The effect of the concentration of nanomodifiers and the moisture content of samples on the change in the properties of epoxy polymers

Автор: Nizin D.R., Nizina T.A., Spirin I.P., Chibulaev I.A., Pivkin N.A.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Construction materials science

Статья в выпуске: 6 Vol.16, 2024 года.

Бесплатный доступ

Introduction. Nanomodification significantly enhances the performance characteristics of composite materials, particularly those based on polymers. A wide range of materials from natural to artificially created are being studied as nanoobjects. At the same time, carbon nanostructures, such as fullerenes, graphene and carbon nanotubes, are of great interest from the perspective of comprehensively improving material performance. The use of carbon nanotubes for the modification of building materials for various functional purposes, even at low (less than 1% by mass) and ultra-low (less than 0.1% by mass) concentrations, demonstrates a remarkable capability to enhance a multitude of parameters. At the same time, there are technological challenges associated with the need for compound homogenization, requiring the use of ultrasonic processing and other techniques. A new approach to applying nanomodifiers, including single-walled graphene nanotubes, emerged after the launch of a new synthesis facility by OCSiAl in 2020, as well as the introduction of these nanotubes into polymer compounds in the form of masterbatches, which are nanotube concentrates. Methods and materials. This research involved a masterbatch based on single-walled carbon nanotubes TUBALL MATRIX M201 manufactured by OCSiAl.ru LLC. The polymers were made on the basis of low-viscosity epoxy resin Etal–247 and two hardeners manufactured by ENPTs EPITAL JSC –Etal-45M and Etal-1472. Tensile testing was performed on briquet specimens according to GOST 11262-2017. The tests involved AGS-X series bursting machine with TRAPEZIUM X software at a temperature of 23±2 °C and a relative air humidity of 50±5%. The mechanical properties (tensile and deformation) of the polymers were measured in three different moisture conditions: equilibrium-moisture, dry, and moisture-saturated. Results and discussion. The research revealed variations in ultimate tensile strength, tensile elongation and elongation at break, tensile modulus as a function of SGNT concentration and the moisture content of the studied polymers (series “without conditioning”, “moisture-saturated”, and “dried”). Mathematical models were developed to assess the effect of the nanomodifier and moisture content on changes in the properties of the polymers under study. The research has identified the optimal concentrations of the nanomodifier injected for enhancing the elastic and strength characteristics of epoxy polymers. Conclusion. The research indicates that masterbatches based on TUBALL MATRIX M201 single-walled carbon nanotubes hold potential for enhancing the properties of epoxy polymers.

Polymer materials, epoxy resins, hardeners, nanomodifiers, masterbatches, carbon nanotubes, tensile strength, elongation, elastic modulus, moisture content

Короткий адрес: https://sciup.org/142242742

IDR: 142242742 | DOI: 10.15828/2075-8545-2024-16-6-499-509

Текст научной статьи The effect of the concentration of nanomodifiers and the moisture content of samples on the change in the properties of epoxy polymers

Original article

Nanomodification significantly enhances the performance characteristics of composite materials, particularly those based on polymers [1–9]. Nanoobjects encompass a diverse range of materials, both natural and artificially created. At the same time, scientists have increasingly focused on the study of fullerenes, graphene,

CONSTRUCTION MATERIALS SCIENCE and carbon nanotubes (CNTs), recognizing their potential both as independent subjects of research and as promising modifiers of other materials.

Nanosized particles, due to their large specific surface area, significantly impact material structure formation, influencing the entire range of technological and operational characteristics [9–10]. Studies [2, 3, 5] have demonstrated that the presence of CNTs alters the rate at which chemical reactions proceed, leading to a shift in the maximum heat release to lower temperatures. Additionally, the total amount of the integral thermal effect during the reaction tends to decrease [9]. In most cases, the utilization of CNTs necessitates additional ultrasonic treatment, which significantly influences the curing kinetics, thermal, physical and mechanical characteristics of polymer materials [9, 11]. Careful attention must be paid to the intensity, duration, and other parameters of this treatment, particularly in industrial settings. At the same time, the vast majority of scientific studies strongly suggest that actively introducing CNTs into polymer composite materials (PCMs) is a viable approach for improving their physical and mechanical properties, thereby achieving desired functional properties.

Various studies [12–19] have highlighted the significant potential of using nanosized particles to modify polymers for construction applications. This is attributable to the potential for achieving a significant enhancement of PCMs performance properties at low (0.1–1%) and ultralow (less than 0.1%) concentrations of nanoparticles, thereby demonstrating the economic feasibility of this modification method. Polyvinyl chloride, widely used in the construction industry for a broad range of molded products, roofing materials, etc., and epoxy-based composites, used as protective and decorative coatings and for the fabrication of high-strength reinforced plastics for structural applications, have achieved significant prevalence [12, 20–23].

The introduction of optimal concentrations of both single-walled and multi-walled nanotubes into the composition of polymer binders leads to a significant improvement in performance characteristics [8, 12, 14–16, 19, 24, 25]. Several studies [6, 12] have highlighted the inconsistencies in experimental data obtained when modifying epoxy resins with CNTs, both in terms of curing rate and mechanical properties. The main conditions for the effective modification of polymer binders with CNTs, identified in almost all studies, are [26, 27]:

-

– uniform CNT distribution over the matrix volume;

-

– ensuring high adhesion of the CNT surface to the polymer matrix;

-

– CNT orientation in the direction of the load impact.

At the same time, multiple research studies have highlighted the influence of injecting carbon nanotubes on both the reinforcement and the curing/structure formation processes in polymer matrices. Under conditions insufficient for complete curing of the polymer matrix (lack of hardener, low temperature), the presence of initial or functionalized CNTs in the system promotes a higher degree of curing, consequently resulting in a more refined mesh structure than that obtained for unmodified compositions. Therefore, in turn, it leads to improved performance indicators such as modulus of elasticity, deformation at rupture, glass transition temperature, etc.) [27].

Despite significant interest from PCM manufacturers, widespread industrial use of carbon nanotubes is currently hampered by a number of factors that impede their widespread industrial application. A major obstacle is the difficulty in implementing technologies in the production process that can disperse and evenly distribute CNTs throughout the polymer matrix volume [28]. Studies [10, 25] have shown that nanoparticles tend to aggregate when using nanomodifiers to enhance polymer materials. At the same time, research has shown that the dispersion of CNTs and other nanofibers using traditional methods is often hindered by their tendency to form entangled “bundles” [30, 31].

Until recently, multi-walled carbon nanotubes (MCNTs) were more prevalent in the construction industry because their production cost was considerably lower than that of single-walled nanotubes. The introduction in 2020 of a new facility for the synthesis of high-quality single-walled graphene nanotubes (SGNTs) by OCSiAl, with an annual production capacity of 50 tons [32], may alter the selection prioritization of MCNTs and SGNTs as modifying additives, including in practical construction applications, even within the next few years. OCSiAL’s graphene nanotubes are commercially available as concentrated suspensions (so-called masterbatches), which significantly simplifies their incorporation into composite materials, ensuring proper dispersion without significant alteration of existing production processes. The existing scientific literature exhibits a limited amount of research focused on polymer materials, especially epoxy binderbased, modified with SGNTs as part of masterbatches manufactured by OCSiAL [33–35]. Research [34, 36] has shown that this type of nanotubes acts as an accelerator for the curing process of polymers based on DER-330 epoxy-dian resin and DEH-24 hardener. However, a significant increase in dynamic viscosity is observed across the entire range of measured temperatures at SGNT contents above 0.055% by mass. The authors attribute it to the formation of oriented layers of polymer macromolecules on the surface of the nanotubes, as well as their high aspect ratio.

In August 2020, the Oxilab design company (Leningrad region, Gatchina) started selling Carbix Epoxy masterbatch designed for epoxy self-leveling toppings [37], which opens up additional opportunities for the use of SGNTs in polymer coating compositions. It is evident that research and development of polymer composites nano-

CONSTRUCTION MATERIALS SCIENCE modified with masterbatches will continue at a rather high rate in the coming years, requiring intensified research to assess their properties as well as the durability and resistance of the resulting composites to various operational factors.

It is known that polymers are highly sensitive to the concentrations of moisture in their structure [38–44]. Moisture sorption by polymeric composites triggers structural relaxation, exhibits a partially reversible plasticizing effect, and participates in hydrolysis and post-curing reactions [45]. This research aimed to investigate the influence of moisture content on the properties of nanomodified polymers, particularly in their equilibrium moisture states (fully dried and moisture-saturated), with a focus on understanding the behavior of these polymers in field climatic conditions. This includes identifying both reversible and irreversible changes in their properties.

METHODS AND MATERIALS

The research involved epoxy polymer samples based on Etal-247 resin and two hardeners, Etal-45M and Etal-1472, both manufactured by ENPTs EPITAL JSC. Etal-247 epoxy resin (technical specifications TU 2257-247-1882619507) is a low-viscosity modified resin with Brookfield viscosity of 650÷750 cP at 25 °C. Mass fraction of epoxy groups for Etal-247 is at least 21.4÷22.8%. Etal-1472 is an amine type hardener; Etal-45M is a mixture of aromatic and aliphatic di- or polyamines modified with salicylic acid.

Polymer mixtures were modified with a concentrate based on single-walled carbon nanotubes TUBALL MATRIX M201 (technical specifications TU 20.59.59006-72254670-2018) manufactured by OCSiAl.ru LLC, which is a mixture of 2,3-epoxypropylneodecanoate and carbon tubes at a ratio of 90:10% by mass. The concentration of the injected masterbatch was 0.05; 0.1; 0.3 and 0.5% by mass of the polymer binder. Overhead stirrer stirrer SH-II-6C equipped with a milling dispersing head was used for mixing. The stirring speed was 2,500 rpm, and the stirring duration was 20 minutes.

To determine the elastic-strength parameters of the studied polymers, briquet specimens were made according to GOST 11262-2017 “Plastics. Tensile Test Method” (Type 2). Tensile testing involved AGS-X series bursting machine with TRAPEZIUM X software at a temperature of 23±2 °C and a relative air humidity of 50±5%. The mechanical properties (tensile and deformation) of the polymers were measured in three different moisture conditions: equilibrium-moisture, dry, and moisture-saturated. Specimens were dried at a temperature of 60±2 °C, moisturized in desiccators above water at 23±2 °C in accordance with GOST R 56762-2015 “Polymer Composites. Method for Determining Moisture Absorption and Equilibrium State.” At least 10 specimens were tested in parallel for each series.

RESULTS AND DISCUSSION

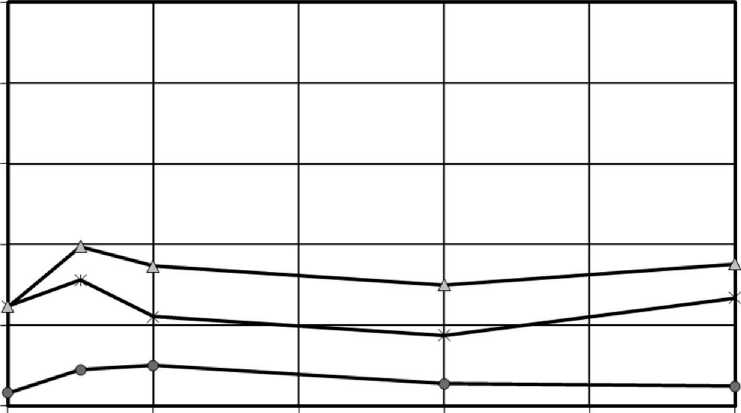

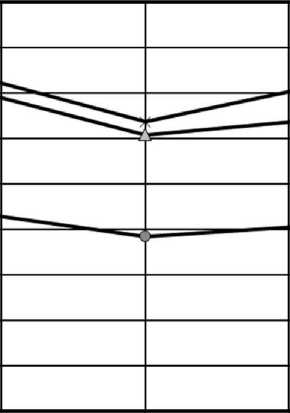

Figures 1 and 2 show the curves of variation of tensile strength and modulus of elastic for nanomodified epoxy polymers as a function of SGNT content and moisture state across multiple specimen series. For the convenience of visual representation, the curves are built in the same range of elastic-strength indicators. Histograms of variations in the specimen weight during moisture saturation and drying are shown in Figure 3. Numerical values of the moisture content of various specimen series of the polymers under study, as well as the tensile strength, tensile elongation and elongation at break are shown in Table 1.

It is found (Fig. 1, 2; Table 1) that Etal-1472 hardener makes it possible to obtain Etal-247 resin-based epoxy polymers with a complex of better parameters than for Etal-45M. In particular, the tensile strength, elongation and modulus of elasticity for the polymer containing Etal-247/Etal-1472 exceeds similar indicators for Etal-247/ Etal-45M, respectively, by 1.5, 1.6 and 1.3 times (“without conditioning” series). This effect is slightly higher (up to 1.6÷1.7, 1.7 and 1.4÷1.5 times) for the “moisture-saturated” and “dried” series. At the same time, the tensile strength at break of the polymer cured by Etal-1472, depending on the moisture state, exceeds the value when using Etal-45M hardener for the “without conditioning”, “moisture-saturated” and “dried” series by 30, 9 and 15%, respectively. Elongation at break increases the most for moisture–saturated specimens – 1.2 times. For the “dried” series, this value for the Etal-247/Etal-45M polymer exceeds the elongation at break of the Etal-247/ Etal-1472 polymer by 15%.

Nanomodification of polymer binders with various (0.05; 0.1; 0.3 and 0.5% by mass) concentrations of TUBALL MATRIX M201 masterbatch increases (Fig. 1) the ultimate tensile strength of control compounds (“without conditioning” series) by 9% (Etal-247/Etal-45M) and 18% (Etal-247/Etal-1472), and the highest levels of improvement in strength values were achieved with a minimum level of injected SGNTs – 0.05% by mass. Removal of free moisture from the structure of polymer specimens for all studied polymers leads to an increase in strength values for all nanomodified compounds, while moisture saturation leads to a decrease. In general, the ratio of ultimate tensile strengths in boundary states (“dried” to “moisture-saturated”) varies: from 1.4 to 1.6 times for the Etal-247/Etal-45M polymer; from 1.5 to 1.6 times for the Etal-247/Etal-1472 polymer. The levels of variation in the tensile strength at break, depending on the moisture state, also vary within the same intervals. Variation of the tensile modulus for boundary moisture states reaches, respectively, 26–34 and 16–25% for compounds cured with Etal-45M and Etal-1472.

CONSTRUCTION MATERIALS SCIENCE а 75

Iuua 匸 s ә—s【咼

25 О

0.2 0.3 0.4 0.5

Concenti ation of TUB ALL MATRIX M201,%

Moistxue state of samples (Etal-247/Etab45M):

-

-*—without conditioning —•-moistiue-satiuated f-diied

re^s 二auaus ә^иәі

Concentration of TUB ALL MATRIX M201,%

Moistiue state of samples (Etal-247/Etai-1472):

-

—*—without conditioning —o-moistine-satuiated —Л-diied

Fig. 1. Change in the ultimate tensile strength of epoxy polymers (a – Etal-247/Etal-45M; b – Etal-247/Etal-1472) depending on the SGNT concentration and moisture state of the specimen series

Taking into account a certain variation in the initial (“without conditioning” series) moisture state of polymers (see Table 1), as well as the change in moisture content during moisture saturation and drying to a constant mass (Fig. 3), the results were subjected to mathematical processing to obtain polynomial dependencies describing the change in polymer properties depending on the nanoadditive concentration and the moisture state of the

CONSTRUCTION MATERIALS SCIENCE

а 3200

b 0 0.1 0.2 0.3 0.4 0.5 Concentration of TUB ALL MATRIX M201,% Moisture state of samples (Etal-247/Etal-45M): -^-without conditioning —Ф-moistiire-satiuated -^dried b 3200 BJPV КНОІЗВІӘ jo srqnpos O^^SH 0 0.1 0.2 0.3 0.4 0.5 Concentration of TUB ALL MATRIX M201,% Moisture state of samples (Etal-247/Etal-1472): —*—without conditioning —o—moistiue-saturated f—diied Fig. 2. Change in the tensile modulus of epoxy polymers (a – Etal-247/Etal-45M; b – Etal-247/Etal-1472) depending on the SGNT concentration and moisture state of the specimen series specimen series. To do this, a plan was synthesized for each compound and the levels of variation were calculated (Table 2). The differences in numerical values of moisture content (x2) are explained by the different levels of achieved moisture content of the “moisture-saturated” series polymers. Increase in the reliability of mathematical models involved the use of a third degree polynomial: CONSTRUCTION MATERIALS SCIENCE Table 1 Changes in the elastic-strength parameters of nanomodified epoxy polymers depending on the SGNT concentration and moisture state of the specimen series* Parameter under study SGNT concentration, % by mass 0 0.05 0.1 0.3 0.5 “without conditioning” series Tensile strength at break, MPa 32.9 53.1 38.0 64.3 33.1 60.5 31.0 53.6 37.2 52.9 Tensile elongation, % 3.30 4.28 4.32 5.43 3.51 4.59 3.98 3.99 3.94 3.85 Elongation at break, % 5.08 5.50 6.27 5.96 6.62 5.42 5.74 3.99 5.10 4.09 Moisture content, % by mass 0.786 0.684 0.207 0.289 0.495 0.351 0.442 0.382 0.258 0.369 “moisture-saturated” series Tensile strength at break, MPa 23.1 38.9 28.3 43.1 29.6 43.4 27.2 38.8 27.1 40.9 Tensile elongation, % 2.96 3.23 3.61 4.39 3.48 4.37 3.71 3.94 3.57 4.06 Elongation at break, % 5.69 6.84 5.23 6.17 4.14 5.12 4.64 3.95 4.44 4.10 Moisture content, % by mass 2.723 2.242 2.396 3.110 2.166 3.139 2.276 3.316 2.397 3.107 “dried” series Tensile strength at break, MPa 36.9 63.5 44.6 71.1 42.3 70.5 40.0 60.2 42.6 59.9 Tensile elongation, % 4.16 4.80 4.83 6.40 4.32 5.61 4.63 4.84 5.06 4.23 Elongation at break, % 6.33 5.48 5.40 6.59 4.32 5.71 4.72 4.84 5.61 4.23 Moisture content, % by mass ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 *the numerator – values for the Etal-247/Etal-45M polymer, the denominator – values for the Etal-247/Etal-1472 polymer y = b0+ b1•x1+ b2•x2+ b12•x1•x2+ b11•x12 + + b22•x22+ b1122•x12•x22+ b111•x13+ b222•x23, (1) where x1is the SGNT concentration, code value; x2is moisture content level, code value. Fig. 4–6 show three–dimensional surfaces allowing to visually trace the effect of different levels of polymer moisture content on the effectiveness of their nanomodification. It was found that the maximum levels of ultimate tensile strength and modulus of elasticity, as well as tensile strength at break for the Etal-247/Etal-1472 polymer are reached for SGNT concentrations of 0.05-0.1% by mass. A further increase in the nanomodifier consumption to 0.3% leads to a decrease in the above strength param- eters, which indicates that it is not reasonable to introduce SGNTs above 0.1% of the binder mass. The Etal-247/ Etal-45M polymer compound shows a similar, though less pronounced, pattern. All types of the resulting three-dimensional surfaces exhibit a sharp decrease in strength parameters with the moisture content approaching the limit levels, reaching 1.45–2.11 times for the polymers under study. As a rule, in the field operation, polymer materials are rarely in limit (moisture-saturated and dried) conditions for a long time. However, even the formation of an “average” moisture saturation level, corresponding to polymers cured by Etal-45M (1.35% by mass) and Etal-1472 (1.65%), can lead to a decrease in the ultimate tensile strength, respectively, CONSTRUCTION MATERIALS SCIENCE Table 2 Levels of variation in the factors under study* Polymer under study Variable factors Levels of variation –1 0 +1 Etal-247/Etal-45M x1 SGNT concentration, % by mass 0 0.25 0.5 x2 Moisture content, % 0 1.35 1.35 Etal-247/Etal-1472 x1 SGNT concentration, % by mass 0 0.25 0.5 x2 Moisture content, % 0 1.65 1.65 а % CSSEE uldmps.£ 1.5 - 0.5 - O-0.5 - О 0.05 0.1 0.3 0.5 Concentiation of TUB ALL MATRIX M201,% Moistui e state of samples (Etal-247/Etal-45M): □ moisture-saturated □ dried b -1 - —— u — 0 0.05 0.1 0.3 0.5 Concentiation of TUB ALL MATRIX M201, % Moisture state of samples (Etal-247/Etal-1472): □ moisture-saturated □ dried Fig. 3. Change in the average mass of nanomodified polymer specimen series moisture-saturated and dried to a constant mass (according to GOST 56762): a – Etal-247/Etal-45M; b – Etal-247/Etal-1472 CONSTRUCTION MATERIALS SCIENCE 0 20-25 口 25-30 □ 30-35 □ 35-40 □ 40-45 □ 3 5-40 0 40-45 □ 55-60 □ 60-65 □ 45-50 □ 50-55 □ 65-70 □ 70-75 Fig. 4. Three-dimensional surfaces describing the change in ultimate tensile strength of epoxy polymers (a – Etal-247/ Etal-45M; b – Etal-247/Etal-1472) depending on the SGNT concentration and the average moisture content of the specimen series 0 5 0 5 4 4 «л§ WMUMS 里-sue гр匸SCCWJO snspos A-6MSEP JO s三二pop/ □ 1400-1600 □ 2000-2200 □ 1600-1800 □ 2 200-2400 □ 1800-2 000 □ 2000-2200 □ 2600-2800 □ 2200-2400 □ 2 800-3 000 □ 2400-2600 Fig. 5. Three-dimensional surfaces describing the change in the modulus of elasticity of epoxy polymers (a – Etal-247/ Etal-45M; b – Etal-247/Etal-1472) depending on the SGNT concentration and the average moisture content of the specimen series by 1.14÷1.50 and 1.35–1.57, which must be taken into account when designing polymer compounds. CONCLUSION Research results have revealed the impact of the concentration of the nanomodifier (a masterbatch based on TUBALL MATRIX M201 single-walled carbon nano- tubes) on the change in the elastic-strength properties of polymers based on Etal-247 low-viscosity epoxy resin. The use of this resin with Etal-45M and Etal-1472 low-viscosity hardeners can significantly improve technological performance of the resulting polymer compounds, which is important in the development of protective coatings for building products and structures. Nanomodification of epoxy polymers with the injection of ultra-low CONSTRUCTION MATERIALS SCIENCE 0 5 0 7 6 6 □ 20-25 025-30 口30-35 □ 35-40 □ 40-45 □ 30-35 口35-40 040-45 045-50 □ 50-55 Fig. 6. Three-dimensional surfaces describing the change in tensile strength at break of epoxy polymers (a – Etal-247/ Etal-45M; b – Etal-247/Etal-1472) depending on the SGNT concentration and the average moisture content of the specimen series concentrations (≤0.1% by mass) of TUBALL MATRIX M201 has been proven effective. The use of carbon nanotubes in the form of masterbatches as a nanomodifier provides their uniform distribution over the epoxy polymer volume without involving additional process techniques, including widespread ultrasonic treatment that leads to the curing process intensification and, as a result, a decrease in the viability of mixtures. Different moisture content levels (“without conditioning”, “moisture-saturated” and “dried”) were found to significantly affect the properties of nanomodified epoxy polymers. A mathematical model has been developed to predict the elastic and strength properties of epoxy polymers based on Etal-247 epoxy resin as a function of the SGNT concentration and specimen moisture content.

Список литературы The effect of the concentration of nanomodifiers and the moisture content of samples on the change in the properties of epoxy polymers

- Rakov E.G. Chemistry and application of carbon nanotubes; Uspekhi Chem. 2001; 70 (10):934–973.

- Puglia D., Valentini L., Kenny J.M. Analysis of the cure reaction of carbon nanotubes/epoxy resin composites through thermal analysis and raman spectroscopy; J. of Applied Polymer Science. 2003; 88:452–458.

- Valentini L., Armentano I., Puglia D., Kenny J.M. Dynamics of amine functionalized nanotubes/epoxy composites by dielectric relaxation spectroscopy; Carbon. 2004; 42:323–329.

- Wu J., Chung D.D.L. Calorimetric study of the effect of carbon fillers on the curing of epoxy; Carbon. 2004; 42:3003–3042.

- Zhou T., Wangand X., Wang T. Cure reaction of multi-walled carbon nanotubes/ diglycidyl ether of bisphenol A/2-ethyl-4- methylimidazole (MWCNTs/DGEBA/ EMI-2,4) nanocomposites: effect of carboxylic functionalization of MWCNTs; Polymer International. 2009; 58: 445–452.

- Badamshina E.R., Gafurova M.P., Estrin Ya.I. Modification of carbon nanotubes and synthesis of polymer composites with their participation; Uspekhi Chem. 2010; 79(11):1027–1063.

- Irzhak V.I. Epoxy composite materials with carbon nanotubes; Uspekhi khimii. 2011;80(8):821–840.

- Kondrashov S.V., Shashkeev K.A., Popkov O.V., Solov’yanchik L.V. Promising technologies for producing functional materials for structural purposes based on nanocomposites with CNTs (review); Proceedings of VIAM: electronic scientific and technical journal. 2016; 3. Article 07.

- Kablov E.N., Kondrashov S.V., Yurkov G.Yu. Prospects for the use of carbon-containing nanoparticles in binders for polymer composite materials; Russian nanotechnologies. 2013; 8(3):28–46.

- Simonov-Emelyanov I.D., Pykhtin A.A., Mikhalchenko K.A. Influence of the size of nanoparticles and their agglomerates on the physicomechanical properties of epoxy nanocomposites; Russian nanotechnologies. 2018;7-8:24–29.

- Khozin V.G. Strengthening of epoxy polymers. Kazan: Publishing House PIK “Pechat House”; 2004.

- Khozin V.G., Nizamov R.K., Abdrakhmanova L.A. Modification of construction polymers (polyvinyl chloride and epoxy) with single-walled carbon nanotubes; Construction materials. 2017;1-2:55–61.

- Lesovik V.S., Strokova V.V. On the development of the scientific direction “Nanosystems in construction materials science”; Construction materials. 2006; 9. Science. 8:18–20.

- Figovsky O.L., Beilin D.A., Ponomarev A.N. Advances in the application of nanotechnology in building materials; Nanotechnology in construction: scientific online journal. 2012; 4(3):6–21.

- Nizina T.A., Kislyakov P.A. Optimization of properties of epoxy composites modified with nanoparticles; Construction materials. 2009;9:78–80.

- Kislyakov P.A., Nizina T.A. Nanomodified epoxy composites for construction purposes / Advanced materials. 2010;9:113–116.

- Khozin V.G., Starovoytova I.A., Maisuradze N.V., Zykova E.S., Khalikova R.A., Korzhenko A.A., Trineeva V.V., Yakovlev G.I. Nanomodification of polymer binders for structural composites; Construction materials. 2013;2:4–10.

- Ashrapov A.Kh., Abdrakhmanova L.A., Nizamov R.K., Khozin V.G. Study of polyvinyl chloride composites with carbon nanotubes; Nanotechnology in construction: Scientific online journal. 2011;3:13–24.

- Khozin V.G., Abdrakhmanova L.A., Nizamov R.K. General concentration pattern of effects of nanomodification of building materials; Construction materials. 2015;2:25–33.

- Nizina T.A. Protective and decorative coatings based on epoxy and acrylic binders. Saransk: Publishing house of the Mordov. University; 2007

- Selyaev V.P. Polymer coatings for concrete and reinforced concrete structures / V.P. Selyaev, Yu.M. Bazhenov, Yu.A. Sokolova, V.V. Tsyganov, T.A. Nizina. – Saransk: Publishing house of SVMO; 2010.

- Polymer concretes: monograph / V.P. Selyaev, Yu.G. Ivaschenko, T.A. Nizina. – Saransk: Publishing house of the Mordov. University; 2016.

- Nizina T.A., Selyaev V.P., Nizin D.R. Climatic resistance of epoxy polymers in a temperate continental climate: monograph. – Saransk: Publishing house of the Mordov. University; 2020.

- Abdrahmanova L.A., Burnashev A.I., Nizamov R.K., Khozin V.G. Nanomodifified wood-polymer composites on the basis of polyvinylchloride; The III International Conference NTC-2011 «Nano-technology for eco-friendly and durable construction. Cairo. 2011:23–27.

- Starovoitova I.A., Khozin V.G., Korzhenko A.A., Khalikova R.A., Zykova E.S. Structure formation in organoinorganic binders modified with multi-walled carbon nanotube concentrates; Construction materials. 2014;1–2:12–20.

- Du H., Bai J., Cheng Y-M; J. eXPRESS Polymer Letters. 2007 ; 1;5:253–273.

- Bogatov V.A., Kondrashov S.V., Mansurova I.A., Minakov V.T., Anoshkin I.V. On the mechanism of reinforcement of epoxy resins with carbon nanotubes; All materials. Encyclopedic reference book. 2012;4:7–11.

- Kahramanov N.T., Azizov A.G., Osipchik V.S. et al. Nanostructured composites and polymer materials science; Plastic masses. 2016;1-2:49–57.

- Mikitaev A.K., Kozlov G.V., Zaikov G.E. Polymer nanocomposites: variety of structural forms and applications. M.: Nauka; 2009.

- Rakov E.G. Production of thin carbon nanotubes by catalytic pyrolysis on a support; Uspekhi Chem. 2007. Vol. 76;1:3–19.

- Zhirikova Z.M., Kozlov G.V., Aloev V.Z. Predicting the degree of reinforcement for polymer/carbon nanotubes nanocomposites / Plastics. 2013;7:29–31.

- Kolerova V. Nanotubes at a low start. OCSiAl is the world’s largest manufacturer of graphene single-walled nanotubes. Expert. 2020;9. access mode: https://www.rusnano.com/about/press-centre/media/20200225-expertocsial-nanotrubki-na-nizkom-starte.

- Shadrinov N.V. Study of the influence of carbon nanotubes on the deformation properties of butadiene-nitrile rubber by atomic force microscopy; Collection of reports of the XXII scientific and practical conference “Rubber industry: raw materials, materials, technologies”. Moscow. 2017:95–100.

- Novikovskiy E.A., Ananyeva E.S. Features of the implementation of the technological process of modifying epoxy compounds with carbon nanotubes and ultradisperse particles; Polzunovsky Bulletin. 2016;1:102–107.

- Kychkin A. Research of influence of carbon nano tubes on elastic-strength properties of epoxy resin / A. Kychkin, E. Anan’eva, A. Kychkin, A. Tuisov; Procedia Structural Integrity: materials of 9th Eurasian Symposium on the Problems of Strength and Resource in low Climatic Temperatures, EURASTRENCOLD-2020. Yakutsk, Russia, September 14–17, 2020. 2020; 30:59–63. https://doi.org/10.1016/j.prostr.2020.12.036. – 0.46

- Novikovskiy E.A. Modification of epoxy composites with ultradispersed carbon particles of thermal and detonation synthesis. diss. cand. tech. sciences. Barnaul; 2017.

- “OxyLab” began selling a new masterbatch for epoxy self-leveling floors. – access mode: https://plastinfo.ru/information/news/46061_11.08.2020/.

- Nizin, D.R., Nizina, T.A., Selyaev, V.P., Klimentyeva, D.A., Kanaeva, N.S. Changes in the moisture contentof epoxy polymer samples under natural climatic aging; Climate-2021: Modern approaches to assessing the impact of external factors on materials and complex technical systems. Proceedings of the VI All-Russian Scientific and Technical Conference. Moscow. 2021:41–52.

- Nizina T.A., Nizin D.R., Kanaeva N.S., Klimentyeva D.A., Porvatova A.A. Influence of humidity state on the kinetics of damage accumulation in the structure of epoxy polymer samples under the action of tensile stresses Expert: theory and practice. 2022;1: 37–45.

- Startsev V.O., Panin S.V., Startsev O.V. Sorption and diffusion of moisture in polymer composite materials with impact damage Mechanics of composite materials. 2015;6: 1081–1094.

- Maxwell A.S., Broughton W.R., Dean G., Sims G.D. Review of accelerated ageing methods and lifetime prediction techniques for polymeric materials NPL Report DEPC MPR 016. 2005.

- Nizin D.R. Modeling the effect of moisture content on the performance properties of epoxy polymers taking into account natural climatic aging / D.R. Nizin, T.A. Nizina, V.P. Selyaev, I.P. Spirin Polymer composite materials and production technologies of the new generation: VII All-Russian scientific and technical. conf. Moscow, 11/24/2023. NRC “Kurchatov Institute”; VIAM. 2023:171–194.

- Nizin D.R. Analysis of the influence of climatic factors on changes in the physical and mechanical characteristics of polymeric materials taking into account their moisture content / D.R. Nizin, T.A. Nizina, V.P. Selyaev, I.P. Spirin Modern energy-saving thermal technologies (drying and thermal processes) SETMT-2023: collection of scientific papers of the eighth int. scientific-practical. conf., Moscow. 2023:275–279.

- Nizin D.R., Nizina T.A., Maryanova A.V., Mironov E.B. Moisture absorption of 3D-printed PETG plastic samples; Bulletin of MGSU. 2023; 18(7):1078–1088. https://doi.org/10.22227/1997-0935.2023.7

- Startsev, V.O., Plotnikov, V.I., Antipov, Yu.V. Reversible effects of moisture influence in determining the mechanical properties of PCM under climatic influences; Proceedings of VIAM. 2018;5:110–118.