The effect of temperature and humidity treatment on the strength set of fine-grained concrete with the addition of saponite-containing material

Автор: Morozova М.V.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Manufacturing technology for building materials and products

Статья в выпуске: 3 Vol.16, 2024 года.

Бесплатный доступ

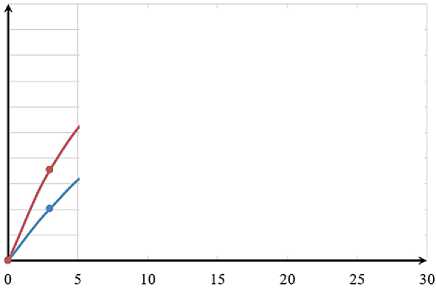

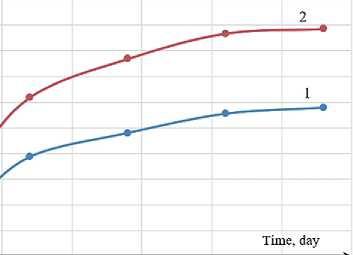

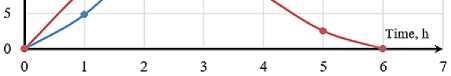

Introduction. To restore and develop the Solovetsky Islands road network concrete slabs could be used. Currently, compositions with additives of industrial waste, including micro- and nanoscale, are being actively introduced to improve the performance characteristics of the road slabs. For the Arkhangelsk region, saponite-containing waste from the mining industry could be used as a material. At the same time, one of the ways to accelerate the process of gaining strength of composites is steaming. However, studies related to the effect of temperature and humidity treatment on the hardening process of a composite with a highly dispersed saponite-containing material (SCM) have not been previously studied. It is known that the process of moisture sorption with a finely dispersed additive allows controlling structure formation during concrete hardening, improving its operational characteristics. However, under conditions of high humidity, the quantitative content of tempering water, calculated based on the value of water absorption of the SСM, can significantly change and affect the process of gaining the strength of the composite. Therefore, the purpose of this research is to study the effect of temperature and humidity treatment on the strength gain of fine-grained concrete with the addition of SCM. It has been established that the accelerated method of concrete hardening has only a positive effect on the formation of a strong and dense structure. However, in the case of using highly dispersed saponite-containing material as an additive, the opposite effect (decrease in strength) associated with sorption properties and features of its structure can be observed. Methods and Materials. The SCM recovered from the recycled water was dried to constant weight and dispersed on a planetary ball mill. Particle size was determined by dynamic and electrophoretic light scattering, and specific surface area was determined by nitrogen sorption (BET theory). The strength of samples of fine-grained concrete of the control and experimental (with the addition of SCM) compositions was gained in two ways: under normal conditions and by an accelerated method using steaming. Strength tests of cube samples with dimensions of 70×70×70 mm were carried out on an automatic test press according to GOST 10180. The microstructure of the samples was examined by scanning electron microscopy. Results and Discussion. The separated, dried and ground saponite-containing material (powder) had an average particle size of 445±40 nm and a specific surface area of 50 670±10 m2/kg. In continuation of the studies, control (FGC) and test samples of fine-grained concrete (FGCscm) were made. The amount of a highly dispersed additive was introduced into the concrete mixture based on previously obtained results of kinetic studies of the water absorption process of saponite-containing material. The determination of the strength characteristics of 1-FGC and 1-FGCscm, hardening under normal conditions, was carried out on day 28. Samples of 2-FGC and 2-FGCscm, a day after sealing with water, were placed in a steaming chamber. After the expiration of the holding time, they were gradually cooled and their strength characteristics were determined. It has been established that the accelerated method of gaining strength of finegrained concrete, by steaming, has a positive effect only on control samples. For a composite with the addition of SCM, temperature and humidity treatment has the opposite effect. Thus, the dynamics of strength gain of 1-FGC and 1-FGCscm are of the same type. At the initial moment of time, an active site of strength gain is observed, but on day 7, the compressive strength of the samples of the experimental composition is 40% higher than that of the control one. At the accelerated curing method in the first two hours (isothermal heating stage), an active strength increase was observed in 2-FGC and 2-FGCscm. The subsequent curing of the control specimens has a linear dependence with a gradual increase in strength to the design strength in six hours. For 2-FGCscm, after two hours of steaming, the strength sharply begins to decrease, and after six hours – visible destruction of the concrete structure occurs. Consequently, prolonged temperature and humidity exposure of concrete with highly dispersed SSM admixture leads to a decrease in the strength characteristics of the specimens. Most likely, it is connected with moisture oversaturation of the composite structure. Therefore, in continuation of the research, electronic photographs were taken of the microstructure of concrete after three hours of holding in the steaming chamber. Thus, the microstructure of 2-FGCscm is mainly represented by spongy particles, and the number of formed needle-like (tobermorite crystals) – decreased significantly, compared to the control.

Saponite-containing material, steaming, temperature and humidity treatment, fine-grained concrete, highly dispersed additive, swelling, compressive strength

Короткий адрес: https://sciup.org/142240867

IDR: 142240867 | DOI: 10.15828/2075-8545-2024-16-3-227-234

Текст научной статьи The effect of temperature and humidity treatment on the strength set of fine-grained concrete with the addition of saponite-containing material

Original article

Morozova М.V. The effect of temperature and humidity treatment on the strength set of fine-grained concrete with the addition of saponite-containing material. Nanotechnology in Construction. 2024; 16(3): 227–234. – EDN: DXLKDK.

T he Solovetsky Islands are the most popular and sought-after historical and cultural complex of the Arkhangelsk region [1, 2]. In order to preserve and develop the cultural and natural heritage of the archipelago, the Government of the Russian Federation, by Order No. 163-r dated 05.02.2016, approved an action plan, which is being implemented with the support of the Ministry of Construction of the Russian Federation and includes the modernization of the engineering, housing and communal and social infrastructure of the island.

An important component for the implementation of this plan is the development and restoration of the road network of the archipelago, associated with the reconstruction and rehabilitation of existing facilities, construction of new permanent and temporary transport highways [3]. For example, concrete slabs can be used to restore and develop the road network of the Solovetsky Islands. These prefabricated, constructed from individual products, road pavements are manufactured in factories with observance of technological rules and concrete care regimes, ensuring their necessary quality. The advantage of reinforced concrete slabs is the possibility of traffic movement immediately after the pavement construction [4, 5].

Currently, to improve the performance characteristics of concrete products, compositions with additives of industrial wastes [6–8], including micro- and nano-level [9–14], are actively introduced.

An important economic component of this approach is associated with the use of local (locally distributed) raw material base. For example, for the Arkhangelsk region as such a material can be used saponite-containing waste from the mining industry. The effectiveness of its use in compositions with cement has been proved by a number of studies. Thus, in [15, 16] it was found that when obtaining fine-grained concrete, the addition of highly dispersed saponite-containing material (SCM), reduces binder consumption due to the chemical transformation of compounds that are part of rock minerals [17, 18], and increases performance characteristics such as strength, frost resistance and water resistance. Therefore, the possibility of using fine-grained concrete with SCM additive for the production of road slabs is of particular importance from both economic (reduction of cement consumption) and environmental (utilization of industrial waste) points of view. Steaming is one of the ways to accelerate the strength gain process of composites. This makes it possible to significantly reduce the production time of concrete products without reducing their quality and increase the volume of products. However, studies related to the effect of temperature and humidity treatment on the hardening process of a composite with the addition of saponite-containing material have not been studied before. At the same time, it was established [19] that the sorption of moisture by a highly dispersed SCM, which controls the structure formation during concrete hardening, makes it possible to improve the performance characteristics of the composite. In addition, when designing the composition of the product, the quantitative content of the mixing water is calculated based on the amount of water absorption of saponite-containing ma-

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS terial, which optimizes the content of the aqueous phase in the system. However, in conditions of high humidity, this ratio can change significantly and affect the process of gaining strength of the composite.

Therefore, the purpose of this work is to study the effect of temperature and humidity treatment on the strength set of fine-grained concrete with the addition of saponitecontaining material.

Studies [20] have shown that under normal hardening conditions, the formation of tricalcium silicate (C3S) leads to the formation of weakly crystalline calcium silicate hydrates (C–S–H) followed by the formation of portlandite [21, 22]. An increase in ambient temperature causes the bonds in C–S–H to become unstable [23], and at 70оС – C2SH crystals are formed, the accelerated formation of which leads to a decrease in the mechanical properties of the composite. This negative effect can be compensated by reducing the Ca/Si ratio, which is achieved by increasing the microdisperse component in the concrete mixture.

In addition to calcium hydrosilicate crystals, which are the main strength carriers, fibrous tobermite-like compounds are also formed in concrete. Currently, there are many works devoted to the artificial synthesis of tobermorite crystals [20, 24]. Therefore, the effect of high temperatures on the processes of its formation is well studied. It has been established that crystal formation occurs at 160–180оС, and heating to 300оС turns tober-morite into riverside. In the case of prolonged treatment with saturated steam (on the first day of concrete hardening), tobermorite at a temperature of 15оС is replaced by xonotlite [25]. Therefore, the accelerated method of concrete hardening should have only a positive effect on the formation of a strong and dense structure. However, if a highly dispersed saponite-containing material is used as an additive the opposite effect (decrease in strength) may be observed, associated with sorption properties and features of its structure.

METHODS AND MATERIALS

MATERIALS: To conduct research, experimental samples of saponite-containing suspension were taken from a tailings dump at a depth of one meter. Then, SCM was isolated from recycled water by the method of electrolyte coagulation based on the transfer of highly dispersed solid phase particles to a state close to isoelectric.

For the manufacture of samples of fine-grained concrete, portland cement CEM II/A-S 32.5N from the manufacturer “Eurocement” was used as a binder. The filler is medium – sized sand from the “Kenitsy” deposit, Arkhangelsk region. The sealing water is tap water, conforming to GOST 23732-2011.

METHODS: The saponite-containing material isolated from recycled water was dried in a “BINDER” drying cabinet to a constant mass at a temperature of

105оС. To obtain a highly dispersed solid phase, a mechanical dispersion method and a planetary ball mill “Retsch PM100” were used. The grinding of the material was carried out for 90 minutes at a rotor rotation speed of 420 rpm using grinding media in the amount of 20 pieces made of carbide tungsten (balls with a diameter of 20 mm).

The particle size was determined using the Delsa Nano Series Zeta Potential and Submicron Particle Size Analyzers (“DelsaNano”) submicron particle Size analyzer by measuring dynamic and electrophoretic light scattering. The resulting highly dispersed sample was characterized by nitrogen sorption on the “Autosorb-iQ-MP” analyzer according to the value of the specific surface of the Ssp (BET theory).

The modulus of size and the true density of sand were determined according to GOST 8735-88, and the true density of saponite-containing material according to GOST 21216-2014. The chemical composition of the SCM was determined on an X-ray fluorescence analyzer “Metexpert”.

The production of samples of fine-grained concrete of control and experimental (with the addition of SCM) compositions was carried out according to standard methods. The strength set of the samples was determined in two ways: under normal conditions (a cabinet chamber “KNT-60” was used to store concrete and cement samples with automatic temperature and humidity maintenance) and by an accelerated method using steaming (universal steaming chamber “KUP-1” according to GOST 9758-86 and GOST 25485-89).

Strength tests of cube samples with a size of 70×70×70 mm were carried out on an automatic test press “TP-1000” (compressive strength according to GOST 10180). The compressive strength was determined as the arithmetic mean of three parallel measurements.

To study the microstructure of fine-grained concrete samples by scanning electron microscopy, a Zeiss Sigma VP electron microscope (CCU “Arctic” at the M.V. Lomonosov NArFU) was used.

RESULTS AND DISCUSSION

The isolated, dried and crushed saponite-containing the material (in powder form) had an average particle size of 445±40 nm and a specific surface area of 50 670±10 m2/kg.

The true densities of sand (modulus of size Mk = 2.21) and SCM were 2640 kg/m3 and 2630 kg/m3, respectively.

A certain elemental composition (Table 1) of the saponite-containing material, and in terms of oxides, showed that the main components of the analyzed sample are oxides of silicon, magnesium and iron.

From the presented data, it follows that saponitecontaining material does not contain elements harmful

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Table 1

The elemental composition of SCM and in terms of oxides

In continuation of the research, control (FGC) and experimental (with the addition of SCM) samples of finegrained concrete (FGCscm) were produced, the compositions of which are shown in Table 2. The amount of a highly dispersed additive that was introduced into the concrete mixture was calculated based on previously obtained results of kinetic studies of the water absorption process of saponite-containing material [19]. The uniformity of mixing of the highly dispersed mineral additive with the initial raw materials was achieved by sequential mixing of the binder and filler with the addition of SCM.

As noted above, the strength set of the samples was carried out in two ways: under normal conditions (1-FGC; 1-FGCscm) and accelerated, by steaming (2-FGC; 2-FGCscm) at a temperature of 80оС for six hours. The strength characteristics of 1-FGC and 1-FGCscm were determined on day 28 (design age).

Samples of 2-FGC and 2-FGCscm, a day after sealing with water, were removed from metal molds and placed in a steaming chamber. After the expiration of the exposure time, the samples were gradually cooled, wiped with a dry cloth to remove excess moisture and their strength characteristics were determined.

The dynamics of the strength gain of fine-grained concrete of experimental and control compositions is shown in Figure 1.

Thus, the accelerated method of gaining strength of fine-grained concrete, by steaming, has a positive effect only on control samples. For a composite with the addition of SCM, temperature and humidity treatment has the opposite effect.

The results obtained (Fig. 1) showed that the dynamics of the strength gain of samples hardening under normal conditions is of the same type for both experimental and control formulations. At the initial moment of time (7 days), an active area of strength gain is observed. How-

Table 2

Composition of fine-grained concrete samples

|

Sample |

Composition for the production of one m3 of concrete mix, kg |

Density, kg/m3 |

|||

|

cement |

sand |

water |

SCM |

||

|

Control, FGC |

557 |

1380 |

283 |

– |

2107 |

|

Experienced, FGCscm |

557 |

1358 |

390 |

22 |

2292 |

05050505050 544332211 «Jdw с ғ й^^зддои^и ◎■-ssaJdluoQ

а

Fig. 1. Dynamics of strength gain of fine-grained concrete samples during hardening: a) under normal conditions; b) accelerated method (steaming); 1 – control composition; 2 – experimental composition

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Fig. 2. The appearance of the samples after steaming the composition: a) control; b) experimental

ever, already on day 7, the compressive strength of the samples of the experimental composition is 40% higher than that of the control one. The design strength (for 28 days) for 1-FGC was 28.94 MPa (class B20), and for 1-FGCscm – 44.28 MPa (class B30). It is worth noting that the introduction of a highly dispersed saponite-containing additive contributes to an increase in the strength class of concrete and leads to a reduction in the cement component.

With the accelerated hardening method, the dynamics of strength gain of 2- FGCscm has an excellent character. So, in the first two hours (the isothermal heating stage), an active area of strength increase is observed in both samples. Moreover, for an experienced person, this area is characterized by greater intensity. The subsequent hardening of 2- FGC has a linear relationship with a gradual increase in strength to the design strength in six hours. For 2-FGCscm, after two hours of steaming, the strength begins to decrease sharply, and after six hours, a visible destruction of the concrete structure occurs (Fig. 2).

Studies have shown that the isothermal heating stage has a positive effect on the strength set of 2-FGCscm samples only in the initial period (within two hours). Prolonged steaming of this concrete leads to a decrease in the strength characteristics of the prototypes, which is most likely due to moisture saturation of the composite structure.

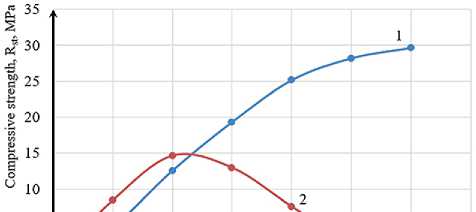

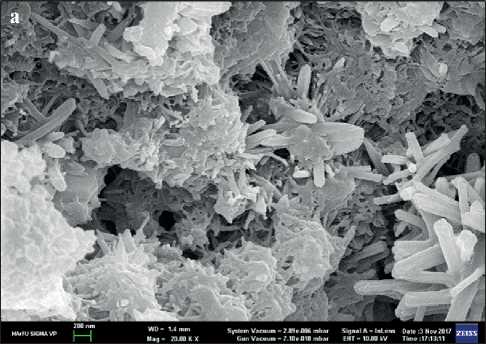

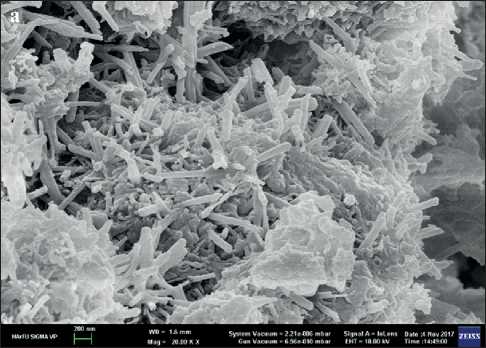

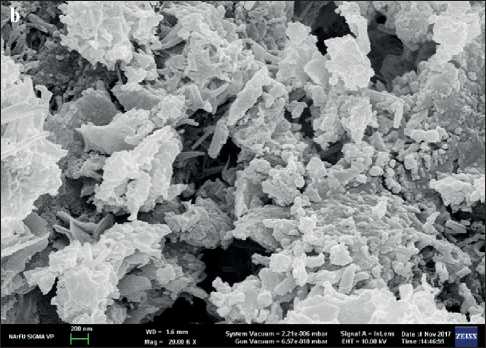

In order to explain the sharp decrease in the strength of concrete with highly dispersed saponite-containing admixture, photographs were taken of the microstructure of the samples after three hours of conditioning in the steaming chamber “KUP-1” (Fig. 3).

Scanning electron microscopy (SEM) of the composites, which gained design strength after 28 days, showed that the structure of the experimental and control samples is represented in the form of conglomerates of particles and hydrosilicate neoplasms, the size of which varies from 2 to 20 microns. In both materials, there are spongy, with developed microporous surface, and needle-like particles. Moreover, the number and length of the latter in the structure of the experimental sample increases almost

2 times compared to the control sample. Additional formation of needle-shaped crystals indicates the presence of submicrocrystals of hydrosilicates of the tobermorite group, which are formed in the presence of highly dispersed saponite-containing additive and play the role of an additional binder. After temperature and humidity treatment of fine-grained concrete with high-dispersed admixture, its microstructure was represented mainly by spongy particles, and the number of formed needles – significantly decreased compared to the control one. There is also observed a significant formation of voids in the experimental sample, which can be attributed to defects in the structure of the obtained concrete.

It is known that saponite has a three-layer crystalline structure, and the distance between its packets can easily change, since the connection between them is conditioned only by van der Waals forces. This fact can lead to significant swelling of highly dispersed clay powders under the action of moisture (water).

Such swelling of fine mineral admixture particles creates overpressure in the microstructure of the curing composite. This process causes the destruction of the internal structure of fine-grained concrete with SCM and leads to a decrease in its strength characteristics during steaming.

In the continuation of research to confirm the above hypothesis, the following experiment was performed, a 2 g weight of saponite-containing material was placed in a glass-measuring cylinder with a volume of 50 cm3 and 20 ml of water was added. The obtained reaction mixture was intensively stirred by shaking and allowed to stand for 30, 90, 180 min (Table 3).

The obtained data (Table 3) showed that all samples of highly dispersed saponite-containing material actively absorbed water. Thus, after 30 minutes the material increased in volume by 3.6 times, and after three hours – by 5.5 times, compared to the initial one.

CONCLUSION

An important practical conclusion that can be made because of the presented experimental results is the fol-

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

The control structure

Experienced personnel

Fig. 3. Microstructure of fine-grained concrete samples during hardening: a) under normal conditions; b) accelerated method (steaming)

Table 3

The change in the amount of swelling of saponite-containing material from time to time

MANUFACTURING TECHNOLOGY FOR BUILDING MATERIALS AND PRODUCTS

Список литературы The effect of temperature and humidity treatment on the strength set of fine-grained concrete with the addition of saponite-containing material

- Mazilova E.A. Development of Arctic tourism on the example of the Solovetsky archipelago. In the collection: Russian North and the Arctic: fundamental problems of history and modernity. Collection of scientific articles. Compiled by O.V. Zaretskaya. Arkhangelsk. 2019; 55-61.

- Grushenko E.B. Development of tourism industry on the Solovetsky Islands. Nauka-2020. 2016; 5(11).

- Tsvetkov A.Yu. Strategy of recreational and infrastructural development of the Solovetsky Islands. Economics and Entrepreneurship. 2018; 2(91): 282-286.

- Zinevich S.I., Kayumov A.K. Slabs for prefabricated road pavements with the least “key” effect. Science and Technology. 2022; 21(3): 196-200.

- Trofimov V.I., Egorov A.R., Khitrich G.A. Prefabricated Road Slabs for Arctic Zones. Scientific Bulletin of the Arctic. 2022; 12: 51-56.

- Sharifov A., Akramov A.A., Umarov U.Kh., Khokiyev M.K., Akhmedov M.F. Effects of microfilling mineral additives in concrete. Polytechnic Bulletin. Series: Engineering Research. 2020; 1(49): 150-154.

- Poorna P.S., Mohamed I.A., Lakshmi P.S., Gayathri G., Beulah M., Sudhir M.R. A comprehensive investigation of the effect of mineral additives to bituminous concrete. Materials Today: Proceedings. 2021; 46(1): 714-721. https://doi.org/10.1016/j.matpr.2020.12.090

- Zhen H., Lingling H., Yang L., Jun H., Yixin S. Use of sandstone powder as a mineral additive for concrete. Construction and Building Materials. 2018; 186: 276-286. https://doi.org/10.1016/j.conbuildmat.2018.06.228

- Xianfeng W., Shaocong C., Zhenhong Y., Jun R., Xiaogang Z., Feng X. Self-healing concrete incorporating mineral additives and encapsulated lightweight aggregates: Preparation and application. Construction and Building Materials, 2021; 301: 124119. https://doi.org/10.1016/j.conbuildmat.2021.124119

- Korolev E.V., Grishina A.N., Inozemtsev A.S., Ayzenshtadt A.M. Investigation of kinetics of structure formation of cement disperse systems. Part I. Nanotechnologies in Construction. 2022; 14(3): 176-189. https:// doi.org/10.15828/2075-8545-2022-14-3-176-189

- Korolev E.V., Grishina A.N., Inozemtsev A.S., Ayzenshtadt A.M. Investigation of kinetics of structure formation of cement disperse systems. Part II. Nanotechnologies in construction. 2022; 14(4): 263-273. https://doi.org/10.15828/2075-8545-2022-14-4-263-273

- Korovkin M.O., Korotkova A.A., Eroshkina N.A. Efficiency of complex mineral additive in fine-grained selfcompacting concrete. Regional architecture and construction. 2021; 3(48): 114-122.

- Pichugin A.P., Chesnokov R.A., Tamarova V.S., Pivkina A.D. Strengthening of road soil bases by mineral binders with disperse additives. Far East: problems of development of architectural and construction complex. 2021; 1: 178-183.

- Gaowen Z., Zhen Z., Guanzhou R., Tao W., Peng J., Shijun D., Mei S., Henghui F. Utilization of recycled concrete powder in modification of the dispersive soil: A potential way to improve the engineering properties. Construction and Building Materials. 2023; 389: 131626. https://doi.org/10.1016/j.conbuildmat.2023.131626

- Morozova M.V., Ayzenshtadt A.M., Makhova T.A. Application of saponite-containing material for obtaining frost-resistant concrete. Industrial and Civil Engineering. 2015; 1: 28-31.

- Lesovik V., Ayzenshtadt A., Frolova M., Lesovik R., Strokova V. «Green» Composites for North-Arctic Region Development // The Open Ecology Journal. 2014; 7: 32-36.

- Glaser A.M. Amorphous and nanocrystalline structures: similarity, differences, mutual transitions. Russian Chemical Journal. 2002; 46(5): 57-63.

- Prsembaev M.K., Kovalev Y.N., Yaglov V.N. Features of the processes of hydration and hardening of cement in the presence of nanoparticles. Bulletin of East Kazakhstan State Technical University named after D. Serikbaev. 2020; 1: 175-184.

- Morozova M.V. Sorption of water phase by mineral saponite-containing additive in fine-grained concrete. Bulletin of Belgorod State Technological University named after V.G. Shukhov. 2018; 4: 20-25.

- Mingxu C., Lingchao L., Shoude W., Piqi Z., Wenlong Z., Shuxin Z. Investigation on the formation of tobermorite in calcium silicate board and its influence factors under autoclaved curing. Construction and Building Materials. 2017; 280-288.

- Oh J.E., Clark S.M., Wenk H.R. Experimental determination of bulk modulus of 14 Å tobermorite using high pressure synchrotron X-ray diffraction. Cement and Concrete Research. 2012; 42(2): 397-403.

- Tikkanen J., Cwirzen A., Penttala V. Effects of mineral powders on hydration process and hydration products in normal strength concrete. Construction and Building Materials. 2014; 72: 7-14.

- Meducin F., Zanni H., Noik C. Tricalcium silicate (C3S) hydration under high pressure at ambient and high temperature. Cement and Concrete Research. 2008; 38(3): 320-324.

- Kaftaeva M.V., Rakhimbaev I.Sh. To the question of phase composition of hydrosilicate binder of autoclaved aerated concrete. International Journal of Applied and Fundamental Research. 2013; 10(3): 370-372.

- Galitskov K.S., Baranova M.N., Bolkhovetsky A.S. Investigation of the influence of the structural-phase composition of the aerated concrete on the internal heat generation in the process of its autoclave treatment. Town-planning and architecture. 2023; 13(51): 73-78.