The control of rheological behaviour for 3D-printable building mixtures: experimental evaluation of «nano» tools prospects

Автор: Slavcheva G.S., Artamonova O.V.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Study of properties of nanomaterials

Статья в выпуске: 3 Vol.11, 2019 года.

Бесплатный доступ

The extrudability and firm stability are the criteria rheological characteristics of building 3D printable mixtures. This paper presents the results of experimental studies of the rheological behaviour of fresh cement pastes as matrices for 3D printable mixtures. The squeezing test, with constant plate speed, has been used for determination plasticity of cement pastes as criteria of their extrudability. As a result, the typical rheological models of the fresh cement pastes have been identified. In addition, the value of plastic yield stress was evaluated as criteria for the extrusion process. The squeezing test, with constant strain rate, has been used for determination structural and plastic strength, plastic deformations as criteria for the ability of a 3D printable mixture to hold shape during multi-layer casting. It is shown that these properties are significantly controlled by the plasticizer and viscosity modifying additives as factors of changes of disperse system «cement + water» properties. It is established that electrolytes, nanodispersed adsorption-active inorganic modifying additives increase the plasticity of the fresh cement pastes. At the same time, the nanodispersed adsorption-active inorganic modifying additives develop plastic strength as criteria of firm stability. The introduction of inorganic polymers, inert to cement, improves the structural strength of fresh cement pastes but significantly reduces their plasticity. It is shown that the management of rheological behaviour of 3D printable mixtures should be based only by the complex using of chemical addi-tives such as electrolytes, plasticizers and nanodispersed inorganic viscosity modifying additives.

3D-printable building mixtures disperse systems, rheological behaviour, addictives

Короткий адрес: https://sciup.org/142227494

IDR: 142227494 | УДК: 666.9.03 | DOI: 10.15828/2075-8545-2019-11-3-325-334

Текст научной статьи The control of rheological behaviour for 3D-printable building mixtures: experimental evaluation of «nano» tools prospects

В общем семействе инновационных 3D аддитивных процессов роботизированного создания строительных объектов в настоящее время доведен до стадии промышленного внедрения метод 3D-печати как наиболее приемлемый для практики строительства. Строительная 3D-печать включает стадии приготовления вязкопластичной смеси, транспортирования ее из смесителя в экструдер, экс-трудирование, послойную укладку, твердение напечатанных слоев. Общепризнано, что эффективность и технологичность строительной 3D-печати определяется совокупностью критериальных характеристик смесей: пластичностью для реализации процесса экструзии (extrudability), формоустойчивостью при укладке слоев (buildability), скоростью структуро-образования и твердения (structural build-up) [1–5].

В результате накопления массива экспериментальной информации, например [7–13], получена и апробирована достаточная большая номенклатура смесей. Анализ работ показывает, что для строительной 3D-печати используют две группы смесей: грубодисперсные (размер частиц d > 100 мкм) и ми-кродисперсные (размер частиц d ~ 1÷100 мкм). Полученные смеси характеризуются многокомпонент-ностью, в их составах одновременно используются суперпластификаторы, модификаторы вязкости, регуляторы структурообразования, наполнители и заполнители различного химико-минералогического состава и дисперсности. Однако в настоящее время однозначно не выявлено влияние свойств и концентрации используемых компонентов смесей на их реологическое поведение в условиях 3D-печати.

Авторский подход к моделированию и управлению реологическим поведением вязко-пластичных смесей в процессах 3D-печати и оптимизации их составов основан на положениях структурной реологии дисперсных систем, приоритет теоретического обоснования которых принадлежит советской школе физико-химической механики [14–16]. Исходя из этого, нами в работе [17] обоснованы основные средства управления реологическим поведением вязкопластичных смесей, рассматриваемых как гетерогенные системы «дисперсная фаза + дисперсионная среда». Авторами экспериментально установлено [18–19], что концентрация дисперсной фазы в дисперсионной среде (В/Т-отношение в системе) является определяющим фактором регулирования пластичности и структурной устойчивости смесей. При этом оптимальные значения концентрации дисперсной фазы с определенным компонентным составом для каждой конкретной дисперсной системы в значительной мере определяются характеристиками дисперсионной среды. Показано, что по отношению к дисперсионной среде факторами управления реологией вязкопластичных смесей являются ионный состав, вязкость, плотность дисперсионной среды. В качестве средств их регулирования предложено варьировать виды и дозировки трех групп добавок: электролитов, пластификаторов и модификаторов вязкости как средств из арсенала «нано» [17]. В соответствии с нанотехнологическими принципами «сверху – вниз» и «снизу – вверх»при введении добавок электролитов и ПАВ происходит изменение состояния поверхности твердых частиц дисперсной фазы. Введение добавок-модификаторов вязкости и наномодификаторов определяет изменение пространственно–геометрической и энергетической обстановки в конденсационном объеме дисперсной системы.

Данная статья посвящена обсуждению результатов системной экспериментальной оценки эффективности влияния добавок-модификаторов вязкости на комплекс реологических характеристик модельных цементных систем, рассматриваемых в качестве матриц смесей для 3D-печати.

ОСНОВНАЯ ЧАСТЬ

Методика исследований

Исследовались 5 типов цементных систем (табл. 1). В качестве исходных компонентов систем использовали портландцемент ЦEM I 42,5Н (ГОСТ 31108-2016), суперпластификатор (СП) торговой марки Sika, добавки-модификаторы вязкости, техническую воду. Концентрация добавок и величины В/Ц в исследованных системах оптимизированы по результатам предыдущего этапа исследований [18–19]. Для оценки реологического поведения вязко-пластичных смесей использованы методы сдавливающей реометрии (squeeze flow rheometry) как инструмента моделирования реологического поведения и идентификации реологических характеристик вязко-пластичных смесей применительно к условиям 3D-печати [1–5]. При реализации экспериментов для сдавливающих тестов использовались цилиндрические образцы цементного теста, радиус которых R был равен их высоте h0 = 25 мм. Испытание проводилось непосредственно после изготовления цементного теста. Для проведения сдавливающих тестов образец помещался между двумя гладкими пластинами, диаметр которых соответствовал размеру образца, и загружался в универсальную напольную гидравлическую испытательную систему «INSTRON Sates 1500 HDS». Для оценки пластичности смесей, определяющей их экструдируемость, реализован сдавливающий тест с постоянной скоростью деформирования ν = 5 мм/c в соответствии с методикой,

STUDY OF PROPERTIES OF NANOMATERIALS • ИССЛЕДОВАНИЕ СВОЙСТВ НАНОМАТЕРИАЛОВ

Таблица 1

Характеристика составов смесей

Полученные в процессе испытаний кривые «нагрузка N-перемещение ∆» интерпретировались в виде кривых зависимости приведенной нагрузки F* от относительного изменения высоты образца hi/R.

Fi* = Phi/ πR2, (1)

где hi = (h0 –∆), h0 – начальная высота образца, ∆ – перемещение в i-тый момент времени, величина R принималась постоянной и равной радиусу образца в начале испытания.

В первой точке перегиба полученных экспериментальных кривых рассчитывались величина оценки предела пластичности Ki(I) (plastic yield value [3]):

Ki (h/R) = √3F*/2. (2)

Для оценки формоустойчивости проводился сдавливающий тест с постоянной скоростью нагружения ν = 0,5 Н/c, методика проведения обосно- вана нами [19] на основании подходов [5] к оценке формоустойчивости смесей от последовательно нарастающего давления в процессе послойной 3D-печати. При проведении испытаний сдавливание производилось до разрушения образцов, в процессе опытов фиксировались кривые «перемещение ∆ – время t»,«нагрузка N-перемещение ∆». По полученным экспериментальным кривым рассчитывались значения структурной прочности цементных систем в моменты, соответствующие началу деформирования и началу трещинообразования образцов по формуле:

σ = P/πR2. (3)

В результате пластичность и устойчивость смесей в условиях, моделирующих действие сжимающих напряжений при экструзии и послойной укладке, оценивались согласно критериям, обоснованным нами в работе [19]:

– оценка предела пластичности Ki(I),

– структурная прочность σ0 в момент начала деформирования, характеризует способность си-

STUDY OF PROPERTIES OF NANOMATERIALS • ИССЛЕДОВАНИЕ СВОЙСТВ НАНОМАТЕРИАЛОВ стемы сопротивляться деформированию при нагружении,

– пластическая прочность σpl и величина относительных пластических деформаций ∆pl в момент начала трещинообразования, характеризующие способность системы деформироваться без разрушения.

Результаты экспериментальных исследований

Сдавливающий тест с постоянной скоростью деформирования и пластическое поведение цементных систем

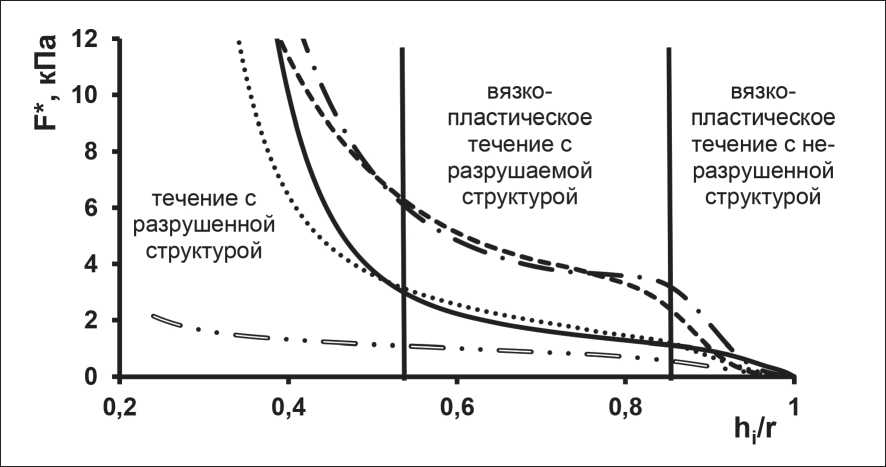

Установлено, что при действии низких сжимающих напряжений структура вязкопластичных смесей сохраняет устойчивость («placing phase» [3]) – первый участок экспериментальных кривых F* = f(hi/R) (рис. 1). Сопоставление кривых F* = f(hi/R) с классической реологической кривой П.А. Ребиндера [14] позволяет соотнести этот участок с пластическим течением дисперсной системы с неразрушенной структурой. При возрастании напряжений на втором участке система пластически деформируется, а ее структура теряет устойчивость («perfect response phase» [3]).

Данный участок можно соотнести с вязкопластическим течением с интенсивно разрушаемой структурой на кривой П.А. Ребиндера.

Резкое возрастание нагрузки и интенсификация течения на третьем участке связаны с полным разрушением структуры дисперсной системы «цемент + вода».

Полученные экспериментальные F* = f(hi/R) кривые можно разделить на три типа. Первый тип имеет выраженный горизонтальный участок пластического деформирования между двумя точками перегиба (система Ц–В–СП–К). Для данной системы пластическое течение без разрушения структуры возможно в узком диапазоне действия сдавливающих напряжений F* = ∼ 3,3÷4,0 кПа, значение оценки предела пластичности Ki(I) составляет 2,75 кПа (табл. 2).

Поэтому системы с таким типом реологического поведения недостаточно пластичны для экструзии без разрушения их структуры. Для второго типа кривых не фиксируются ярко выраженные переходы между участками кривой (системы Ц–В–СП, Ц–В–СП–ПФК, Ц–В–СП–МК), значения оценки предела пластичности Ki(I) находятся в диапазоне 0,95÷1,28 кПа.

Такие системы обладают наилучшей способностью к экструзии, вследствие их способности к вязкопластическому течению без разрушения структуры в диапазоне сдавливающих напряжений F ∼ 2,0÷4,0 кПа. Третий тип кривой характерен для систем, структура которых необратимо разрушается в начальный момент нагружения при F* < 0,5 кПа (система Ц–В–СП–М). В результате они теряют

Рис. 1. Кривые зависимости приведенной нагрузки F* от относительного изменения высоты образца hi/R для образцов цементного теста в процессе испытаний на сдавливание с постоянной скоростью деформирования. Обозначено: ____ Ц–В–СП; ..... Ц–В–СП–ПФК; __ . Ц–В–СП–К; _ _ _ Ц–В–СП–МК;

= .. = Ц–В–СП–М

STUDY OF PROPERTIES OF NANOMATERIALS • ИССЛЕДОВАНИЕ СВОЙСТВ НАНОМАТЕРИАЛОВ

Таблица 2

Реологические характеристики цементных систем

Сдавливающий тест с постоянной скоростью нагружения и формоустойчивостью

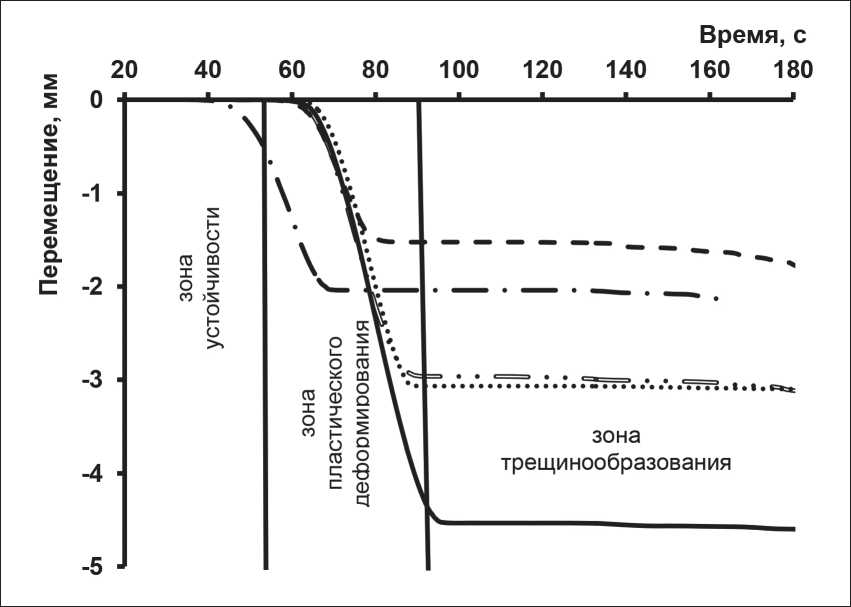

Анализ полученных экспериментальных кривых «∆–t» (рис. 2) показывает, что на них выделяются 3 характерных участка.

Первый участок характеризуется отсутствием деформаций при действии нагрузки. Второй участок – это участок пластического деформирования. Третий участок – это участок микротрещинообразования, предшествующий разрушению структуры.

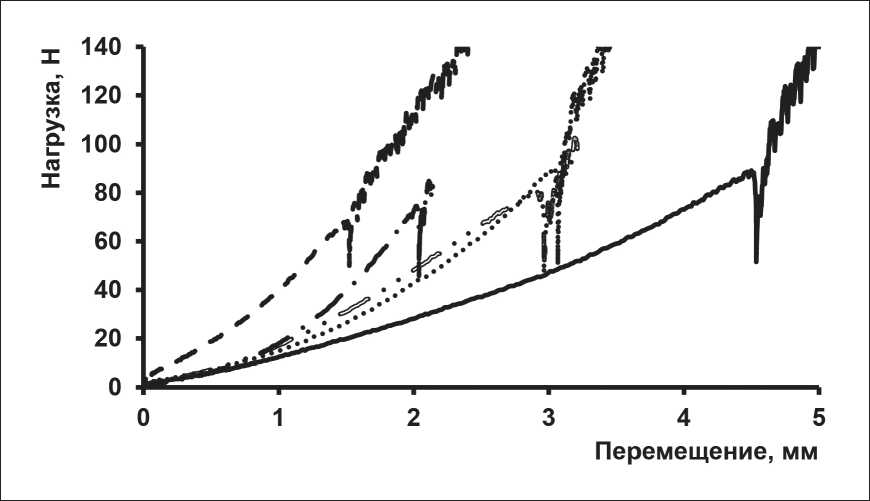

На экспериментальных кривых «N–∆» (рис. 3) момент появления микротрещин однозначно фиксируется пиком резкого падения нагрузки.

Для систем с камедью и метакаолином Ц–В– СП–К и Ц–В–СП–МК характерно наличие мно-

Рис. 2. Кривые «перемещение ∆ – время t» для образцов цементного теста в процессе испытаний на сдавливание с постоянной скоростью нагружения. Обозначено: ____ Ц–В–СП; ..... Ц–В–СП–ПФК;

__ . Ц–В–СП–К; _ _ _ Ц–В–СП–МК; = .. = Ц–В–СП–М

STUDY OF PROPERTIES OF NANOMATERIALS • ИССЛЕДОВАНИЕ СВОЙСТВ НАНОМАТЕРИАЛОВ

Рис. 3. Кривые «нагрузка N – перемещение ∆» для образцов цементного теста в процессе испытаний на сдавливание с постоянной скоростью нагружения. Обозначено: ____ Ц–В–СП; ..... Ц–В–СП–ПФК;

__ . Ц–В–СП–К; _ _ _ Ц–В–СП–МК; = .. = Ц–В–СП–М

жественных пиков колебаний нагрузки на кривых «N–∆» (рис. 3), свидетельствующих о наличии довольно длительного промежутка между моментом появления первых микротрещин и разрушением. Для этих систем характерна самая высокая структурная прочность σ0 и минимальные пластические деформации (см. рис. 2, 3 , табл. 2), наименьшие значения пластической прочности σpl, то есть они лучше всего способны сопротивляться деформированию при нагружении. При введении пирофосфата калия и мела (системы Ц–В–СП–ПФК и Ц–В–СП–М) не зафиксировано существенного изменения структурной и пластической прочности, но в 2 раза возрастает величина пластических деформаций по сравнению с эталонной системой Ц–В–СП без модификаторов вязкости.

ОБСУЖДЕНИЕ РЕЗУЛЬТАТОВ

Введение ПАВ и модификаторов вязкости различной природы в гетерогенно-дисперсную систему «цемент + вода» влияет на поверхностные явления на границе раздела фаз и молекулярные взаимодействия между твердыми частицами. Так, ранее было установлено [21], что при введении суперпластификаторов в соответствии с нанотехнологическим принципом «сверху – вниз» изменяется состояние поверхности твердых частиц дисперсной фазы. Достигаемое снижение энергии взаимодействия частиц цемента способствует нарастанию пластичности си- стемы и переход ее в текучее состояние при низких значениях приведенной нагрузки F* (см. рис.1, система Ц–В–СП).

Добавки пирофосфата калия, метакаолина и мела, действуя в соответствии с нанотехнологическим принципом «снизу – вверх», изменяют пространственно–геометрическую и энергетическую обстановку в конденсационном объеме дисперсной системы. Пирофосфат калия в комплексе с СП еще более пластифицирует систему за счет участия его в обменных химических реакциях с частицами дисперсионной фазой. Его анионная составляющая взаимодействует с фазами цементного клинкера с образованием труднорастворимых солей гидратов, а катионная составляющая сохраняется в жидкой фазе, повышая щелочность среды и ионную силу раствора, что повышает текучесть системы Ц–В– СП–ПФК. Частицы метакаолина и мела способны к формированию полимолекулярных слоев адсорбированной воды на их развитой и активной поверхности. Поэтому при их введении происходит снижение энергии взаимодействия частиц цемента за счет наличия в межзерновом объеме частиц, покрытых толстыми слоями адсорбированной воды. В результате это способствует нарастанию пластичности системы. Рост структурной прочности вязко-пластичной системы Ц–В–СП–МК может быть обусловлен структурирующим действием наночастиц метакаолина на дисперсионную среду. При ведении мела потеря устойчивости и повышение текучести

STUDY OF PROPERTIES OF NANOMATERIALS • ИССЛЕДОВАНИЕ СВОЙСТВ НАНОМАТЕРИАЛОВ системы Ц–В–СП–М связаны с тем, что размер частиц мела значительно превышает критический размер частиц для данной гетерогенной дисперсной системы, приводя к агломерации частиц и потере агрегативной устойчивости. Камедь является инертным компонентном по отношению к дисперсной фазе. В соответствии с нанотехнологическим принципом «сверху – вниз» данная добавка влияет только на свойства дисперсионной среды, повышая ее плотность и вязкость. В итоге увеличивается структурная прочность системы, но в силу структурирования жидкой фазы резко понижается ее пластичность, повышается жесткость и формоустойчивость.

ЗАКЛЮЧЕНИЕ

Прикладные инженерные решения по управлению реологией смесей для 3D-печати могут быть основаны на комплексном использовании хими- ческих добавок электролитов, пластификаторов и модификаторов вязкости как средств из арсенала «нано». Применение электролитов, ультрадисперс-ных адсорбционно-активных неорганических модификаторов, изменяющих ионную силу раствора и пространственно–геометрическую и энергетическую обстановку в конденсационном объеме дисперсной системы, является фактором повышения пластичности цементных систем. Введение неорганических модификаторов наноразмерного диапазона дисперсности способствует одновременно повышению структурной прочности и, соответственно, формоустойчивости цементных систем к действию нагрузки в процессе печати конструкций. Введение инертных по отношению к цементу неорганических полимеров, изменяющих плотность и вязкость дисперсионной среды, позволяет повысить структурную прочность смесей, но существенно снижает их пластичность.

Список литературы The control of rheological behaviour for 3D-printable building mixtures: experimental evaluation of «nano» tools prospects

- Engmann J., Servais C., Burbidge A.S. Squeeze flow theory and applications to rheometry: A review // Journal of Non- Newtonian Fluid Mechanics. – 2005. – 132(1–3). – Pp. 1–27.

- Russel N., Lanos C. Plastic Fluid Flow Parameters Identification Using a Simple Squeezing Test // Applied Rheology. – 2003. – 13(3). – Pp. 3 – 5.

- Toutou Z., Roussel N., Lanos C. The squeezing test: A tool to identify firm cement-based material’s rheological behaviour and evaluate their extrusion ability // Cement and Concrete Re-search. – 2005. – 35(10). – Pp. 1891–1899.

- Perrot A., Mélinge Y., Rangeard D., et al.Use of ram extruder as a combined rheo-tribometer to study the behaviour of high yield stress fluids at low strain rate // Rheologica Acta. Springer Verlag. – 2012. – 51(8). – Pp. 743–754.

- Perrot A., Rangeard D., Pierre A. Structural built-up of cement-based materials used for 3D-printing extrusion techniques // Materials and Structures. – 2016. – 49. – Pp. 1213–1220.

- Shakor P., Sanjayan J., Nazari A., et al.Modified 3D printed powder to cement-based mate-rial and mechanical properties of cement scaffold used in 3D printing // Construction and Building Materials. – 2017. – V. 138. – Pp. 398–409.

- Tay Y.W., Panda B, Chandra S., et al. Processing and Properties of Construction Materials for 3D Printing // Materials Science Forum. – 2016. – V. 861. – Pp. 177–181.

- Paul S.C., Tay Y.W.D., Panda B., et al. Fresh and hardened properties of 3D printable cementitious materials for building and construction // Archives of Civil and Mechanical Engineering. – 2018. – 18(1). – Pp. 311–319.

- Ngo T.D., Kashani A., Imbalzano G., et al. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges // Composites Part B: Engineering. – 2018. – V. 143. – Рр. 103–110.

- Weng Y., Li M., Qian S., et al. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model // Construction and Building Materials. – 2018. – V. 163. – Pр. 600–610.

- Malaeb Z., Hachem H., Tourbah A., et al. 3D Concrete Printing: Machine and Mix Design // International Journal of Civil Engineering and Technology. – 2015. – 6(4). – Pp. 14–22.

- Kazemian A., Yuan X., Cochran E., et al. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture // Construction and Building Materials. – 2017. – V. 145. – Pp. 639–647.

- Le T.T., Austin S.A., Lim S., et al. Mix design and fresh properties for high-performance printing concrete // Materials and Structures. – 2012. – 45(8). – Pp. 1221–1232.

- Rebinder P.A. Selected works. Surface phenomena in disperse systems. Physico-chemical mechanics. – Moscow: Ed. The science, 1979. – 381 с. (In Russian).

- Uryev N.B. Physico-chemical dynamics of structured nanodispersed systems and nanodispersed composite materials. Part 1 // Physicochemistry of the surface and protection of ma-terials. – 2010. – Vol. 46, № 1. – С. 3–23. (In Russian).

- Uryev N.B. Highly concentrated disperse systems. – Moscow: Ed. Chemistry, 1980. – 319 с. (In Russian).

- Slavcheva G.S., Artamonova O.V. The rheological behavior of disperse systems for 3D print-ing in constrcution: the problem of control and possibility of «nano» tools application. Nanotehnologii v stroitel’stve = Nanotechnologies in Construction. 2018, Vol. 10, no. 3, pp. 107–122. DOI: 10.15828/2075-8545-2018-10-3-107-122. (In Russian).

- Slavcheva G.S., Artamonova O.V. Rheological behavior of 3D printable cement paste: criterial evaluation // Magazine of Civil Engineering. – 2018. – 08(84). – Pp. 97–108.

- Slavcheva G.S., Shvedova M.A., Babenko D.S. Analysis and criterial evaluation of the rheological behavior of mixtures for construction 3D-printing // Stroitel’nyeMaterialy. – 2018. – 12. – Pp. 34–40. (In Russian).