Technologies of small innovative enterprises as a result of intellectual activity: application of nanotechnologies in the liquidation of orphan wells

Автор: Trifanichev V.M., Tudvachev A.V., Guzov Ya.Yu., Guzov Yu.N., Polyakov N.A.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 3 Vol.16, 2024 года.

Бесплатный доступ

Introduction. Small innovative enterprises are able to solve the problems of technological support of the construction sector. A special place is occupied by enterprises created on the basis of the results of intellectual activity (RIA) of higher educational institutions. The activities of small companies created with the participation of universities have a number of advantages. The scientific and educational environment creates additional opportunities for small businesses in conducting research and development, as well as opens up access to human resources. An example of the commercialization of RIA is the technological developments based on nanomaterial of St Petersburg University enterprises in solving the problem of abandonment of orphan wells, which contribute to the pollution of groundwater. Methods and materials. Abandoned wells are abandoned according to “standard designs” that provide for the abandonment of only the wellbore limited by the inner diameter of the casing pipes, and do not contain technical solutions for the elimination of behind-the-casing flows. Results. An ownerless well, after its abandonment according to the “standard project”, continues to contaminate groundwater, but on a permanent basis, since repeated abandonment of such wells is practically impossible. Each such “abandoned” well is an officially created channel for groundwater contamination in the long term. Discussion. The article contains an analysis of the existing technology of abandonment of wells, including ownerless ones, as well as the justification of the futility of its use to eliminate sources of groundwater pollution. An alternative solution based on the use of modern nanomaterials is proposed. Conclusion. Examples of successful application of the proposed technology with the use of cemented nanomaterials for the liquidation of emergency wells in the North-West region are given. Based on the study, conclusions and recommendations are made.

Small innovative enterprises, nanomaterials, orphan wells, cement stone leaching, behind-the-casing flows, sources of groundwater pollution, reservoir pressure, standard projects, «Plug-back mixture LP»

Короткий адрес: https://sciup.org/142240872

IDR: 142240872 | DOI: 10.15828/2075-8545-2024-16-3-267-275

Текст научной статьи Technologies of small innovative enterprises as a result of intellectual activity: application of nanotechnologies in the liquidation of orphan wells

Original article

Introduction. Small innovative enterprises are able to solve the problems of technological support of the construction sector. A special place is occupied by enterprises created on the basis of the results of intellectual activity (RIA) of higher educational institutions. The activities of small companies created with the participation of universities have a number of advantages. The scientific and educational environment creates additional opportunities for small businesses in conducting research and development, as well as opens up access to human resources. An example of the commercialization of RIA is the technological developments based on nanomaterial of St Petersburg University enterprises in solving the problem of abandonment of orphan wells, which contribute to the pollution of groundwater. Methods and materials. Abandoned wells are abandoned according to “standard designs” that provide for the abandonment of only the wellbore limited by the inner diameter of the casing pipes, and do not contain technical solutions for the elimination of behind-the-casing flows. Results. An ownerless well, after its abandonment according to the “standard project”, continues to contaminate groundwater, but on a permanent basis, since repeated abandonment of such wells is practically impossible. Each such “abandoned” well is an officially created channel for groundwater contamination in the long term. Discussion. The article contains an analysis of the existing technology of abandonment of wells, including ownerless ones, as well as the justification of the futility of its use to eliminate sources of groundwater pollution. An alternative solution based on the use of modern nanomaterials is proposed. Conclusion. Examples of successful application of the proposed technology with the use of cemented nanomaterials for the liquidation of emergency wells in the North-West region are given. Based on the study, conclusions and recommendations are made.

INTRODUCTION competitive environment presupposes the acti-ion of enterprises in the scientific and technical

sphere, where the key role is assigned to small innovative enterprises (SMEs). A special place is occupied by enterprises created on the basis of the results of intellectual activity (RIA) of higher educational institutions. The activities of small companies created with the participation of universities have a number of advantages. The scientific and educational environment creates additional op- portunities for small businesses in conducting research and development, as well as provides access to human resources (training and advanced training on the basis of the university). Universities actively use the resource base in priority scientific areas not only to conduct fundamental research, but also to stimulate the technological processes of SIE [1–4]. For example, the Sparrow Hills Innovation and Technology Centre is being developed at Moscow State University, and the leading science park with modern unique equipment is being developed at St. Petersburg State University.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

An example of the successful implementation of technological innovations in the construction sector is the activities of such enterprises as the Geological Centre of St. Petersburg State University and the Water Centre of St. Petersburg State University. The direction of research and commercialization of intellectual property lies in the plane of technological support for projects in petroleum geology, ecology, modeling of groundwater reserves, elimination of the consequences of emergencies due to oil spills, alternative energy, new waterproofing materials and other areas in construction.

New solutions for the environmental protection of water wells are associated with the use of innovative technologies of insulation materials. The problem of groundwater pollution became especially relevant in the post-perestroika period, when many wells that had owners who previously controlled their condition turned out to be ownerless. These were wells of all categories: water intake, parametric, prospecting, exploratory, operational, mothballed and abandoned. Today what is important is not why and how this happened, but the fact that the wells left unsupervised and collapsing in the bowels of the earth cause irreparable damage to groundwater [2, 9].

Over the past decade, work has been carried out in various regions of the Russian Federation to identify and eliminate ownerless wells, mainly water intakes. But the question arises, how exactly are the wells abandoned, and are the sources of groundwater pollution really eliminated with their abandonment?

METHODS AND MATERIALS

Causes of behind-the-casing flows in wells

A source of natural (groundwater) water pollution is defined as “a source that introduces chemical, biological or physical pollutants into surface or groundwater”.1

It can be seen from the definition that the phrase “source of pollution” does not quite apply to ownerless wells, since drilled wells are only conducting channels through which substances polluting groundwater move from the source towards the aquifer. Therefore, the main task that must be solved during the abandonment of a well is the isolation (elimination) of all channels created in the rock mass during drilling and arrangement of wells.

Such channels include: the internal space of the production (filter) string, connected to the aquifer through its perforated part or open wellbore, and the behind-the-cas-ing space, bounded by the walls of the well and the casing string along their outer diameter. Since the main feature by which ownerless wells are found and fixed are pipes of various diameters located in the ground, sometimes ac- companied by the remains of pavilions or concrete rings, then not just wells, but wells with non-recoverable casing pipes are subject to liquidation [15, 16].

To eliminate the possibility of pollutants penetrating into the aquifers, it is necessary to fill the annulus of the well, as well as the internal space of the casing pipes, with a sealed non-destructive material.

Traditionally, it is believed that such a material is oilwell cement slurries [6–8, 15–16, 18], but inspections of production wells for the tightness of their behind-the-casing space indicate the opposite.

Let us consider the conditions for the formation of cement stone in the annulus space at the stage of drilling and well construction, as well as the causes for the inevitable occurrence of behind-the-casing flows in wells when using cement slurries as an insulation material.

High-quality insulation of casing strings and separation of productive formations is a condition for long-term trouble-free operation of wells. Interlayer inflows and annular flows that appear at the initial stage of well operation are the result of the formation of a microannular space at the rock-casing contact already at the stage of cement stone formation [10].

During drilling and wellbore formation, the existing balance of stresses in the rock mass is disturbed, but is compensated by the hydrostatic pressure of the drilling fluid injected into the well during drilling. Properly selected drilling fluid parameters eliminate the negative impact of both rock and reservoir pressures on the well walls. During the construction of wells in the intervals determined by the design solutions for their construction, casing pipes are installed, designed mainly for fixing the walls, and in production wells also for the installation of water-lifting equipment. To separate the horizons penetrated by the well, oilwell cement slurries are traditionally used, as a result of the crystallization of which cement stone is formed in the behind-the-casing space.

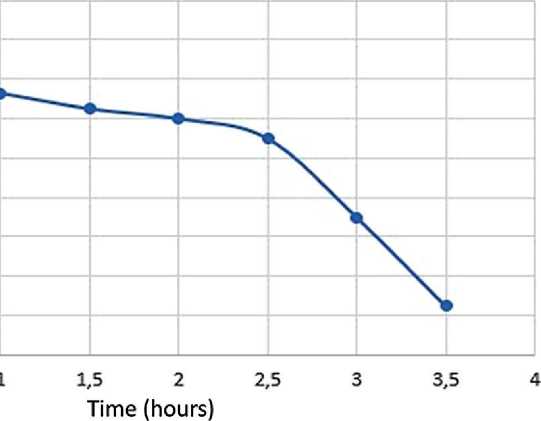

It is generally accepted that during casing cementation, the cement slurry delivered to the casing space instead of the flushing fluid used in drilling maintains the stress balance established in the rock mass and, consequently, excludes the negative impact of reservoir pressure on the forming cement stone [5, 13]. But that’s not the case. The hydrostatic pressure created by the cement slurry in the casing space decreases after the beginning of its crystallization and after 4–5 hours has almost zero values (Fig. 1) [12, 17].

This means that after the hydrostatic pressure of the cement slurry drops below the bedded pressure, compressive pressure is exerted on the forming cement stone from the aquifer, and it contributes to the formation of a microannular space in contact with water-bearing rocks

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION so 1

-gsedo-M (ed*)岂nssa」d

о о 6 4

1 1

о о 2 о

1 1

20о

Fig. 1. Change in the hydrostatic pressure of the cement slurry in the time range after the beginning of its crystallization

-

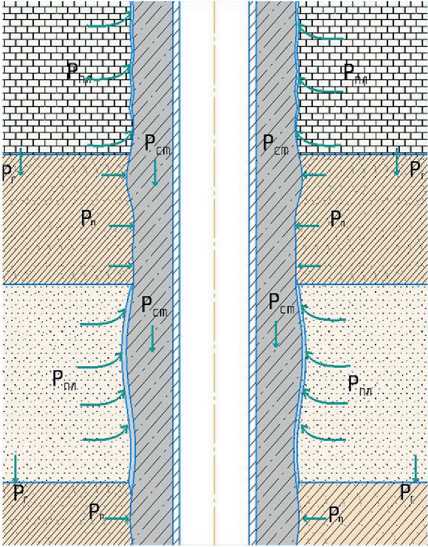

[12] . Under the influence of reservoir pressure, the leachate from the aquifer rushes into this micro-ring space, impairing the adhesion of the forming cement stone to the rocks located higher in the section (Fig. 2).

After cementation of the casing space in the process of further drilling of the well to the design depth, casing pipes and cement stone are subjected to dynamic loads by rotating drill pipes, which contributes to the formation

Ест- Pst - static pressure

Еп- Pp - pore pressure

Епл-Pres- reservoir pressure

Permeable collector

Impermeable rocks (waterproof)

Permeable collector

Fig. 2. Formation of cement stone in the space behind the column

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION of microcracks already at the casing pipe-cement stone contact. Thus, already at the stage of drilling and arrangement of the well, conditions are created for the occurrence of behind-the-casing flows in its behind-the-casing space. Over time, the aggressive action of formation filtrates contributes to the leaching of cement stone and transformation of microcracks into full-fledged cracks with gradual destruction of cement stone. Since cement-based hardening cement slurries are used in all wells without exception, the destruction of cement stone in the behind-the-casing space is a natural and inevitable phenomenon. The period of occurrence of behind-the-casing flows depends only on the values of reservoir pressures of the exposed horizons, the quality of the cement slurry and the technology of its delivery to the behind-the-casing space.

Knowing what behind-the-casing isolation technologies were used in the construction of hydrogeological wells and wells for solid minerals (especially in the postperestroika period), it can be unequivocally stated that wells that have been in operation for more than 10 years already have behind-the-casing flows. The only exception is the case when water-sensitive clay rocks are present in the geological section opened by the well, which, when interacting with water, swell and fill the voids formed in the space behind the casing during the destruction of the cement stone.

RESULTS AND DISCUSSION

Abandonment of wells according to standard designs

Most ownerless wells intended for abandonment have a service life of more than 25 years, that is, all of them have behind-the-casing flows.

In order to officially abandon a well, it is necessary to develop design documentation for its abandonment [14], and this requires initial technical information about it. As a rule, there is no technical documentation for an ownerless well. Pre-project inspection of ownerless wells is reduced to determining the coordinates of the discovered wellhead, visual inspection of casing pipes coming to the surface, measuring their diameters and current depths. The rest of the parameters necessary for the development of design solutions can be found in the record cards that are stored in geological funds. However, it is not possible to find these cards for all wells, and the information indicated in them does not always coincide with the data obtained during a visual inspection of the well. As a rule, special work on the wellbore survey in order to determine the actual depth and structure is not carried out before the development of design solutions for its abandonment. Therefore, the initial data for the development of projects for the abandonment of ownerless wells are conditional, as well as the design solutions themselves.

The only (and very old) regulatory legal act that regulates technical solutions for the abandonment of all wells (except for oil and gas wells) in order to “... prevent pollution and salinization of aquifers through the well, as well as undesirable mixing of waters of different quality and depletion of aquifers during gushing” – these are the “Rules for liquidation plugging of boreholes for various purposes, backfilling of mine workings and abandoned wells to prevent pollution and depletion of groundwater. 1967 (hereinafter referred to as the “Rules”) [16]. But it also defines the abandonment of a well as “... Filling the wellbore (full plugging) or part of it (partial plugging) with cement, clay or other impermeable material... ” [16]. And, although the Rules contain sections devoted to the elimination of behind-the-casing flows in wells with non-recoverable casing, the wording used allows unscrupulous designers to justify a technology convenient for the Customer in order to save on the abandonment of wells that are no longer needed by anyone. After all, the abandonment of an ownerless well alone is an order of magnitude cheaper compared to the complete abandonment of a well, which includes the insulation of the annulus.

Technical solutions for well abandonment according to the “standard design” are as follows:

-

– development of the wellbore and its cleaning from debris that has accumulated there or has been artificially created, from the wellhead to the real bottom;

-

– cleaning of casing pipe walls from corrosion and flushing of the entire wellbore after the above operations;

-

– disinfection of the aquifer followed by backfilling of the sand and gravel mixture into the perforated part of the filter column (at the interval of the aquifer);

-

– filling of the wellbore with backfill material (usually cement mortar);

– wellhead arrangement, including digging a pit around the casing pipe (pipes if more than one string enters the surface); cutting these pipes below the surface level and welding the cut pipe(s) with a metal plate; erection of a concrete bollard with an appropriate identification plate. [21].

The final document fixing the abandonment of an ownerless well is an act signed by the parties involved in this process, on the basis of which information on the elimination of the source of groundwater pollution is transmitted to the authorities.

From the described technology, it is obvious that design solutions for the abandonment of ownerless wells, in which there are non-recoverable casing pipes, are reduced only to the liquidation of their wellbores. The need to insulate the behind-the-casing space of the well is not mentioned in the “standard designs”, technical solutions for the elimination of behind-the-casing flows are not being developed, no work is being carried out in the behind-the-casing space of wells.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Clause 22 of the Rules states: “Wells that have opened several aquifers with different chemical compositions and with different groundwater pressures shall be plugged by installing cement bridges at the intervals of aquicludes that separate the aquifers... The number of cement bridges is equal to the number of aquifers ” [16]. As you know, nothing is the same in nature, heads of groundwater are always different, which means that it is necessary to design the installation of bridges in all wells that have opened aquifers. But it is this clause 22 that is used to justify the exclusion of behind-the-casing insulation during well abandonment. It is enough to substantiate, based on modern hydrogeological studies, that there are (conditionally) no regional aquicludes, and the horizons included in the conditionally combined aquifer complex have similar heads and chemical composition, and the work to eliminate behind-the-casing overflows can be excluded from the design solutions. And if we rely not only on modern research, but also look at the stock materials (reports compiled 50–60 years ago), it turns out that the same aquifers present in the region had not only aquicludes, but also different static levels and chemical composition of water [16]. In addition to the information already available, the number of wells drilled in this region over the past 50 years (including those that have already been abandoned) and the similarity of the parameters of the aquifers included in the joint complex become quite explainable.

It is worth recalling that the lack of insulation of the casing space in wells contributes to the entry of pollutants into the aquifers not only from the horizons located downstream of the section, but also from the surface of the earth: during snow melting, with rain streams [21]. And the presence of behind-the-casing water manifestations (griffins) in the wells that have opened the pressure horizon contributes to a change in the hydraulic parameters of all overlying permeable horizons, increasing groundwater levels, and thereby complicating construction work (for example, the city of Velikiye Luki, Pskov region) [20].

What can happen (and is happening) with wells abandoned according to “standard designs” in the long term is shown in Figure 3.

Abandonment of the wellbore does not eliminate the entry of pollutants into the aquifers through the behind-the-casing space from pollution sources located both at depth and on the surface. Only one channel through which toxic substances enter aquifers is being eliminated. The main channel – the behind-the-casing space of the well – remains open and accessible for the entry of pollutants into groundwater. At the same time, the behind-the-casing space of wells tends to increase in volume due to the destruction of unstable rocks that make up the walls of wells (Fig. 3) [21].

After signing the well abandonment certificate by the parties involved in the process, the well receives the of-

Fig. 3. Consequences of well abandonment according to the “standard design”

ficial status of abandoned, but at the same time there retains the ability to move pollutants through the behind-the-casing space. The probability of re-abandonment of the well is zero, since it is possible to get into the wellbore after its cementation only after the removal of the wellhead material (cement stone) from it, i.e. after its drilling, but in old wells this is associated with the risk of violating the integrity of the casing pipes [21].

Thus, wells, that are subject to abandonment but have not yet been abandoned, can be considered temporary conductors of pollutants, since under favorable circumstances they can be abandoned in full, i.e. with the separation of horizons in the casing space of the well. As long as the well is not abandoned, this possibility remains, even if only theoretically. A well, in which only the wellbore, i.e. the inner space of the casing pipes, has been abandoned according to the “standard design”, becomes a permanent conductor of pollutants into groundwater, i.e. channels for the migration of substances polluting groundwater remain and it is no longer possible to eliminate them [21].

Thus, the abandonment of wells, including ownerless ones, according to the “standard design” instead of protecting groundwater leads to their further permanent and irremediable pollution, but officially [21].

As an alternative to “standard projects” for the abandonment of wells, including ownerless wells, design solutions are offered based on the technology of abandonment of overflow wells with behind-the-casing flows (griffins), which has been practiced in the NorthWest region for more than 10 years [20]. The basis of this technology is the nanomaterial “Plug-back mixture LP”, which has proven itself very well in the liquidation of overflowing wells with behind-the-casing flows. And only thanks to this material, it became possible to repair

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION and abandon wells that opened the pressure aquifer at a depth of less than 30 m.

In its initial state, the “Plug-back mixture LP” is a viscoelastic mixture that is delivered to the area of the water manifestation source, fills the pores and cracks of the host rocks, colmating the latter. A distinctive feature of the presented material is its ability to increase in volume when in contact with water, displace water from pores and cracks, filling the vacated space. [19]. In addition, when entering a water stream (e.g., a stream of water moving in a casing space and having a discharge at the wellhead or in the overlying permeable horizon), the homogeneous mass of the Plug-back mixture LP separates into small particles, which rush along the flow into the reclaimed channels. Gradually swelling and getting stuck in narrow places, and then sticking to each other, the particles of the cement mixture, as it were, gather again into a homogeneous mass and colmate the channels through which the water moved. Possessing good adhesive properties to casing metal and rocks, Plug-back mixture LP forms a non-hardening, hydrophobic shield that prevents the movement of filtrate in the casing space. The shield being created is capable of withstanding reservoir pressures of more than 5 MPa. [20]. Technological properties of the Backfill Slurry make it possible to liquidate and repair overflowing wells with griffins, which have opened pressure horizons at a depth of 10 m or more. The grouting material is resistant to dynamic loads and, in the event of the latter (subsidence of the soil, etc.), is able to independently fill newly formed voids and (or) cracks, colmating them. A plastic impermeable hydrophobic shield is created in the casing space, separating the aquifers.

Over the 10 years of the technology’s existence, more than 40 overflowing wells with behind-the-casing flows have been repaired and abandoned, and in almost all wells, the roof of the pressure aquifer lay at a depth of up to 50 m. There were no negative results. There is experience in using plug-back mixtures LP as an insulating material for casing pipes at the stage of construction of water wells equipped on a pressure aquifer.

As a demonstration of the practical application of the technology described above, we will limit ourselves to just two examples.

The abandonment of the well in the city of Belozersk, which opened the pressure horizon at a depth of 20 m, was carried out according to the technology described above using the “Plug-back mixture LP”. Since the wellhead was lost due to the intensive development of the griffin funnel, in order to prevent suffusion and further development of the funnel, the latter was filled with gravel. And to deliver the backfill material to the roof of the aquifer, auxiliary wells had to be drilled. Figures 4–5 depict the moment of maximum development of the funnel and the site after the work on the localization of water manifestation [11].

In 2016, on the territory of a cottage village located in the valley of the Setovka stream, during the drilling of an exploratory water well (16 Polevoy Lane) from a depth of 9 m, there was an outpouring of water with a characteristic smell of hydrogen sulfide, with a flow rate of 80 m3/h and a static level of +15–17 m. In contrast to the case in Belozersk, the flow rate of the well decreased over time, and at the time of the beginning of the abandonment did not exceed 25–30 m3/h. The work was complicated by the low depth of the well, but the technology developed by the specialists of the Geological Center of St. Petersburg State University and the use of the nanomaterial “Plug-back mixture LP” made it possible to eliminate water leaks. Figures 6–7 depict the moment of the beginning of water manifestation and the territory of the site after the abandonment of the well and its arrangement [20].

METHODS AND MATERIALS

For the abandonment of abandoned wells in full, i.e. isolation of all conductive channels that contribute

Fig. 4. Scale of development of the griffin funnel

Fig. 5. Area after well abandonment

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 6. Well under repair, 2016

Fig. 7. Area after well abandonment, Oct. 2021

to the entry of pollutants into aquifers associated with a particular well the following technology is proposed.

Since casing pipes are installed in abandoned wells and it is not possible to extract them, preliminary perforation of casing strings above the roof of the aquifer is necessary to deliver the backfill material to the annulus. For their perforation, it is proposed to use pipe cutters used in the elimination of accidents in wells. Pipe cutters, by the principle of their operation, allow you to form windows along the circumference of the casing pipes. They are easy to operate and, unlike shaped rotary hammers, do not require special permits for their use. The width of the formed windows is determined by the width of the pipe cutter incisors and is within 10–12 mm, which is enough to deliver LP backfill material to the behind-the-casing space. If necessary, the number of process windows can be increased to two or three.

The cement packer on the injection string (drill pipes of the TBSU) is installed in the well above the process window (if there are several of them, then higher than the uppermost one) by 200–300 mm and expanded. A confined space is created under the packer with an exit to the pipe through technological holes.

Prior to the insulation works, the annulus tightness is tested with a pressure of no more than 1 MPa, based on the results of which a decision is made either to carry out work on the insulation of the behind-the-casing space, in the presence of behind-the-casing flows, or to dismantle the injection equipment, in case of establishing the fact of tightness of the behind-the-casing space.

Only after the completion of all the above complex of works should the wellbore be insulated. And as an insulating material for the elimination of channels created by a drilled well in a rock massif, which contribute to the pollutions of groundwater, the technology prescribes the use of the nanomaterial “Plug-back mixture LP”.

CONCLUSION

-

1. A well abandoned according to the “standard design”, i.e. without elimination of behind-the-casing flows, continues to have a negative impact on groundwater.

-

2. When developing design solutions for abandonment of wells with non-recoverable casing pipes, measures should be taken to eliminate behind-the-casing flows. And when they are abandoned, the behind-the-casing space of wells should be insulated with an impermeable nanomaterial “Plug-back mixture LP”, which ensures the separation of aquifers in the long term.

-

3. It is necessary to review and revise the regulatory document “Rules for liquidation plugging of boreholes for various purposes, backfilling of mine workings and abandoned wells to prevent pollution and depletion of groundwater. 1967” and to make changes to the technology of well abandonment taking into account modern innovative technologies and experience in the use of the nanomaterial “Plug-back mixture LP” in the abandonment of overflowing wells and griffin formations.

-

4. For the period of work on the development and approval of a new regulatory document defining the technology of abandonment of wells with the mandatory elimination of behind-the-casing flows, it is necessary to suspend work on the design and abandonment of wells, primarily ownerless wells.

-

5. The solution to the problem of environmental protection of boreholes is based on the technological innovations of the university’s SIEs: the development of insulating nanomaterials capable of effectively solving the problems of groundwater pollution.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Список литературы Technologies of small innovative enterprises as a result of intellectual activity: application of nanotechnologies in the liquidation of orphan wells

- Motovilov O.V. (ed.) Management of Innovations and Intellectual Property of the Firm. Monograph. 2nd edition. Moscow, Prospekt; 2018.

- Polyakov N.A. Formation of the strategy of small innovative enterprises of St. Petersburg State University. Sustainable development: society and economy. Materials of the III International Scientific and Practical Conference “Sustainable Development: Society and Economy”. St. Petersburg State University. Scythia-Print LLC St. Petersburg; 2016.

- Guzov Yu.N., Polyakov N.A., Titov V.O., Vashchuk A.E. Conditions for the Russian Federation Arctic zone innovative development. E3S Web of Conferences International Conference on Efficient Production and Processing, ICEPP 2020. Volume 161; 2020.

- Lukashov N.V. Ekonomika znanii [Economics of Knowledge]. Publisher: Prospekt LLC, Moscow; 2020.

- Agadulin I.I., Ignatyev V.N., Sukhorukov R.Y. Ecological Aspects of Leakiness of Behind-the-Casing Space in Wells for Various Purposes. Electronic Journal Oil and Gas Business. 2011; 4.

- Basargin Yu.M. Technology of overhaul and underground workover of oil and gas wells. Krasnodar. Owl. Kuban; 2002.

- Bashkatov D.N., Rogovoy V.L. Drilling of water wells. Moscow. Kolos; 1976.

- Bulatov A.I., Danyushevsky V.S. Cement materials. Moscow. Subsoil; 1987.

- Vyazov B. The problem of abandoned wells requires an urgent solution. Oil and Capital Magazine, 2024; January.

- Egorova E.V., Vybornova T.S. Well casing. Analysis of the formation of fluid-developing channels in the cemented space of wells and measures to ensure high-quality support. Nefteservis. 2017; 2.

- Nadezhen A. Taming the “hellwell”. Vologda. Region. 04.04.2020.

- Piskunov E.L., Leusheva E.L. Analysis of the Causes of the Appearance of Behind-the-Column Flows. Collection of reports of the All-Russian Scientific and Technical Conference with International Participation, dedicated to the 60th anniversary of the Department of Well Drilling. Tomsk Polytechnic University Publishing House, 2014; 288-295.

- Ponizov, A.V., Vereshchagin, P.M., Chulkov, N.V., et al. Conditions, Consequences and Ways to Prevent Behind-the-Casing Fluid Flows through Wellbore Sites at Sites of Deep Disposal of Liquid Radioactive Waste. Journal Geoecology. Engineering geology. Hydrogeology. Geocryology. 2019; 2: 56-67.

- Resolution No. 2127 dated November 30, 2021 “On the Procedure for Preparing, Coordinating and Approving Technical Projects for the Development of Mineral Deposits, Technical Projects for the Construction and Operation of Underground Structures, Technical Projects for the Liquidation and Conservation of Mine Workings, Boreholes and Other Structures Related to the Use of Subsoil, by Types of Minerals and Types of Subsoil Use”.

- Safety rules in the oil and gas industry. “Federal Service for Environmental, Industrial and Nuclear Supervision. Order No. 534 dated December 15, 2020.

- Rules for liquidation of plugging of boreholes for various purposes, backfilling of mine workings and abandoned wells to prevent pollution and depletion of groundwater. Ministry of Geology, 1967.

- Raikevich S.I. Inter-column pressures and behind-the-casing movements of fluids in wells. Ways to solve the problem. Proceedings of the International Technological Symposium “Intensification of Oil Production”. Institute of Oil and Gas Business.Moscow; 2003: 579-587.

- Ryazanov Y.A. Encyclopedia of drilling fluids. “Letopis” Publishing House; 2005.

- Trifanichev V.M. Innovative Technologies in the Creation of Impervious Curtains. Journal Hydrotechnics. 2009; 4(17).

- Trifanichev V.M., Tudachev A.V. Pouring Wells: What Are They Dangerous about and What is To Do with It. 2022; 7: 54-63.

- Trifanichev V.M. Liquidation of ownerless wells. Geology and Subsoil Use. 2022; 6(10): 86-93.