The effect of substitute nature on the effectiveness of boron-nitrogen wood preservatives and flame retardants

Автор: Stepina I.V., Strokova V.V., Erofeev V.T.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Manufacturing technology for building materials and products

Статья в выпуске: 5 Vol.17, 2025 года.

Бесплатный доступ

Introduction. Antiseptic and antipyretic treatment of wood is a prerequisite for its use in modern construction technologies. The use of boron compounds for these purposes has a significant advantage: the formation of stable chemical bonds between the molecules of the modifiers and the hydroxyl groups of the main components of wood (cellulose and lignin) due to boron-amine coordination on the surface of the modified material. By changing the chemical composition of boron-based modifiers, it is possible to control the properties of the surface of modified wood. In this regard, the aim of the study was to develop the optimal composition of boron-based modifiers that would provide long-lasting and effective protection against microorganisms and elevated temperatures while preserving the unique natural properties of pine wood. Methods and materials. The study was carried out using methods of thermal analysis, evaluation of the fire-retardant effectiveness of boron compounds, and determination of the fungus resistance of pine wood samples modified with boron compounds. Results. Boron compounds, in which one hydroxyl group at the boron atom is replaced by a phenyl radical, showed higher effectiveness against mold and wood-destroying fungi and provided the second group of fire protection effectiveness at lower concentrations compared to boron-nitrogen compounds with three hydroxyl groups at the boron atom. Discussion. The introduction of a phenyl radical into boron-nitrogen compounds sharply increases their effectiveness as antiseptics and flame retardants, allowing a fivefold reduction in working concentration without loss of protective properties. Low concentrations of phenylborates (5–10%) reduce processing costs. The minimum concentration of modifiers minimizes the impact on the natural structure of the material. Stable coordination bonds between boron-nitrogen compounds and cellulose and lignin prevent the leaching of reagents. Phenylborate-based compositions are optimal for the comprehensive protection of lignocellulosic materials in construction in accordance with environmental requirements. Conclusion. The study proved that the nature of the substituent in boron compounds is a decisive factor in their effectiveness. Phenyl-containing boron-nitrogen compounds combine high biocidal activity, thermal stability, and fire protection at minimum concentrations, offering an economically and environmentally sustainable solution for wood modification.

Wood, cellulose, lignin, boron-nitrogen compounds, modification, biostability, heat resistance

Короткий адрес: https://sciup.org/142246073

IDR: 142246073 | DOI: 10.15828/2075-8545-2025-17-5-530-537

Текст научной статьи The effect of substitute nature on the effectiveness of boron-nitrogen wood preservatives and flame retardants

Original article

Степина И.В., Строкова В.В., Ерофеев В.Т. Влияние природы заместителя на эффективность боразотных антисептиков и антипиренов древесины. Нанотехнологии в строительстве. 2025;17(5):530–537. – EDN: FBUBVM.

The use of wood in modern construction requires the implementation of antiseptic and antipyretic measures. [1–4]. Developing effective modifiers that provide a longterm protective effect is an urgent task. In research [5] flame retardancy was induced in maple (Acer velutinum) and ash (Fraxinus excelsior) wood and bark by means of mixtures consisting of bio-based materials such as starch (S) and glue (G) and water-based paint, MINWAX (M)

in two different combined formulations with perlite (P) as the main fire retardant. The study found that the lowest and the highest mass loss occurred in the untreated-ash and untreated-maple wood samples with bark, while the lowest weight percent gain was related to PSGM-treat-ed ash wood samples with bark, and the highest weight percent gain was related to PSGM-treated maple wood samples without bark. The lowest time to ignition and glowing point time were measured in the untreated-maple wood samples without bark, and the highest of them were

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS measured in the PSGM-treated ash wood samples without bark [5].

In book [6] the authors describe the contribution of basic components (melamine, pentaerythritol, ammonium polyphosphate), additional components (chlorinated paraffin, urea, cellulose, carbon nano additives, etc.) and polymer binders of intumescent compositions on the process of charring [6]. In research [7] the use of impregnation based on soda ash and boric acid as one of the ways to increase the fire resistance of wood is considered. The method of testing the initial impregnation on three types of wood is described. The result of the tests was a justification for the use of this impregnation to increase the fire resistance of wood. Self-cleaning surfaces, scratch and weathering resistance, and biocides properties have been achieved through nanoparticles (NPs) applications [8]. Studies evaluating the performance of NPs from silver (Ag), boron (B), copper (Cu), zinc (Zn), zinc oxide (ZnO), zinc borate (B2O6Zn3), and titanium dioxide (TiO2) on wood protections have reported promising findings. Tests performed against termites, rot, mold and stain fungi, and UV degradation have demonstrated that some biocides have their properties improved in nanoscale [8].

The research [9] summarizes the latest developments in wood protection research in academia. The review shows that wood durability can be improved with protection products containing preservatives and wood modification systems. The review covers oil borne preservatives [10–14], water borne preservatives [15–18], natural wood preservatives [19–22], and newer preservative systems [23–27]. The results of the research studies contribute to the safe use of preservatives, improved wood modification methods, and the processing and utilization of treated materials. It was noted that an important condition for the effective use of protective agents is the duration of their protective effect, which increases their economic efficiency. Earlier studies showed that boron-nitrogen compounds form stable chemical bonds with the components of wood’s lignocarbohydrate complex [28–30]. Forming such bonds prevents the modifier from leaching out of the building material composition during operation, thus providing a long-lasting protective effect. For this reason, protective compositions based on boron-nitrogen compounds are promising for antiseptic and antipirating treatments for construction materials. Therefore, studying the relationship between the protective effect and the composition of boron-nitrogen modifiers is a relevant task.

METHODOLOGY

We used boron-nitrogen compounds (BNC) as modifiers, which were obtained according to the method described in references [31, 32]. The BNC were monoethanolamine borate (MEAB), diethanolamine borate (DEAB), monoethanolamine phenylborate (MEAPB), and diethanolamine phenylborate (DEAPB). The sapwood of air-dried pine was used as the substrate. Wood modification was carried out by immersing the samples in BAC solutions at room temperature with constant stirring for three hours. Then, the samples were air-dried until they reached a constant weight.

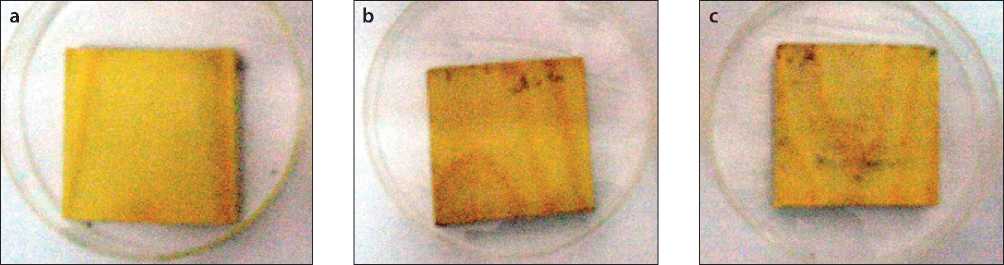

According to the method described in GOST 9.04889, modified samples of pine wood sapwood were tested for fungus resistance. The surface of the 5×5×1 cm wood samples was infected with a fungal spore suspension with a concentration of 1–2 million spores/mL Aspergillus niger van Tieghem, Aspergillus terreus Thom, Aureobasidium pullulans (de Bary) Arnaud, Paecilomyces variori Bainier, Penicillium funiculosum Thom, Penicillium ochro-chloron Biourge, Scopulariopsis brevicaulis Bainier, Trichoderma viride Pers. Ex Fr . Additionally, spores of wood-destroying fungi ( Serpula lacrimans ВКМ-465 and Antrodia sinu-osa BKM F-1741) were introduced into the suspension. Unmodified wood samples were used as controls. The samples infected with the aforementioned fungal suspension were placed in an open Petri dish in an exicator. The samples were then incubated under conditions that were optimal for fungal growth: a temperature of 27–28 °C and a humidity level of 98%, for 28 days. After 14 days, intermediate examinations of the samples were carried out visually and with microcopying at 60× magnification.

At the end of the tests, the stage of fungal development was evaluated using a 5-point system (GOST 9.048-89): “0” points: Absolutely clean samples with no germinated conidia or colony development (visually and under a microscope). “1” point: Visually clean samples with only small foci of mycelium visible under a microscope in the form of individual spots; sporonostasis is absent. “2” points: Superficial mycelium development in the form of numerous spots; sporonostasis is absent. A score of “3” indicates abundant growth of mycelium on the surface of the sample and the beginning of sporulation. A score of “4” indicates that continuous growth of mycelium and sporulation are clearly visible upon visual inspection. A score of “5” indicates deep mycelium infestation of the entire area of the sample with intense sporulation.

The thermal analysis of the wood samples was performed using a DuPont 9900 thermal analyzer. Studies on the TGA-951 thermoanalyzer were carried out in a heated air atmosphere at heating rates of 5 and 10 °C/min. The construction and processing of thermoanalytical curves were carried out using the TA Universal Analysis 2000 program.

The assessment of the fire protection efficiency of BNC was carried out in accordance with GOST R 53292-2009, p. 6.1, using the “Ceramic Tube” installation. A vertically oriented wood sample was placed in the flame of a gas burner installed in the reaction chamber of the ceramic tube and exposed to heat for two minutes. The criterion for the degree of fire retardant effective-

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS ness of BNC was the amount of mass loss of the standard samples after the test. If the mass loss of the samples is no greater than 9%, the flame retardant belongs to group I. If the mass loss is more than 9%, but less than or equal to 25%, the composition belongs to the II group of flame retardant effectiveness. A mass loss of more than 25% indicates that the composition does not provide fire protection for wood and is not flame retardant.

RESULTS AND DISCUSSION

The experimental data (Table 1) obtained to determine the resistance of wood to mold and wood-destroying fungi demonstrate the effectiveness of boron-nitrogen compounds in suppressing fungal growth on the surface of modified wood samples. The tests were carried out at different BNC concentrations (10%, 30%, and 50% for MEAB and DEAB; 5% and 10% for MEAPB and DEAPB, as the latter two are less soluble in water). The results were evaluated based on the surface area covered by fungal mycelia using a 0-to-5 point scale, where 0 is no growth and 5 is maximum infestation.

As shown in Table 1, boron-nitrogen compounds in which one hydroxyl group at the boron atom is replaced by a phenyl radical (e.g., MEAPB and DEAPB) are more effective against mold and wood-destroying fungi at lower concentrations than BAS, which has three hydroxyl groups at the boron atom.

According to the experimental data in Table 1, a 10% concentration of MEAFB provides complete protection against the development of fungal mycelia. In contrast, a 50% concentration of the modifier is required when using MEAB/DEAB for the same purpose. When control samples were tested without boron-nitrogen modifiers, significant fungal growth was observed (Fig. 1), confirming the need for biocidal treatment.

Control and fungus-resistant wood samples (DEAB50%, DEAB50%, and DEAPB10%) were subjected to thermal analysis. As seen in Table 2, an increase in heating rate (from 5 to 10 °C/min) leads to a widening of the temperature intervals of degradation. For instance, for the control sample, the upper limit of the first interval increases from 150 to 160 °C, the second from 380 to 400 °C, and the third from 470 to 475 °C at a heating rate of 10 °C/min. For samples modified with a 50% DEAB solution, the changes are even more significant. At a heating rate of 10 °C/min, the upper limit of the first interval increases from 150 to 185 °C and the upper limit of the second interval increases from 383 to 392 °C. Concurrently, as the heating rate increases, there is a decrease in mass loss during the initial

Table 1. Results of fungus resistance assessment

|

BNC |

Concentration BNC, % |

Appearance of samples after testing |

Fungal development stages |

|

MEAB |

10 |

There is abundant growth of mycelium on the surface of the sample and the beginning of sporulation |

3 |

|

30 |

Superficial mycelium development occurs in the form of numerous spots with no sporulation |

2 |

|

|

50 |

The samples were clean. No germinated conidia or fungal colonies were detected |

0 |

|

|

DEAB |

10 |

There is abundant growth of mycelium on the surface of the sample and the beginning of sporulation |

3 |

|

30 |

Superficial mycelium development occurs in the form of numerous spots with no sporulation |

2 |

|

|

50 |

The samples were clean. No germinated conidia or fungal colonies were detected |

0 |

|

|

MEAPB |

5 |

Under a microscope, small Mycelium centers appear in the form of separate spots. Sporulation is absent |

1 |

|

10 |

The samples were clean. No germinated conidia or fungal colonies were detected |

0 |

|

|

DEAPB |

5 |

Under a microscope, small Mycelium centers appear in the form of separate spots. Sporulation is absent |

1 |

|

Control |

– |

Fungi cover 80–85% of the surface. |

5 |

Table 2. Some characteristics of thermoanalytical curves

|

TG curve characterization |

Wood (control) |

Wood+ MEAB50% |

Wood+ DEAB50% |

Wood+ MEAPB10% |

||||

|

Heating rate, °C/min |

5 |

10 |

5 |

10 |

5 |

10 |

5 |

10 |

|

Degradation temperature range, оС |

30–150 |

30–160 |

30–150 |

30–150 |

30–150 |

30–185 |

30–150 |

30–150 |

|

Mass loss, % |

9.23 |

7.3 |

7.24 |

7.2 |

8.73 |

7.63 |

7.82 |

3.62 |

|

Peak temperature, оС |

60 |

70 |

58 |

67 |

66 |

87 |

100 |

110 |

|

Degradation temperature range, оС |

150–380 |

160–400 |

150–390 |

150–404 |

150–383 |

185–392 |

150–410 |

150–420 |

|

Mass loss, % |

60.2 |

65.9 |

58.9 |

58.6 |

53.1 |

53.1 |

59.34 |

60.93 |

|

Peak temperature, оС |

325 |

340 |

326 |

341 |

324 |

338 |

350 |

360 |

|

Degradation temperature range, оС |

380–470 |

400–475 |

390–650 |

404–650 |

383–650 |

392–650 |

410–650 |

420–670 |

|

Mass loss, % |

30.3 |

26.6 |

26.5 |

28.2 |

30.9 |

33.7 |

24.13 |

24.80 |

|

Peak temperature, оС |

452 |

458 |

466 |

487 |

468 |

495 |

500 |

510 |

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 1. Stages of fungal development: a – 0; b – 1; c – 2; d – 3; e – 5

degradation step (e.g., for the control sample, the mass loss decreases from 9.23% to 7.3%, and for the DEAB50% sample, the mass loss decreases from 8.73% to 7.63%), as well as an increase in peak maximum temperature (e.g., for the control sample, the peak maximum temperature increases from 60 °C to 70 °C, and for the DEAB50% sample, the peak maximum temperature increases from 66 °C to 87 °C). 66 → 87 °C for the first interval). These changes may be related to the acceleration of the evaporation processes of moisture and volatile substances.

Surface modification using a 50% MEAB solution results in decreased mass loss in the first step (7.3% versus 9.23% for the control) and increased maximum temperature in the third step (487°C versus 458°C for the control) at a heating rate of 10°C/min. These results indicate an increase in thermal stability. However, the total mass loss

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

(94.1%) is lower than that of the control (99.73%), suggesting incomplete degradation. Wood samples modified with a 50% DEAB solution during the second stage of degradation, at a heating rate of 10 °C/min, exhibited decreased mass loss (53.1% versus 65.9% for the control) and increased maximum temperature (338 °C versus 340 °C for the control). This indicates a slowing of thermo-oxidative degradation processes. Samples modified with a 10% MEAB solution demonstrate the greatest thermal stability, characterized by the lowest mass loss and a maximum temperature of 510 °C in the third stage (vs. 458 °C for the control).

The modifiers MEAB, DEAB, and MEAPB increase the maximum degradation temperature of the wood they modify, indicating an increase in the modified wood’s thermal stability. MEAPB is the most effective of the investigated flame retardants. The heating rate affects the distribution of mass loss by stages. At 10 °C/min, the processes shift to higher temperature regions.

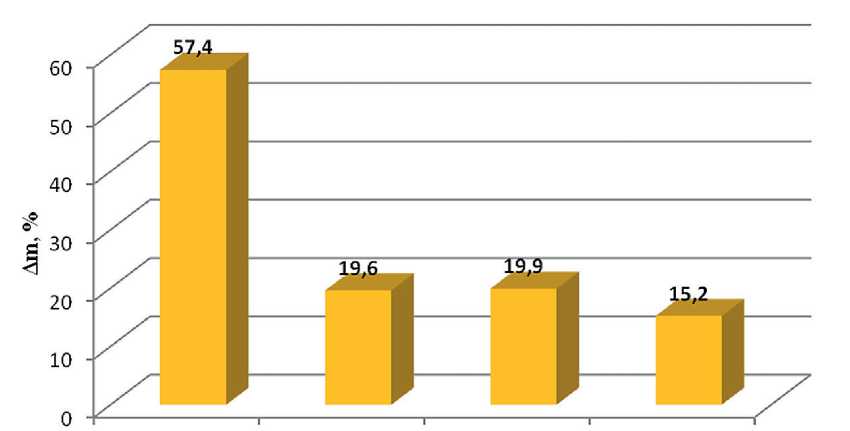

Fig. 2 presents the results of the fire retardant efficiency assessment of BAS. The consumption of the 50% MEAB and DEAB compositions was 150 g/m², and the consumption of the 10% MEAPB composition was 320 g/m². The mass loss value of the modified wood samples does not exceed 20%. According to the GOST R 53292-2009 methodology (p. 6.1), the 50% MEAB and DEAB compositions, as well as the 10% MEAPB composition, belong to the second group of fire retardant effectiveness. Modifying the surface of wood with these compositions passes it into the category of hard-to-flame materials.

Thus, BNC with a phenyl substituent (MEAPB and DEAPB) required a concentration five times lower than analogs without a substituent (MEAB and DEAB). To achieve complete protection against fungi (a score of 0 according to GOST 9.048-89), a 10% concentration of MEAFB was sufficient, whereas a 50% concentration of MEAB or DEAB was required (Table 1). Control samples without treatment exhibited maximum lesions (score 5), which confirms the necessity of modification.

BNC modification increased the thermal degradation temperature of wood. MEAPB had the greatest effect; the peak degradation temperature was 510 °C (compared to 458 °C for the control at a heating rate of 10 °C/min; see Table 2). Decreased mass loss during the initial degradation step (e.g., 3.62% for MEAPB vs. 7.3% for the control) indicates slower moisture and volatile evaporation. Increasing the heating rate from 5 to 10°C/min shifts the degradation processes to higher temperatures, reducing mass loss in the initial stages.

All tested compositions (MEAB 50%, DEAB 50%, and MEAPB 10%) are classified as group II fire protection materials (with a mass loss of less than 25%, according to GOST R 53292-2009). The mass loss of the modified samples did not exceed 20%, placing wood in the category of flame-retardant materials (Fig. 2).

CONCLUSION

The introduction of the phenyl radical into BAS dramatically increases its effectiveness as an antiseptic and flame retardant. This allows for a fivefold reduction in the working concentration without loss of protective properties.

Operational benefits. Reagent savings: Low concentrations of MEAPB/DEAPB (5–10%) reduce treatment costs. Preservation of natural wood properties: Minimal modifier concentration minimizes impact on the natural

Control MEAB50% DEAB50% MEAPB10%

-

Fig. 2. Mass loss values of wood samples during fire tests

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS structure of the material. Durability of protection: Stable coordination bonds between BNC and cellulose and lignin prevent the leaching of reagents.

Application perspectives. MEAPB-based formulations are optimal for integrated protection (biological and fire resistance) in environmentally compliant construction, such as the Russian National Housing Project. Further research can focus on optimizing formulations for other wood species and industrial implementation.