The influence of atmospheric factors on the effectiveness of fire protection for wooden facade structures

Автор: Korolchenko O.N., Tsarichenko S.G., Konstantinova N.I.

Журнал: Nanotechnologies in Construction: A Scientific Internet-Journal @nanobuild-en

Рубрика: The results of the specialists’ and scientists’ researches

Статья в выпуске: 5 Vol.17, 2025 года.

Бесплатный доступ

Introduction. The article discusses how artificial wood aging affects the retention of its fireproofing efficiency to evaluate the ability of a fire-bio-moisture-resistant impregnating agent to protect facing timber materials of facade systems exposed to weathering, such as varying temperature and humidity, if standardized levels of fire hazard and integrity are maintained and the impregnating agent has water-soluble phosphorus and nitrogen compounds of the nanoscale range. Research focus and methods. A specimen of pine wood was subjected to artificial aging for 120 days, which is equivalent to 15 years of outdoor operation. The method of pressurized impregnation was applied to pre-treat the specimen with the fireproofing agent. Climate testing was followed by a comparative evaluation of combustibility parameters according to a standard experimental method used to distribute combustible and hardly combustible materials between combustibility groups. Besides, before and after aging, all surfaces of fireproof wood specimens were subjected to thermo-analytical studies and visual inspection. Results and discussion. Results of combustibility group identification and principal thermal decomposition parameters of fireproof pine timber remained nearly the same before and after climate testing. Further comparative visual examination of surfaces of timber specimens identified no external changes. Conclusion. Research on the stability of fireproofing properties in pressure-impregnated timber shows that it can retain its effectiveness for up to 15 years under natural weathering conditions.

Modified timber, pressurized impregnation, thermal decomposition parameters, artificial aging of timber, hardly combustible material, cladding of building facades

Короткий адрес: https://sciup.org/142246078

IDR: 142246078 | DOI: 10.15828/2075-8545-2025-17-5-585-593

Текст научной статьи The influence of atmospheric factors on the effectiveness of fire protection for wooden facade structures

Original article

Корольченко О.Н., Цариченко С.Г., Константинова Н.И. Влияние атмосферных факторов на эффективность огнезащиты фасадных конструкций из древесины. Нанотехнологии в строительстве. 2025;17(5):585–593. – EDN: GRLHSB.

Wood has been used as a building material since ancient times due to its affordability, workability, and good structural characteristics, such as high strength, elasticity, and relatively low density. Besides, timber buildings and structures have high thermal insulation and acoustic properties; they ensure indoor comfort and healthy indoor climate. Timber is a renewable natural material and an environmentally friendly product; in the course of construction, timber structures consume less energy than those made of other materials, and, thus, reduce the carbon footprint.

Today, these properties of timber determine the relevance of its use as a structural material in house construction. However, it is noteworthy that timber as a structural material has a number of weaknesses, if compared with reinforced concrete. Timber structures are susceptible to moisture, fungi, and fire hazards; the length and height of timber structures have certain limits.

Nevertheless, construction of multi-storey timber houses is now increasingly relevant due to the development and implementation of new technologies and the use of advanced building materials employed to construct durable and reliable public, residential, and industrial buildings [1]. Actions are taken to improve the legal framework, technical regulations, and to expand the scope of application of timber structures [2]. These efforts will foster the design and construction of multi-storey build- ings whose structures have timber, so that their number of stories reaches twelve.

Fire hazards for materials and structures are among the limiting factors, decelerating the development of multi-storey timber housing. Hence, fireproofing is a highly relevant focus of a great number of research projects [3, 4].

In addition to compliance with certain fire safety requirements, design and construction of building facades must make buildings safe from weathering during longterm operation [5]. This necessitates a certain amount of research to be conducted to determine the service life of fireproof timber, taking into account actual climatic conditions of building operation. Towards this end, novel methods must be developed to prognosticate the durability of timber that has standardized fire safety.

Several studies focus on the effect of natural and artificial aging of timber on its fire hazard. Their authors study changes in the structure and chemical composition of timber [6], and the ability of timber, treated with various compounds, to retain fireproofing properties [7, 8].

Some works describe a large number of experimental studies, focused on the fire hazard of timber, and confirm the effect of various factors on the fire hazard (timber species and variety, conditions and duration of use, humidity, fire intensity, etc.). Dependence between the age of timber, on the one hand, pyrolysis and thermo-oxidative decomposition, on the other hand, is also studied; ther-

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES mo-physical characteristics are determined, and charring rates are found for different temperature modes [7, 8].

However, comprehensive studies, aimed at investigating the behavior of fireproof timber materials used in facade systems exposed to weather effects during the fire, are yet to be made, and this fact contributes to the relevance of (1) evaluation of the effect of fireproofing on timber and (2) analysis of timber flammability in terms of compliance with regulatory requirements after long-term operation. The relevance of the issue is also explained by the lack of methods in the domestic regulatory practice that allow predicting the service life of fireproof timber structures.

The aim of this research is to study the applicability of a fire-bio-moisture-resistant impregnating agent that contains water-soluble phosphorus and nitrogen compounds of the nanoscale range to protect facing timber materials of facade systems exposed to weathering, namely, varying temperatures and humidity, while retaining the standardized level of fire hazard and integrity. This research encompasses the following tasks:

– selecting and substantiating accelerated climate testing modes for fireproof timber;

– confirming the stability of timber fireproofing after accelerated climate testing in compliance with regulatory fire hazard values applied to cladding materials of facade systems.

RESEARCH FOCUS AND METHODS

When fireproofing properties of timber are identified, it is extremely important to consider not only the initial characteristics of fireproofing agents, but also their ability to remain effective throughout the entire service life of the material. It is noteworthy that some foreign standards, used to identify fireproofing properties of timber, do not evaluate changes in their effectiveness during natural or artificial aging of timber. This creates a certain gap in the methodological approach, since real conditions of operation strongly affect the durability of fireproofing. As for the methodology, regulatory documents, governing the testing the quality of paint and varnish products, are often used to identify the effect of real climatic conditions of operation on fireproofing, and, therefore, their application disregards timber fireproofing.

For example, European regulatory documents [9, 10] address the effect of artificial and natural weathering. As a rule, artificial aging of timber has short cycles lasting for 3 hours. Each cycle is a combination of UV radiation exposure for 2.5 hours followed by spraying with water for 0.5 hours. Here, the total duration of cyclic testing can reach 12 weeks, which allows simulating a relatively long period of operation in an accelerated mode. However, these modes may not fully cover the entire range of climate effects characteristic of different regions.

Domestic regulatory practice applies a standard [11] to evaluate the ability of a fire retardant, applied as a fireproofing agent, to remain effective when exposed to environmental factors that correspond to conditions of timber use indoors. According to this standard, artificial aging of fireproof timber lasts for 14 days. Aging operations include sequential cyclic exposure of specimens in a drying oven at various temperatures, including (60±5) °C and (23±5) °C and at the relative humidity of (65±5) %. Although this approach is relevant for indoor conditions, it does not simulate aggressive outdoor climate effects.

Evidently, to identify the fireproofing properties of products, applied to treat timber structures used outdoors, it is necessary to make sure that exposure conditions correspond to actual operating conditions. The main factors affecting the process of washout and degradation of fireproofing compounds under these conditions may include high humidity, frequent freeze-thaw cycles, and large temperature variations. These factors contribute to the physical washout of components and the chemical degradation of the fireproofing coating or impregnating compound. Therefore, when selecting accelerated climate testing modes, the authors analyzed and subsequently used Method 3 [12] for this research, because it encompassed more severe and diverse conditions of exposure.

According to this method, fireproof timber specimens are placed in a specialized climate chamber capable of precisely controlling environmental parameters. The exposure algorithm was as follows: a temperature of (40±2) °C and relative humidity of (97±3) % for 6 hours; a temperature of (20±2) °C and relative humidity of (97±3) % for 2 hours. Further, specimens were exposed to low temperatures, namely, a temperature of minus (32±3) °C and relative humidity of (80±1) % for 3 hours. After that, specimens were exposed to high temperatures, namely, a temperature of (60±2) °C and relative humidity (80±1) % for 7 hours; and the final stage of the cycle had a temperature of (20±2) °C and relative humidity (80±1) % for 6 hours. The duration of one complete test cycle was 24 hours. It is noteworthy that eight test cycles are equivalent to one year of exposure to real weathering. For the purpose of this study, a model service life of 15 years was chosen for timber, which required experiments to be conducted for 120 days (15 years • 8 cycles = 120 cycles, each cycle lasting 1 day with a total of 120 days). This approach greatly reduces the duration of the experiment while maintaining the adequacy of modeling long-term effects.

A timber-modifying composition, containing watersoluble phosphorus and nitrogen compounds of the nanoscale range, was investigated as a protective agent. In addition to principal fireproofing components, this compound has complex biocides, that prevent the biological degradation of timber, and special bio-based plasticizers

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES that improve the penetration and adhesion of the compound to timber. The compound was applied by pressurized impregnation, whose effectiveness and mechanism of action were previously confirmed in several works [13, 14]. The fire-bio-proofing impregnating agent has complex reactive compounds that modify the internal structure of timber. This modification triggers a change in the main stages of thermal decomposition of timber by affecting properties of the resulting coke layer. As a result, a release of combustible gases is reduced during pyrolysis and the thermo-oxidative capacity of the material decreases [14], which is key to the fireproofing effect.

An important factor determining the effectiveness of fire-bio-proofing of timber is the choice of pressurized impregnation for this impregnating agent. The main methods include the “heating – cold bath” technique and autoclave impregnation. In the first case, processes take place at atmospheric pressure; they involve alternating modes of timber treatment with an impregnating compound and can be performed in three ways:

– heating and impregnation take place in one bath with (1) the replacement of the hot solution of the protective agent with the cold one without taking timber products out of the bath or (2) filling the bath with the cold solution of the protective agent after steam heating;

– heating and impregnation take place in one bath by means of “soaking” timber products in the hot solution of the protective agent until timber cools down;

– heating and impregnation take place in two baths with the transfer of impregnated products from one bath to another.

This method is unsuitable for pressurized impregnation due to low excess pressure; it is more labor-intensive and time-consuming, since the total impregnation time needed to make timber “hardly combustible” is, at least, 24 hours.

Autoclave treatment methods are used to ensure pressurized impregnation of the fire-bio-proofing compound, to boost the timber protection efficiency, to reduce energy consumption, and to save time. Autoclave methods can also be applied differently [15].

– the Rueping method, involving “air pressure – liquid pressure – vacuum”, is used for impregnation with oily antiseptics. In this case, excess pressure cannot remove most of moisture from pores, which means that the compound cannot penetrate into the entire surface of timber, and water remains in its pores;

– the “vacuum-pressure” method involves sequential vacuuming of a specimen to remove moisture from the timber structure; after that, the specimen is treated with a protective compound under pressure, which allows only a limited amount of impregnating liquid to penetrate to a small depth and this cannot ensure effective protection if compared to other methods.

– the “vacuum-pressure-vacuum” method involves vacuuming in an autoclave: vacuuming to remove excess moisture and air from timber pores; filling the autoclave with a fire-bio-proofing compound under pressure; having the specimen treated this way for a certain time and its further vacuuming, followed by exposing the specimen to high pressure.

This method of treating timber specimens is employed to get the compound to penetrate deeply into the capillary-porous structure of timber. Further, repeated vacuuming and exposing the specimen to high pressure contribute to more optimal and uniform penetration of the compound into the material, ensuring maximum saturation of timber with active ingredients, thereby increasing the effectiveness of fire-bio-proofing.

According to the results of tests, the pine timber specimen, whose fireproofing is performed by pressurized impregnation, belongs to the group of hardly combustible materials, or combustibility group G1. This is an extremely important value, as it indicates a great reduction in the fire hazard of treated materials, which allows its use in facade cladding systems dur to its fire hazard characteristics, fully complying with the requirements of current fire safety standards [16].

After a full cycle of climate tests, a comprehensive comparative evaluation of the condition and properties of fireproof timber was made. The evaluation included not only the determination of combustibility parameters using measuring instruments and testing equipment in accordance with paragraph 7 [17], but also detailed thermo-analytical studies and a thorough visual inspection of all surfaces of fireproof timber specimens both before and after timber aging. This comprehensive approach is employed to have a comprehensive idea of changes in the material exposed to weathering.

RESULTS AND DISCUSSION

Combustibility parameters (Table 1) studied by a standard method of experimental evaluation of combustible and hardly combustible materials made of fireproof pine timber [17] before (specimens 1–3) and after climate testing (specimens 4–6) show little changes in values of mass loss (m, %) and maximum temperature increase (∆t) in specimens. This is key evidence demonstrating the ability of the agent to remain effective and maintain its properties as a hardly combustible material even after the long-term exposure to aggressive climates.

The visual inspection of the surface of fireproof timber specimens was also conducted before and after timber aging. The local visual inspection was conducted as follows: inspected surfaces were located at a distance of no more than 600 mm, at an angle of 30° with an illumination level of 500 lx. A 10x magnifying glass was used in the detailed examination of the surface. Comparative studies of sur-

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Table 1. Fireproof pine timber specimens of combustible and hardly combustible materials before and after climate testing: group placement as a result of an experiment

Advanced methods of thermal analysis, including thermogravimetry (TG) and differential thermogravimetry (DTG), were applied to fireproof timber to thoroughly study the effect of timber aging on the timber ability to retain the extent of its fireproofing. These methods allow tracking changes in the specimen mass depending on temperature and time, as well as determining the extent of these changes, which gives an idea of processes of thermal decomposition of the material.

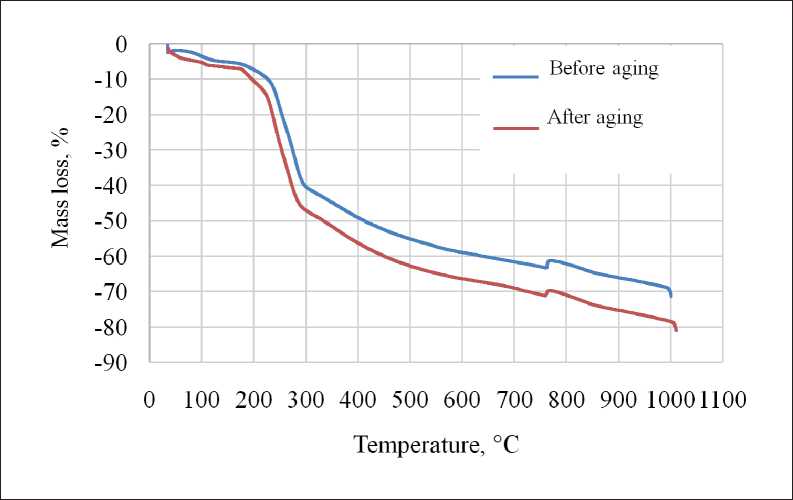

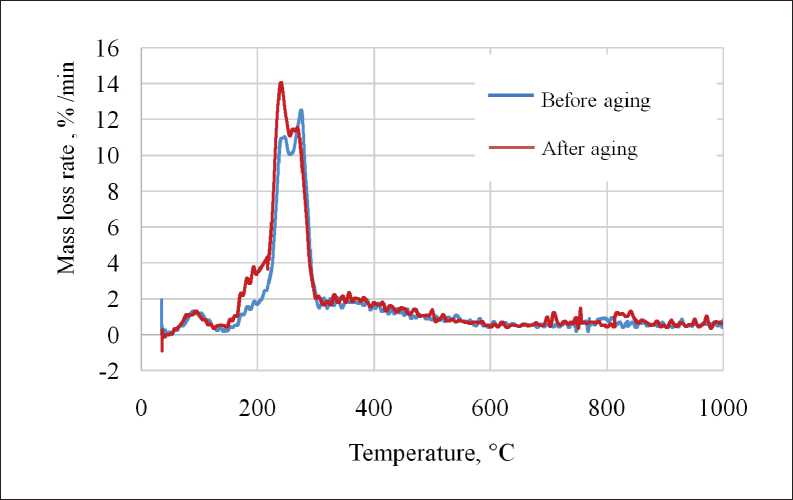

To conduct the studies, equal-size primary samples (5 items) were extracted from different spots of each pine timber specimen using a cutting tool. An average sample was made of these primary samples: it was a carefully homogenized amount of material taken from the total mass of the primary sample to ensure representativeness. Three micro-specimens were prepared from the selected average sample of material and subjected to testing by the method of thermal analysis. This approach minimizes the effect of local inhomogeneities in the material. Table 2 and Fig. 1 and 2 show the results of three parallel tests of average samples, which increases the data reliability. The studies were conducted using the Henven HQT 4 synchronous thermal analyzer. Conditions of thermal analysis were strictly pre-determined: the heating rate was 20 °C/min; C the medium was inert (nitrogen) in the process of specimen heating to 700°, which allows pyrolysis to be studied without active oxidation, and above 700 °C, air served as the medium to analyze

Table 2. Thermal analysis of pressure impregnated pine timber before and after climate testing

|

Mass loss ∆m. %. at temperature. оС |

Coke residue, %, at Т, оС |

Ash residue, %, at Т, оС |

||||||||||

|

Mass loss, % |

∆m 100 |

∆m 200 |

∆m 300 |

∆m 400 |

∆m 500 |

∆m 600 |

∆m 700 |

∆m 800 |

∆m 900 |

750 |

1000 |

|

|

Before aging |

∆m av |

3.72 |

7.61 |

40.22 |

48.53 |

54.25 |

57.88 |

60.5 |

61.16 |

64.92 |

37.1 |

28.9 |

|

After aging |

∆m av |

3.38 |

9.37 |

41.47 |

49.29 |

55.36 |

58.49 |

60.94 |

62.66 |

66.37 |

28.9 |

20.2 |

|

Temperature, °С, in case of mass loss |

||||||||||||

|

Temperature, °С |

Т 5% |

Т 10% |

Т 20% |

Т 30% |

Т 40% |

Т 50% |

Т 60% |

|||||

|

Before aging |

Т av |

139 |

223 |

249 |

270 |

298 |

421 |

680 |

||||

|

After aging |

Т av |

165 |

211 |

244 |

266 |

293 |

406 |

656 |

||||

|

Characteristics of maximums of DTG peaks in the temperature range (maximum temperature Тmax, °С / maximum mass loss rate Amax, %/min-1) |

||||||||||||

|

Range, оС |

50–140 |

200–255 |

255–300 |

|||||||||

|

Before aging |

Т max.av |

91 |

254 |

275 |

||||||||

|

After aging |

Т max.av |

92 |

242 |

270 |

||||||||

|

Before aging |

А max.av |

1.2 |

11.1 |

12.5 |

||||||||

|

After aging |

А max.av |

1.3 |

13.8 |

11.8 |

||||||||

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES

Fig. 1. Dependence between mass loss of pressure impregnated pine timber and heating temperature before and after climate testing

Fig. 2. Dependence between the mass loss rate of pressure impregnated pine timber and heating temperature before and after climate testing

combustion processes and ash residue formation; the sample weight was (21±2) mg.

Dependencies shown in the graphs (Fig. 1, Fig. 2) and data shown in Table 2 demonstrate that the main parameters of thermal decomposition of fireproof pine timber before and after climate testing remain virtually unchanged. This indicates a highly stable chemical structure of the fireproofing compound and its resistance to degradation under the effect of outdoor factors. In particular, there is a coincidence between the number of main DTG maximums and intervals between them, which indicates that thermal decomposition mechanisms remain the same. The intensity of peaks and maximum temperature differ insignificantly, which confirms that

THE RESULTS OF THE SPECIALISTS’ AND SCIENTISTS’ RESEARCHES the reactivity of fireproofing components also remain the same.

Results of previous experimental studies aimed at the placement of fire-bio-proof timber specimens into combustibility groups according to [18] (method 2) suggest the following classification parameters based on the results of three experiments. The arithmetic mean of simultaneously recorded maximum temperature readings of smoke gases of four thermocouples installed in the gas exhaust pipe of the test bench is Tmax = 130 °C; the arithmetic mean of damage lengths for each of the four tested specimens is ∆L = 52 %; the mass damage of four tested specimens is ∆m = 3%; the after-flame time is afterH-flaemne ctimee, according to the combustibility placement test based on the correspondence between values of all parameters, the material belongs to combustibility group G1.

Nearly identical numerical values of classification characteristics were found from tests according to the method used to determine groups of hardly combustible materials and combustible solids and materials (Table 1), such as fireproof timber before and after aging.

The testing time was (300±2) seconds. As a result of three experiments, the maximum temperature of gaseous combustion products of the specimens did not exceed 240 °C, and the mass loss was 11%, which indicates that fire-bio-fireproof timber belongs to the group of hardly combustible materials.

Two methods of combustibility evaluation were applied in this project to analyze the results of experimental studies and comparative test results. The results of this analysis suggest with a high degree of certainty that the fireproofing agent under study is capable of ensuring such characteristics that make it possible to place the timber facade material into the standardized combustibility group G1 for a long period of operation. It confirms that this compound is applicable to facade structures, whose fire safety requirements are especially tight.

CONCLUSION

The results of studies on the stability of fireproofing properties of timber, treated by pressurized impregnation under conditions as close as possible to real outdoor atmospheric conditions, convincingly demonstrate the ability of this compound to retain its fireproofing properties for a period equivalent to 15 years of outdoor use.

This unequivocal conclusion stems from nearly identical results of combustibility evaluation parameters obtained before and after the accelerated artificial aging of timber. Moreover, the similarity between the main placement characteristics of thermal analysis of fireproof timber (such as temperature intervals of mass loss, temperatures of DTG peak maximums, and mass loss rates) before and after exposure to climate factors serve as a supplementary confirmation of stability and durability of the fireproofing effect.

Therefore, this comprehensive research proves the usability and efficiency of timber, treated by the pressurized impregnation method, as a structural or facing material for outdoor use, for example, as the cladding for building facades. Not only does the use of such material ensure the durability and aesthetic appeal of timber facade systems, but it also complies with strict fire safety requirements, which unlocks the potential for the development of multistory timber construction.