The Chemical Analysis of Glass Samples from Roman Era Cemeteries in the Crimean Piedmont

Автор: Khrapunov I.N., Stoyanova A.A., Lubkova T.N., Shabanov S.B.

Журнал: Archaeology, Ethnology & Anthropology of Eurasia @journal-aeae-en

Рубрика: The metal ages and medieval period

Статья в выпуске: 1 т.50, 2022 года.

Бесплатный доступ

We assessed the chemical composition of more than 40 fragments of glass vessels from the Roman Period cemeteries in the Crimean piedmont— Druzhnoe, Neyzats, and Opushki, using X-ray spectral microanalysis. The results suggest that the glass from all the cemeteries belonged to the soda-lime-silica group, based on natural soda. The samples fall in glass groups “Levantine I”, “HIMT”, and “Roman glass”, typical of central and peripheral Roman manufacture in 0–500 AD. Most vessels are made of glass with a high content of iron, manganese, and titanium, as in the HIMT group, most common in Europe since 300 AD. The likely workshops are those in the Syro-Palestinian area, northern Egypt, and Sinai, pointing to contacts of the northern Pontic with other parts of the Greco-Roman world. The composition of glass from all the three cemeteries is the same, suggesting that the sub-mountainous Crimea imported glassware from the same workshops.

Roman glass ware, chemical composition, X-ray spectroscopic microanalysis, Northern Black Sea region, Crimea, ancient cemeteries

Короткий адрес: https://sciup.org/145146849

IDR: 145146849 | DOI: 10.17746/1563-0110.2022.50.1.106-115

Текст научной статьи The Chemical Analysis of Glass Samples from Roman Era Cemeteries in the Crimean Piedmont

In the Northern Black Sea region, glassware appears with the Greek colonists at the turn of the 6th–5th centuries BC and gradually conquers local markets. In ancient times, glass vessels were luxury items, but over time they became widely used in everyday life. This became possible with the development of glassmaking in the 1st millennium BC, especially the emergence and spread of the blowing technique, which made it possible to produce glassware quickly and in large quantities. Vessels began to be made in various shapes in accordance with their purpose. Flasks or bottles were made for storing liquids and bulk products, while jugs, dishes and plates, cups, bowls, kantharoi, etc. for the tableware.

In Roman period, glassware, along with other antique imports, appeared in the sub-mountainous Crimea. Here, on barbarian settlements and burial grounds, a large number of glass vessels (both intact and fragmented) were found. These were items of exchange or trading, gifts to leaders or war trophies. For many decades, experts have been systematizing and analyzing this category of finds. New materials are introduced, typologies of glass products are developed, chronological boundaries of their existence are established, and assumptions are made about the ways in which glass vessels appeared in the sub-mountainous Crimea. The effectiveness of research is ensured by the use of natural scientific methods. The prospects of such an approach are obvious: it will bring the study of glass vessels of the Roman period stored in Crimean museums at a qualitatively new level. So far, only the first steps are being taken in this direction (Rumyantseva, Trifonov, 2021).

In recent years, natural scientific methods have been widely used in the study of ancient glassmaking. For example, modern archaeometric studies have confirmed the data of written sources on the main composition of ancient glass: the products of Greco-Roman glassmaking belong to the soda-lime-silica glass group and have a composition typical of glass made on natural soda (Scott, Degrise, 2014: 21). Such glass became widespread in Europe and the Near East in the second half of the 1st millennium BC to the 9th century AD. Before this period, ash from saltmarsh plants served as the basis for glass production (Devulder, Degryse, 2014: 87). It was found out that in the ancient era, glassmaking included two production stages—glass melting and glass working, which were separated not only technically, but also geographically (Rumyantseva, 2011: 87). In one place, glass mass was made, then it was transported in ingots to different parts of the ancient world, where various glass products were made from these semi-finished products. This feature of glass production is confirmed by analyses (Degryse et al., 2014: 107, 112).

The purpose of this work is to introduce the results of the analysis of the chemical composition of glass vessels from Roman era cemeteries located in the south of the Crimean Peninsula. Research materials are 46 samples from three cemeteries: Druzhnoe (4), Neyzats (30), and Opushki (12). One specimen is dated to the 1st century BC–1st century AD; two samples to the 2nd century–first half of the 3rd century AD; another sample to the second half of the 3rd century AD. The rest of the samples date to the 4th century AD.

Materials from the excavations of the cemeteries of Druzhnoe, Neyzats, and Opushki, including glass vessels, are stored in the collections of the Central Museum of Taurida (Simferopol).

Methods

Chemical composition of the glass samples was identified by electron probe (X-ray spectral) microanalysis in the Laboratory of Local Methods of Substance Research of the Faculty of Geology of the Lomonosov Moscow State University. The studies were carried out in flat-polished sections, precoated with a carbon film 25 nm thick. To prepare flat-polished sections, fragments of glass vessels were poured with epoxy resin into blocks, using the cold pouring technique. The blocks were then ground using abrasive papers of various grits (including P2500 for fine grinding and polishing) and polished with diamond abraders, with successive grain reduction to surface roughness value of <0.1 μm.

For analytical measurements, we used a JSM-6480LV scanning electron microscope (Jeol Ltd., Japan) equipped with an X-MaxN energy dispersive spectrometer (Oxford Instruments, Great Britain), with an ultrathin window and a crystal active zone area of 50 mm2. Analytical measurements were carried out at an accelerating voltage of 20 kV and an electron probe current of 10 nA. With a deadly time value of 23– 26 %, the data processing rate was ca 13–16,000 PPS.

The same conditions and exposure time (100 sec.) were also set when measuring standards— stoichiometric compounds and natural minerals (standards from the Catalog of Standards for Electron Probe Microanalysis by Jeol Ltd., Japan; standards of the National Institute of Standards and Technology, USA). The relative measurement error of the main (more than 10 wt%) components, estimated according to the standards of the corresponding minerals, did not exceed 1 %. For minor components (from 1 to 10 wt%), the relative error was within 5 %. The detection thresholds for all analyzed elements do not exceed 0.01– 0.05 wt%. Analysis of the glass composition with a small amount of microliths was carried out by scanning a surface with an area of 0.06 mm2. The reproducibility was assessed by a three-stage analysis of individual samples. The INCA program (Oxford Instruments, version 21) was used to process the results using the XPP correction algorithm. Oxygen was calculated by stoichiometry

(Fe and Mn were assumed to be bivalent, the remaining elements in the highest oxidation states).

The relative standard deviation characterizing the reproducibility of the analysis results does not exceed 1 % for SiO 2 , 3 % for Na 2 O, Al 2 O 3 , CaO, 5 % for MgO, K 2 O, Cl, 10 % for SO 3 , FeO, as well as MnO, Sb 2 O 5 , PbO (with content of more than 0.1 wt%). The relative standard deviation at an oxide content of 0.01–0.1 wt% (for P 2 O 5 , TiO 2 , CoO, CuO, as well as MnO, Sb 2 O 5 , PbO) averages 30 %; with an oxide content of 0.1– 0.2 wt% (for P 2 O 5 , TiO 2 , CuO) 10–20 %.

Results

Druzhnoe cemetery is located in the center of the sub-mountainous Crimea, southeast of the city of Simferopol, near the village Druzhnoe, on the slope of the mount of Shpil (Fig. 1). The first small excavations of the cemetery were carried out in 1984. In 1990– 1994, systematic research of the site was carried out by the archaeological expedition of the Simferopol State University. In the burials of the second half of the 3rd to 4th century AD, more than 20 glass vessels, intact and fragmented, were found. Their description and characteristics are given in a summarizing monograph devoted to the findings of the study of the cemetery (Khrapunov, 2002: 56–57).

From the collection of the cemetery, four samples of glass vessels were analyzed—three cups and a flask. Glass samples No. 1 and 4 are transparent, thin, and colorless (Table 1), No. 2 and 3 have blue and olive tint.

According to the results of the analysis, the glass belongs to the type of soda-lime-silica glass, has a

Fig. 1 . Map of Crimea. Location of the described cemeteries.

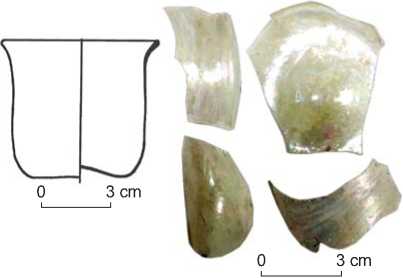

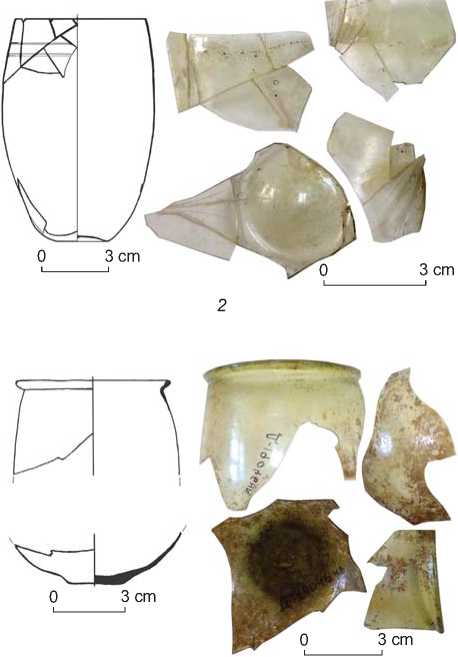

composition typical of glass made on natural soda, in which the content of K2O does not exceed 0.62 %, MgO 0.82 % (boundary value for these oxides is 1.5 % (Scott, Degryse, 2014: 21)). Manganese was used as a bleaching agent (MnO2 content was 1.0– 1.8 %). No impurities of Cu, Co, Sb, and Pb were found. In terms of composition, the olive-tinted glass from which flask No. 3 was made (Fig. 2, 1 ) (see (Khrapunov, 2002: Fig. 89, 2 )) shows a higher content of FeO – ca 1 % (in other samples 0.48– 0.66 %); and blue-tinted glass (sample No. 2) has no significant differences from colorless glass (samples No. 1, 4). Notably, the glass of the second half of the 3rd century AD (No. 4) (Fig. 2, 2 ) (see (Ibid.: Fig. 93, 7 )) differs in chemical composition from the other three vessels in a lower content of Na2O (13.7 and 18.8 %, respectively, Table 2) and Cl (0.8 and 1.24 %), and a higher content of CaO (8.2 and 5.7 %), Al 2 O 3 (2.7 and 2.1 %), MnO (1.8 and 1.2 %). The lower content of sodium oxide may be due to the effect of leaching; however, this fact is usually recorded when analyzing the ground surface, and not the prepared flat-polished sections.

Neyzats cemetery is located in the central part of the sub-mountainous Crimea, on the right bank of the Zuya River, 1 km south of the village Balanovo (see Fig. 1). The site has been known since 1927. Its systematic archaeological research was carried out in 1996–2015 by the expedition of the Taurida National University. During the excavations of the cemetery, more than 150 intact and fragmented glass vessels were found. Their description and characterization are given in several publications (Khrapunov, 2011; Shabanov, 2011).

For microanalysis, 30 samples were selected, dating to the 2nd–4th centuries AD. The sample is dominated by cups of various shapes, which became widespread in the late Roman period in the Crimean piedmont; there are also jugs and a plate. The analyzed glasses are transparent, colorless, of light blue, greenish, olive, and light brown shades.

The analysis has shown that all the glass from the Neyzats cemetery, as well as from the previous one, refers to the soda-lime-silica type, i.e. soda type. The maximum content of K2O in the entire sample is 0.88 % (average 0.50 %), the maximum content of MgO is 1.13 % (average value 0.75 %).

The colorless glass of a cup with a cylindrical body (No. 33) (Fig. 2, 3 ), dated to the 2nd– first half of the 3rd century AD, contains both antimony and manganese (Sb2O5 – 0.89 %, MnO –

Table 1. Fragments of glass vessels from the described Crimean cemeteries

|

Find No. |

Vessel |

Place of discovery, grave No. |

Inv. No. |

Date |

Source |

|

1 |

2 |

3 |

4 |

5 |

6 |

|

Druzhnoe |

|||||

|

1 |

Cup |

3 |

– |

4th century AD |

Khrapunov, 2002: Fig. 71, 16 |

|

2 |

ʺ |

D-4974 |

Ibid.: Fig. 71, 17 |

||

|

3 |

Flask |

18 |

D-5210 |

Ibid.: Fig. 89, 2 |

|

|

4 5 |

Cup Cup |

20 4 |

D-5391 Neyzats D-8253 |

Second half of the 3rd century AD 4th century AD |

Ibid.: Fig. 93, 7 Shabanov, 2011: Fig. 6, 40 |

|

6 |

Jug |

D-8255 |

Ibid.: Fig. 7, 50 |

||

|

7 |

Cup |

15 |

D-8308 |

Ibid.: Fig. 1, 4 |

|

|

8 |

ʺ |

19 |

D-8415 |

Ibid.: Fig. 1, 5 |

|

|

9 |

ʺ |

22 |

D-8455 |

Ibid.: Fig. 1, 8 |

|

|

10 |

ʺ |

D-8457 |

Ibid.: Fig. 4, 32 |

||

|

11 |

ʺ |

D-8490 |

Ibid.: Fig. 1, 7 |

||

|

12 |

ʺ |

33 |

– |

Ibid.: Fig. 3, 19 |

|

|

13 |

ʺ |

115 |

D-10593 |

Ibid.: Fig. 6, 42 |

|

|

14 |

ʺ |

163 |

D-11217 |

Ibid.: Fig. 2, 11 |

|

|

15 |

ʺ |

180 |

KP-51723 А-28251 |

Ibid.: Fig. 2, 12 |

|

|

16 |

ʺ |

200 |

D-11849 |

Ibid.: Fig. 11, 71 |

|

|

17 |

ʺ |

201 |

– |

Ibid.: Fig. 4, 27 |

|

|

18 |

ʺ |

224 |

D-12938 |

Ibid.: Fig. 2, 14 |

|

|

19 |

Jug |

230 |

D-12948 |

Ibid.: Fig. 7, 51 |

|

|

20 |

Cup |

275 |

D-14616 |

Ibid.: Fig. 5, 38 |

|

|

21 |

Jug |

– |

Ibid.: Fig. 8, 56 |

||

|

22 |

Cup |

D-14617 |

Ibid.: Fig. 5, 36 |

||

|

23 |

ʺ |

D-14618 |

Ibid.: Fig. 5, 57 |

||

|

24 |

ʺ |

306 |

D-14848 |

Ibid.: Fig. 2, 16 |

|

|

25 |

ʺ |

D-14855 |

Ibid.: Fig. 4, 28 |

||

|

26 |

Plate |

D-14893 |

Ibid.: Fig. 11, 72 |

||

|

27 |

Cup |

D-14926 |

Ibid.: Fig. 2, 17 |

||

|

28 |

ʺ |

321 |

D-15067 |

Ibid.: Fig. 12, 27 |

|

|

29 |

ʺ |

371 |

D-16319 |

Ibid.: Fig. 1, 1 |

|

|

30 |

ʺ |

485 |

D-18292 |

Ibid.: Fig. 6, 45 |

|

|

31 |

ʺ |

500 |

D-18952 |

Not published (excavations by I.N. Khrapunov, 2012) |

|

|

32 |

ʺ |

510 |

D-19046 |

Second half of the 3rd century AD |

Khrapunov, 2016: Fig. 2, 3 |

|

33 |

ʺ |

584 |

D-20190 |

2nd to first half of the 3rd century AD |

Not published (excavations by I.N. Khrapunov, 2015) |

|

34 |

Cup |

Pit with vessels No. 6 |

D-16391 |

4th century AD |

Shabanov, 2011: Fig. 6, 41 |

Table 1 (end)

|

1 |

2 |

3 |

4 |

5 |

6 |

|

Opushki |

|||||

|

35 |

Cup |

2 |

D-12725 |

4th century AD |

Shabanov, 2020: Fig. 2, 2 |

|

36 |

ʺ |

124 |

D-20530 |

Ibid.: Fig. 2, 1 |

|

|

37 |

? |

190 |

D-22128 |

1st century BC to 1st century AD |

Ibid.: Fig. 1, 4 |

|

38 |

Cup |

253 |

D-22725 |

4th century AD |

Ibid.: Fig. 2, 3 |

|

39 |

ʺ |

260 |

D-22754 |

Ibid.: Fig. 2, 5 |

|

|

40 |

ʺ |

262 |

D-22764 |

Ibid.: Fig. 2, 7 |

|

|

41 |

ʺ |

274 |

D-22799 |

Ibid.: Fig. 2, 4 |

|

|

42 |

ʺ |

D-22797 |

Ibid.: Fig. 2, 9 |

||

|

43 |

Cup |

D-22784 |

Ibid.: Fig. 2, 8 |

||

|

44 |

Bowl |

D-22793 |

Ibid.: Fig. 2, 10 |

||

|

45 |

Cup |

287 |

KP-64079 А-34685 |

Shabanov, 2021: Fig. 4, 1 |

|

|

46 |

Balsamarium |

307 |

– |

2nd to first half of the 3rd century AD |

Not published (excavations by I.N. Khrapunov, 2020) |

0.30 %). These elements are used as glass decolorizers. Studies have shown that in the production of glass only one of the decolorizers was always used; in the raw material collected during excavations and explorations of glass-making centers, two decolorizers have never been recorded together. The presence of both manganese and antimony in colorless glass suggests its modification during secondary production. Such glass is considered to be the result of the wide use of glass waste (Jackson, 2005: 771). In the composition of the glass from which the cup was made (sample No. 33), Al 2 O 3 is 1.90 %, SiO 2 – 67.66, CaO – 5.90, MgO – 0.48, K2O – 0.49, oxides of cobalt, copper, and lead less than 0.01 %.

Glass of a cup with a thickened bottom (No. 32) (Fig. 2, 4 ), dated to the second half of the 3rd centuryAD, was manganese-decolorized (MnO 1.33 %). The reduced content of Na2O (14.17 %) may be the result of leaching. The glass shows a higher content of Al2O3 (2.97 %) and CaO (7.85 %), while oxides of cobalt, copper, lead, and antimony are less than 0.01 %.

Glass vessels dating back to the 4th century AD, according to the chemical composition, can be subdivided into four groups (see Table 2): group 1 is manganese-decolorized glass; group 2 is manganesedecolorized glass, containing an admixture of Cu and Pb; group 3 is antimony-decolorized glass, which often leads to an increase in the average value of Na2O and a decrease in CaO, Al2O3, and other oxides (Schibille,

Sterrett-Krause, Freestone, 2017: 1226, 1230); group 4 is glass containing both Mn and Sb.

Vessels made of glass of group 1 are the most abundant in the total sample—22 specimens out of 30 (No. 6–11, 13–24, 27–29, 31). The average value of MnO is 1.2 %. The content of Na2O in the samples is 14.7–21.0 %. The reduced content of Na, as noted above, may be due to the leaching of samples during weathering. The Na2O content of less than 17 % was found in five samples, which are generally characterized by elevated contents of Al2O3 and CaO, the content of cobalt, copper, lead, and antimony oxides is less than 0.01 %.

Glass of a greenish and olive tint of group 2 is represented by two cups (No. 30, 34) (Shabanov, 2011: Fig. 6, 41 , 45 ). The average value of CuO in it is 0.1 %, PbO – 0.4, Al 2 O 3 – 2.05, SiO 2 – 64.75, CaO – 5.86, the content of cobalt and antimony oxides is less than 0.01 %.

The antimony-decolorized glass from group 3 is also represented by two specimens, including fragments of a large plate (No. 12, 26) (Ibid.: Fig. 3, 19 ; 11, 72 ). The average value of Sb2O5 is 0.6 %, MnO – 0.02, Al 2 O 3 – 1.93, SiO 2 – 66.41, CaO – 6.22, the content of cobalt, copper, and lead oxides is less than 0.01 %.

Group 4 glass was used to make two glass vessels (no. 5, 25) (Ibid.: Fig. 4, 28 ; 6, 40 ). It contains both antimony and manganese in comparable amounts of ca 0.61 %. These vessels were probably manufactured

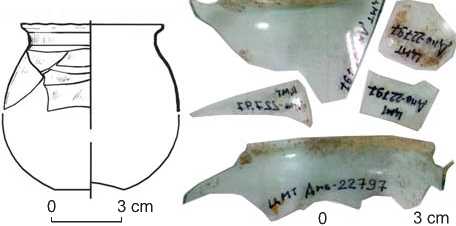

Fig. 2. Fragments of glass vessels.

1 – No. 3; 2 – No. 4; 3 – No. 33; 4 – No. 32; 5 – No. 42.

using glass waste. In glass of group 4, as in glass of group 3, the content of oxides of cobalt, copper, and lead is less than 0.01 %.

Opushki cemetery is located 15 km east of Simferopol, in the central part of the sub-mountainous Crimea (see Fig. 1). The site became famous owing to the destruction by robbers in 2002. Its research has been carried out intermittently since 2003 by the archaeological expedition of the Crimean Federal University. 24 intact and fragmented glass vessels were found at the site. Most of them are described in a special publication (Shabanov, 2020). For analysis, 12 samples were selected, which are mainly cups of various types, a bowl, and two vessels of an indeterminate shape. In their composition, the maximum content of K2O is 0.94 %, (average value 0.63 %), the maximum content of MnO is 0.91 % (average 0.59 %).

In this sample, noteworthy is one specimen—a fragment of the wall of a polychrome glass vessel with a moderately blue ornament, dated to the 1st century BC–

1st century AD, which was made using the “core” technique (No. 37) (Ibid.: Fig. 1, 4 ). In the laboratory, areas of blue transparent glass and light-blue opaque glass were analyzed separately. In both areas, CoO (0.05–0.1 %) and CuO (0.13–0.22 %) admixtures were recorded, giving the glass a blue-light-blue color. The specimen shows a slightly increased (relative to the previously described samples) content of P2O5 (0.1 %) and FeO (1.17–1.28 %). Light-blue opaque glass has a high content of PbO (12.1 %) and Sb2O5 (3.9 %). In the transparent blue glass of the specimen, Sb admixture is absent, Pb is 0.15 %. The presence

Table 2. Averaged chemical composition of glass of the 4th century AD vessels from the described Crimean cemeteries, wt%

Another specimen is a fragment of the lower part of a transparent brown glass balsamarium (No. 46), which is dated to the 2nd–the first half of the 3rd century AD and shows the absence of Co, Cu, Sb, Pb admixtures. The content of iron oxide is 0.31 %, manganese oxide 0.20 %, which can be assessed as low. At the same time, this glass is characterized by an increased content of phosphorus oxide (P2O5) – 0.13 %, Al2O3 – 2.56 %, SiO 2 – 68.48 %, CaO – 7.17 %.

According to the samples of vessels dated to the 4th century AD, two groups of glass can be distinguished (see Table 2): group 1 is manganese-decolorized glass; group 2 is antimony-decolorized glass.

In a sample of products made of group 1 glass (No. 35, 39–45), decolorized with manganese (average MnO content 1.12 %), there is no admixtures of Sb, Co, Cu. Lead was recorded only in the glass of cup No. 42 (PbO content 0.17 %) (see Fig. 2, 5 ) (Ibid.: Fig. 2, 9 ). This specimen shows a low content of sodium oxide (15.85 %) and an increased content of calcium oxide (9.61 %, which is the maximum content among all the analyzed glasses from the three cemeteries).

Group 2 glass (No. 36, 38) contains 0.5–1.1 % Sb2O5, 0.03 % MnO. It is characterized by a reduced content of K2O, CaO, FeO, as well as phosphorus oxide (P2O5); oxides of cobalt, copper, and lead are less than 0.01 %.

Discussion

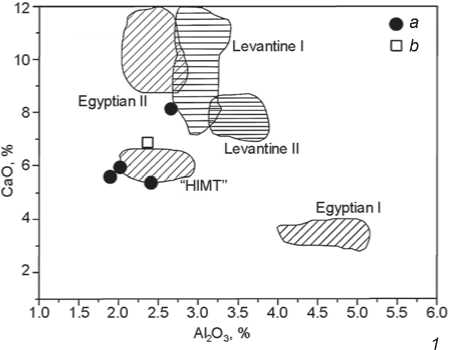

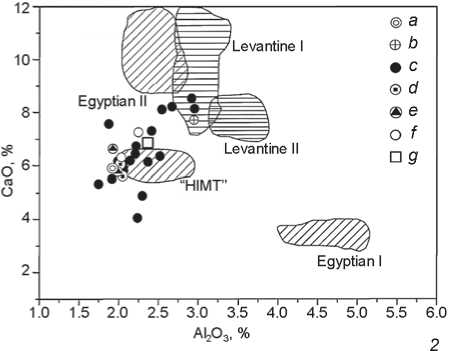

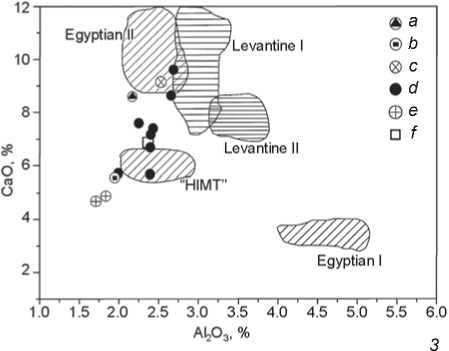

Glass from all the three sites was made on the basis of natural soda, which excludes the possibility of its production in workshops located on the territory of modern Iran, where at that time the ash from saltmarsh plants was used as a raw material. The most probable place for the manufacture of glass for the vessels under study were glass-making centers of the Syro-Palestinian area, northern Egypt, and Sinai. This is evidenced by the chemical composition of the analyzed samples. They belong to three groups of soda glass common in the 1st millennium AD on the territory of Europe and the Eastern Mediterranean: Levantine I, “HIMT” (“high iron, manganese, titan”), and “Roman” glass of the 1st–3rd centuries AD (Fig. 3) (Rumyantseva, 2015: 29).

The Levantine I group consists of the products of glass-making centers of the Levant dating back to the 4th–7th centuries AD. It includes one vessel from Druzhnoe, two from Opushki, and five from the Neyzats cemetery. All the vessels were found in burial complexes of the 4th century AD; this is the time of distribution of Levantine glass products.

Fig. 3. The main groups of soda glass of the 1st millennium AD (after (Drauschke, Greiff, 2010: Fig. 9)), and the ratio of calcium and aluminum oxides in the samples from Druzhnoe ( 1 ), Neyzats ( 2 ), and Opushki ( 3 ).

1 : a – 4th century AD, b – “Roman” glass of the 1st–3rd centuries AD; 2 : a – 2nd to first half of the 3rd century AD, b – second half of the 3rd century AD, c – group 1 (4th century AD), d – group 2 (4th century AD), e – group 3 (4th century AD), f – group 4 (4th century AD), g – “Roman” glass of the 1st–3rd centuries AD;

3 : a – blue glass (1st century BC to 1st century AD), b – blue glass (1st century BC to 1st century AD), c – second half of the 3rd century AD, d – group 1 (4th century AD), e – group 2 (4th century AD), f – “Roman” glass (1st–3rd centuries AD).

Most of the vessels from Neyzats (about 70 %) are probably made of glass of the “HIMT” group, which became widespread in Europe since the 4th century AD. The abundance of products made from this glass is explained, on the one hand, by a spike in the mass production of glassware ca 350 AD, changes in the quality of raw materials, technical features of the manufacture of glass products (Foster, Jackson, 2009: 194–195; Nenna, 2014: 186), and on the other hand, by the process of political instability in the empire, its collapse, which led to a change in the raw material base and, consequently, to the replacement of the chemical composition of glass (Nakai et al., 2014: 240). Researchers admit the possibility of competition between glass producers of the Levantine I and “HIMT” groups, in which the former apparently were losing (Nenna, 2014: 186).

The “HIMT” group was identified in the 1990s by the samples from Carthage and Aosta in northern Italy. In the 2000s, the collection was replenished with finds from the territory of France, Great Britain, Holland, Egypt, Cyprus, etc. (Ibid.: 177, 179). The glass of this group is characterized by a yellowish or olive color, a high concentration of Pb, Mn, and Ti. Unfortunately, it has not yet been possible to determine exactly where the glass of the “HIMT” group was made, but given the high concentration of Ti in its composition, which is a “stable characteristic” of the sands of northern Egypt and the Nile delta (Rumyantseva, 2015: 39), it can be assumed that it was Egypt.

The group of the so-called Roman glass of the 1st–3rd centuries AD consists of vessels of green-blue glass, quite homogeneous in chemical composition. It was manufactured with the use of manganese as decolorizer, although the admixtures of antimony found in the samples suggest the use of glass waste. In the search for a source of raw material for the workshops involved in the manufacture of glass of this group, the researchers raised questions about its homogeneous composition. The “Roman” glass was first believed to have appeared on the Levantine coast, but in the course of additional isotope analyses it was found out that such production centers could have been in the Western Mediterranean and Northwestern Europe

(Degryse, Schneider, 2008: 1998; Rumyantseva, 2015: 40–41). In the sample of glass vessels considered in this article, this group probably includes nine vessels from the cemeteries of Neyzats and Opushki, but none from Druzhnoe, which can be explained by the small number of vessels from this site. In the Opushki cemetery, “Roman” glass finds make up the majority of the analyzed vessels (almost equal in number to the vessels of the “HIMT” group). Apparently, this should be explained by the still small number of glass vessels from the 4th century AD complexes found at this cemetery.

Conclusions

The results of X-ray spectral microanalysis showed that the composition of glass of 46 vessels from the cemeteries of Druzhnoe, Neyzats, and Opushki, located in the sub-mountainous Crimea, corresponds to the main groups of glass that were distributed on the territory of the Roman empire and its periphery in the first centuries of the new era. The most likely place for the manufacture of glass for the vessels discussed in this paper can be considered the glassmaking centers of the Syro-Palestinian area, northern Egypt, and Sinai. The analyses showed a high degree of consistency in the composition of glass from all the three cemeteries. Consequently, glassware came to people who made burials in the Crimean piedmont from the same workshops. The absence of fragments of “Roman” glass among the analyzed samples from Druzhnoe is probably due to the small number of the studied vessels from this necropolis.

Glassware, like other finds from barbarian burial grounds, is the evidence of close contacts between the Northern Black Sea region and other territories of the ancient world. Most likely, barbarians of the Crimean piedmont got the glass products not directly from the manufacturing centers, but through the Bosporan Kingdom and Chersonese. However, this can be asserted after obtaining the results of X-ray spectral microanalysis of composition of the glass from which the vessels found on the territory of the Bosporus and Chersonese states were made. A deep study of these findings will make it possible to identify common features and peculiarities in the chemical composition of certain categories and types of glass vessels; and the full introduction of all analyses into general circulation will ensure their use in solving problems of the origin and distribution of glass in the 1st millennium AD.

Acknowledgments

This study was supported by the Russian Foundation for Basic Research, Project No. 19-59-23001 “Population of the Crimean Mountains and the Hungarian Lowland in the Roman Period: Migrations and Contacts”.

Список литературы The Chemical Analysis of Glass Samples from Roman Era Cemeteries in the Crimean Piedmont

- Degryse P., Ganio M., Boyen S., Blomme A., Scott B., Brems D., Carremans M., Honings J., Fenn T., Cattin F. 2014 Primary glass factories around the Mediterranean. In Glass Making in the Greco-Roman World. Results of the “ARCHGLASS” Project. Leuve: Leuven Univ. Press, pp. 97-112.

- Degryse P., Schneider J. 2008 Pliny the Elder and Sr-Nd isotopes: Tracing the provenance of raw materials for Roman glass production. Journal of Archaeological Sciences, vol. 35 (7): 1993-2000.

- Devulder V., Degryse P. 2014 The sources of natron. In Glass Making in the Greco-Roman World. Results of the “ARCHGLASS” Project. Leuve: Leuven Univ. Press, pp. 87-95.

- Drauschke J., Greiff S. 2010 Chemical aspects of Byzantine glass from Carič in Grad/ Iustiniana Prima (Serbia). In Glass in Byzantium - Production, Usage, Analyses. Mainz: Verl. des Römisch-Germanischen Zentralmuseums, pp. 25-46.

- Foster H.E., Jackson C.M. 2009 The composition of “naturally coloured” late Roman vessel glass from Britain and the implications for models of glass production and supply. Journal of Archaeological Science, vol. 36 (1): 189-204.

- Jackson C.M. 2005 Making colourless glass in the Roman period. Archaeometry, vol. 47 (4): 763-780.

- Khrapunov I.N. 2002 Mogilnik Druzhnoe (III-IV vv. nashey ery). Lyublin: Wydawnictwo Uniwersytetu Marii Curie-Skłodowskiej. (Monumenta Studia Gothica; [vol.] 2).

- Khrapunov I.N. 2011 Nekotoriye itogi issledovaniy mogilnika Neizats. In Issledovaniye mogilnika Neizats. Simferopol: Dolya, pp. 13-113.

- Khrapunov I.N. 2016 Dve podboiniye mogily III v. n.e. iz nekropolya Neizats (Krym). Rossiyskaya arkheologiya, No. 2: 132-149. Nakai I., Matsuzaki M., Sawamura D., Abe Y.,

- Schachner A. 2014 Chemical characterization of Roman and Early Byzantine glass from Boğazköy/Ḫattuša and its vicinity. Istanbuler Mitteilungen, Bd. 64: 237-260.

- Nenna M.D. 2014 Egyptian glass abroad: HIMT glass and its markets. In Neighbours and Successors of Rome. Traditions of Glass Production and Use in Europe and the Middle East in the Later 1st Millennium AD. Oxford: Oxbow Books, pp. 177-193.

- Rumyantseva O.S. 2011 Steklodelatelnoye proizvodstvo v rimskoye vremya i epokhu rannego Srednevekovya: Istochniki, fakty, gipotezy. Rossiyskaya arkheologiya, No. 3: 86-97.

- Rumyantseva O.S. 2015 Steklo I tys. n.e.: Proiskhozhdeniye i rasprostraneniye po dannym khimicheskogo analiza. KSIA, iss. 237: 20-49.

- Rumyantseva O.S., Trifonov A.A. 2021 Pityevoy rog i shpory iz pogrebeniya 28 mogilnika Skalistoye III v Yugo-Zapadnom Krymu: Sostav stekla i emali i danniye o proiskhozhdenii. In Istoriya i arkheologiya Kryma, iss. XIV. Simferopol: [s.n.], pp. 57-70.

- Schibille N., Sterrett-Krause A., Freestone I.C. 2017 Glass groups, glass supply and recycling in late Roman Carthage. Archaeological and Anthropological Sciences, vol. 9 (6): 1223-1241.

- Scott R.B., Degryse P. 2014 The archaeology and archaeometry of natron glass making. In Glass Making in the Greco-Roman World. Results of the “ARCHGLASS” Project. Leuve: Leuven Univ. Press, pp. 15-26.

- Shabanov S.B. 2011 Steklyanniye sosudy iz mogilnika Neizats (po materialam raskopok 1996-2011 gg.). Materialy po arkheologii, istorii i etnografi i Tavrii, iss. XVII: 141-191.

- Shabanov S.B. 2020 Steklyanniye sosudy rimskogo vremeni iz mogilnika Opushki v Krymu (po materialam raskopok 2003-2019 gg.). Problemy istorii, fi lologii, kultury, No. 2: 110-134.

- Shabanov S.B. 2021 Sklep IV v. n.e. iz mogilnika Opushki v Krymu. Problemy istorii, fi lologii, kultury, No. 4: 121-136.