Technology of flour confectionery products using emulsion obtained in conditions of cavitation processing

Автор: Taleysnik M.A., Savenkova T.V., Soldatova E.A., Misteneva S. Yu., Mizinchikova I.I.

Журнал: Вестник Мурманского государственного технического университета @vestnik-mstu

Рубрика: Технология и товароведение пищевых продуктов функционального и специализированного назначения

Статья в выпуске: 3 т.21, 2018 года.

Бесплатный доступ

The idea of using the cavitation energy in food industry appeared in the middle of the last century, but due to absence of efficient machineries and developed process theory this method was not used. The attractiveness of using the effects of cavitation in the food industry lies in the possibility of a significant intensification of such most labour and energy-consuming processes as grinding, homogenization, dispersion, emulsification of food disperse systems. Nowadays, lots of works all around the world are dedicated to this phenomenon. This scientific direction has gained it's actuality with the world rate technic development allowing to create the more powerful machineries, capable to processing large volume of liquid. The development of new researching method has made the problem of using the cavitation energy - which has both hydrodynamic and acoustic nature - more attractive. The advantages of using the effects of cavitation on food media have been presented. The expediency of using cavitation in various sectors of the food industry: baking industry, meat industry and dairy industry has been proved...

Emulsion, dispersion, suspension, cavitation, sugar cookies, bakery confectionery products

Короткий адрес: https://sciup.org/142217119

IDR: 142217119 | УДК: 664.681 | DOI: 10.21443/1560-9278-2018-21-3-505-512

Текст научной статьи Technology of flour confectionery products using emulsion obtained in conditions of cavitation processing

Recently, certain progress has been made in the development of fundamentally new mixer designs with cavitation technology standing out.

In particular, there is the well-known technology of preparing baking dough using cavitation activated water followed by hydration-induced structuring of gluten proteins, which allows increasing specific volume and elasticity of bread, slowing down firming of bread and reducing the use of bakery improvers. Cavitation treatment of sugar-salt solutions before their mixing with the dough allows reducing the content of salt and sugar in the bread without changing the product taste and nutritional value [1–4].

In meat industry, studies were conducted on the use of cavitation for producing aromatic emulsions. It has been established that electrolytes (salt, phosphates) have a higher degree of dissociation in cavitation treated water compared to the untreated one, which makes it possible to reduce their quantity in cooked sausage formulations by 10–15 % in comparison to the standard dosage, and thus to improve the quality and environmental safety of the products [5–7].

Cavitation technologies have gained extensive use in the dairy industry. Samples of reconstituted raw materials using cavitation water treatment reveal a slight increase in the dry substances mass fraction, including protein, as well as the increase in their density and dynamic viscosity. The data on the dispersed composition of reconstituted milk has proven the ultrasonic cavitation efficiency on the balance of protein and lactose particles in terms of size: the proportion of particles with dimensions ranging from 202 to 243 nm increases, while the control sample is characterized by the predominance of particles of two size fractions (409 ± 10) nm and (174 ± 10) nm [8–10].

Thus, the cavitation action on the liquid allows obtaining high-quality technological food and biologically active solutions of extracts, emulsions and suspensions [11–12].

The purpose of the present study is to establish the possibility of controlling emulsion quality under conditions of cavitation processing and to determine its effect on the organoleptic, physical and structural-mechanical characteristics of sugar biscuits.

Materials and methods

The study objects were experimental samples of emulsions for sugar cookies and samples of sugar cookies with optimized structural-mechanical and organoleptic characteristics. Physicochemical and organoleptic parameters of emulsion and biscuits were determined using standard methods. Organoleptic indicators were examined in accordance with GOST (All Union State Standard) 24901-89 and GOST 5897-90 1 ; mass fraction of moisture – by the sample drying in the drying chamber according to GOST 5900-73 2 ; mass fraction of fat – by the extraction-weight method according to GOST 31902-2012 3 ; biscuit absorptivity – in terms of mass increase in the product when immersed in the water at the temperature of 20 °C for a certain time (2 minutes) – according to GOST 10114-80 4 . Absorptivity depends on the products porosity and is characterized by the items mass ratio after wetting to the mass of dry products, which is expressed as a percentage. The water activity was determined with AquaLab 4TE analyzer (Decagon Devices, USA) using the mirror-cooled dew point sensor method; rheological characteristics of the emulsion (effective viscosity) was determined by the rotational viscometer Rheotest-2; plastic strength of the cookies – with the KP-3 tool belonging to Professor Volarovich.

Results and discussion

The quality of flour confectionery products largely depends on how the semi-finished products and dough are prepared. The processes of obtaining emulsions are among the most important fundamentals of the present day food industry. The use of cavitation effect is one of the most promising ways for forming stable emulsions in the presence of high productivity technical means [13]. There are two types of cavitation: acoustic cavitation occurs in a liquid medium during the passage of a high intensity sound wave; hydrodynamic cavitation takes place due to a sharp local decrease in the fluid pressure as a result of high flow velocities [13–14].

Industrial use of cavitation mixers has shown that they allow to exponentially intensify the mixing processes [4], and the physical phenomena associated with cavitation cause a number of effects (Table 1).

Table 1. Effects caused by cavitation Таблица 1. Эффекты, вызванные кавитацией

|

Effects |

Reason |

• Surface cleaning |

Caused by shocks (short-term pressure pulses) that arise when the bubbles collapse and the microflows appear beside them |

|

• Initiation and acceleration of chemical reactions |

Caused by ionization of gas during the formation of cavitation bubbles |

For the practical implementation of ultrasonic emulsification process, it is necessary to identify optimal exposure regimes and propagation conditions in order to create a uniform ultrasonic field in the mixture of two mutually insoluble liquids and to obtain emulsions with specified dispersion characteristics [13].

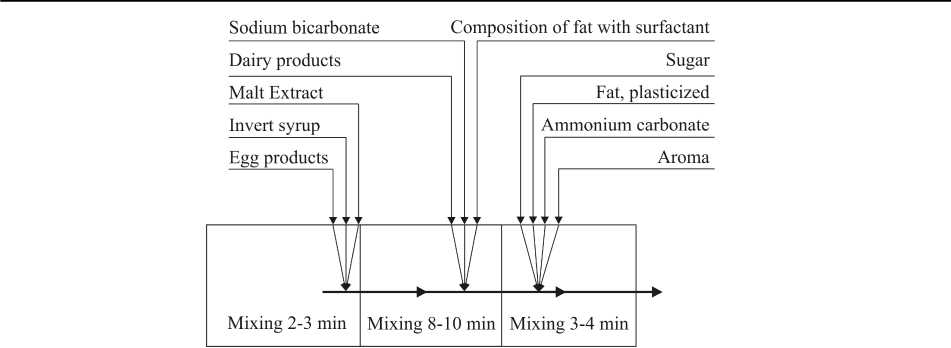

The initial stage of emulsion technology for sugar cookies is the stage of preliminary suspension preparation. VNIIKP has developed the basic scheme for suspension preparation in the three-step process [15–16] (Fig. 1).

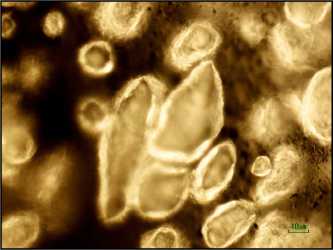

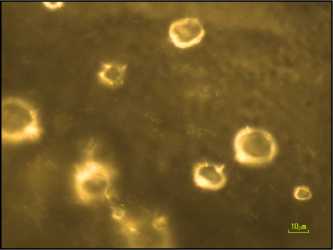

The three-stage method for the preparation of the suspension ensures high uniformity in the distribution of components throughout the volume and a marked decrease in the amount of undissolved solid phase particles and their size [16; 17] (Fig. 2).

It is commonly known that suspensions are unstable systems and can be demixed with time. In order to increase their stability and dispersion, they were treated under cavitation conditions.

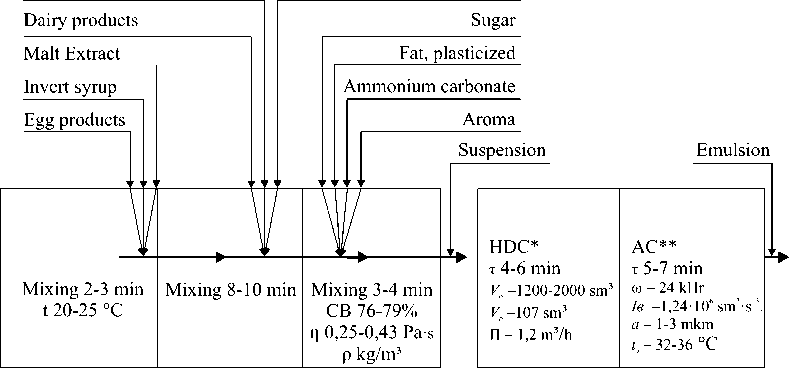

The basic scheme of the emulsion preparation technology using cavitation processing is shown in Fig. 3.

Fig. 1. The basic scheme for suspension obtaining in the three-step process Рис. 1. Основная схема получения суспензии в трехэтапном процессе

The present-day method of suspension preparation (in one step)

Fig. 2. Microphotographs of the suspension structure for various production methods (magnification × 500)

Рис. 2. Микрофотографии структуры суспензии для различных способов производства (увеличение × 500)

Three-stage method of suspension preparation

Composition of fat with surfactant

Sodium bicarbonate

Fig. 3. The basic scheme of emulsion obtained using cavitation processing:

HDC* – hydrodynamic cavitation; τ – processing time; V o – volume of processed emulsion;

V р – reactor volume; П – pump capacity; AC** – acoustic cavitation; ω – oscillation frequency;

К – frequency of emulsion circulation through the reactor; Iв – ultrasound intensity; a – oscillation amplitude;

t э – emulsion temperature

Рис. 3. Основная схема получения эмульсии с использованием кавитационной обработки:

HDC* – гидродинамическая кавитация; τ – время обработки; V o – объем обрабатываемой эмульсии;

V р – объем реактора; П – производительность насоса; AC** – акустическая кавитация;

ω – частота колебаний рабочего органа; К – кратность циркуляции эмульсии через реактор;

Iв – интенсивность воздействия ультразвука; a – амплитуда колебаний; t э – температура эмульсии

The suspension was processed under the conditions of combined action of hydrodynamic and acoustic cavitation with different intensity of ultrasound exposure:

– at the minimum intensity of ultrasound exposure I min = 0.16·10 6 cm 2 ·s –3 ;

– at the maximum intensity of ultrasound exposure I max =1.24·10 6 cm 2 ·s –3 .

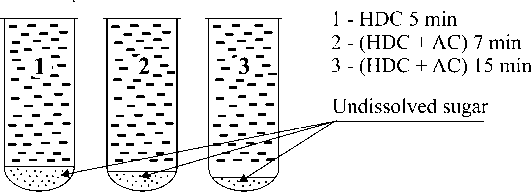

It was found out that at the minimum intensity of ultrasound exposure I min = 0.16·10 6 cm 2 ·s –3 with an increase in the duration of cavitation treatment, the amount of undissolved sugar in the emulsion decreases, while the emulsion temperature rises from 28 to 45 °C (Fig. 4).

Fig. 4. Change in the amount of undissolved sugar in the emulsion preparation during cavitation at the minimum intensity Рис. 4. Изменение количества нерастворенного сахара в эмульсионном препарате при кавитации при минимальной интенсивности

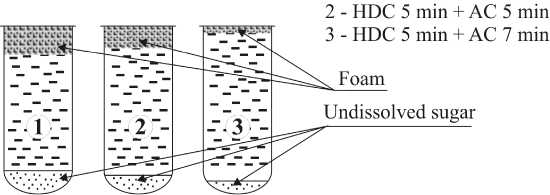

At the maximum intensity of ultrasound exposure I max = 1.24·10 6 cm 2 ·s –3 the optimal duration of ultrasonic treatment is 7 minutes, during which the maximum dispersion of all three phases (S-L-G) (the particle size of the solid phase does not exceed 10 microns) is provided and the stability of the emulsion structure is improved, which is confirmed by a decrease in the amount of undissolved sugar and formed foam (Fig. 5). The temperature of the emulsion does not exceed 36 ° C.

1 - HDC 5 min

Fig. 5. Change in the amount of undissolved sugar and foam depending on the method and duration of the emulsion preparation process

Рис. 5. Изменение количества нерастворенного сахара и пены в зависимости от способа и продолжительности процесса приготовления эмульсии

Studies of the structural and mechanical properties of the finished emulsion show that with the increase of cavitation processing time, an insignificant increase in the viscosity and mass density is obtained (Table 2).

Table 2. Changes in the structural and mechanical properties of the emulsion as a function of time and type of cavitation treatment

Таблица 2. Изменения структурных и механических свойств эмульсии в зависимости от времени и типа кавитационной обработки

|

Indicator |

Samples of the emulsion |

||

|

HDC* 5 min |

HDC 5 min + AC** 5 min |

HDC 5 min + AC 7 min |

|

|

Density, kg/m 3 |

700 |

760 |

780 |

|

Viscosity, Pa.s (at έ = 10 s –1 and temperature 30 ºС) |

2.10 |

2.35 |

2.50 |

Notes. * HDC – hydrodynamic cavitation; ** AC – acoustic cavitation.

As a result of further studies, it was established that the use of emulsion obtained through cavitation processing intensifies the central subsystem (preparation of the dough), which predetermines the possibility of obtaining finished products with specific properties. Evaluation of the quality of finished products showed that the taste and structural characteristics of the cookies prepared using the cavitation processing obtained emulsion were superior to those of the control sample prepared using the existing technology (Table 3).

Table 3. Quality indicators of sugar cookies Таблица 3. Показатели качества сахарного печенья

|

Physical and chemical indicators |

Admissible value in accordance with GOST 24901-2014 |

Cookies samples |

|

|

Existing technology |

Technology using cavitation processing obtained emulsion |

||

|

Humidity, % |

not exceeding 10 % |

5.0 |

5.5 |

|

Density of finished products, kg/m 3 |

– |

560 |

530 |

|

Absorptivity, % |

at least 180 |

190 |

210 |

|

Strength, kPa |

– |

65 |

73 |

|

Water activity |

– |

0.54 |

0.49 |

Evaluation of products after 90 days of storage showed that the organoleptic, physicochemical and microbiological quality indicators of the experimental samples of cookies were practically unchanged and by the end of the storage period, they met the requirements of GOST 24901-2014 and TR TS 021/2011 5 .

Conclusions

Cavitation impact causes changes in the functional and technological properties of liquid food systems (chemical, technological, physical, organoleptic, etc.), which contributes to achieving a certain technological effect. It has been established that the physicochemical effect of high energies leads not only to a decrease in the entropy of the leading processes and technological systems in general, but also to an increase in production efficiency and quality stabilization of the finished product. Effectiveness of the combined impact of hydrodynamic and acoustic cavitation on the increase of consumer indicators of sugar cookies has been proven.

Список литературы Technology of flour confectionery products using emulsion obtained in conditions of cavitation processing

- Шестаков С. Д. Основы технологии кавитационной дезинтеграции: Теория кавитационного реактора и ее приложения в производстве хлебопродуктов. М.: ЕВА-пресс, 2001. 173 с.

- Черных В. Я., Лебедев А. В., Болтенко Ю. А. Разработка реологической модели мякиша хлебобулочных изделий//Высокоэффективные пищевые технологии, методы и средства для их реализации: сб. докл. IV междунар. конф., Москва, 15-16 ноября 2006 г., Ч. I. М.: МГУПП, 2006. С. 60-65.

- Прохасько Л. С., Ярмаркин Д. А. Кавитационная дезинтеграция пищевых сред в производстве хлебопродуктов//Современное бизнес-пространство: актуальные проблемы и перспективы. 2014. № 1. С. 182-184.

- Ярмаркин Д. А., Прохасько Л. С., Мазаев А. Н., Асенова Б. К., Зинина О. В. . Кавитационные технологии в пищевой промышленности//Молодой ученый. 2014. № 8. С. 312-315.

- Ярмаркин Д. А., Прохасько Л. С., Мазаев А. Н., Асенова Б. К., Залилов Р. В. Сонохимическая кавитация в мясном производстве//Молодой ученый. 2014. № 10. С. 220-223.

- Красуля О. Н., Богуш В. И., Долгова О.А., Мишарина Т. А., Хмелев С. С. Использование сонохимии при производстве вареных колбасных изделий//Мясная индустрия. 2013. № 7. С. 20-24.

- Евтушенко А. М., Красуля О. Н., Крашенинникова И. Г., Колкин А. В. Особенности структуры вареных колбасных изделий при использовании сонохимических технологий//Мясная индустрия. 2015. № 7. С. 31-33.

- Попова Н. В. Обеспечение качества восстановленных продуктов переработки молока и интенсификация их производства на основе ультразвукового воздействия: автореф. дис. … канд. техн. наук: 05.18.15. Кемерово, 2014. 18 с.

- Потороко И. Ю., Калинина И. В. Влияние электрофизических методов воздействия на микроструктуру дисперсной среды коровьего молока//Сборник науч. трудов по материалам междунар. науч.-практ. конф. = Сборник научных трудов Sworld. 2010. Т. 6, № 4. С. 74-75.

- Красуля О. Н., Потороко И. Ю., Кочубей-Литвиненко О., Мухаметдинова А. К. Инновационные подходы в технологии молочных продуктов на основе эффектов кавитации//Вестник Южно-Уральского государственного университета. Сер. Пищевые и биотехнологии. 2015. Т. 3, № 2. С. 55-63.

- Промтов М. А. Перспективы применения кавитационных технологий для интенсификации химико-технологических процессов//Вестник Тамбовского государственного технического университета. 2008. № 4. С. 861-869.

- Пищевые технологии будущего и нанопреобразования биополимеров: /под ред. А. Б. Лисицына. М.: Диапазон-В, 2015. 304 с.

- Капустин С. В., Красуля О. Н. Применение ультразвуковой кавитации в пищевой промышленности//Интерактивная наука. 2016. № 2. С. 101-103.

- Федоткин И. М., Гулый И. С. Кавитация: Кавитационная техника и технология, их использование в промышленности. Ч. II. Киев: ОКО, 2000. 898 с.

- Аксенова Л. М., Духу Т. А., Щербакова Н. А., Герасимов Т. В., Талейсник М. А. . Теоретические основы технологий приготовления кондитерских полуфабрикатов в условиях кавитационной обработки//Кондитерское производство. 2011. № 3. С. 26-27.

- Талейсник М. А., Солдатова Е. А., Мистенева С. Ю., Щербакова Н.А., Герасимов Т. В. . Основы технологии мучных кондитерских изделий с использованием суспензионной системы//Кондитерское производство. 2017. № 4. С. 14-17.

- Герасимов Т. В. Развитие технологий мучных кондитерских изделий с использованием кавитации: автореф. дис. … канд. техн. наук: 05.18.01. М., 2015. 25 с.