The effect of fiber activation on the surface properties of a photocatalytic composite material based on it

Автор: Strokova V.V., Nerovnaya S.V., Ogurtsova Y.N., Gubareva E.N.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The study of the properties of nanomaterials

Статья в выпуске: 4 Vol.16, 2024 года.

Бесплатный доступ

Introduction. The active development of construction technologies entails the need to improve the properties of traditional materials, including giving them specific functional characteristics such as photocatalytic activity. One of the promising methods for solving this problem is the introduction of specialized additives into standard building mixes, which include photocatalytic composite materials. Within the framework of this article, the influence of various methods of fiber activation on the surface properties of a photocatalytic composite material created on its basis is considered. Materials and research methods. The effect of pre-activation of basalt (BF), glass (GF) and glass alkali-resistant (GAF) fibers on the surface properties of photocatalytic composite materials (PCM) based on them has been studied. The activation of the fiber surface consisted in thermal (T) and chemical (AA) treatment. The research methodology included: analysis of changes in the concentration of active centers of Brensted acids on the fiber surface before and after activation of their surface, after direct deposition of titanium dioxide on the obtained samples of various types of fibers, followed by an assessment of morphological changes. Results and discussions. The following growth trend has been established for the total number of active centers for PCM: PCM(BF+Т) → PCM(GF+AA) → PCM(BF+AA) → PCM(GAF+AA) → PCM(GF) → PCM(GAF+Т) → PCM(GAF) → PCM(GF+Т) → PCM(BF). According to the results of scanning electron microscopy, it was found that PCM(GF) and PCM(GAF+T) are characterized by a more uniform distribution of titanium dioxide particles over the entire surface of the fiber, creating a film-like appearance, unlike samples of PCM(BF) and PCM(GF), as well as PCM(GAF+AA), on which titanium dioxide particles are unevenly distributed, forming growths or aggregates. The analysis showed that sol-gel deposition of titanium dioxide has a significant effect on the properties of the fiber surface, which may affect the physical and mechanical characteristics of composites and their ability to self-clean, and should be taken into account when developing new functional materials with photocatalytic properties. Conclusion. The results obtained made it possible to evaluate the effectiveness of activation of the fiber surface for subsequent use as a substrate in the composition of photocatalytic composite materials.

Fiber, surface activation, active centers of Brensted acids, titanium

Короткий адрес: https://sciup.org/142242261

IDR: 142242261 | DOI: 10.15828/2075-8545-2024-16-4-329-341

Текст научной статьи The effect of fiber activation on the surface properties of a photocatalytic composite material based on it

Original article

Plaster materials play a key role in modern construction, providing not only aesthetic design of buildings, but also protection of their surfaces from atmospheric influences, moisture and mechanical damage. However, due to the high requirements for the functional characteristics of such materials, in recent years more and more attention has been paid to the development of innovative formulations with additional properties such as self-cleaning, protection from UV radiation, antibacterial properties, etc. [1, 2].

One of the promising directions in this field is the creation of plaster mixtures with self-cleaning properties due to the use of initiators of photocatalytic decomposition of pollutants in their composition. Photocatalytic materials

THE STUDY OF THE PROPERTIES OF NANOMATERIALS capable of decomposing organic pollutants and improving air quality are becoming increasingly in demand in the construction industry, especially in urban environments, where environmental problems and environmental pollution are more relevant than ever. However, the use of a “pure” photocatalytic material in the form of a nanoscale anatase in the composition of a plaster mixture has a number of technological problems, including difficulties with the uniform distribution of the additive, its effect on hydration processes and deterioration of the physical and mechanical properties of the material. The solution to these problems lies in the use of photocatalytic composite materials (PCM), which is a more effective way to ensure the self-cleaning properties of building materials both in terms of photocatalytic activity and in terms of achieving improved physical and mechanical characteristics and durability.

In previous studies [3–6], the possibility of obtaining photocatalytic composite materials using various natural and man-made silica materials as a substrate for nanoscale anatase formed during sol-gel deposition of titanium compounds with subsequent heat treatment was considered. These materials included sedimentary organogenic and chemogenic rocks, as well as man-made pozzolans, such as pyrogenic waste – microsilica. Synthesis and deposition in the sol-gel process allows titanium dioxide to be evenly distributed on the substrate surface, creating a functional photocatalytically active layer with certain acid-base characteristics. The use of a photocatalytic composite material (PCM) of “the silica component (core) – anatase (shell)” system in cement-based building composites demonstrates high efficiency due to the synergy of the Pozzolanic reaction and photocatalytic activity.

In the development of PCM, the selection and characterization of raw materials that act as carriers of the photocatalytic agent is of critical importance. In previous studies [7–10], important criteria for the starting materials were identified, including a high degree of amorphiza-tion, uniform granulometric composition and significant chemical activity of the surface. These properties ensure maximum efficiency of the photocatalytic decomposition of pollutants due to the optimal interaction of ultraviolet radiation with the photocatalytic agent on the surface of the building composite.

Based on the requirements for the carrier and the task of increasing the amount of photocatalytic agent on the surface of the product, a hypothesis has been proposed about the possibility of using fibrous fillers as a substrate for creating PCM. This type of functional additives, on the one hand, provides micro-reinforcement of the cement matrix, positively affecting the physico-mechani-cal properties of the plaster solution, and, on the other, fiber, creating an additional microrelief protruding on the surface of the cement matrix, and being coated with a photocatalyst, will increase the interaction area for pho-tocatalytic reactions.

However, in order to effectively interact titanium dioxide with fiber during deposition and achieve the desired photocatalytic properties of PCM, it may be advisable to pretreat (activate) the fiber surface. At the same time, it is important to maintain the activity of the fiber surface, which is not coated with titanium dioxide to ensure its fixation in the cement matrix of the plaster material.

To assess the effectiveness of titanium dioxide deposition on the fiber surface, studies of the acid-base properties of the fiber surface can be carried out, followed by comparison with the initial parameters. The combination of acid-base properties of a substance is one of the characteristics that reflects the reactivity of the surface in the donor-acceptor interaction. At the same time, understanding the deposition process will help optimize the synthesis process and improve the properties of the final material.

The studies described in [11] were aimed at determining the surface acid-base properties of various fibers both in the initial state and after processing (modified). Treatment is understood as modeling the conditions of deposition of a photocatalytic agent on a substrate in accordance with pre-set parameters of sol-gel synthesis of TiO2, i.e. temperature exposure of 550 °С and exposure in an acidic environment. As a result of the study, it was revealed how the total number of adsorption centers varies depending on the type of fiber and the applied effect. It has been found that the heat treatment of basalt and glass fibers increases the concentration of active centers to 50–60%. However, for glass alkali-resistant fibers, such treatment has a negative effect on their activity. On the contrary, chemical treatment improves the surface activity of alkali-resistant fibers, while for other types of fibers there is no increase in the number of active centers.

This work is a continuation of previously performed studies [11] and is aimed at assessing the effect of various types of modification (activation) of the fiber surface occurring during the production of PCM on the nature of changes in the acid-base properties of both the fibers themselves of various types and PCM based on them for the introduction of the latter into the composition of plaster mixtures.

METHODS AND MATERIALS

To develop a photocatalytic composite material of the «fiber – anatase» system, the technology described in previous studies [4–6, 12] devoted to the creation of a photocatalytic material of the «silica component – ana-tase» system was applied. The basis of the technique is the sol-gel synthesis of titanium dioxide nanoparticles in anatase modification on a carrier. The formation of the structures of films and/or particles of titanium dioxide

THE STUDY OF THE PROPERTIES OF NANOMATERIALS depends on the physico-chemical properties of the reaction mixture, including a titanium precursor (for example, tetrabutoxititane), a solvent (aqueous alcohol solution), and, if necessary, a sol stabilizer (for example, acid). The technological process also provides for high-temperature exposure (up to 550°C) [12].

Characteristics of raw materials

The following raw materials were used for the sol-gel synthesis of titanium dioxide: an aqueous alcohol solution containing 95% ethyl alcohol by volume, corresponding to GOST R 51999-2002 (ZAO RFK, Russia); tetrabutoxititane according to TU 6-09-2738-89 (ZAO PROMKHIMPERM, Russia) with a molecular weight of 340.34 g/mol, mass fraction titanium 14.3%.

The following fibrous fillers were used as a substrate for the photocatalytic material: basalt fiber (BF) produced by OOO Kamenny Vek (Moscow region, Dubna), glass fiber (GF) produced by OOO NZK (Nizhny Novgorod) and glass alkali-resistant fiber (GAF) “ARM STRUCTURE” produced by OOO NPO Structure (Krasnodar). For a correct comparative analysis of various types of fibers, the selection was carried out on the basis of similar geometric parameters, physico-mechanical characteristics and melting temperatures, which should exceed the firing temperature regimes used in the technology of creating a photocatalytic composite material. It should be noted that fibers of organic origin were excluded from consideration due to their low melting point.

To activate the surface of the base under PCM, each of the listed types of fibers was subjected to acid and temperature treatment. For acid treatment, the following were used: nitric acid “KhCh” GOST 4461-77, acetic acid “KhCh” GOST 61-75 and formic acid 85% GOST 5848-73 produced by AO “Baza No. 1 Khimreaktivov”. The choice of these types of acids is based on works [13, 14, 15] in which acids were used to change the acid-base characteristics of the surface of silica and aluminosilicate raw materials, including in order to ensure the formation of a chemical bond between the substrate and titanium dioxide during the synthesis of PCM.

Sample preparation

Acid treatment (acid etching) was used to remove part of the surface layer of the material, namely, to create a rough texture, improve adhesion to other materials, activate the surface for subsequent deposition of titanium dioxide. To do this, the initial fiber samples were immersed in acid pre-diluted to a working concentration of 65% for 120 minutes at room temperature. After that, the fiber samples were removed from the solutions and sent to the drying cabinet at a controlled temperature of 70°C until completely dry.

High-temperature processing of the initial fiber samples was carried out in a muffle furnace at a temperature of 550°C for 120 minutes.

To quantify the concentration and distribution of acid-base centers on the surface of materials, a method for determining the distribution of adsorption centers (DAC) using indicators was used [16–20]. From the entire range of indicators, the following indicators with pKa were used in the studies: 0.8 (crystalline purple), 1.3 (diamond green), 2.1 (fuchsin), 2.5 (methanitroaniline), 3.46 (methyl orange), 5.0 (methyl red), 6.4 (bromocresol purple), allowing to assess the acidic activity of the surface according to Brensted, as the most preferable for increasing efficiency: deposition of titanium dioxide, photocatalysis processes and fiber fixation in the cement system [21–24].

The obtained fiber and PCM samples were subjected to a comprehensive analysis to assess the effect of the method of activation of fiber and sol-gel deposited titanium dioxide on the acidic properties of the fiber surface, and the nature of deposition: measurement of the concentration and distribution of Brensted acid centers on the surface using the indicator method (LEKI SS1207 spectrophotometer (LOIP)), analysis of surface morphology using a scanning electron microscopy, supplemented by an analysis of the elemental composition using an energy dispersive spectrometer (TESCAN MIRA 3 LMU scanning electron microscope (TESCAN)).

RESULTS AND DISCUSSION

Previously, the team of authors considered various types of fiber, performed a theoretical ranking from the position of the influence of surface active centers on the physico-chemical interaction with a titanium-containing catalyst [11]. A study of the concentrations of the active centers of Brensted acids on the surface of the fibers under consideration revealed that in their initial state, the glass alkali-resistant fiber has only a slight advantage. However, the chemical composition of the fibers, characterized by a content of silicon and aluminum oxid → es ranging from 70 to 73%, has minimal differences. This correlates with a slight increase in the number of active centers of Brensted acids in the series “basalt fiber → glass fiber → glass alkali-resistant fiber”. Such changes correlate with variations in the morphology of the fiber surface: basalt fiber has the smoothest surface, while glass fiber and glass alkali-resistant are characterized by local growths.

At the preliminary stage of the study, a comparison was made of the nature of the effect of three types of acids on fiber modification during etching, as a result of which acetic acid was selected. This choice is justified by the fact that after treatment with other types of acids (nitric, formic) with subsequent deposition of titanium

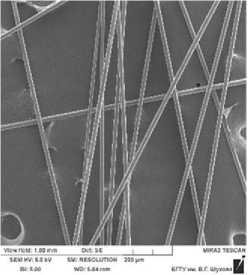

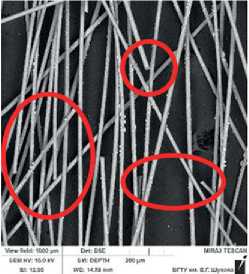

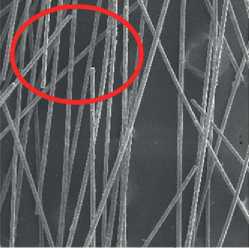

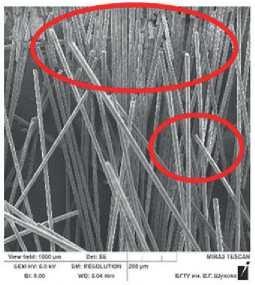

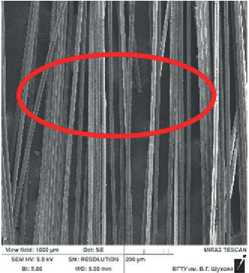

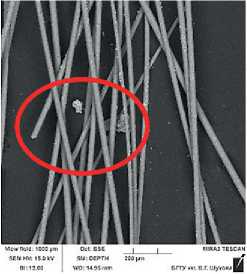

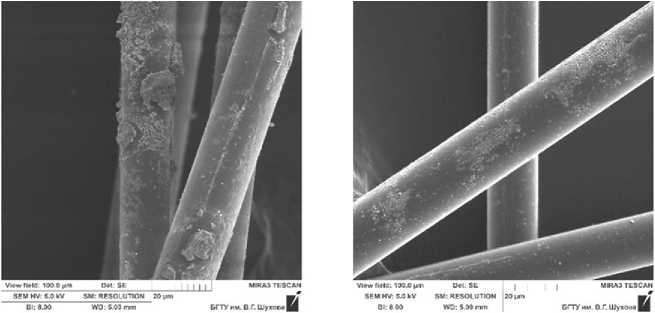

THE STUDY OF THE PROPERTIES OF NANOMATERIALS dioxide on their surface, further use of the obtained materials is impossible due to the loss of physico-mechanical properties, namely an increase in brittleness, followed by unintentional compaction/gluing of fibers during the deposition of titanium dioxide (Fig. 1, areas circled with a red marker), which is unacceptable for further use in the composition of the plaster mixture, since it leads to an uneven distribution of PCM.

As a result, a comparative analysis of the following types of materials was carried out:

– fiber in its initial state: basalt fiber (BF), glass fiber (GF), glass alkali-resistant fiber (GAF);

fiber subjected to heat treatment at 550°C for 120 minutes: basalt fiber (BF+T), glass fiber (GF+T), alkali-resistant glass fiber (GAF+T);

fiber subjected to acid treatment at a concentration of acetic acid of 65% for 120 minutes: basalt fiber (BF+AA), glass fiber (GF+AA), glass alkali-resistant fiber (GAF+AA);

photocatalytic composite material based on various types of fiber, respectively: PCM(BF), PCM(GF), PCM(GAF), PCM(BF+T), PCM(GF+T), PCM(GAF+T), PCM (BF+AA), PCM(GF+AA), PCM(GAF+AA).

VirvMt Wl«»

UIW Tt$CM

PCM (BF+AA)

PCM (BF+NA)

PCM (BF+FA)

PCM (GF+AA)

PCM (GF+NA)

PCM (GF+FA)

PCM (GAF+AA)

PCM (GAF+NA)

PCM (GAF+FA)

Fig. 1. The effect of acid treatment on the surface morphology and structure of PCM depending on the type of acid and fiber: AA – acetic acid; NA – nitric acid; FA – formic acid

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Properties of the fiber surface

The analysis of the results obtained in this work showed that after deposition of titanium dioxide on micro-reinforcing fibers, changes in the activity of their surface occur. There are significant changes in the number of active centers of Brensted acids on the surface of fibers, which indicates a modification of their surface.

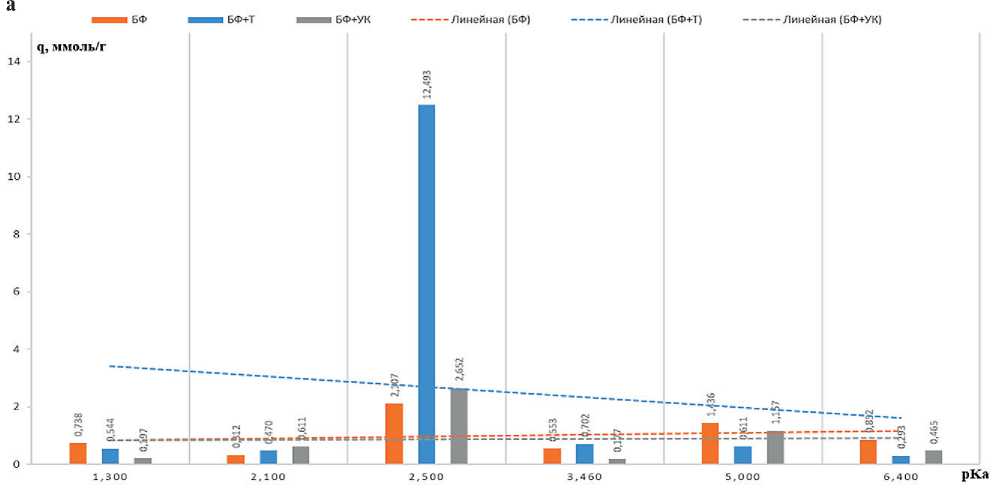

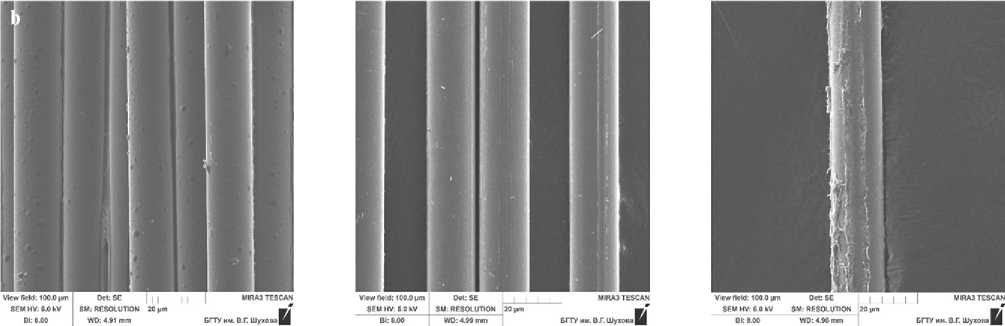

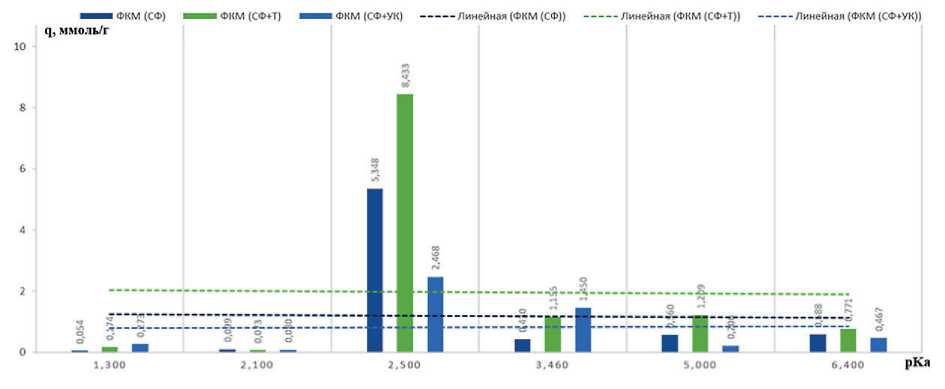

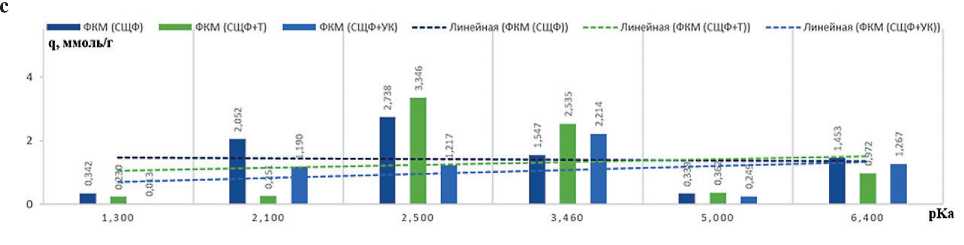

To visually demonstrate the distribution of adsorption centers in the area of Brensted acids (pKa = 0–7) on the surface of the samples, the results are presented separately for each type of fiber (Fig. 2). It should be emphasized that the data for the dissociation constant pKa = 0.8 are not displayed due to their insignificant numerical values.

Fig. 2–3 show the results of determining the distribution and concentration of Brensted acid centers and

Fig. 2. Distributions and concentration of adsorption centers in the area of Brensted acids on the surface of samples of various fibers (initial, subjected to thermal and acid treatment): a – basalt; b – glass; c – glass alkali-resistant

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 2. The End

microstructural surface features for the initial fibers, as well as those subjected to thermal and acid treatment.

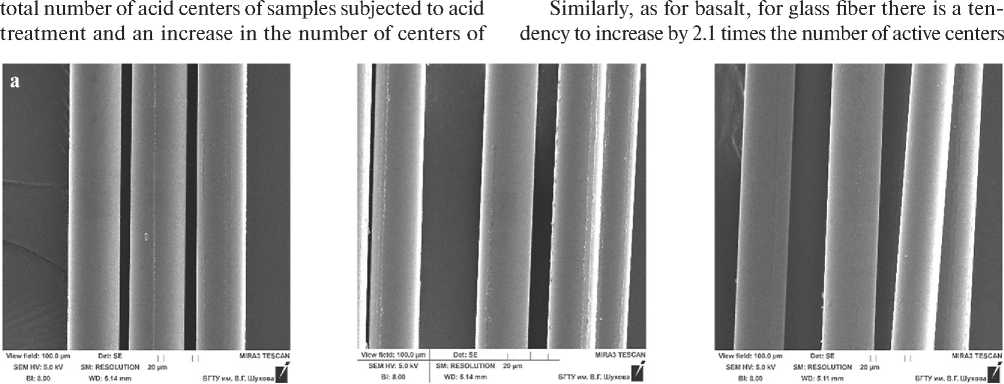

The distribution of adsorption centers on the surface of basalt fiber (see Fig. 2, a) shows a slight decrease in the samples subjected to heat treatment relative to the initial fiber by almost 2.5 times. These indicators correlate with the statement that as the surface roughness increases, its activity increases (see Fig. 3, a).

вғ

вғ+т

ВҒ+АА

GF

GF+T

GF+AA

Fig. 3. The effect of the activation method on the change in the microstructure of the surface of various types of fiber: a – basalt; b – glass; c – glass alkali-resistant

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

GAF+AA

GAP

GAF+T

Fig. 3. The End

after heat treatment (see Fig. 2, b ). There is an increase in the number of adsorption centers of the sample subjected to acid treatment in the pKa: 2.1; 5.0; 6.4. At the same time, the total number of acid centers of the GF+AA sample decreased by 1.3 times.

In the process of acid etching, it was possible to increase the surface roughness of the glass fiber (see Fig. 3, b ), but there is no significant effect on the change in the number of adsorption centers on the surface. Nevertheless, it should be noted that, as in the case of basalt fiber, there was an increase in the number of adsorption centers after activation of the surface by heat treatment.

In the case of glass alkali-resistant fiber, the opposite effect is observed: the number of active centers in samples subjected to surface activation by acid etching increases by 1.6 times and decreases by 2 times after heat treatment (see Fig. 2, c ). At the same time, there are no significant visible changes (see Fig. 3, c ).

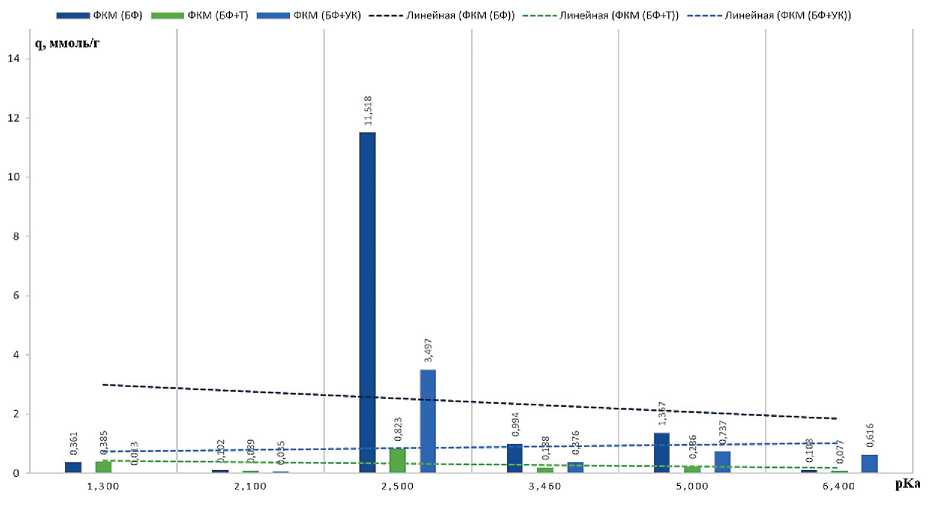

PCM Surface Properties

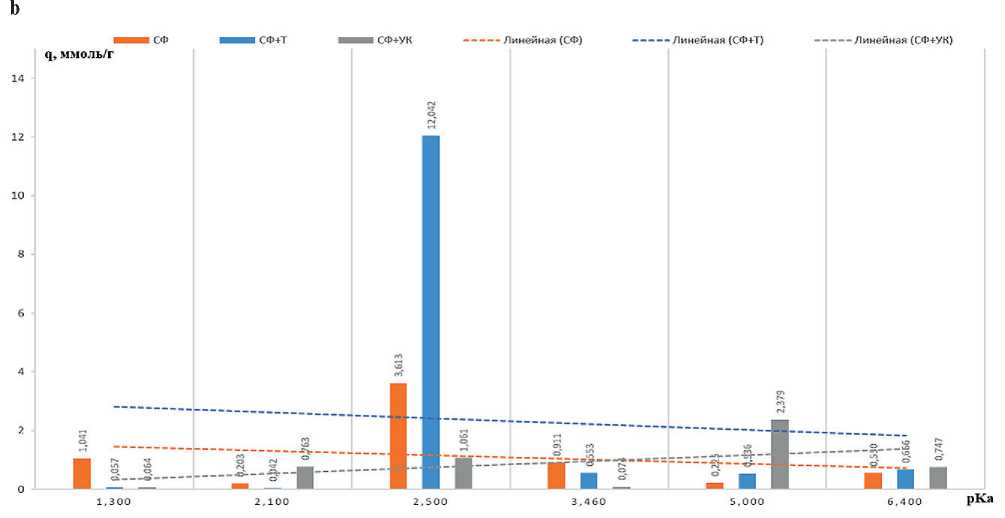

Analysis of the results of the distribution of active adsorption centers on the surface of a photocatalytic composite material based on basalt fiber (PCM(BF)) (Fig. 4, a ) revealed a significant predominance of indicators with a dissociation constant pKa = 2.5. There is also a slight increase in active centers on the surface of PCM based on basalt fiber treated with acetic acid PCM (BF+AA). However, other indicators are characterized by a decrease in the number of active centers for all PCM. With respect to the total number of acid centers, the obtained PCM based on basalt fiber can be arranged from the smallest to the largest as follows: PCM(BF+Т) → PCM(BF+AA) → PCM (BF).

Consider the distribution of active adsorption centers on the surface of a glass fiber-based PCM (GF)) (Fig. 4, b). As in the case of basalt fiber, there is a predominance of peak values at pKa = 2.5, which indicates the activity of Brensted acid centers. For indicators with pKa = 5 and pKa = 6.4, an increase in the number of active centers is observed for some samples, while in areas with pKa = 1.3 and pKa = 2.1, there is a decrease in the number of centers relative to the initial fiber (see Fig. 2, b). In this group, glass fiber-based PCM samples will be positioned as the total number of active centers increases as follows: PCM (GF+AA) → PCM (GF) → PCM (GF+Т).

Regarding the distribution of adsorption centers on the surface of PCM samples based on glass alkali-resistant fiber (Fig. 4, c ), a smoother distribution of active centers can be noted both on the surface of the initial fiber (see Fig. 2, c ) and on the surface of PCM(GAF). An increase in the concentration of active centers in the area of indicators pKa =1.3; 2.1; 6.4 was recorded in PCM(GAF) samples, while a decrease relative to the initial fiber was observed in other areas of the area of Brensted acid centers. The growth trend of the total number of active centers for PCM based on glass alkali-resistant fiber is as follows: PCM (GAF+AA) → PCM (GAF+Т) → PCM (GAF).

To summarize the data obtained, general information is presented on the number of active Brensted acid centers on the surface of various types of fibers when they are used as carriers in the sol-gel synthesis of titanium dioxide, as well as on the basis of a photocatalytic composite material (Table 1). An analysis of the concentrations of the active centers of Brensted acids on the surface of the studied fibers in the initial state showed that they did not differ significantly under initial conditions, except for a slight advantage in glass alkali-resistant fiber. However, after deposition of titanium dioxide on their surface, an increase in active centers is observed in the following sequence of PCM: based on glass fiber → glass alkali-resistant → basalt fiber.

Basalt fiber subjected to heat treatment followed by deposition of titanium dioxide on the surface showed the least results, since the number of active centers on the PCM decreased by 8.4 times. A slight decrease in the

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 4. Distribution and concentration of adsorption centers on the surface of PCM samples in the area of Brensted acids for various types of fiber: a – basalt; b – glass; c – glass alkali-resistant

number of active centers is observed in heat-treated glass fiber-based PCM, as well as in all types of acid-treated fiber-based PCM.

It should be noted that PCM based on glass alkali-resistant fiber subjected to heat treatment demonstrated an increase in the number of active centers by 2.5 times.

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Table 1

The number of Brensted acid centers on the surface of various fibers and PCM

|

The object of the study |

Number of active centers (q), mmol/g (depending on the treatment and type of fiber) |

||

|

Control (fiber without treatment) |

Heat-treated fiber |

Fiber soaked in acetic acid |

|

|

Basalt fiber |

|||

|

Fiber |

6.00 |

15.11 |

5.26 |

|

PCM |

14.44 |

1.8 |

5.27 |

|

Glass fiber |

|||

|

Fiber |

6.54 |

13.90 |

5.09 |

|

PCM |

7.08 |

11.82 |

4.94 |

|

Glass alkali-resistant fiber |

|||

|

Fiber |

7.11 |

3.55 |

11.27 |

|

PCM |

8.47 |

7.70 |

6.15 |

Fiber-based PCM microstructure

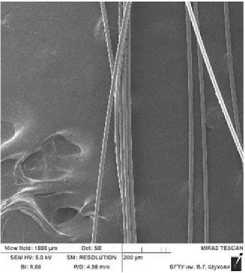

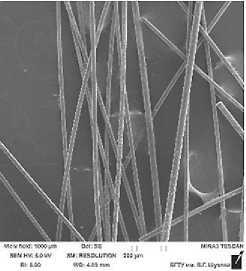

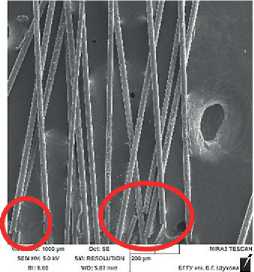

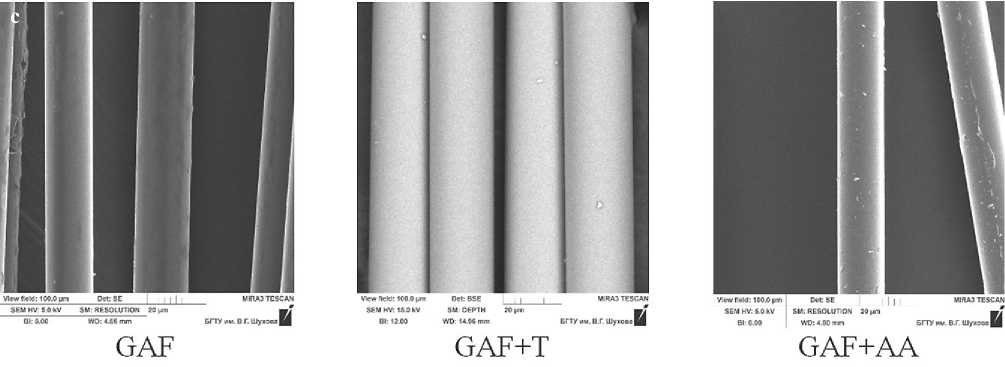

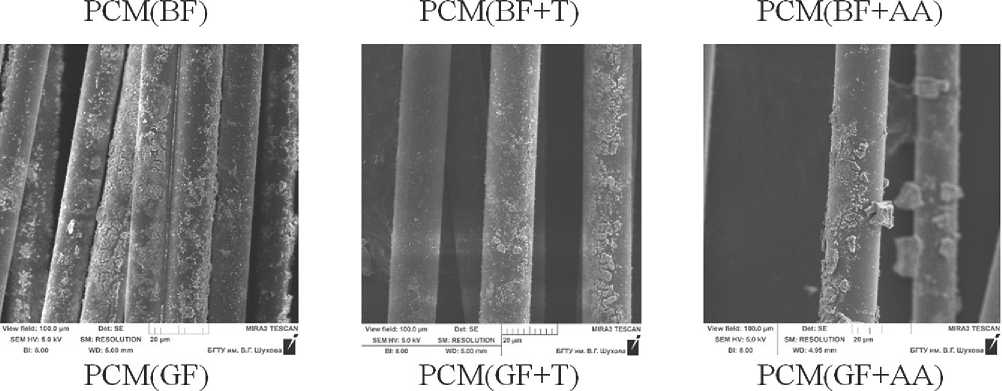

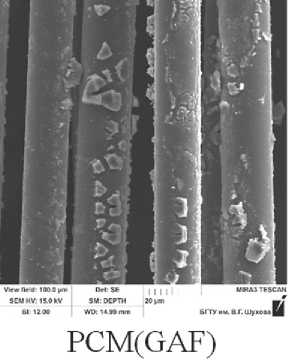

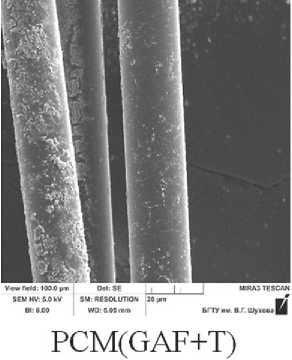

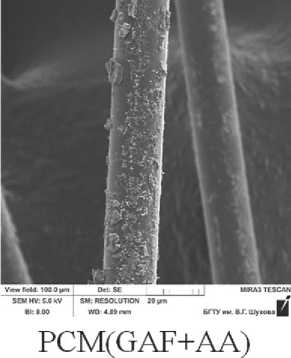

According to the results of scanning electron microscopy, it was found that after deposition of titanium dioxide on the surface of the fiber, both aggregates of particles and elements of TiO2, film structures are formed, which is accompanied by a change in the morphology of the surface and the structure of the fibers (Fig. 5).

The results of electron microscopy allowed to obtain a detailed understanding of the nature of deposition of titanium dioxide on the surface of a fiber of various types, depending on the method of its preliminary activation. After deposition of titanium dioxide on the fiber surface, both aggregates of particles and elements of TiO2 film structures are formed, which is accompanied by a change in the morphology of the surface and the structure of the fibers (see Fig. 5).

Thus, on samples of basalt and glass fiber treated with acetic acid, as well as glass alkali-resistant fiber, titanium dioxide particles form uneven growths or aggregates distributed over the fiber surface. These growths are clusters of particles of different shapes and sizes. This uneven deposition pattern indicates possible features of interaction between the fiber surface and titanium dioxide during synthesis, adhesion between titanium dioxide and fiber.

With regard to the rest of the samples, the following is observed: titanium dioxide particles are evenly distributed over the entire surface of the fiber, creating a semblance of a film. This uniform deposition pattern may be due to a more uniform distribution of active centers on the fiber surface. Unlike the case of basalt fiber, where uneven deposition is explained by the influence of active centers on the formation of growths, here active centers can contribute to the uniform deposition of titanium dioxide particles on the surface of the fiber.

It is possible that the presence of various active sites on the surface of the fiber leads to the preferred deposition of particles in certain areas, which, in turn, influenced the formation of growths. Such uneven deposition can have a significant impact on the properties of the composite material, in particular on the mechanical and physicochemical characteristics of the cement composite with PCM. Uniform coating of the fiber surface with titanium dioxide can lead to an improvement in the photocatalytic activity of the composite with PCM.

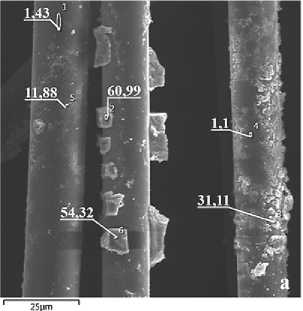

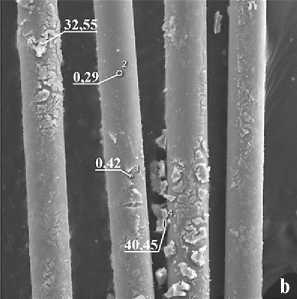

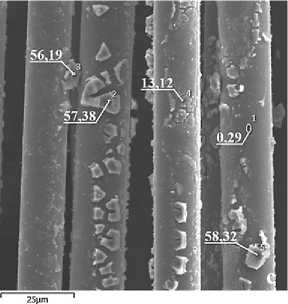

Figure 6 shows the results of the analysis of the elemental composition of the PCM surface based on various types of fibers using an energy dispersion spectrometer, where the weight content of titanium at selected points is indicated in numbers. The points were selected in such a way as to cover different areas of the sample surface and ensure the representativeness of the results. PCM samples with the highest values of the number of Brensted acid centers on the surface of each type of fiber were selected for presentation.

According to the analysis, it was found that the titanium content varies in a wide range. The titanium content in the studied PCM samples, ranging from 0.29 to 1.43%, indicates the formation of a thin coating on the surface of the composite material. A narrower range, from 11.88 to 13.12%, indicates the formation of a denser film, which gives the impression of ingrowth into the structure of the PCM surface. The formation of denser growths, which give the effect of a cracked film, is characterized by an interval of values from 31.11 to 40.45%. Finally, with a titanium content of over 50%, unevenly distributed growths on the surface are observed, which indicates the presence of local active zones on the surface of the fiber acting as crystallization centers, and features of the deposition and film formation process on the FCM. These results allowed

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 5. The effect of the method of modification of various types of fiber on the change in the microstructure of PCM based on them to estimate the distribution of titanium dioxide on the surface of the material and its concentration on various parts of the PCM surface.

The results obtained indicate the possibility of using micro-reinforcing fibers subjected to pre-activation of the surface by heat treatment as components of photocatalytic composite materials for plaster mixtures.

CONCLUSIONS

The conducted study revealed changes in the quantitative content of Brensted acids and surface morphology of both micro-reinforcing fibers subjected to preliminary activation of their surface and PCM based on them. The analysis showed that there is a change in the number of

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 6. Weight content of titanium depending on the surface area and type of PCM: а – PCM (BF); b – PCM(GF+Т); c – PCM(GAF)

25111Tl

Brensted acid centers, which indicates a change in the chemical properties and activity of the fiber surface, the redistribution and formation of new active centers, due to thermal and chemical influences, the interaction of sol-gel synthesis products of titanium dioxide with the active centers of the fiber surface. Thermal treatment of the surface of the initial fibers led to an increase in the number of acid centers in samples of basalt and glass fibers. In turn, the number of active centers on the surface of the PCM (BF+T) decreased by 15 times relative to BF+T, and by 3 times relative to BF. The number of active PCM centers (GF+T) decreased slightly relative to GF+T and increased 1.8 times relative to GF. Regarding the glass alkali-resistant fiber, pre-activation of the surface by heat treatment resulted in a decrease in the number of Brensted acid centers, but, subsequently, PCM (GAF+T) has a larger number of active centers relative to GAF+T. Preliminary activation of the surface of the samples of the initial fibers by etching in acid did not affect the increase in the number of Brensted acid centers, with the exception of GAF+AA (increased by 1.5 times). The number of active fiber-based PCM centers exposed to acetic acid etching remained almost unchanged relative to the values of the control samples. It should be noted that the use of nitric and formic acids for the preliminary activation of the fiber surface leads to an increase in their fragility, followed by unintentional compaction/gluing of fibers during the deposition of titanium dioxide. The following growth trend has been established for the total number of active centers for PCM: PCM(BF+Т) → PCM(GF+AA) → PCM(BF+AA) → PCM(GAF+AA)

→ PCM(GF) → PCM(GAF+Т) → PCM(GAF) → PCM(GF+Т) → PCM(BF).

During the deposition of titanium dioxide on the fiber surface, both aggregates of particles and elements of TiO2 film structures are formed, which is accompanied by a change in the morphology of the surface and the structure of the fibers. The uneven deposition pattern indicates the presence of various active sites on the surface of the fiber, leading to preferred particle deposition in certain areas. The morphology of PCM will have a significant impact on the interaction of micro-reinforcing fibers with the components of the plaster mixture, with the environment (UV radiation, vapors, gases, dispersed particles, etc.) and, consequently, the photocatalytic activity of cement composites with their use.

Based on the conducted research, the following preliminary conclusions can be drawn about the preferred processing methods for each of the studied types of fibers. For glass fiber, the preferred treatment method is thermal, which leads to an increase in the number of acidic Brensted centers, which improves the chemical properties of the fiber surface and promotes the redistribution of active centers, providing an optimal balance between structural changes and the activity of the material. Basalt and glass alkali-resistant fibers, do not need pretreatment. However, the final conclusion will be made after evaluating the photocatalytic activity of both PCM and plaster mixtures with their use, analyzing the durability of PCM in terms of preserving anatase on the fiber surface in the technology of introducing composite material into the plaster mixture.

Список литературы The effect of fiber activation on the surface properties of a photocatalytic composite material based on it

- Hamidi F., Aslani F. TiO2-based photocatalytic cementitious composites: Materials, properties, influential parameters, and assessment techniques. Nanomaterials. 2019; 9(10): 1444. https://doi.org/10.3390/nano9101444

- Pugin K.G. Construction mix with bactericidal properties. Bulletin of the Belgorod State Technological University named after V.G. Shukhov. 2019; 4: 40-46. https://doi.org/10.34031/article_5cb1e65debc933.57283217

- Antonenko M.V., Ogurtsova Yu.N., Strokova V.V., Gubareva E.N. Photocatalytically active self-cleaning cementbased materials. Compositions, properties, and applications. Bulletin of the Belgorod State Technological University named after V.G. Shukhov. 2020; 3: 16-25. https://doi.org/10.34031/2071-7318-2020-5-3-16-25

- Labuzova M.V., Gubareva E.N., Ogurtsova Yu.N., Strokova V.V. The use of photocatalytic composite material in a cement system. Stroitel’nye Materialy. 2019; 5: 16-21. https://doi.org/10.31659/0585-430Х-2019-770-5-16-21

- Gubareva E.N., Ogurtsova Yu.N., Strokova V.V., Labuzova M.V. Comparative assessment of the activity of silica raw materials and photocatalytic composite material based on it. Obogashchenie Rud. 2019; 6: 25. https://doi.org/10.17580/or.2019.06.05

- Strokova V. V., Gubareva E. N., Ogurtsova Yu. N. Evaluation of the properties of silica raw materials as a substrate in a composite photocatalytic material. Bulletin of the Belgorod State Technological University named after V.G. Shukhov. 2017; 2: 6-12. https://doi.org/10.1277/23819

- Balykov A.S., Nizina T.A., Kyashkin V.M., Volodin S.V. Evaluation of the effectiveness of mineral additives in cement systems in the development of photocatalytic core–shell compositions. Nanotechnologies in construction. 2022; 14(5): 405-418. https://doi.org/10.15828/2075-8545-2022-14-5-405-418

- Wang D., Hou P., Stephan D. Huang S., Zhang L., Yang P., Cheng X. SiO2/TiO2 composite powders deposited on cement-based materials: Rhodamine B removal and the bonding mechanism. Construction and Building Materials. 2020; 241: 118124. https://doi.org/10.1016/j.conbuildmat.2020.118124

- Fatimah I., Prakoso N.I., Sahroni I., Miqdam Musawwa M., Sim Y., Kooli F., Muraza O. Physicochemical characteristics and photocatalytic performance of TiO2/SiO2 catalyst synthesized using biogenic silica from bamboo leaves. Heliyon. 2019; 5:11. e02766. https://doi.org/10.1016/j.heliyon.2019.e02766

- Pal A., Jana T.K., Chatterjee K. Silica supported TiO2 nanostructures for highly efficient photocatalytic application under visible light irradiation. Materials Research Bulletin. 2016; 76: 353-357. https://doi.org/10.1016/j.materresbull.2015.12.040

- Nerovnaya S.V., Sivalneva M.N., Strokova V.V., Ogurtsova Yu.N., Gubareva E.N., Klimenkova E.V. Acid-base properties of the surface of micro-reinforcing fibers as a component of a photocatalytic composite material for plaster mixtures. Bulletin of the Belgorod State Technological University named after V.G. Shukhov. 2023;10: 8-19. https://doi.org/10.34031/2071-7318-2023-8-10-8-19

- Strokova V., Gubareva E., Ogurtsova Y., Fediuk R., Zhao P., Vatin N., Vasilev Y. Obtaining and properties of a photocatalytic composite material of the “SiO2–TiO2” system based on various types of silica Raw Materials. Nanomaterials. 2021; 11: 866. https://doi.org/10.3390/nano11040866

- Sychev M.M., Minakova T.S., Slizhov Yu. G., Shilova O.A. Acid-basic characteristics of the surface of solids and control of the properties of materials and composites. St. Petersburg: Khimizdat, 2016. 276 p.

- Miszczak S., Pietrzyk B. Anatase-rutile transformation of TiO2 sol–gel coatings deposited on different substrates/ Ceramics International. 2015; 41:7461-7465. https://doi.org/10.1016/j.ceramint.2015.02.066

- Imran M., Riaz S., Naseem S. Synthesis and characterization of titania nanoparticles by solgel technique / Muhammad Imran et al.. Materials Today: Proceedings. 2015; 2: 5455 – 5461. https://doi.org/10.1016/j.matpr.2015.11.069

- Spectroscopic Investigation of the Anatase-to-Rutile Transformation of Sol−Gel-Synthesized TiO2 Photocatalysts / Nicholas T. Nolan, Michael K. Seery, Suresh C. Pillai. The Journal of Physical Chemistry C. 2009; 113(36): 16151-16157. https://doi.org/10.1021/jp904358g

- Baidarashvili M.M., Sakharova A.S. Investigation of sorption properties of materials using the physico-chemical method of distribution of adsorption centers. Sorption and chromatographic processes. 2020; 20(1):87-94. https://doi.org/10.17308/sorpchrom.2020.20/2383

- Lopanov A.N., Fanina E.A., Guzeeva O.N. Acid-base surface centers of quartz sand in the technology of electrically conductive building mixes. Bulletin of the Belgorod State Technological University named after V.G. Shukhov. 2016; 5: 58-63.

- Baranova N.V., Pashina L.A., Kostochko A.V. Comparative analysis of some methods for determining acidbase properties of the surface of solids from the point of view of studying adhesive interaction. Herald of Technological University. 2014; 17(19): 33-36.

- Tsyganova T.A., Antropova T.V., Myakin S.V., Anfimova I.N. Features of the formation of adsorption centers, thermally modified high-silica porous glasses. Физика и химия стекла. 2020; 46(5): 475-481. https://doi.org/10.31857/S0132665120050121

- Postnova I.V., Sarin S. A., Karpenko T.Yu., Shchipunov Yu.A. Formation of photocatalytically active titanium dioxide on mesoporous silicate with silver nanoparticles synthesized with tannin acting as a template and reducing agent. Reports of the Russian Academy of Sciences. Chemistry, Materials sciences. 2020; 495(1):16–20. https://doi.org/10.31857/S2686953520060114

- Shilova O.A., Kovalenko A.S., Nikolaev A.M., Mjakin S.V., Sinel’nikov A.A., Chelibanov V.P., Gorshkova Y.E., Tsvigun N.V., Ruzimuradov O.N., Kopitsa G.P. Surface and photocatalytic properties of sol-gel derived TiO2@SiO2 core-shell nanoparticles. Journal of Sol-Gel Science and Technology. 2023; 108(2): 263-273. https://doi.org/10.1007/s10971-022-05943-5

- Rimoldi L., Meroni D., Falletta E., Ferretti A.M., Gervasini A., Cappelletti G., Ardizzone S. The role played by different TiO2 features on the photocatalytic degradation of paracetamol. Applied Surface Science. 2017; 424: 198-205. https://doi.org/10.1016/j.apsusc.2017.03.033

- Baranova N.V., Pashina L.A., Necheporenko A.P., Kostochko A.V. Acidic and basic surface centers of cellulose nitrates. Russian Journal of Applied Chemistry. 2015; 88(1): 131-136.