burnished (Fig. 1, a). Coating with slip on both exterior and interior surface may have been used for reinforcement or waterproofing, and elaborately burnishing (polishing) used to give an esthetic appearance to the vessels (Alakbarov, 2015a). While covering by slipping (watery clay solution) in red and then burnishing is more common with the fine quality for open shaped bowls, trays, and basins at Göytepe, in some cases these techniques were applied coarsely for hole-mouthed jars that occurred at this level with stroke marks (Fig. 1, b). Considering the fact that many spatulas have been found at this level, we can assume that, after drying, the ceramics were polished or smoothed with spatulas.

From a total of 92 sherds, 22 sherds of hole-mouthed vessels appear coated with a thin wash paint or completely painted (Fig. 1, c ). The paint, or so-called “washing”, is generally colored with a red pigment, presumably obtained from red ocher (Fig. 2). Washing is only visible on closed vessels on the exterior surface or on both the exterior and interior surfaces. The most of the painted pottery by far is inorganically tempered, e.g. with basalt and sand inclusions.

While pottery assemblages are red, reddish-brown, or light red in color, their cross-section colors vary from buff-gray or buff to black-gray. Traces of mottling are also noticeable owing to firing at varying temperatures. For instance, in few sherds, the slip-color was red; but because of irregular firing, it turned to brownish. Generally, the firing is of relatively fair quality. These assemblages present rather thinner walls and finer paste than those in other groups. Especially, thin walls with an abundant quantity of chaff-temper are common. The sherds show some range of wall thickness between 0.4–1.2 cm. The

Fig. 1. Pottery of group 1.

a – red slipped and burnished pottery; b – rim fragment of coarsely burnished hole-mouthed jar; c – thin-wash-painted pottery; d – in-turned rim for grasping. Hereinafter photographs and drawings by the author.

0 3 cm

Fig. 2. Red ocher for painting.

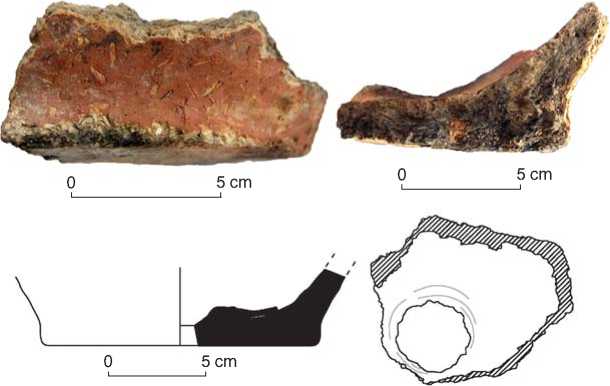

Fig. 3. Washed (completely red-painted) base fragment with “odd” inside.

mouth dimensions of the vessels are from 13 to 36 cm, a base of a vessel is ca 17 cm in diameter. The rims of most vegetable-tempered (perhaps with oval seeds) sherds are partially turned-in at the mouth, perhaps better to grasp the vessel with one hand (see Fig. 1, d ).

Transitions to the base are often elevated, especially in closed vessels, and non-elevated (sharp) bases are encountered in open shaped ones. The slab technique is defined especially on the bottom parts.

One base sherd characterized by its temper made of small seeds is unusual within the Göytepe pottery assemblages. In the middle of the base on the inside, there is a ledge with broken top, and this seems to have been fused with the clay before firing (Fig. 3). Probably, it accidentally fell during the firing, or it is the remnant of the clay. It does not seem to be decorated deliberately.

Group 2: plain ware. Ceramic sherds from walls, rims, and bases are noticeable in this group, which forms 62 % of the bulk. The paste is mainly tempered with small, medium to coarse inorganic material. A large number of the ceramics are tempered with grit inclusions. The coarse-grained temper consists of minerals such as obsidian, mica, basalt, sand, and (in only a few cases) chamotte. Sand is dense with prevailing basalt, and the sherds with this fabric form a majority. Vegetable temper also occurs, and mixed mineral and vegetable temper occur in a few pieces. Mostly, the vegetable temper leaves both large and short imprints on the surfaces.

The pottery tends to be dark gray, brown, buff-gray, or buff. Cores are usually buff, gray, buff-gray, or blackgray. Mottled parts in a few fragments are the result of color change during firing. The great majority of the ceramics were fired well. Their appearance is of coarse to medium quality.

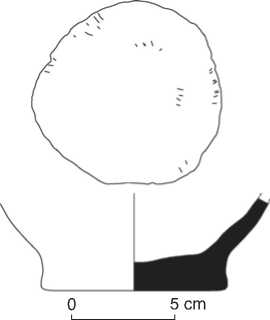

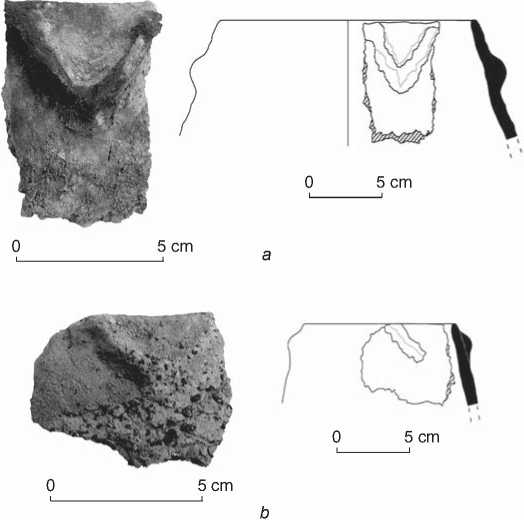

According to the diagnostic fragments, the shapes consist of hole-mouthed jars and basins. Rim diameters vary from 9 to 23 cm in closed vessels, but from 29 to 32 cm in open vessels. Base diameters are between 8 and 20 cm, and the majority are disk-shaped (Fig. 4). Generally, a matting impression is apparent in disk-shaped bases (Fig. 5); however, one example demonstrates mat impression with the wall opening sharply at the base. Some of the bases seem to be shaped on an irregular surface such as the ground etc., and are not further refined. The bases were manufactured with slab technique. The walls are rather thin, between 0.6 and 1.1 cm, and base is 0.4–1.3 cm wide.

In hole-mouthed vessels, breaks often occur a few cm above the base (see Fig. 4). This may indicate the use of molds to shape the lower parts of the vessels. So, it is likely that initially bases were shaped, and then the vessels were further modeled by adding slabs. The vast majority of the ceramics were mostly made in bands with coils attached to the rim, the joints of which are often visible in the breaks. The joints between two bands are often weak, and thus breakages frequently emerge at these points.

Group 3: wet-wiped ware. This group represents 14 % of the analyzed material. In many cases, the wiping appears on the outer and inner surfaces of sherds. The traces of wet-wiping are clearly visible on one surface or both. Most notably, one surface or both the inner and outer surfaces of the vessels appear to have been carefully smoothed horizontally or vertically by using some kind of leather while the vessel still was wet, the effects of this being still visible to the naked eye (Fig. 6). In contrast to the other groups, the paste of ceramics of group 3 is generally characterized only by grit-temper such as small-and medium-sized basalt and sand particles. One sherd is made of well-levigated fine clay without temper. The appearance is of medium to coarse quality.

The shapes attested are hole-mouthed jars, trays, and small bowls. Base pieces are appointed elevated according

Fig. 4. Elevated base of a hole-mouthed jar.

to obtained samples. One rim-to-base fragment was hand-molded, apparently made by modeling a single lump of clay (Fig. 7).

Pots were made in small or large bands 2.5–5.5 cm wide, the joints of which are easily visible at fractures. Base sherds show a thick layer of clay applied over the bottom surface, which denotes slab technique used for molding.

The surface color ranges from buff, buff-gray, black-gray, brown to gray, probably depending on firing conditions, and cross-sections vary from buff, buff-gray to gray. Firing is accurate. Occasionally, incompletely oxidized sherds also show mottled surfaces. Often heavy or slight traces of soot are visible on both inner and outer surfaces of the walls or on the outside and inside of the base pieces, which suggests their use as cooking vessels.

Group 4: applied decoration ware. Ceramics with applied decorations occur almost in all levels at Göytepe. In this particular level, applied decorations account for 3 % of the assemblage. The clay is more compact than in other groups. Judging by the temper visible in the section, we can say that the majority of the sherds are mineral-tempered, while only a small number of sherds are vegetable-tempered.

0 5 cm

'---------------------------' b

Fig. 5. External surface of a sharply opening base with matting impression, and its profile ( a ), external surface of an elevated base with matting impression ( b ).

The majority of the sherds are heavily tempered with basalt and sand. Obsidian inclusions are also attested systematically in small and larger sizes. Joints between coils and bands are clearly detectable almost in all sherds. The coil joint is usually ca 1 cm wide in the rim part and ca 2–5 cm wide for the body.

5 cm

5 cm

b

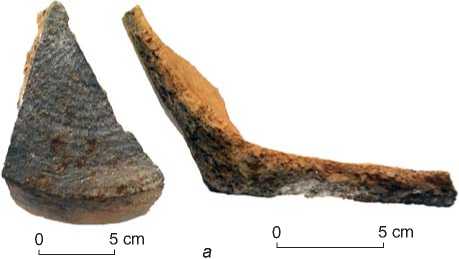

Fig. 6. Wet-smoothed or wiped fragments.

Some pieces are scrambled and softened because they endured the heat of multiple cookings, and are reminiscent of the result of uneven firing. However, in fact, they were fired hard, and show many cracks, possibly because of intense firing. This pottery group is mostly darker in color on the surface of sherds (gray, buff-gray, dark-gray, brown), often with buff or gray-buff core. The inner and outer walls are covered by blackish or dark brown soot. Almost all the sherds have blackish soot on both interior and exterior surfaces of the walls, indicating that they were used mainly as cooking pots.

Appearance is medium to coarse quality. Holemouthed jars are common in this group. The rim’s diameter varies between 12 and 30 cm.

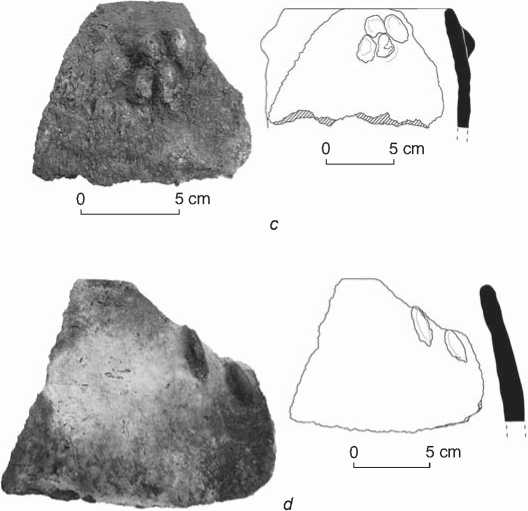

а

The applied decorative motifs are usually found on the exterior surfaces of the hole-mouthed jars. The applied decorations consist of V-shaped motifs (Fig. 8, a), oblique lines (Fig. 8, b), or of oval or circular pellets, applied under the rims. The number of pellets is between one and four. The ends of oval ones are thinned as if they were triangular or rounded. One sherd has unusual features. Its rim was inverted inside (probably for grasping), and the applied pellet was made for ease of grasping, not for decoration (Fig. 9). Exceptionally, one sherd presents oval applied decorations horizontally arranged 0.5 cm below the rim, 4.5 cm apart. Three sherds are totally new according to the positions of decorations:

-

1) four clay pellets, resembling a bunch of grapes, are applied together at a distance of 1.8 cm under the rim (see Fig. 8, c );

-

2) two oval decorations, situated vertically one below the other, resembling granular hanging from the cluster, are fixed 2 cm below the rim part (see Fig. 8, d );

-

3) unknown motif with an applied oblique line hanging from the rim (see Fig. 8, b ).

In many cases, marks indicating thumb or fingerprints can be seen around the applied decorations, left during the modeling process.

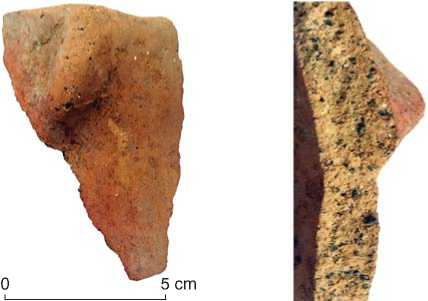

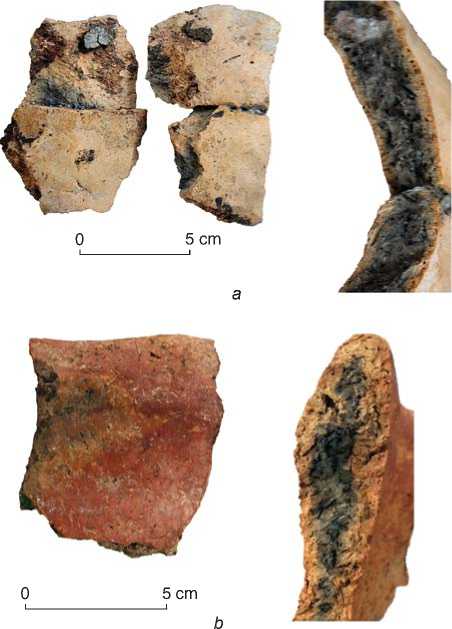

Group 5: bitumen painted and bitumen covered ware. This ceramic group is not abundant and comprises 0.5 % of the assemblage. The sherds feature remains of bitumen lumps on the outer surfaces, which might have been used as a glue to fill cracked areas for reusing of vessel or for waterproofing (Fig. 10). Generally, at Göytepe, bitumen was used for many purposes, such as restoring and painting of vessels, as bitumen sources occur naturally near the site.

Only two small rim- and wall-fragments of thin-walled vessels of this type were found here. One piece is tempered with inorganic and organic particles of plentiful small cut vegetable materials and a few large basalt grains, while another sherd is tempered with small basalt grains. The appearance is medium to fine.

The surfaces are often red or buff, but the section is black-gray because of irregular oxidation. One sherd is slightly polished outside and inside. Its rim was covered with red wash.

Comparison

Though the pottery assemblages are not large at this level, we can compare them with those at contemporaneous sites in the Southern Caucasus. As applied decorations are typical of the grit-tempered ware of the Kura basin of the Shulaveri-Shomu culture, comparisons with group 4 can be drawn with the applied rounded and oval knobs under the hole-mouthed vessels’ rims on exterior surfaces from Shomutepe, which are characteristic of grit-tempered ceramics (Narimanov 1987), Hasansu I (Museibli, Agalarzadeh, Akhundova,

Fig. 8. Applied decorated pottery pieces.

0 5 cm

Fig. 7. Hand-molded rim-to-base fragment.

Fig. 9. Rim inverted inside with applied pellet.

Fig. 10. Pottery-samples with bitumen.

2012), Shulaveris-Gora (Kiguradze, 2001), Imiris-Gora and Chramis Didi-Gora (Kiguradze, 1986), Aruchlo (Bastert-Lamprichs, 2012, 2017), and Aknashen (Chataigner, Badalyan, Arimura, 2014).

In addition, vegetable-tempered partly closed vessels, which seem to have been designed thus intentionally for carrying, are noticed at the Neolithic settlements in the middle Kura valley: Shomutepe (6th millennium BC) (Narimanov, 1986: 118; Akhundov, 2012: Pl. 138, 1 ; 177; 192, 1 ; 206, 7 ; 207), Gargalartepesi (Narimanov,

Mahmudov, 1971: 14; Narimanov, 1986: 27), Menteshtepe (ca 5800–5650 BC) (Lyonnet, 2017: 141–142); at the Neolithic sites of Karabakh steppe: Ilanlitepe (Narimanov, 1969: 397; 1987: 27, 49; Narimanov, Mahmudov, 1972: 14), Chalagantepe (Narimanov, 1986: 8); in Mil Plain sites, dated around MPS 4 (Helwing, Aliyev, 2017: Fig. 39), MPS 5 (D’Anna, 2017: Fig. 12, below), MPS 18 (Ricci, 2012: Fig. 178), MPS 103 (D’Anna, 2017: Fig. 12, above).

Also, several attributes, such as heel-shaped profiles of flat bases, the shapes of the most vessels, matting impressions on the exterior surfaces of the bases, manufacturing and surface treatments, are rather similar to those of the above-mentioned sites. Moreover, manufacturing processes, such as using bands, coils to build up the body parts, slab technique for making bottom parts, including red slipping, followed by polishing surface treatment in vegetable-tempered vessels, and decorating with applied motifs in grit-tempered vessels, are also similar to those found on Neolithic pottery at Menteshtepe, situated a few kilometers distant from Göytepe (Lyonnet et al., 2016; Lyonnet, 2017). Also, red slip and burnishing are of frequent occurrence at Neolithic sites in the Mil Plain (MPS 4, 5, 23, and 103) (Helwing, Aliyev, 2017: 41; D’Anna, 2017: 48, fig. 10).

Though basket impressions are not common in the Mil Plain, these are occasionally attested at both Kamiltepe and MPS 4 (D’Anna, 2017: 48). The bases of two of pithoi also bear woven impressions at MPS 103 (Ibid.: Fig. 11), which bear the same resemblances to Göytepe pottery. Common features, functioning as surface treatments and manufacturing of Mil Plain Neolithic pottery (D’Anna, 2012), are also similar to those found on Neolithic pottery at Göytepe. The resemblances suggest that Göytepe inhabitants had close relationships with the abovementioned contemporaneous settlements.

Conclusions

Göytepe is one of the rare settlements that completely reflect the development process of the Early Neolithic pottery. Therefore the settlement is important for understanding this period in the Southern Caucasus. Göytepe pottery groups in the 4th level are testified by mineral and plant-tempered inclusions and are more or less varied in shapes, but manufacturing technique is almost uniform. As compared to the ceramics from the upper levels (ca 5500 to 5450 BC) found in previous years, pottery assemblages are more inorganic-tempered in the 4th building layer. Most of the pottery was formed by band technique to build the wall parts, and by slab technology to mold base parts. Small vessels were hand-molded without the use of band or slab.

Pottery appears to have been burnt in open fires, in an oxidizing atmosphere, and the firing was often unsteady. The lips (rims) are simple; only rounded and thinned rims have been recorded in this level.

Judging by wear-traces, such as soot and non-soot inside and outside, and shape analysis, pottery samples are likely to represent table (for eating and drinking in small bowls) and common wares (for storage in closed vessels and sharing practices in opened-shaped vessels) in group 1. Common and kitchen wares (cooking jars) are characteristic of groups 2 and 3. However, a great amount of pottery was used as kitchen ware, which is completely represented by hole-mouthed jars. Only one fragment shows different features without any traces of soot. Owing to lack of sherds, the function of group 5 is difficult to determine.

Pottery bearing basket imprints on the base is very common at Göytepe, which is characteristic of the Shulaveri-Shomu culture. However, basket impressions do not occur at the earlier Neolithic site of Mentesh, dated ca 5800–5650 BC (Lyonnet, 2017: 141). This is probably because this site belongs to an early stage of the Shulaveri-Shomu culture. The practice of putting matting under the vessels had probably not yet been mastered at the beginning of the pottery production. Thus, this is not encountered at this stage. It is recorded in the publications about Mentesh that group 1, with its peculiar temper and shape, does not correspond to those most often described for the Shulaveri-Shomu assemblage. But, during the investigations in the middle of 20th century, the researchers assigned chaff and seed inclusions to “vegetable-tempered” type. Seed inclusions are visible in group 1 from the 4th level of Göytepe, which is a few kilometers away from Mentesh. Also, some closed vessels described above are encountered at Göytepe and at Shomutepe (Akhundov, 2012: 142, pl. 138, 1 ; 177; 192, 1 ; 206, 7 ; 207).

Thus, the results of the study have shown some specific attributes of pottery from the 4th building level at Göytepe. Almost all the ceramics from the Neolithic settlements of the Kura basin share similar features and belong to the Shulaveri-Shomu culture. When the Shomutepe culture emerged, it had a local, uniform character, and subsequently had a close relationship with the southeastern cultures of the Karabakh steppe.

Acknowledgments

The author would like to give his great thanks to Dr. Farhad Guliyev, the head of the Göytepe Archaeological Expedition, for his kind support and for making better conditions for my work with the Göytepe pottery at the site and in the expedition house. Also, the author expresses his gratitude to Professor Mehmet Özdogan for his advice at Istanbul University as to clearing some obscure matters about unknown shapes. Thanks also go to Dr. Giulio Palumbi and Dr. Seiji Kadowaki for editing this article, and for advice.