The features of the implementation of injection technologies using polymer-based compositions with adjustable parameters in underground construction. Part II

Автор: Ter-Martirosyan A.Z., Anzhelo G.O., Alexeev V.A.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: Application of nanomaterials and nanotechnologies in construction

Статья в выпуске: 5 Vol.17, 2025 года.

Бесплатный доступ

Introduction. A primary geotechnical challenge pertains to the stabilization of unstable soils due to their inadequate deformation, physical, mechanical, and filtration characteristics, which, in turn, can result in abnormal settlements, the destabilization of the soil mass under external loads, or even its own weight. The advent of chemical technologies on a global scale, along with their development within the Russian Federation, has precipitated the utilization of advanced equipment in conjunction with novel, innovative technologies. This confluence has given rise to novel methodologies and the fabrication of new materials, which have been instrumental in addressing a myriad of geotechnical challenges. The predominant methods of soil stabilization with mineral compounds (predominantly based on Portland cement) possess clear advantages; however, they do not always permit work to be conducted in soils with high water saturation, under conditions of high filtration, or in soils with low deformation indices. Consequently, issues pertaining to cementation stabilization periodically emerge. These issues manifest, for instance, in water-saturated rock soils under high hydrostatic pressures, in various fractured soils complicated by the presence of karst depressions, in dispersed, silty, and organo-mineral structurally unstable soils. Materials and methods. The employment of innovative polymer materials, such as polyurethane-based materials, facilitates the injection of mixtures with optimized strength gain, thereby addressing the issue of soil reinforcement within this process or enhancing the criteria for constraining the propagation of injection mixtures for subsequent cement grouting. Results and conclusion. Laboratory tests and analysis of a number of completed projects allow us to consider this technology effective and practical in complex engineering and geological conditions and beyond design-basis parameters for underground construction projects. The present study was carried out using the material and technical resources of the Main Regional Center for Collective Use of Scientific Equipment and Installations of the Moscow State University of Civil Engineering, with the support of the Ministry of Science and Higher Education of the Russian Federation (agreement No. 075-15-2025-549).

Soil stabilization, soil cementation, soil injection, complex engineering and geological conditions, cuff technology, polyurethane, emergency, construction

Короткий адрес: https://sciup.org/142246081

IDR: 142246081 | DOI: 10.15828/2075-8545-2025-17-5-618-630

Текст научной статьи The features of the implementation of injection technologies using polymer-based compositions with adjustable parameters in underground construction. Part II

Review article

Introduction. A primary geotechnical challenge pertains to the stabilization of unstable soils due to their inadequate deformation, physical, mechanical, and filtration characteristics, which, in turn, can result in abnormal settlements, the destabilization of the soil mass under external loads, or even its own weight. The advent of chemical technologies on a global scale, along with their development within the Russian Federation, has precipitated the utilization of advanced equipment in conjunction with novel, innovative technologies. This confluence has given rise to novel methodologies and the fabrication of new materials, which have been instrumental in addressing a myriad of geotechnical challenges. The predominant methods of soil stabilization with mineral compounds (predominantly based on Portland cement) possess clear advantages; however, they do not always permit work to be conducted in soils with high water saturation, under conditions of high filtration, or in soils with low deformation indices. Consequently, issues pertaining to cementation stabilization periodically emerge. These issues manifest, for instance, in water-saturated rock soils under high hydrostatic pressures, in various fractured soils complicated by the presence of karst depressions, in dispersed, silty, and organo-mineral structurally unstable soils. Materials and methods. The employment of innovative polymer materials, such as polyurethane-based materials, facilitates the injection of mixtures with optimized strength gain, thereby addressing the issue of soil reinforcement within this process or enhancing the criteria for constraining the propagation of injection mixtures for subsequent cement grouting. Results and conclusion. Laboratory tests and analysis of a number of completed projects allow us to consider this technology effective and practical in complex engineering and geological conditions and beyond design-basis parameters for underground construction projects. The present study was carried out using the material and technical resources of the Main Regional Center for Collective Use of Scientific Equipment and Installations of the Moscow State University of Civil Engineering, with the support of the Ministry of Science and Higher Education of the Russian Federation (agreement No. 075-15-2025-549). KEYWORDS: soil stabilization, soil cementation, soil injection, complex engineering and geological conditions, cuff technology, polyurethane, emergency, construction

Ter-Martirosyan A.Z., Anzhelo G.O., Alexeev V.A. The features of the implementation of injection technologies using polymer-based compositions with adjustable parameters in underground construction. Part II. Nanotech-nologies in construction. 2025;17(5):618–630. – EDN: IAYMCC.

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Особенности реализации инъекционных технологий составами на полимерной основе с регулируемыми параметрами в подземном строительстве. Часть II

AННОТАЦИЯ

Введение. Одной из основных геотехнических проблем является закрепление неустойчивых грунтов в связи с их недостаточно высокими показателями по деформационным, физико-механическим, фильтрационным характеристикам, что может привести к ненормативным осадкам, дестабилизации грунтового массива под действием внешних нагрузок или даже собственного веса. Благодаря развитию химических технологий как в мире, так и в Российской Федерации, использованию современного оборудования в совокупности с новыми инновационными технологиями возникают новые методы и создаются новые материалы для решения широкого спектра возникающих геотехнических задач. Основные методы стабилизации грунтов минеральными составами (в основном, на базе портландцемента), несмотря на очевидные преимущества, не всегда позволяют производить работы в сильно водонасыщенных грунтах, в условиях высокой фильтрации, в грунтах с низкими показателями деформации. Так, периодически возникают проблемы цементационного закрепления, например, в водонасыщенных скальных грунтах при высоких гидростатических напорах, в различных трещиноватых грунтах, осложненных наличием карстовых воронок, в дисперсных, илистых и органоминеральных структурно-неустойчивых грунтах. Материалы и методы. Применение инновационных полимерных материалов, например, на полиуретановой основе позволяет производить инъекцию смесей с максимально быстрым набором прочности материалов, что позволяет решать проблематику усиления грунтов в рамках данного передела или повышать критерии ограничения распространения инъекционных смесей для последующего нагнетания цементных растворов. Результаты и выводы. Проведенные лабораторные испытания и анализ ряда реализованных объектов позволяют считать данную технологию эффективной и практически применимой в сложных инженерно-геологических условиях и непроектных параметрах при реализации объектов подземного строительства. Данное исследование выполнено с использованием материально-технической базы Головного регионального центра коллективного пользования научным оборудованием и установками НИУ МГСУ при поддержке Министерства науки и высшего образования Российской Федерации (соглашение № 075-15-2025-549).

Тер-Мартиросян А.З., Анжело Г.О., Алексеев В.A. Особенности реализации инъекционных технологий составами на полимерной основе с регулируемыми параметрами в подземном строительстве. Часть II. Нанотехнологии в строительстве. 2025;17(5):618–630. – EDN: IAYMCC.

RESULTS

To further investigate the performance of the materials in soil environments, a series of polyurethane-based injection polymer compositions were examined, given their prevalence in numerous applications. The selected type of injection mixture allows for its use with high efficiency in a variety of applications, including soil stabilization, the creation of antifiltering curtains and cut-offs, the elimination of active leaks, and the mitigation of water seepage in the underground structures etc.

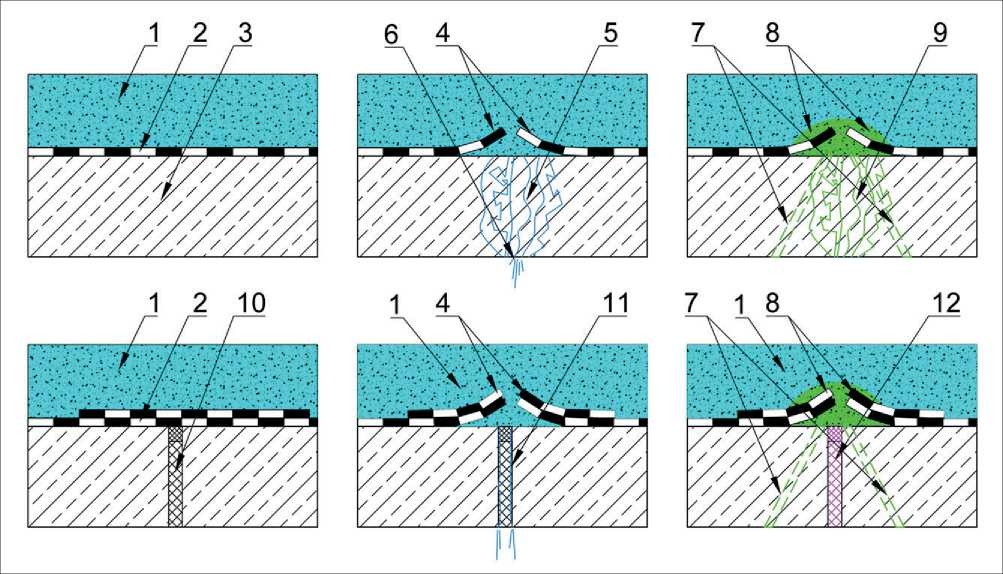

In the field of waterproofing solutions, the implementation of polymer mixtures is subject to regulatory oversight, as delineated by established standards. Numerous design organizations have developed a range of standard schemes and technical solutions (see Fig. 4) aimed at restoring the waterproofing capabilities of structures in instances where these properties have been compromised. The majority of these technologies and materials are well-known, have been widely and successfully implemented, and are not discussed further in this article in the context of their application in the restoration of waterproofing of underground structures.

However, when implementing injection stabilization and soil reinforcement technology using polymer materials, design organizations in the Russian Federation mainly refer to the provisions of SP 22.13330.2016 “Foundations of Buildings and Structures” and SP

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 4. Standard polymer mixture injection schemes for the purpose of restoring the waterproofing of structures: 1. Water-saturated soil. 2. Water-proofing layer. 3. Underground structure. 4. Damage to the waterproofing layer (tears, severe deformation, detachment, punctures, integrity damage etc.) 5. Micro-channels for filtering the water medium in the structure. 6. Leakage/water seepage from the reverse side of the structure. 7. Holes for injecting grouting mixtures. 8. Soil treatment area at the point of water-proofing failure for local restoration. 9. Partial or complete filling of micro-channels. 10. Expansion joint in structures. 11. Filtration channels in the expansion joint. 12. Restoration of the expansion join.

45.13330.2017 “Earthworks, Basements and Foundations.” These documents do not provide technology parameters and requirements for modern polyurethane, epoxy, and acrylate compositions. Instead, they refer to the use of urea-formaldehyde and phenol-formaldehyde resins. However, these resins are practically not used at present due to the toxicity of the materials and the complexity of the work.

In light of the findings from the research conducted at several locations by the authors [11, 12, 13, 16] and in accordance with numerous other sources [25, 28, 30, 31], it has been observed that regulatory and technical documents are deficient in certain requirements for the injection of polymer compositions into soil masses.

A comprehensive review of the extant literature on the subject was conducted, encompassing studies conducted by foreign researchers. The objective of this review was to ascertain the completeness, adequacy, and predictability of the results of injection work under specified conditions. The specified conditions included the type of task to be solved, the characteristics of the soil mass and the subsequent injected soil volume, the criteria for selecting compositions, and quality control methods etc. The fol- lowing section presents the primary conclusions derived from the articles authored by [46–79].

Studies [46, 47] note that the utilization of polyurethane compounds (both independently [46] and as an additive to mineral solutions [47]) makes it possible to quickly increase the strength and stability of weakened soils, noting such problems as achieving uniform resin distribution and accurately assessing injection volumes and pressure. Further research by the authors focuses on optimizing injection parameters, studying long-term characteristics and understanding the interaction between compositions and soils, improving the method, and developing design recommendations for various soil conditions.

In the following articles [48, 49], the authors explore the process of injecting polyurethane compositions into weak organo-mineral soils. They confirm the possibility of increasing the compressive strength of the stabilized soil to 5 MPa. A paucity of documented studies exists on the macro- and micro-level characteristics of stabilized organo-mineral soils treated with polyurethane.

A review of the extant literature reveals several case studies [50, 51] that examine the implementation of a patented injection lifting technology [50] for the purpose of

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION elevating slabs. This technology utilizes elevated injection pressures of polyurethanes with high foaming coefficients. The conclusions indicate a paucity of theoretical and practical research worldwide on the implementation of this technology for lifting structures, with the majority of research focusing on the process of lifting the foundation and monitoring this technology. Consequently, a range of monitoring methods have been developed globally to regulate the injection process and ensure sufficient monitoring with a satisfactory degree of control over the foundation lifting process in various geotechnical scenarios. Nonetheless, the implementation of this technology in the domain of soil stabilization and foundation reinforcement has been constrained by several factors. Primarily, there has been an absence of adequate scientific, theoretical, and experimental substantiation for the collective behavior of the composite (“soil-injection composition”) and a paucity of a sophisticated calculation method that would facilitate the prediction of alterations in the characteristics of the treated soil mass post-injection.

Article [52] presents data from studies conducted in rock in coal mine roofs with varying degrees of fracturing, proving that it is not necessary to fill 100% of the fractures in the rock mass to achieve stability. A study was conducted that revealed the efficacy of video inspection through boreholes in identifying areas of damage prior to the introduction of polyurethane. This method was found to be instrumental in selecting the necessary technology parameters.

The authors of [53, 54] evaluated the design parameters of the technology using numerical modeling of the behavior of foamed polyurethane [53] and measurement of soil mass deformations [54] during injections into clayey and dispersed soils. The study was conducted using Plaxis 3D software and geotechnical support with fiber optic dynamic probing sensors.

Studies [55, 56, 57, 58] note the high potential of injections of polymer compositions based on polyurethanes, accompanied by a lack of theoretical understanding and practical application [55, 58], insufficient data on polymer behavior, for example, under cyclic loading [56], strong dependence on favorable soil conditions, and unpredictability of compositions under different conditions [57].

The characteristics of slopes behavior with stabilized soil zones in diverse variations are reflected in the work [59] with numerical modeling in the GeoStudio (SLOPE/W) 2D software package. The authors confirmed the high convergence of the results based on the findings of experimental tests. The data presented in [59] aligns with the experimental studies conducted by L. Miranda, L. Caldeira [60], Sina Ghahremani [61], and Feng Cheng [62] (finite element method in the ABAQUS software package). These studies concluded that the polyurethane composition should be studied as a soft rock and that it demonstrates, in essence, plastic behavior under large deformations, as well as high shear strength and low permeability at the same time. It is hypothesized that these fundamental results may stimulate and assist in conducting tests at sites under controlled conditions related to polyurethane injection and evaluating its effectiveness under different conditions, which will contribute to the further application of the technology.

The authors of [63] address the aspect of high antifiltration properties of soils injected with polyurethanes and epoxies to prevent the spread of hazardous and polluting substances into groundwater aquifers. The criteria established by the project further confirmed their actual achievement and their compliance with the US Nuclear Regulatory Commission standard.

A series of studies [64, 65, 66, 67] were conducted to evaluate the effectiveness of polyurethane injection compositions in performing various tasks [64], the method of restoring railway track structures under conditions of high vibration [65, 68], and emergency restoration of road infrastructure [66]. The authors also note the peculiarities of using polyurethane systems that restore the stability of ground properties in complex engineering and geological conditions [64, 65, 67], while at the same time there is a lack of standardized quality control when implementing this new technology [66].

The authors [68, 69, 70] conducted a series of experiments on physical modeling. The objective of these experiments was to examine the operation of polyurethane injection systems through water inflow channels during the elimination of water seepage and leaks [68]. The authors also conducted analytical and experimental studies of the factors of mixture propagation in various types and kinds of pore spaces and fracturing of soil masses [69]. Finally, the authors investigated features in terms of selecting compositions for increased propagation radii at reduced pressures [70].

As indicated by articles [71, 72], the injection of polyurethanes results in optimal penetrating and sealing effects on medium and large pores [71], accompanied by a high adhesion strength of the injection composition to sand [72].

In the study [73] by Yuan Chao et al., the stability of optimized composites (mixed polyurethane-mineral compositions) in high-temperature environments and their ability to adapt to large deformations of rock masses are examined. The study demonstrates that such materials possess a significant advantage in plugging cracks in deep underground rock masses.

As part of the optimization of polyurethane compositions, experiments were conducted with mixtures modified with silane and epoxides, which increase strength and impact toughness and improve the mechanical properties of resins and composites based on them [74]. Concurrently, the impact of operating temperature and ambient humidity on the deformation, cracking, and

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION destruction mechanisms of polyurethane plugging materials [75] is being examined through a three-point bending test. The collected data demonstrated that the environmental factors, specifically temperature and humidity, exerted a negligible influence on the morphology of polyurethane grouting material failure. The study [76] analyzed a discrete element numerical model of polyurethane porous elastic mixtures and examined the entire process of particle displacement and the development of small cracks in mixtures under uniaxial compression. In the context of uniaxial compression, it was observed that the displacement of particles on the outer periphery of the specimen exceeded that of the particles situated within the central region of the specimen. The distribution of cracks exhibited a general randomness, and the presence of cracks was noted on the upper and inner surfaces of the specimen in the subsequent stages of loading. In order to mitigate the impact of crack formation and facilitate the healing of microcracks, the development of self-healing polyurethane materials [77] has been underway. These materials are being created by incorporating furfurylamine and bismaleimide into the polymer structure.

The necessity of precise operational evaluation of the efficacy of control over the consolidation of embankment dams, roads, foundations, and other structures is of considerable practical importance. Given the nature of polyurethane as a two-phase system, characterized by its porosity and the relatively low levels of dielectric permeability and losses exhibited, the development of microphysical and dielectric models is a viable undertaking. The findings indicate that the dielectric permittivity exhibits an upward trend with increasing density and a slight decline with rising frequency. This study [78] provides a theoretical foundation for the non-destructive testing of polyurethane grouting materials in large-volume fixed structures.

It is hypothesized that in the future, polyurethanes with enhanced characteristics and a broader range of applications will be attainable, resulting in a reduction in their ultimate cost due to the optimization of technological processes and the automation of production [79].

A review of the extant literature on the subject [46–79] reveals the following salient points:

– injection into fractured rock soils has been demonstrated to yield the most predictable results, attributable to the restriction of propagation channels outside the fractured zone. This method involves the injection of materials into highly permeable structures, such as fractured soil, dam embankments, various limestones, and gypsum;

– outcome of injection work is contingent upon a comprehensive understanding of the interaction between injection compositions and soils, as well as the injection regime;

– regulatory and technical documentation from regulatory authorities on the injection of polymer compositions in the countries of the researchers has not yet appeared. This documentation would clearly define the parameters [48, 49, 55, 58, 59, 60, 62];

– implementation of successful projects is predominantly attributable to scientific and technical support, in conjunction with the continual adjustment of injection parameters and the regulation of injection mixture properties;

– characteristics of the stabilized soil and injection polymer compositions, as well as the requirements for them, are not described. There is no justification for their use and comparison with other compositions;

– issue of polymer durability, including its behavior in soil, is not adequately addressed. The loss of bearing capacity in previously reinforced soil can result in catastrophic consequences;

– compensatory lifting by the expanding compositions is not fully reflected. The criteria for expansion in different conditions are not specified based on the final result, and the characteristics of the polymer itself are not given (this is especially important for polymers with high foaming coefficients and low deformation characteristics);

– a plethora of control and forecasting methodologies have been put forth; however, there is a paucity of elaboration concerning the rationale behind their selection for particular circumstances.

The aforementioned analysis enables the identification of the primary methodologies for the implementation of technologies for soil reinforcement by injection with polymer compounds (predominantly polyurethane-based): void and cavity filling, impregnation injection, and soil compaction by injection with foaming compounds. Given the absence of standardization and design methodologies, composition selection, and work control, it is imperative to investigate the properties of injection mixtures and reinforced soils, formulate subsequent recommendations, and refine the methodology within the framework of physical objects.

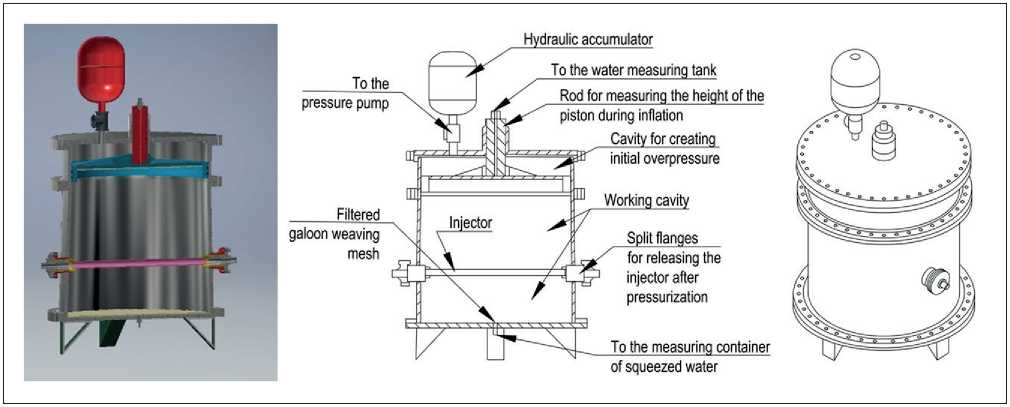

MGSU, in conjunction with partner organizations, has proposed a laboratory method for determining the primary parameters of injection compounds when injected into VIMs (Volume Injection Model) (see Fig. 5). This method facilitates the analysis of a broad spectrum of technological parameters.

In collaboration with MGSU, production organizations are engaged in research endeavors focused on the analysis of diverse soil types. This research aims to elucidate the propagation of injection mixtures across varied environmental contexts. Additionally, the study encompasses the examination of alterations in the physical and mechanical characteristics of soils. This investigation is further complemented by the assessment of the interde-

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION pendencies between alterations in the stress-strain state of soil masses. The research framework encompasses the utilization of large-scale models, incorporating diverse properties of injection mixtures, such as expansion coefficients and structure formation kinetics. In addition, the study incorporates injection parameters, including specific consumption and maximum injection pressure.

In order to adapt the design parameters that were utilized in the design justifications for projects and regulations for measures employing injection grouting technology, a Volume Injection Model (VIM) was developed (Figs. 5, 6). A model of this type was previously developed by Vedeneev VNIIG JSC based on the model by A. Be-zuizhen. However, the Volumе Injection Model proposed by the authors exhibits a number of significant differences.

The VIM consists of a metalcylinder with a working chamber diameter of 1 m and a height of 0.8 m. A section of a cuff column is located at the center of the cylinder (Fig. 7). The perforations in the cuff column are prevented from becoming contaminated by soil by a rubber cuff. A movable piston is situated in the upper portion of the model, simulating soil pressure and the weight of the structure.

In the context of experimental design, the value of the piston pressure exerted on the soil specimen is determined in accordance with the specific objectives of the experiment. Pressure sensors are embedded within the soil mass that has been placed within the model, enabling the real-time monitoring of parameters associated with solution injection.

Fig. 5. Large VIM (Volumе Injection Model) diagram

Fig. 6. Large VIM installation on the production site for the injection grouting process simulation

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 7. Cuff column in the VIM volume

These parameters, if deemed necessary, facilitate the estimation of the stresses that arise within the soil mass. Consequently, they enable the correlation of the calculated stresses with the associated modes and injection volumes, which are then incorporated into the initial calculation model.

In contrast to the large volumetric model developed at Vedeneev VNIIG JSC, the VIM facilitates the examination of modified soils and injection materials without the necessity of their layer-by-layer disassembly.

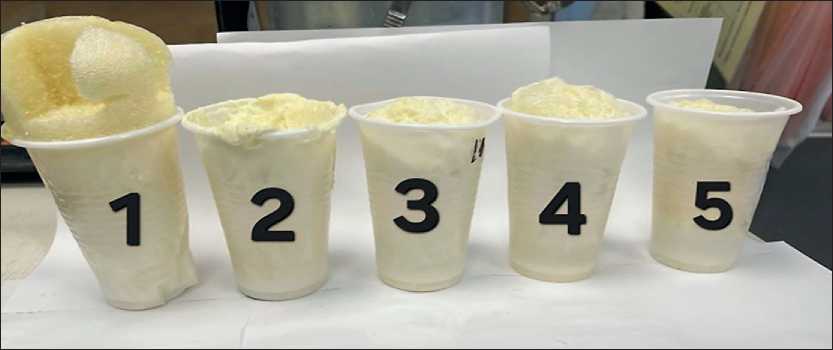

However, due to the absence of a comprehensive classification system for polyurethane compositions employed for soil stabilization, the present study undertakes the initial development of criteria for injection polyurethanes and the subsequent evaluation of the characteristics of polyurethane mixtures exhibiting varying degrees of porosity (a pivotal parameter in determining the final properties).

In order to ascertain the fundamental properties of various polyurethane compositions, manufacturers, in conjunction with recommendations from the Moscow State University of Civil Engineering, examined numerous injection compositions, with the foaming coefficient serving as the variable factor that exerts the most significant influence on the deformation characteristics of the material. The corresponding results are displayed in the table.

In experiments, it is always necessary to take into account the difference in the types of polyurethane reactions, which also depend on various factors (Fig. 8): there are hydroactive polyurethanes (which expand significantly upon contact with water and intensify the reaction) and non-hydroactive polyurethanes (the foaming coefficient depends primarily on the ratio and types of components and hardening conditions).

Analysis of the results of studies by domestic and foreign authors, examination of the experience of completed projects, analysis of the nature of pore space filling for clayey and sandy soils (tests of fractured rock soils were conducted as part of other studies) showed that the mass of stabilized soils when injected with polymer mixtures (mainly with a foaming coefficient of more than 4–5) can be divided into three parts: pre-injection, central, and edge (according to Sabri M.M., see Fig. 9) [52, 56]. It has been established that the maximum values of both deformation and physical-mechanical properties are confined to the central part of the reinforced massif.

Table 1. Key parameters of injection polyurethane systems

|

Type |

1 |

1.5 |

3 |

4 |

|

Bulk weight, [kg/m] |

1250±250 |

800±140 |

400±100 |

300±50 |

|

Deformation characteristic, MPa |

750…950 |

50…350 |

10…50 |

Flexible |

|

Foaming coeff. |

1–1.15 |

1.5–2.5 |

2.5–4 |

4–5 |

|

Reaction start time [s] |

120 |

120 |

120 |

120 |

|

Type |

5 |

9 |

12 |

20 |

|

Bulk weight, [kg/m] |

180±40 |

120±30 |

95±20 |

35±5 |

|

Deformation characteristic, MPa |

Flexible |

Flexible |

Flexible |

Flexible |

|

Foaming coeff. |

5–8 |

8–12 |

12–20 |

more than 20 |

|

Initiation of foaming reaction [s] |

120 |

120 |

120 |

120 |

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION

Fig. 8. Evaluation of the foaming criterion at various parameters

Fig. 9. Network of channels for distributing polyurethane-based polymer composition from the injection point

For all types of polyurethanes, a sharp decrease in deformation indicators after foaming by 2–4 times and transition to a plastic state was noted. It is imperative to acknowledge that when assessing the viability of polyurethane formulations for injection into soil masses, characterized by variable degrees of water saturation, significant variations in terms of area, season, and local conditions, may be present. Consequently, in order to enhance the anti-filtration properties of soils (or eliminate leaks, emergency plugging), it is recommended to consider hydroactive polyurethanes. Conversely, for soil stabilization, it is more optimal to consider non-hydroactive polyurethanes, which possess more predictable characteristics and are not contingent on the degree of water presence in the mass.

A comprehensive analysis encompassing open sources, completed projects, and laboratory studies yielded the following observations regarding injection processes in dispersed and clayey soils. Upon injection, the polymer solution undergoes a process of degradation, creating a network of cracks that extend radially from the injection point. These cracks propagate along the path of least hydraulic resistance, expanding perpendicular to the injection axis. In the case of dispersed soils, a high degree of penetration of the injection mixture into the intergranular space of sand particles is also observed. The injection mixture also spreads along the crack, sealing it simultaneously. This process forms a fixed polymer segment. At a sufficiently constant injection pressure, the mixture finds other channels of propagation. The technology employed in clay soils to achieve a substantial enhancement in soil deformation characteristics is analogous, albeit it necessitates higher pressures, is distinguished by a diminished overall spread area of the composition, and propensities to induce uncontrolled deformation of the soil mass. Consequently, a network of channels containing polymer filler is established, accompanied by areas of reinforced soil (partially impregnated or compacted) in proximity to these channels. This phenomenon is predominantly attributable to the compaction effect resulting from the expansion of the polymer composition. Furthermore, when the expansion coefficient is sufficiently high, the deformation characteristics of the material itself are lower than those of the surrounding compacted soil mass. The most suitable method for determining the increase in the deformation characteristics of the stabilized mass is to probe the soil near the injection points, which provides indirect indicators of the stabilized massif.

A multitude of studies have documented the beneficial effects of polyurethane injection [44, 45, 52, 56], which include an increase in the calculated resistance of soils,

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION a decrease in the water content of soil masses, stabilization of structurally unstable soils or the most weakened areas of the solid mass, and a decrease in sedimentary deformations.

A substantial body of research has demonstrated the efficacy of polyurethane mixtures with high foaming coefficients (10 and above). However, it is crucial to acknowledge that the injection material exhibits inferior deformation characteristics compared to the surrounding soil mass. The enhancement of soil properties is predominantly accomplished through additional compaction, which increases the packing density of dispersed soils, rather than through the formation of additional bonds between them. This latter process, characterized by complete injection impregnation of the pore structure, is a more dependable method for soil stabilization. Concurrently, there is an absence of laboratory data confirmed at the sites, and there has been no monitoring of changes in the characteristics of soils stabilized with highly foaming polymer compositions. Potential risks associated with a violation of the soil mass’s stress-strain state include the presence of a substantial quantity of highly deformable polyurethane layers within the soil thickness. These layers can substantially diminish the deformation characteristics of the foundation, potentially resulting in non-standard settlements. This is particularly hazardous in the context of potential depolymerization in complex engineering-geological conditions.

The selection of soil stabilization technology [16, 80] must be economically justified, a consideration of particular importance in a market economy. In this context, factors such as the optimization of materials and technologies [27], the criteria for import substitution [81], and the costs associated with sanctions (given the continued import reliance on certain polymer materials, including those from countries susceptible to supply interruptions) must be taken into account. Additionally, the use of secondary resources [82, 83], the development of novel innovative materials [84, 85], and the standardization [86] of these materials must be considered, as must research [84, 87] in this area. When selecting between polymer and mineral injection compositions, it is imperative to undertake a technical and economic comparison of the options for addressing the geotechnical problem, encompassing the variations in the feasibility of employing mineral compositions [88, 89], while taking into account the advantages and disadvantages associated with their utilization [90, 91].

CONCLUSION

The results of the analysis of injection technologies demonstrate the potential for addressing a broad spectrum of geotechnical challenges. These challenges include, but are not limited to, soil stabilization, the establishment of antifiltering curtains, the restoration of waterproofing capabilities in underground structures, compensation injection, and the implementation of specialized construction methodologies in underground mining operations.

A thorough examination of the authors’ experiences [46–79] reveals the following key points:

Concurrently, the most significant challenge pertains to the accelerated growth of the global chemical industry, which has facilitated the introduction and implementation of numerous injection products. A notable concern is the absence of regulatory documentation and longterm monitoring for these implemented facilities, which hinders the assessment of their effectiveness.

Specialists at Moscow State University of Civil Engineering conduct analyses of a wide range of different injection mixtures and provide recommendations for

APPLICATION OF NANOMATERIALS AND NANOTECHNOLOGIES IN CONSTRUCTION optimizing their properties, including for more effective penetration of the compositions, which will ensure the transformation of the properties of foundation soils and the operational reliability of building structures, underground and buried structures, and hydraulic engineering facilities. The project involves researching and adapting various compositions with low viscosity and adjustable setting and hardening times. Materials of this type can be used to solve a number of design problems, taking into account the specifics of underground and hydraulic engineering construction, such as soil pressure, head, and groundwater level. In addition, the inclusion of such injection methods using highly penetrating materials allows for an assessment of their effectiveness, which in turn can shape the required properties of injection compositions, which are not currently regulated. It is expected that the introduction of these technologies will significantly increase the reliability and service life of underground structures, reduce the costs of their operation and repair, and minimize the risks associated with soil stabilization, repair, water inflows and water seepage, as well as corrosion of structures.